Method for designing molded lines of rotor of helical lobe compressor

A technology of screw compressors and rotor profiles, which is applied in mechanical equipment, machines/engines, rotary piston pumps, etc., can solve problems such as failure to meet market requirements, late screw compressors, and high noise, and achieve good social benefits. Noise reduction, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to understand the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings, data tables and specific embodiments.

[0018] The technical principle and scheme adopted in the present invention are introduced in detail as follows:

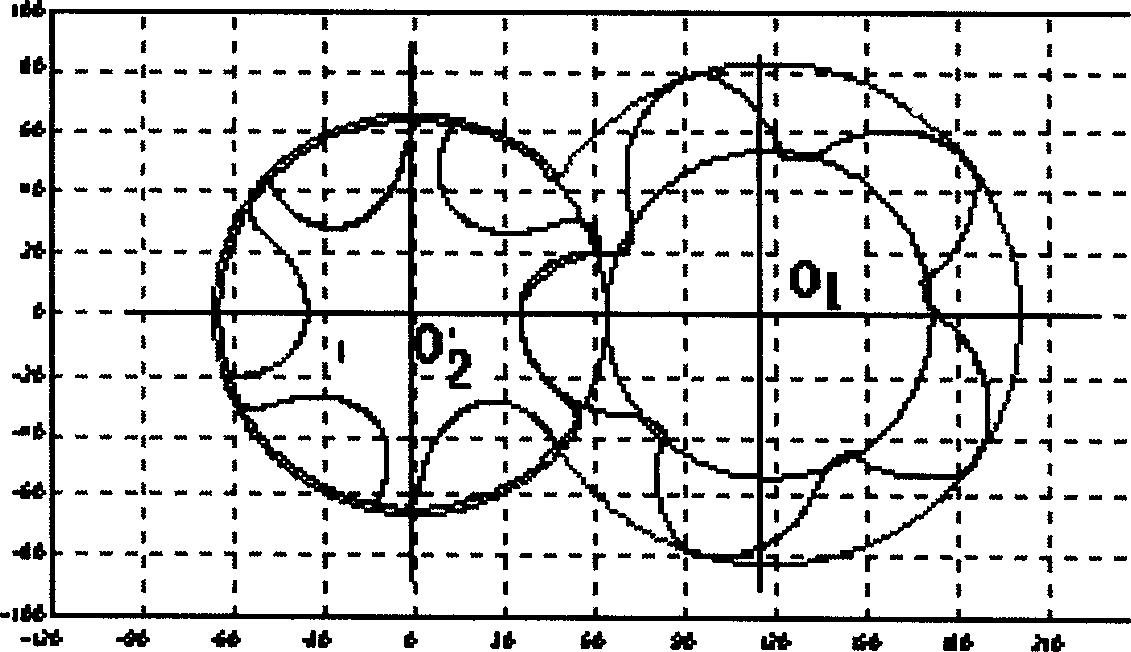

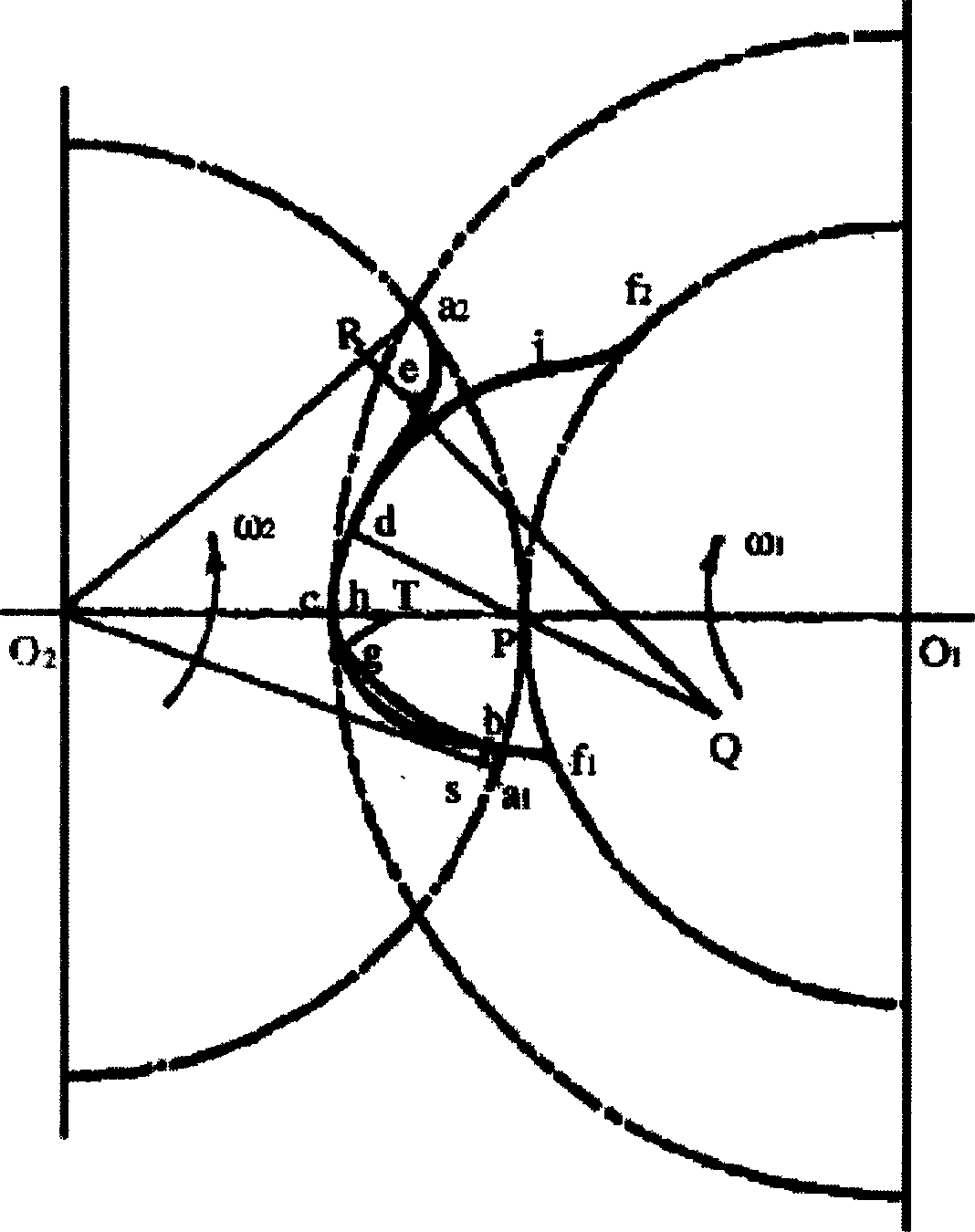

