Heat transfer pipe with internal threads

A heat transfer tube and internal thread technology, which is applied to the field of internal thread heat transfer tubes, can solve the problems of low heat transfer performance with thin and high teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

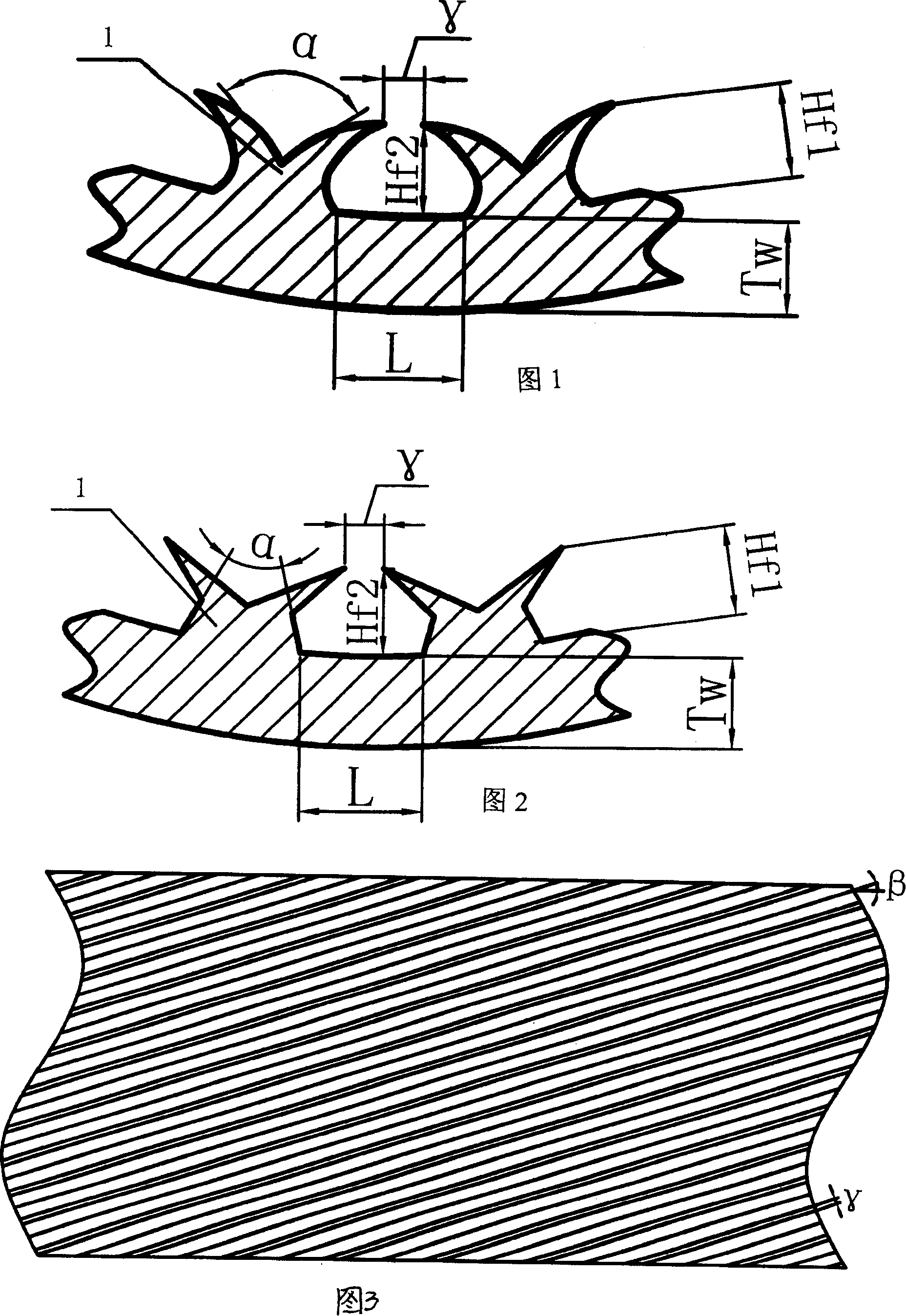

[0005] The present invention will be described in detail in conjunction with the above-mentioned drawings. The inner surface of the heat transfer tube is provided with evenly distributed helical teeth 1 of the same height. The cross section of the tooth is a Y-shaped tooth, and the two sides of the tooth are concave arcs. The top of the tooth is two convex arcs (see Figure 1); another structure of the Y-shaped tooth is a concave fold line on both sides of the tooth, and the tooth top is a concave fold line (see Figure 2); the cavity The width γ of the mouth is 0.01-0.25 mm, and the maximum width of the cavity is larger than γ (see Figures 1 and 2). The tooth height Hf1 is 0.06-0.3mm, Hf2 is 0.06-0.3mm, Hf1 and Hf2 can be equal or unequal, the bottom thickness TW of the tooth is 0.15-0.6mm, and the addendum angle α is 15°-180°. For the φ4-7mm heat transfer tube of the room air conditioner, the number of circumferential teeth of the helical teeth is 30-150, the tooth height is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com