Patents

Literature

46results about How to "Ease of shifting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

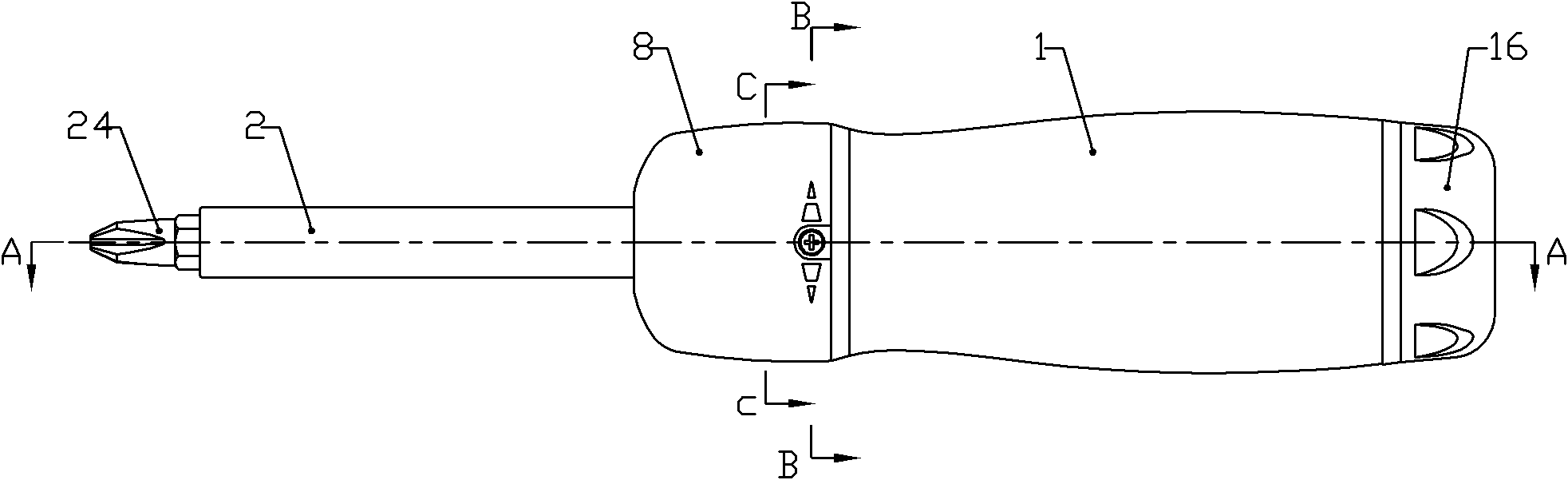

