Automatic press-fitting system for nail-shooting pill clip

A nail-shooting bullet and nail-shooting technique, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of slow work flow, increased production costs, and high labor costs, so as to improve press-fitting efficiency and save labor. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

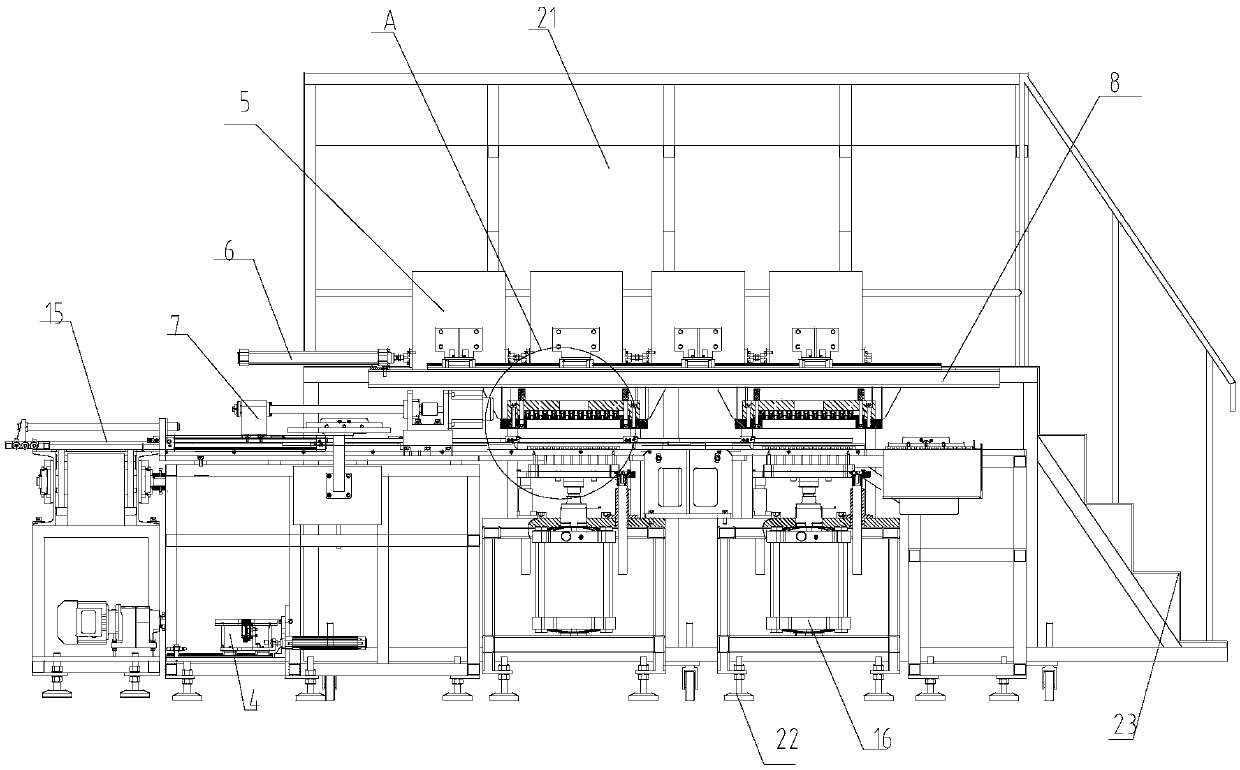

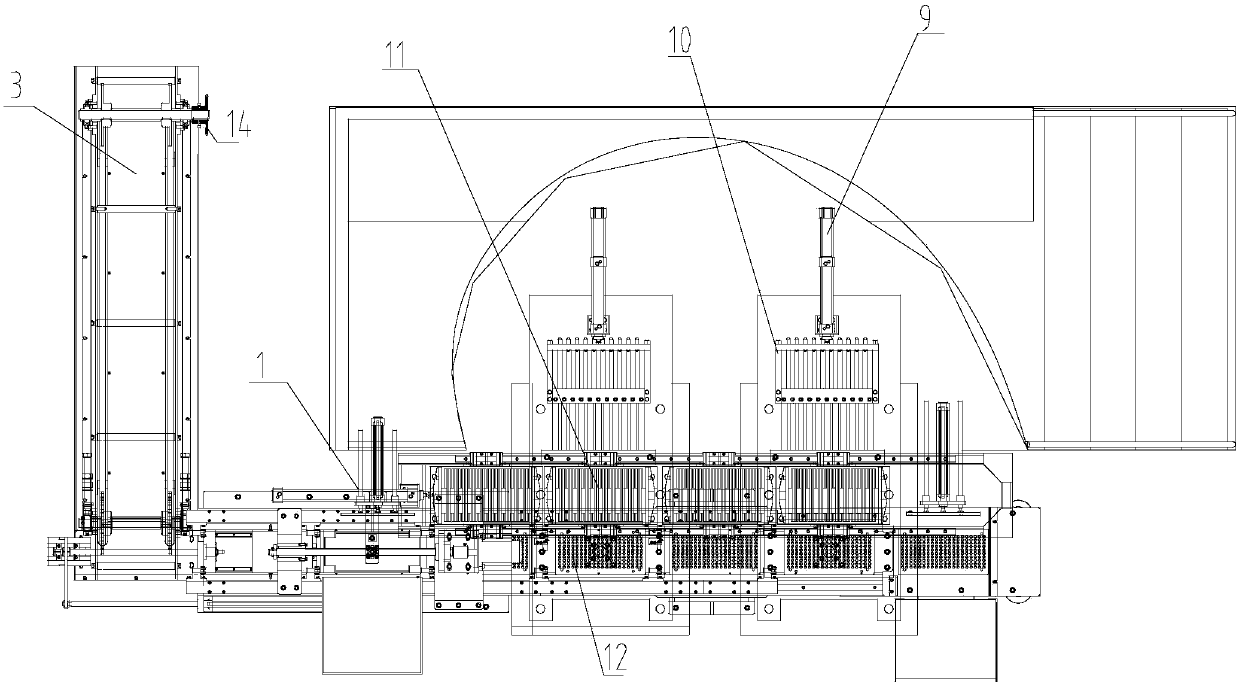

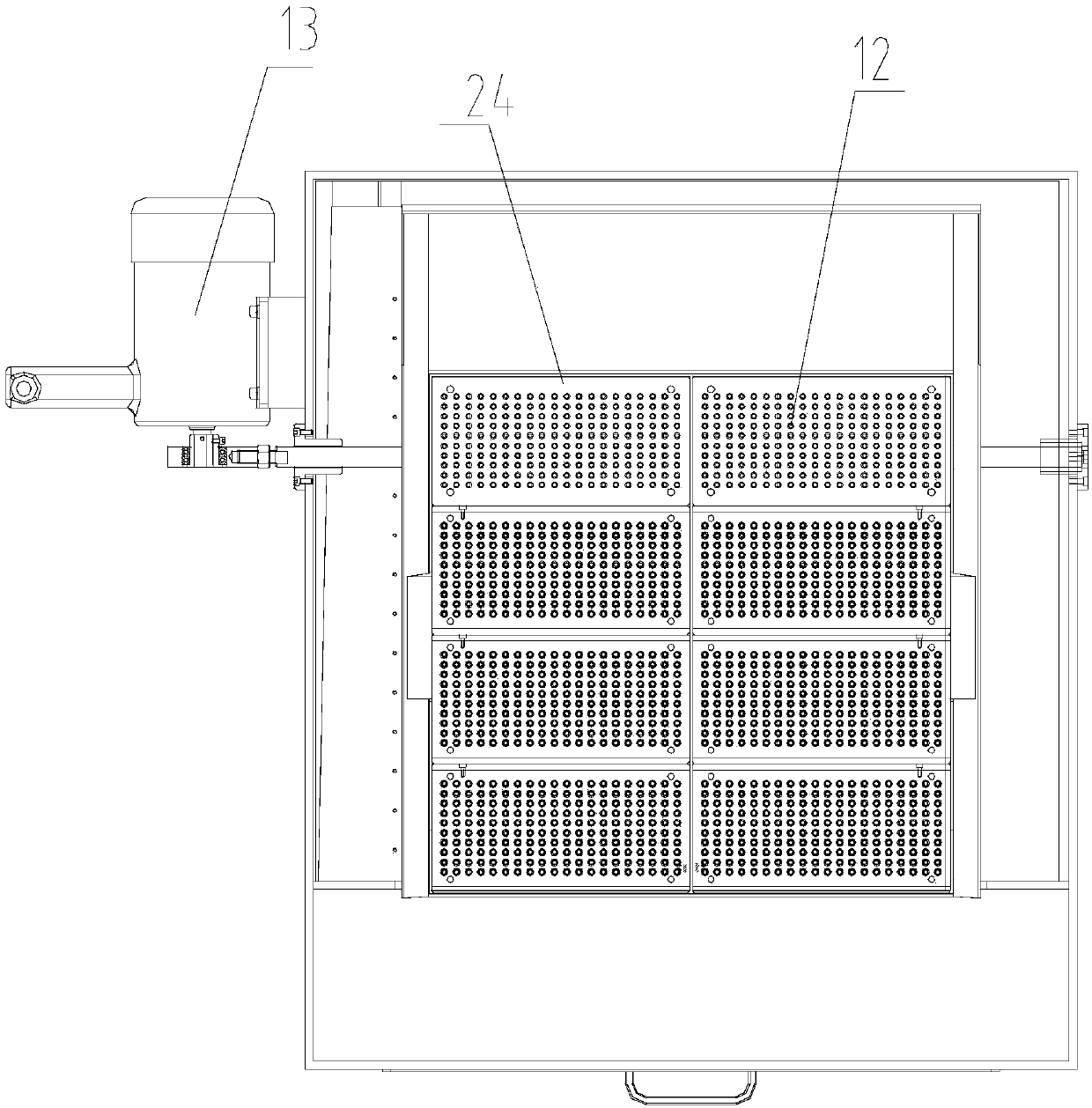

[0018] The present invention proposes an automatic press-fitting system for nail-shooting magazine clips, which includes a base 1 and a rocking plate device 2 installed on the base 1, a feeding system 3, a clip loading device 5, a fixing plate 8, The first cylinder 9, the push plate 10, the nail shooting bullet flow transfer plate 12 and the second cylinder 16, the rocking plate device 2 cooperates with the nail shooting bullet flow transfer plate 12 to load the nail shooting bullet into the nail shooting bullet The circulation plate 12, the rocking plate device 2 is connected to the feeding system 3, the nail shooting bullet circulation plate 12 is matched with the feeding system 3, and the first cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com