Ratchet screw driver

A screwdriver and ratchet technology, applied in the field of screwdrivers, can solve problems such as inconvenient to hold by hand, complex structure, etc., and achieve the effect of simple and compact structure, large number of teeth, and large torque transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings of the description.

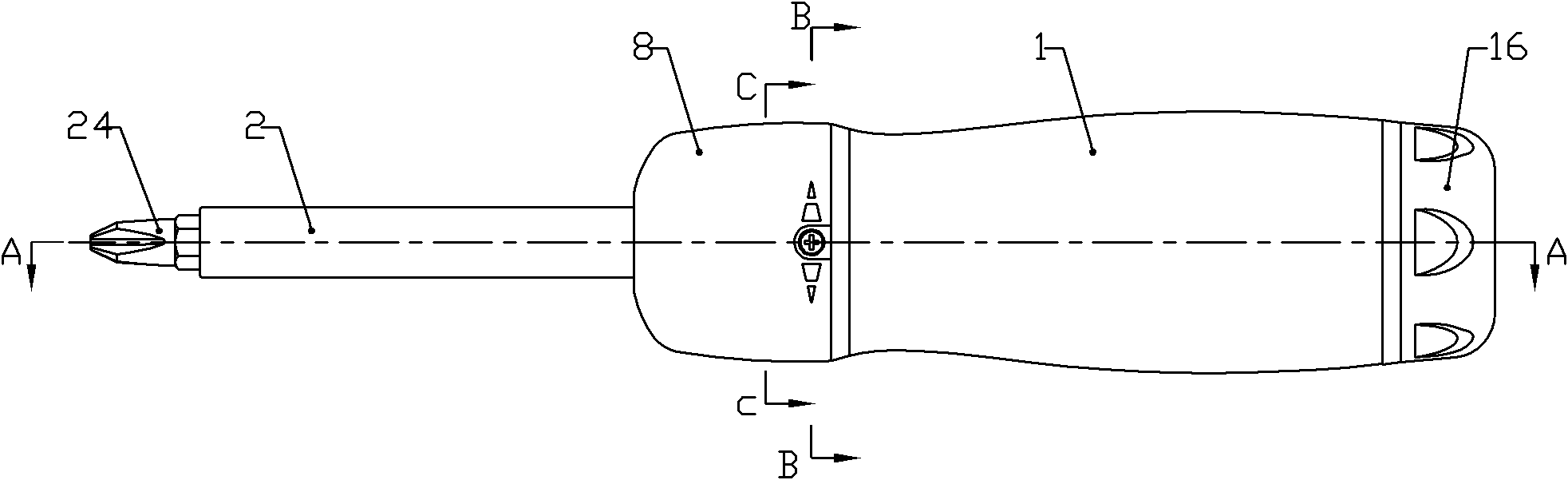

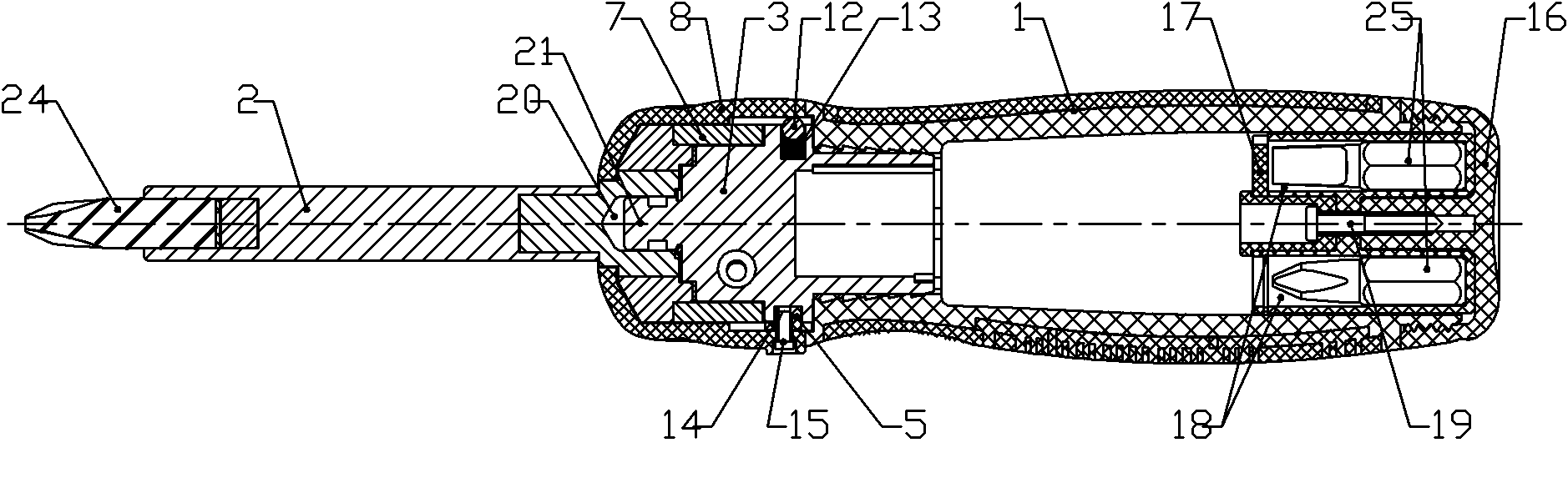

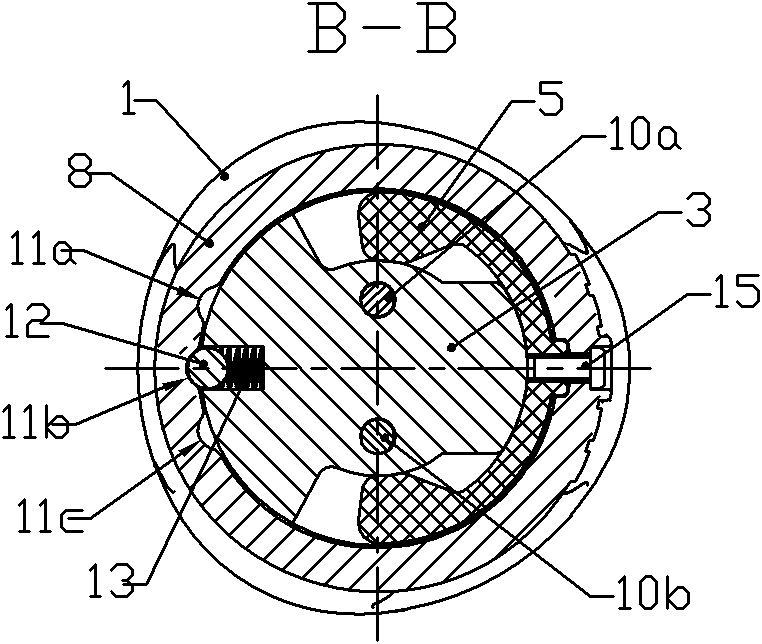

[0035] Such as figure 1 , 2 As shown, the ratchet screwdriver includes a handle 1 and a screwdriver 2, of which: see Figure 4 , Figure 11 , the front end of the handle 1 has a pawl seat 3, on which two opposite swingable pawls 4a, 4b are symmetrically arranged and a dial 5 for controlling the positions of the two pawls, the dial There are two shifting blocks 6a, 6b respectively corresponding to the two ratchets 4a, 4b on the 5; the tail of the ratchet 2 has a ratchet sleeve 7, and the inner wall of the ratchet sleeve 7 has internal ratchet teeth distributed in a ring shape, and the ratchet sleeve 7 sets On the pawl seat 3 and its inner ratchet is at least engaged with one of the two pawls 4a, 4b; and a control member that can be positioned on the handle 1 is used to change the position of the dial 5, specifically, The control member can be a sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com