Retractable rope used for elevator

A technology for ropes and elevators, applied in the field of stretched ropes for elevators, can solve the problems of no change in the flexibility of the carrier, easy torsion of the traction rope, and reduced service life, and achieve good bending fatigue resistance, uniform force, and improved The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

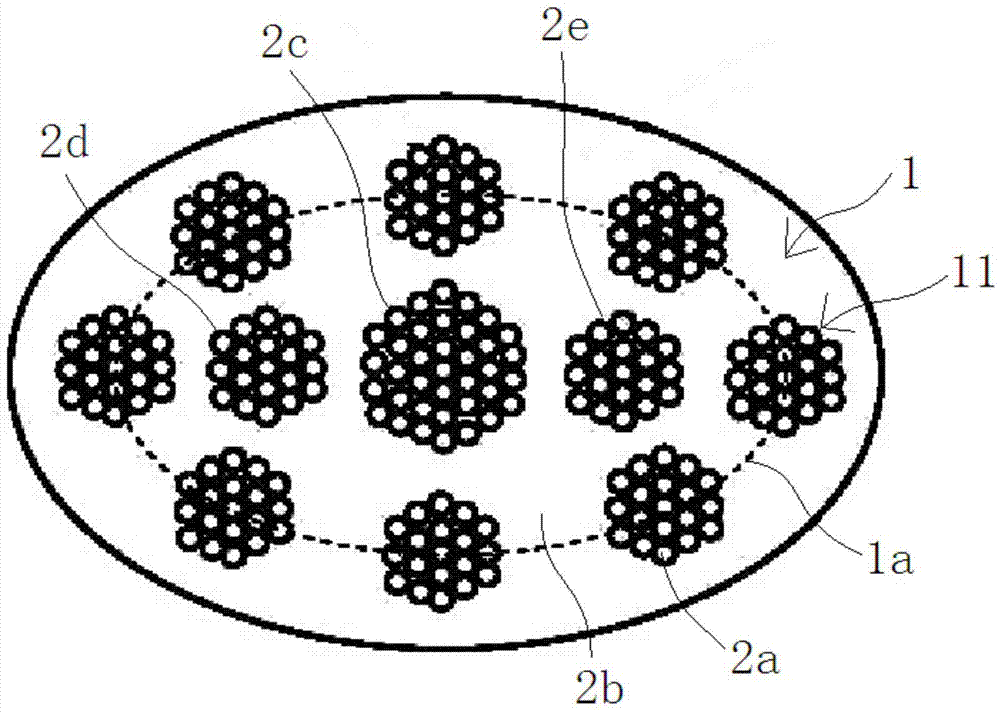

[0052] Such as figure 1 As shown, the elevator tensile rope shown in the figure is composed of a covering layer 1 and 11 bearing bodies. The cross section of the tension rope is designed with an ellipse shape, and the minor axis of the ellipse is perpendicular to the length direction of the tension rope. The outer peripheral surface of the tensile rope forms an outer ellipse 1a, and the ratio r of the major axis to the minor axis of the outer ellipse 1a should not be too large, and the reasonable range is 1≤r≤2. The ratio between the focal length of the outer ellipse 1a and the major axis is 1.618.

[0053] The covering layer 1 is made of non-metallic elastomer material, specifically made of thermoplastic polyurethane rubber. The polyurethane elastomer material is filled between the load-bearing core wires and is wrapped around the periphery of the tensile rope. During the operation of the elevator, the tensile rope bends when passing through the traction sheave. Due to the dif...

