Complex precise cycloidal speed reducer

A cycloid reducer, precise technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of limited first-stage transmission ratio, etc. The effect of improving load-carrying capacity and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

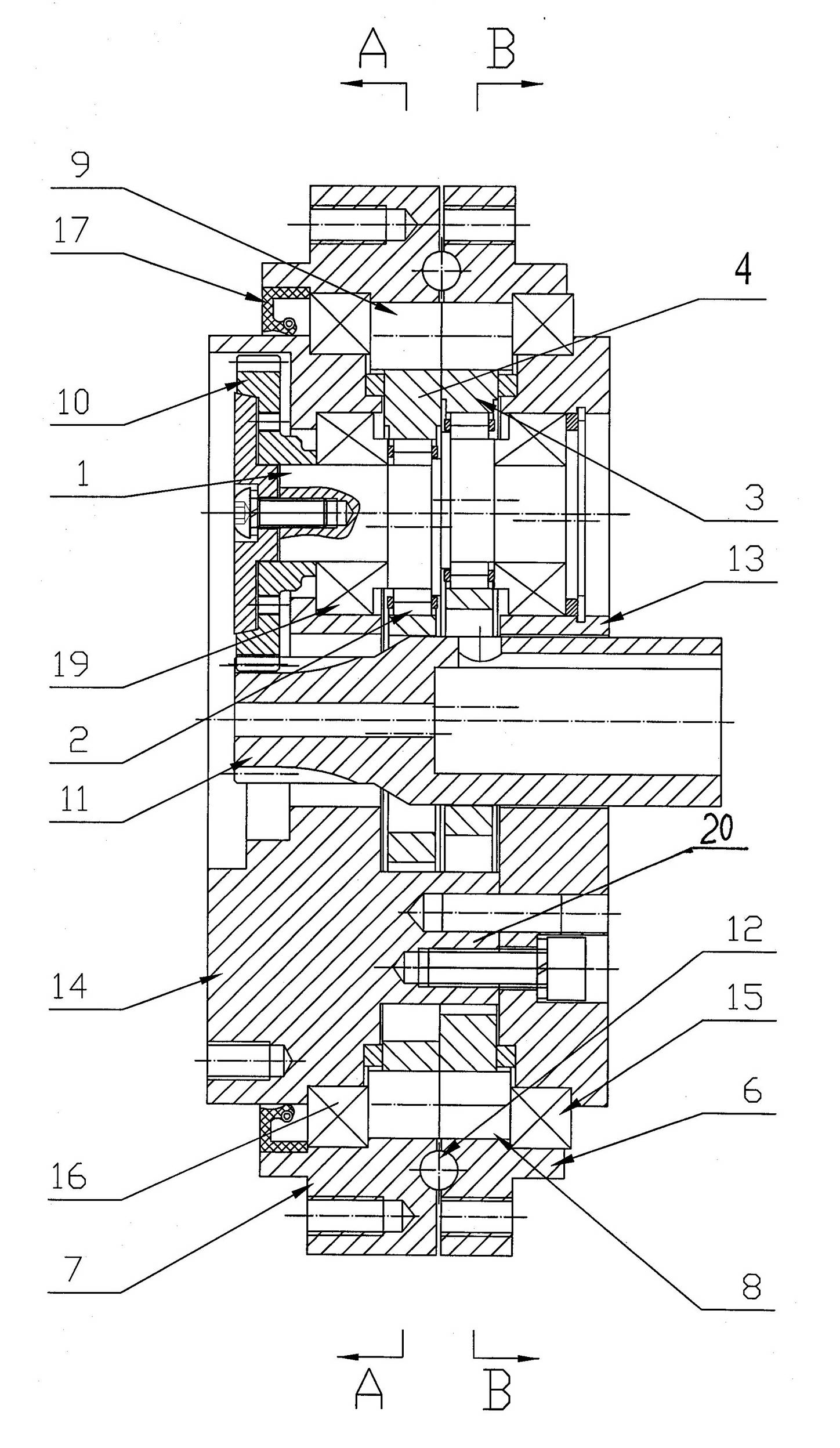

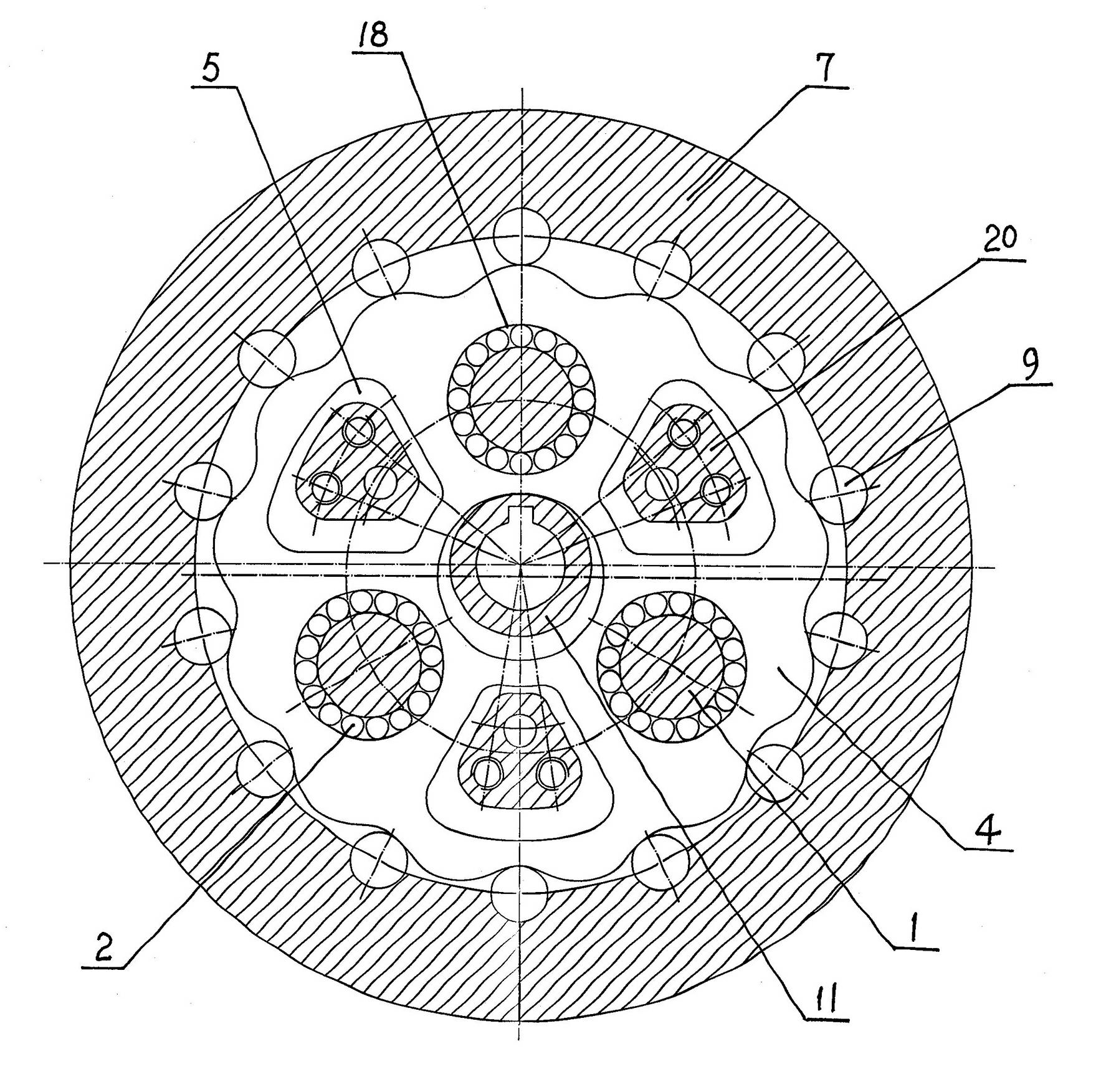

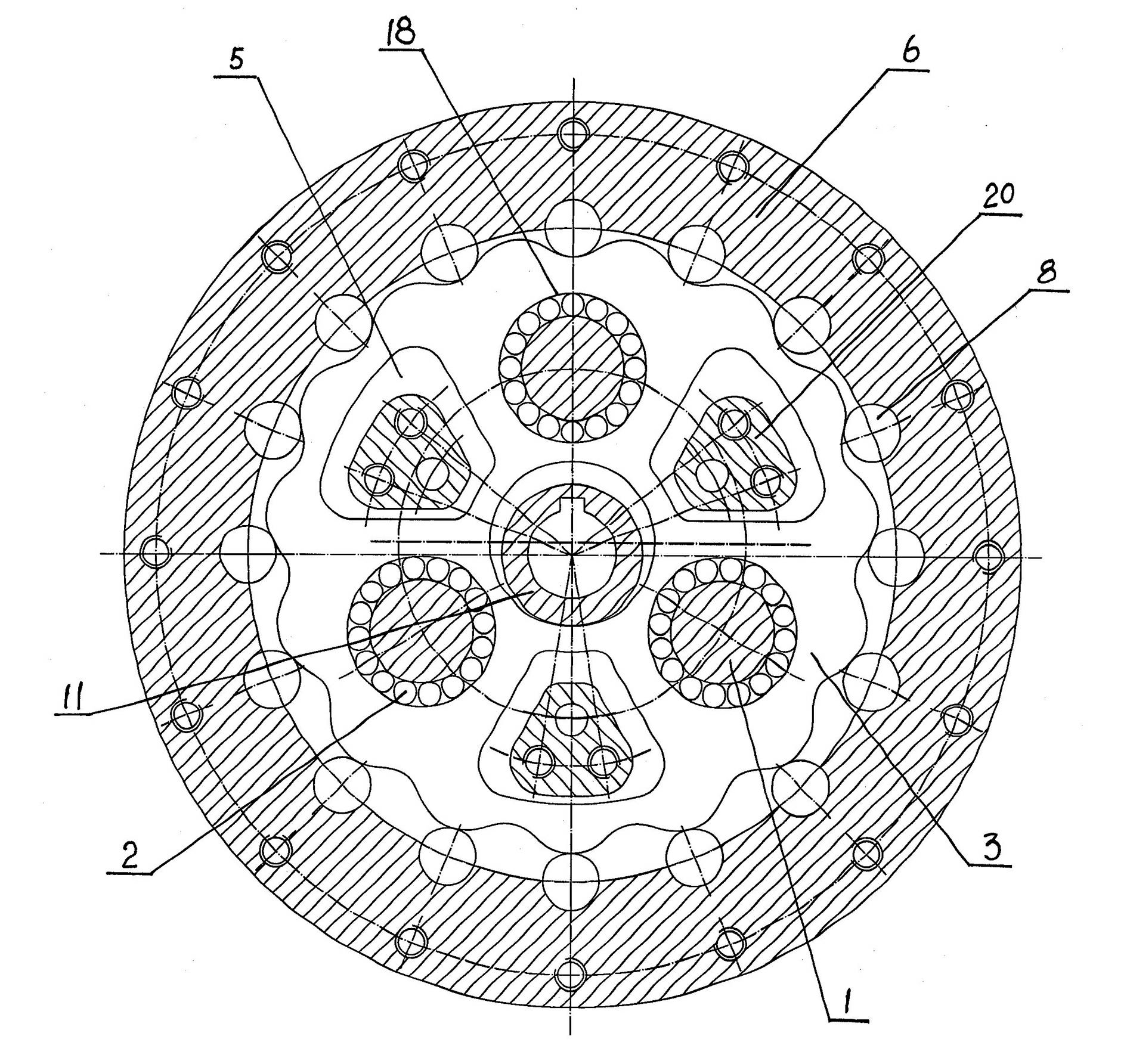

[0015] As shown in the figure, the present invention includes an eccentric shaft 1, and the eccentric part of the eccentric shaft 1 is connected to the cycloid wheel through the arm bearing 2. There are multiple eccentric positions that are staggered. The cycloidal wheels outside each eccentric position are divided into two groups: the reverse cycloidal wheel 3 and the forward cycloidal wheel 4. The reverse cycloidal wheel 3 and the forward cycloidal wheel 4 have different numbers of teeth and are set The connection hole 5, the reverse cycloid wheel 3 and the forward cycloid wheel 4 can also be designed as a cycloid wheel group consisting of a plurality of cycloid wheels, and each row of cycloid wheels in each cycloid wheel group is staggered by 360 degrees / n, n is the row number. The pin gear housing is divided into a stationary pin gear housing 6 and an output pin gear housing 7. The reverse cycloidal wheel 3 cooperates with the stationary pin tooth pin 8 fixed on the stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com