Face-gear bending fatigue test mechanism and method

A technology of bending fatigue and face gear, which is applied in the field of face gear bending fatigue test mechanism, can solve the problems such as unable to load the face gear tooth test, and achieve the effects of short test period, improved test efficiency and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

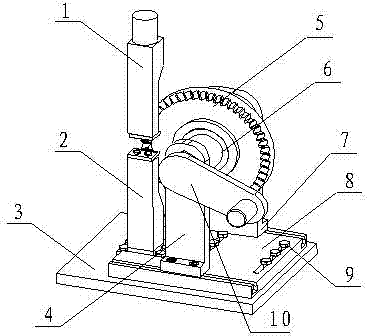

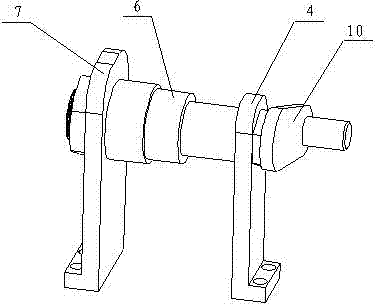

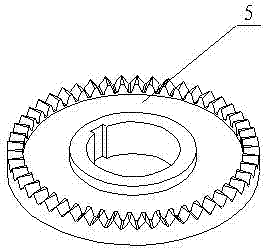

[0025] Such as Figure 1-Figure 6 As shown, the face gear bending fatigue test mechanism is composed of a loading part and a supporting part. The loading part includes a loading rod 1, a loading indenter 11 installed on the loading rod 1, and the supporting part includes a face gear support shaft 6, which is installed on a face gear support. The rocker 10 on the shaft 6, the support rod 2, the support pressure head 12 installed on the support rod 2, the installation plate 3, the axial adjustment plate 8, the right bracket 4 and the left side bracket installed on the axial adjustment plate 8 Bracket 7 , screws for fixing the axial adjustment plate 8 on the mounting plate 3 . The loading head 11 and the support head 12 are both involute toothed, so as to ensure that the gears on the surface to be tested are tightly meshed with the involute toothed loading head 11 and the involute toothed supporting head 12 respectively. .

[0026] During the test, install the mounting plate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com