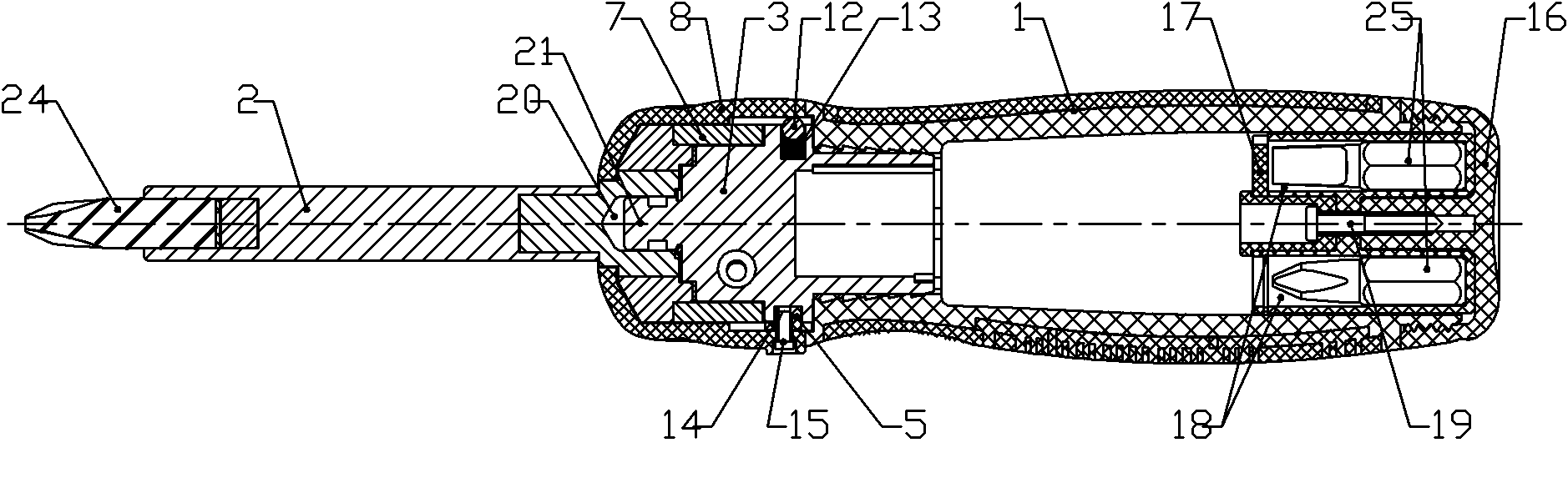

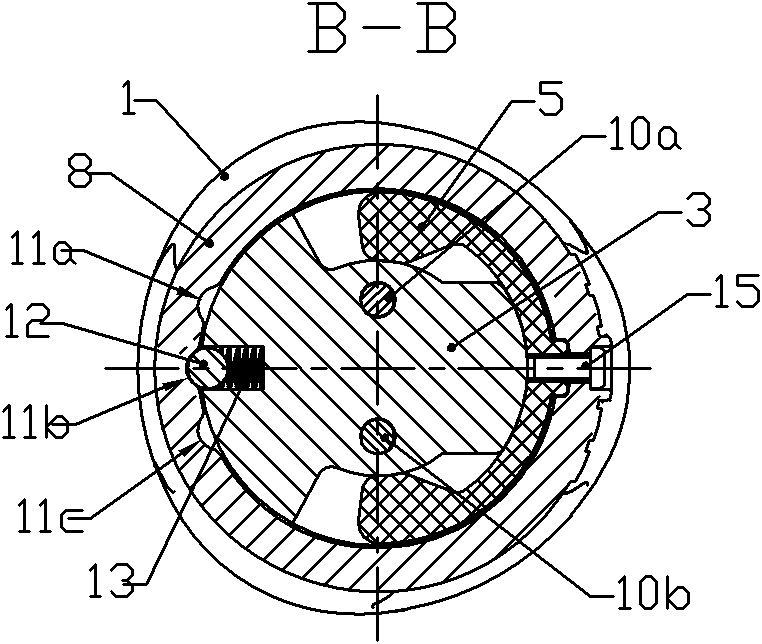

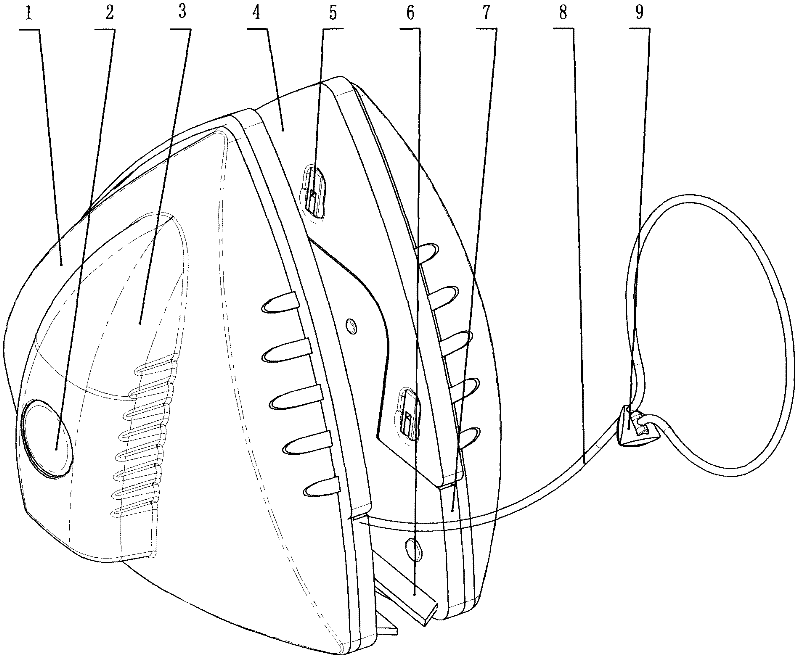

