Cable press-fitting equipment

A technology of equipment and cables, which is applied in the field of cable press-fitting equipment, can solve problems such as vibration, accidental injury to staff, and low efficiency, and achieve the effects of increasing press-fitting quality, increasing press-fitting efficiency, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

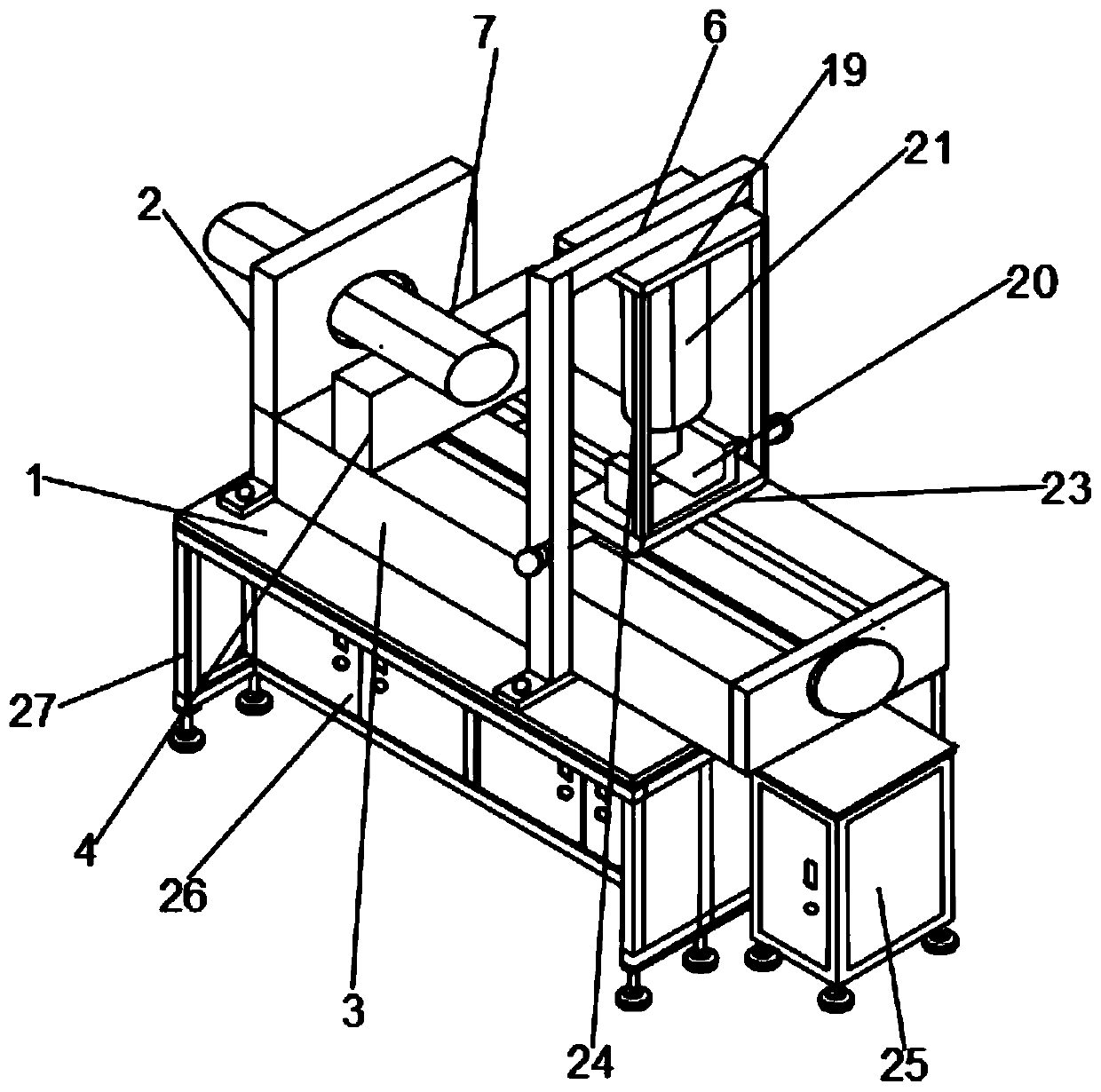

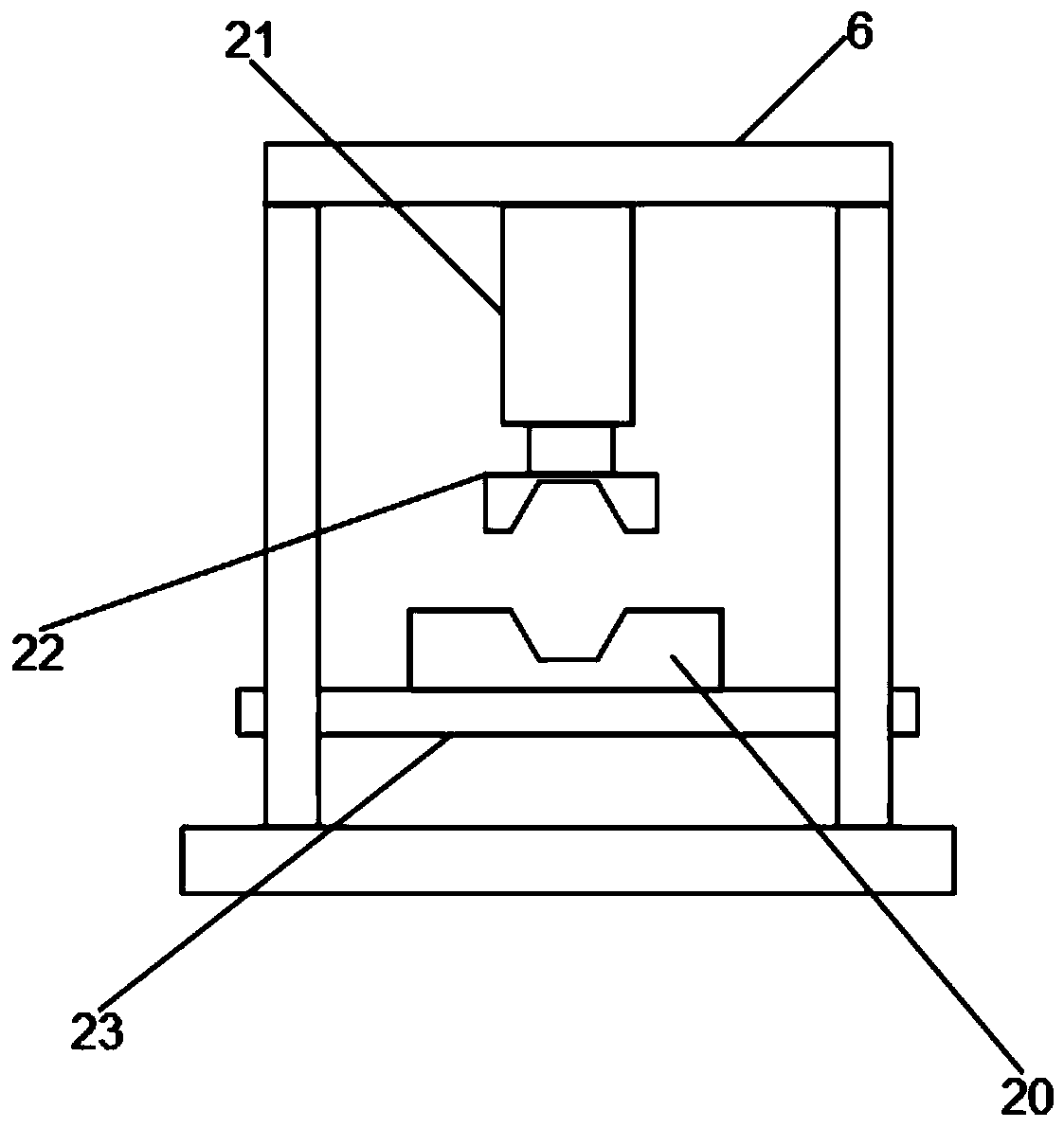

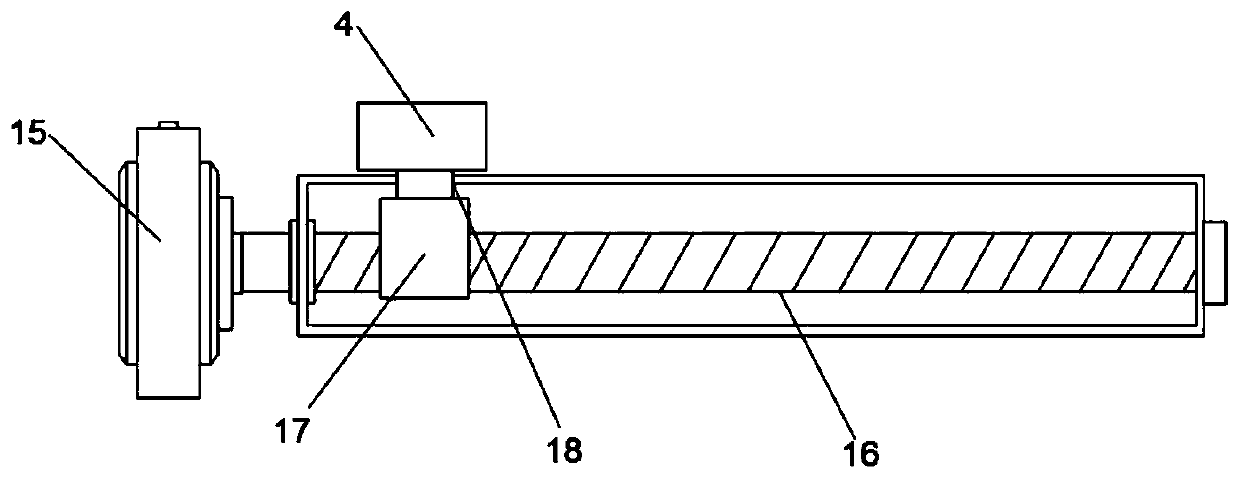

[0024] Such as Figure 1-Figure 5 As shown, a cable crimping device provided in this embodiment includes a workbench 1 and a first support plate 2 fixedly mounted on the top of the workbench 1 by a screw, and a housing 3 located on one side of the first support plate 2. The housing 3 Welded on the upper surface of the workbench 1, the upper part of the housing 3 is slidably provided with a second support plate 4, the upper part of the second support plate 4 is integrally formed with a fixed pipe 7, and the screw on the workbench 1 is fixed with a gantry 6, The inner screw rod of the gantry frame 6 is fixedly equipped with a pressing mechanism, and the inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com