Design method for face gear slotting cutter tooth form

A gear shaper and face gear technology, which is applied in computing, special data processing applications, instruments, etc., can solve the problem of lack of reverse design method of face gear parts, and achieve the effect of good transmission performance, cost saving and processing efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

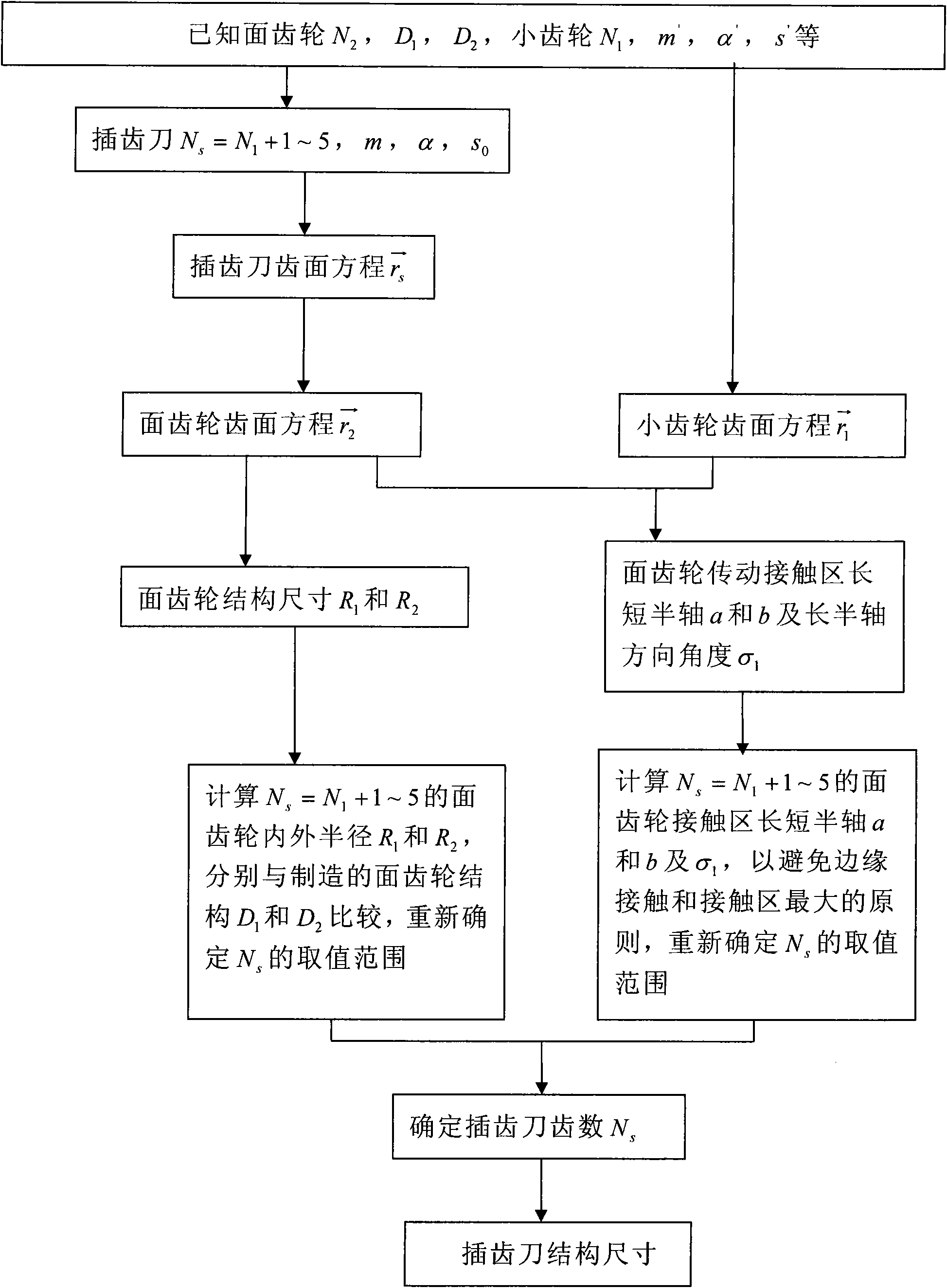

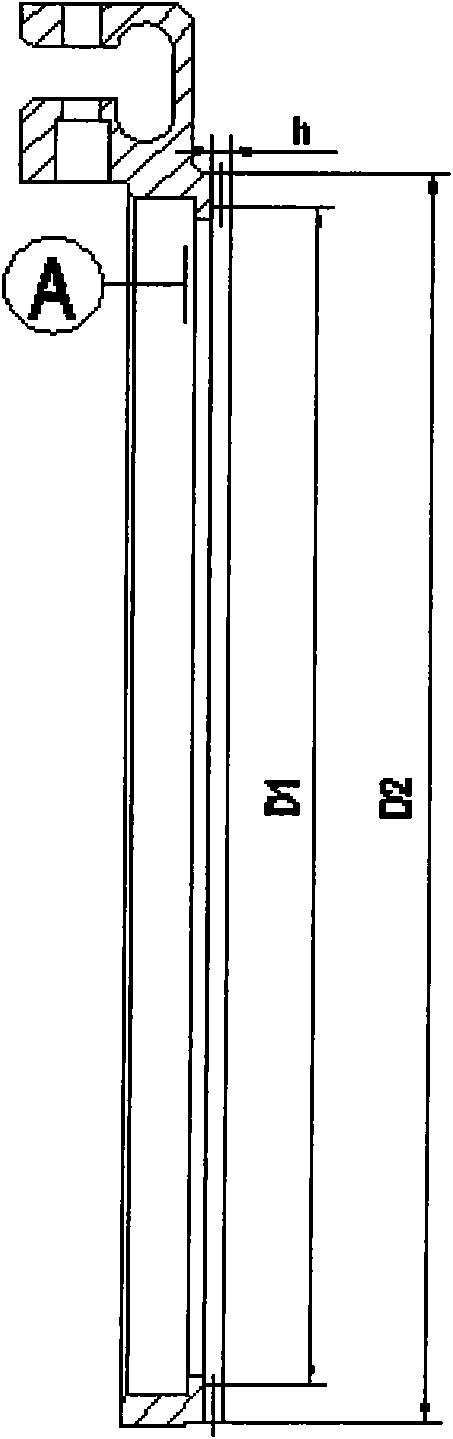

[0029] The present invention is a special face gear shaper tool designed for face gear shaper processing. Taking a certain type of face gear shaper cutter as an example, the structure realization process of the gear shaper cutter is as follows: figure 1 shown. This implementation example is aimed