Quick change chuck of electric tool

A technology for quick-change chucks and power tools, which is applied to manufacturing tools, clamping, metal processing equipment, etc., can solve the problems of low replacement efficiency, affecting processing procedures, and troublesome operation, and achieves simple structure, simple operation, and avoidance of overheating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

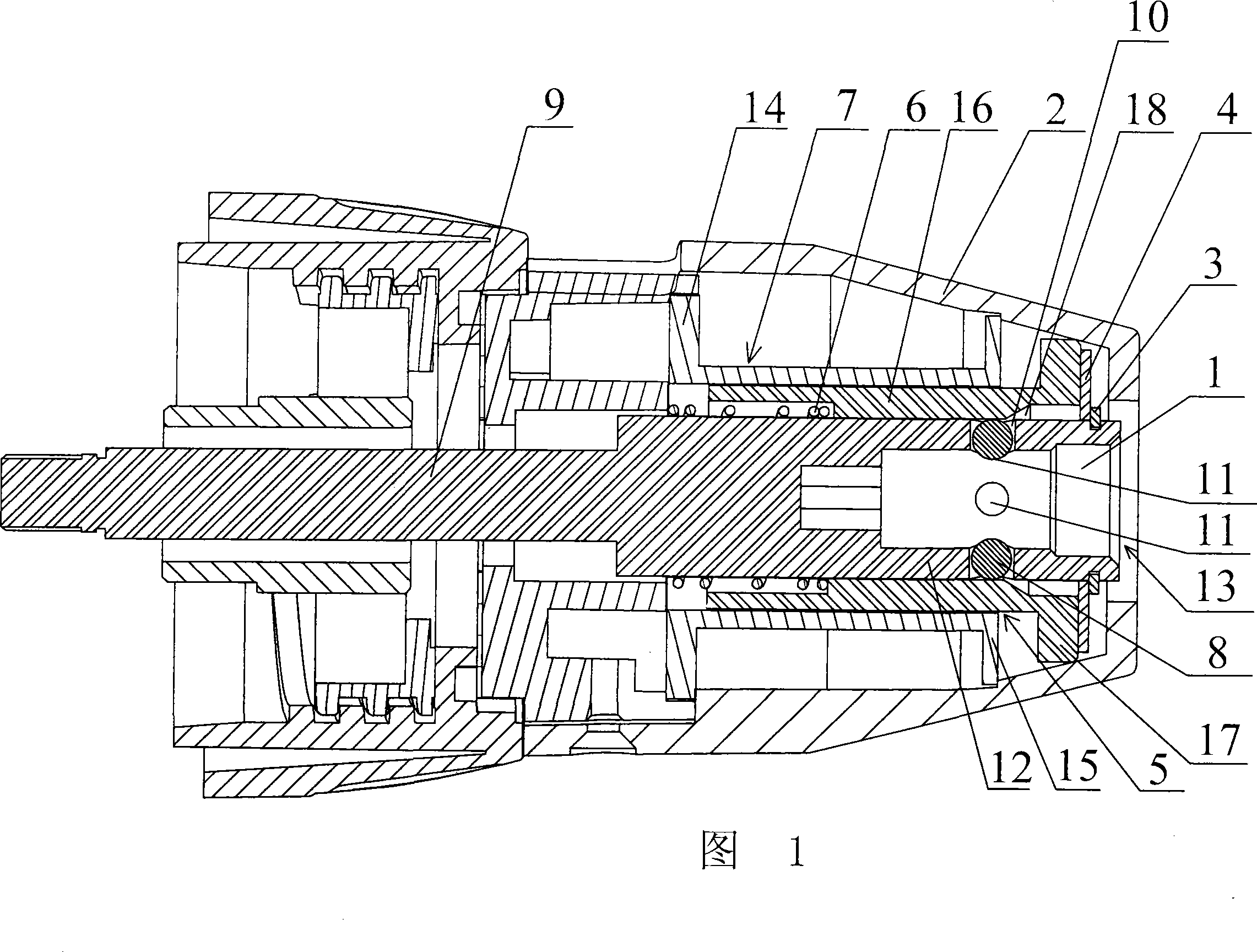

[0012] As shown in the figure: an axial hole 13 is provided at one end of the main shaft 9 for installing the drill bit, and a shaft sleeve 1 closely matched with it is installed in the axial hole 13, and a diameter is provided on the main shaft wall 12 outside the shaft sleeve 1. To the round bottom hole 10, put the positioning ball 8 in it, and the diameter of the positioning ball 8 is greater than the depth of the round bottom hole 10, and the shaft sleeve 1 corresponding to the round bottom hole 10 is also provided with a location for the spherical part of the positioning ball 8 to sink into. Slot 11, the outer surface of the main shaft wall 12 is covered with spring 6, the right end of spring 6 leans against the positioning frame in the quick change chuck, the left end of spring 6 pushes against the vertical wall of sliding sleeve 5 which is sleeved outside spring 6, and sliding sleeve 5 is interrupted Permanently cover the opening of the round bottom hole 10, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com