Mid-size vehicle speed changer with main tank and auxiliary tank

A technology for automotive transmissions and sub-transmissions, applied to components with teeth, belts/chains/gears, transmissions, etc., can solve the problems of no synchronizer in the main box, high working intensity, and difficulty in shifting gears, and achieve a compact structure , good meshing performance and large number of gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

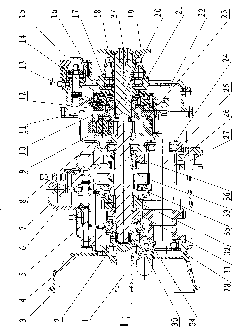

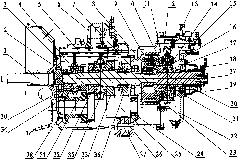

[0015] like figure 1 As shown, the preferred embodiment of the present invention includes a main box and an auxiliary box connected to each other. The main box has a first shaft 1 as a power input, a second shaft 4 and an intermediate shaft 25 for power transmission.

[0016] The first shaft 1 is supported on the main box housing 3 through a full cylindrical roller bearing 2 with a snap ring on the outer ring. One end of the second shaft 4 is supported on the inner hole of the first shaft 1 by a needle bearing, and the other end is supported on the main box casing 3 by a cylindrical roller bearing 7 with a stop ring on the outer ring, and at the same time extends into the auxiliary box middle.

[0017] In this embodiment, the first, second, third, and fourth forward gears are provided on the second shaft 4 , which are respectively 30 , 31 , 32 , and 33 in the figure, and a reverse gear 36 . Each forward gear is vacantly sleeved on the second shaft 4 through a needle bearing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com