at figure 2 The surface gear structure diagram shown, the steps to realize the gear shape cutter tooth structure are as follows:

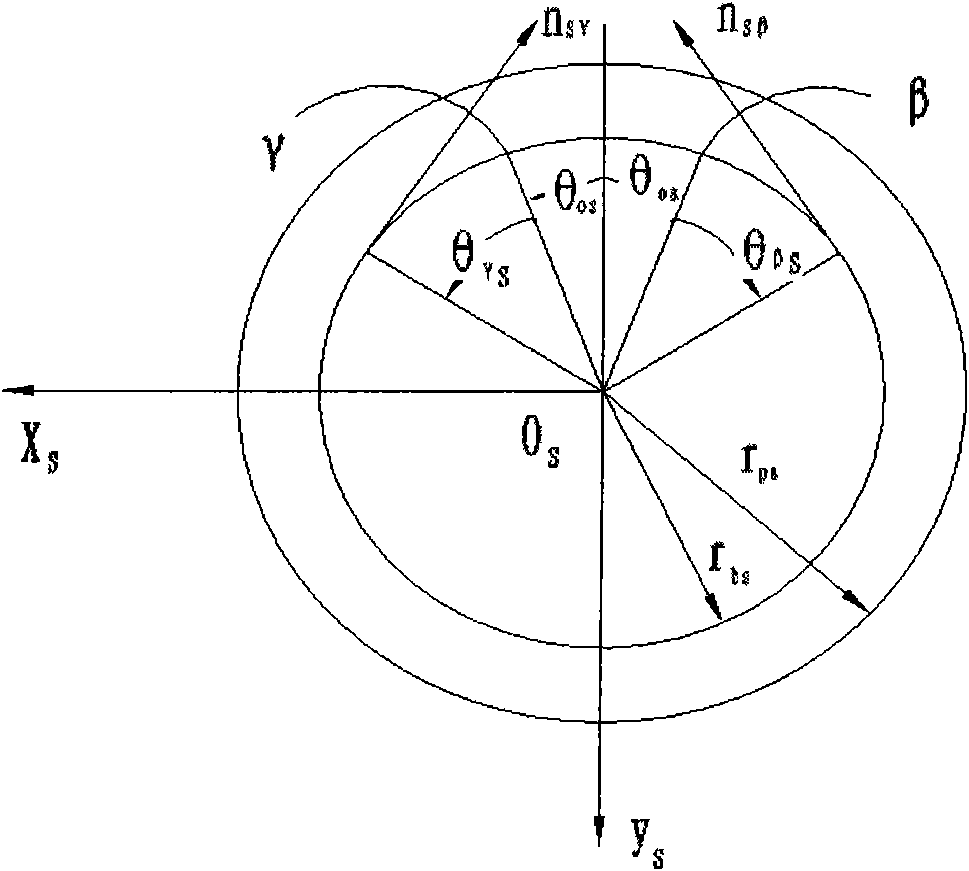

[0030] (1) Known face gear teeth number N 2 , Face gear structure size (inner and outer diameter D 1 and D 2 ), number of pinion teeth N 1, pinion modulus m′, pinion pressure angle α′, pinion indexing arc tooth thickness s′, pinion precision grade, according to the principle of point contact surface gear transmission and surface gear and pinion are processed by the same tool , to determine the number of teeth N of the face gear shaper cutter s The range is than the number of pinion teeth N 1 1 to 5 more (it is not determined until step (8) whether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com