Embodiment 2

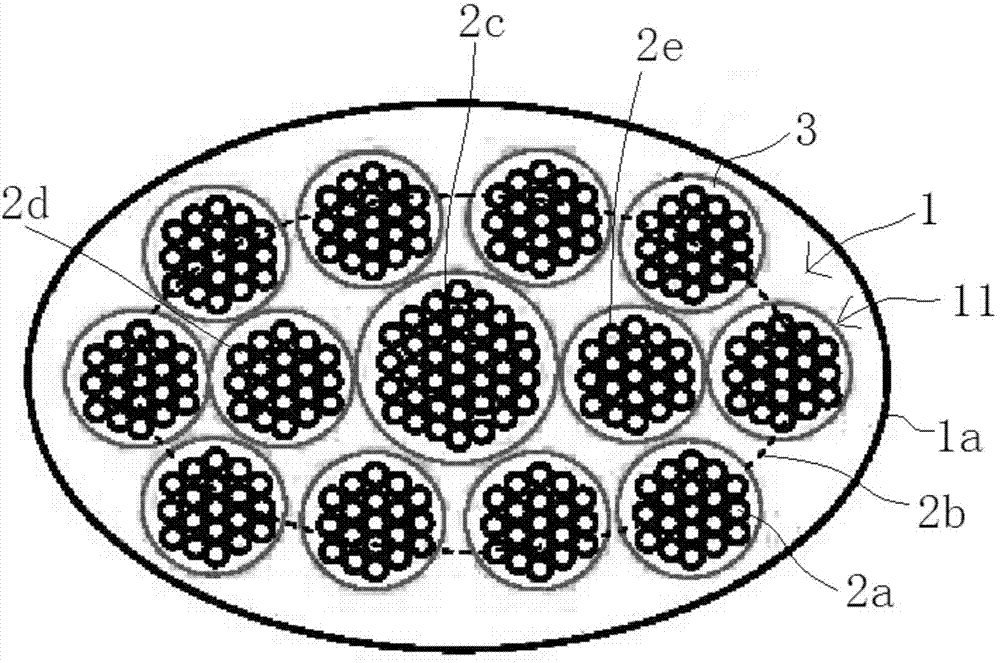

[0060] Such as figure 2 As shown, the difference between the elevator tensile rope of this embodiment and the elevator tensile rope of Example 1 is that the high-strength steel wire of this embodiment is coated with a polytetrafluoroethylene resin coating 3 with good lubricating properties. The thickness of the polytetrafluoroethylene resin coating layer 3 is 0.3-0.6 mm, so that the adjacent steel cord cores are arranged more closely, and then the thermoplastic polyurethane rubber of the coating layer 1 is used to fill the remaining parts. In addition, each bearing body is sealed with a special lubricant to further reduce the wear between the high-strength steel wires twisted together, thereby increasing the life of the traction rope.

[0061] In addition, the number of carriers in this embodiment is increased to 13 compared to Embodiment 1, and it is also arranged in two layers inside and outside. The ten carriers 2a of the outer layer are distributed on the circumference of an ...

Embodiment 3

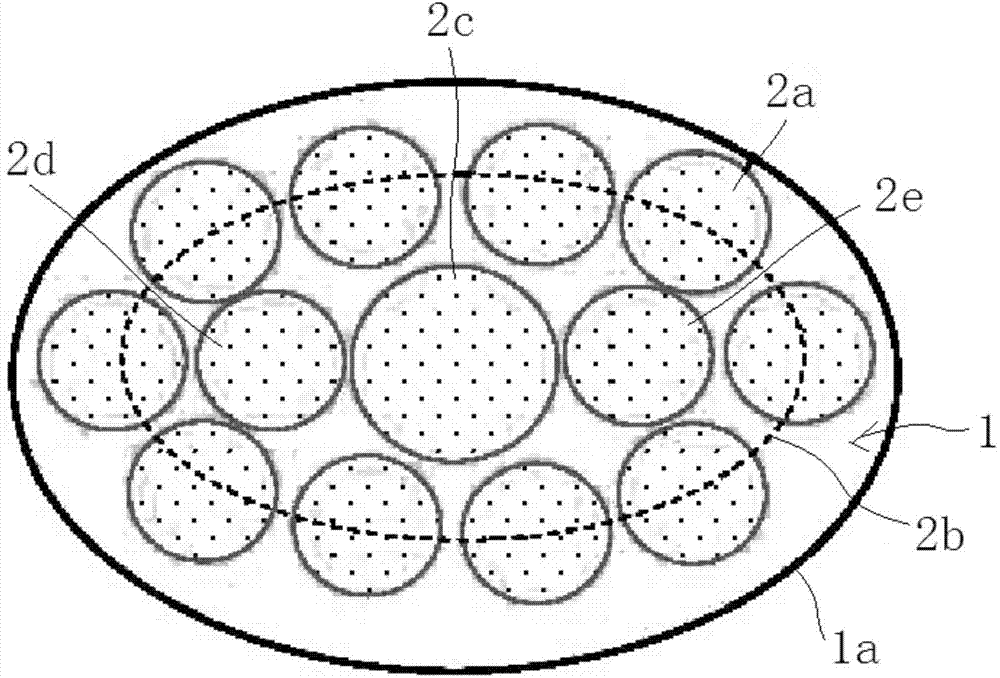

[0064] Such as image 3 As shown, the difference between the elevator tensile rope shown in the figure and the elevator tensile rope of Example 2 is that all the supporting bodies 2a, 2c, 2d, 2e are made of carbon fiber or aramid with high strength and high modulus. Made of fiber-reinforced resin-based composite material. The volume ratio of high-strength and high-modulus carbon fiber or aramid fiber to the resin matrix is not less than 9:1.

[0065] Because the high-strength, high-modulus carbon fiber or aramid fiber resin matrix composite material itself has good bending fatigue resistance, there is no need to reduce the cross-sectional size of the carrier to improve the life. Therefore, the area of the bearing body can be further increased while keeping the overall outer size unchanged, so that the rope has higher bearing capacity and resistance to torsional deformation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com