Adjustable arc building wood formwork

A wood formwork and adjustable technology, which is applied in the directions of architecture, building structure, formwork/formwork components, etc., can solve the problems of complex structure of adjustment components, inability to achieve infinite adjustment angle, etc., and achieve the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

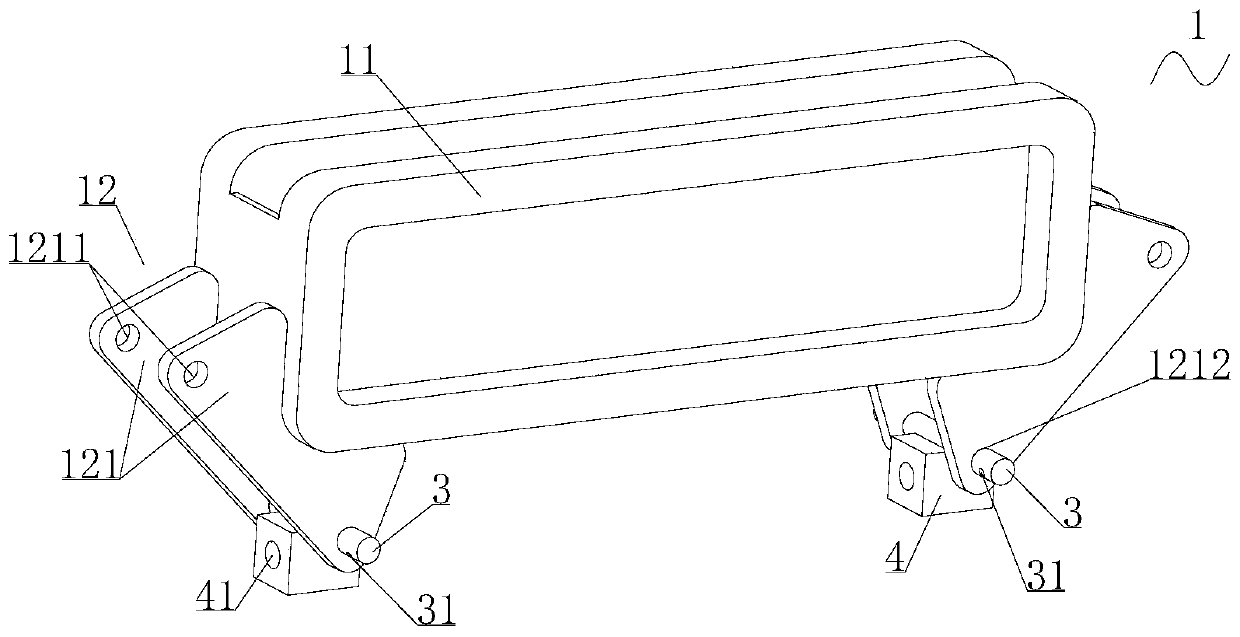

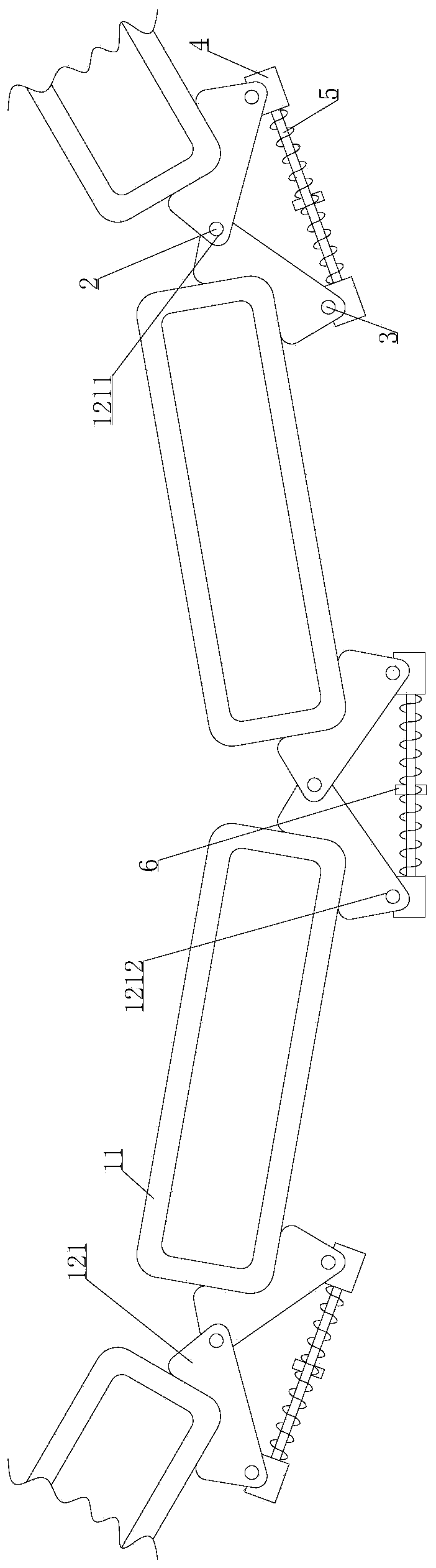

[0018] The present invention provides to achieve the above purpose, an adjustable circular arc building wooden formwork of the present invention, comprising a plurality of adjusting brackets 1 connected end to end and a wooden formwork placed on the adjusting bracket 1, the adjusting bracket 1 It is composed of a back corrugation 11 and two adjusting members 12. The two adjusting members 12 are respectively fixed on both sides of the back corrugating 11. The adjusting member 12 is composed of two adjusting plates 121. The plate 121 is fixed in parallel on one side of the back flute 11 , the two adjusting plates 121 are respectively provided with a first hinge hole 1211 and a second hinge hole 1212 , and the adjusting member 12 in the adjusting bracket 1 The two adjusting plates 121 of the other adjusting bracket 1 are clamped in the two adjusting plates 121 of the adjusting member 12 in the other adjusting bracket 1, and pass through the first hinge hole 1211 inserted into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com