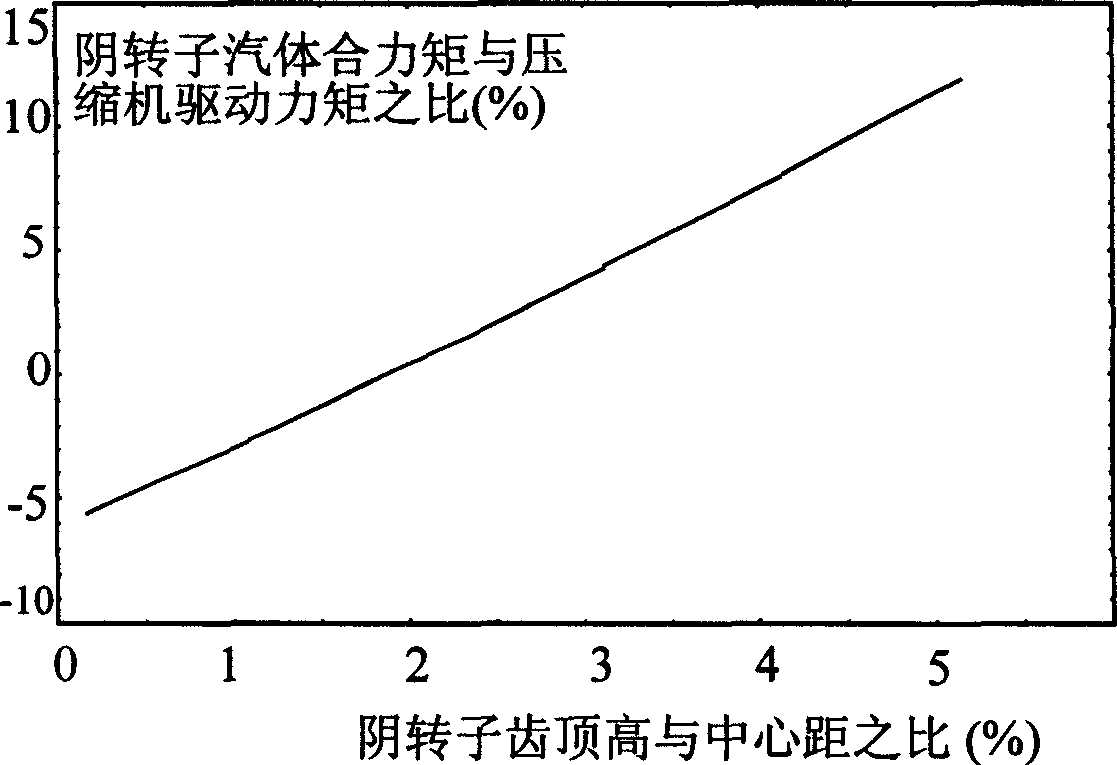

[0019] 1) When designing the profile, first of all, according to the general requirements for the screw compressor rotor profile and the special requirements of the actual use occasion, one or several curves should be preliminarily selected to form the tooth curve, and then its geometric characteristics should be calculated quantitatively Value and predict its performance, adjust and optimize such as tooth number combination and profile structure parameters, etc., and finally a new type of line with superior performance can be obtained. The present invention has a great improvement in the composition tooth curve of the screw rotor profile than the usua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com