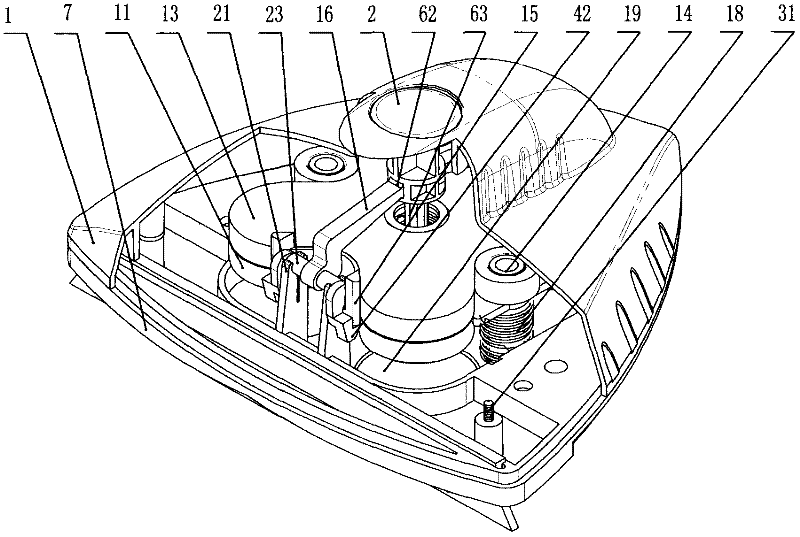

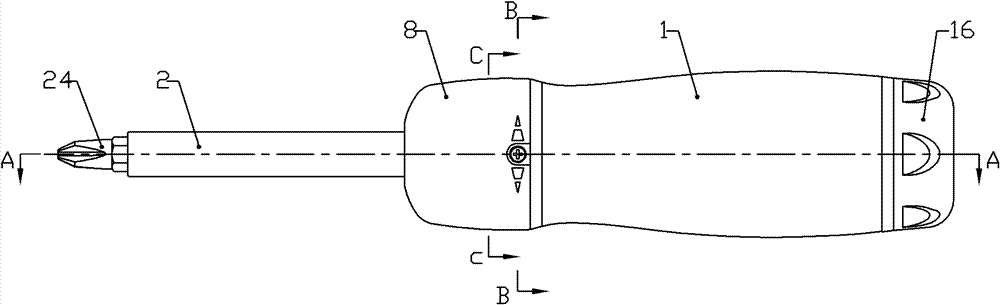

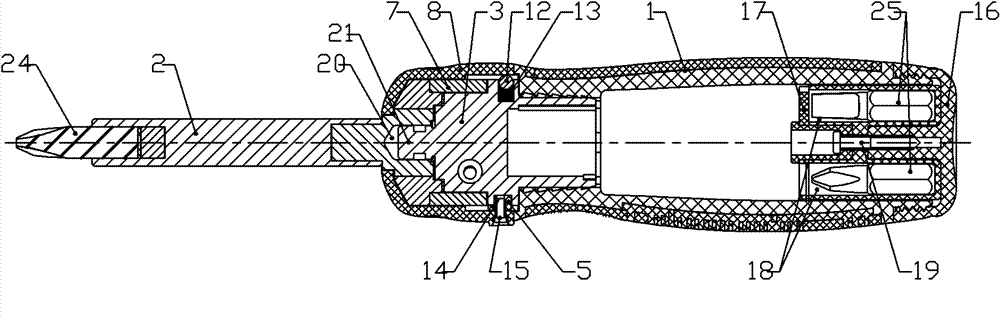

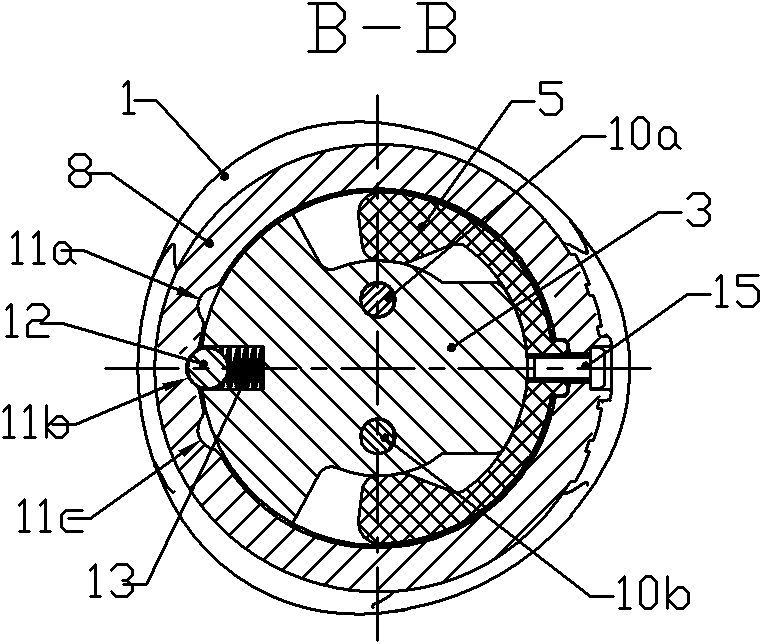

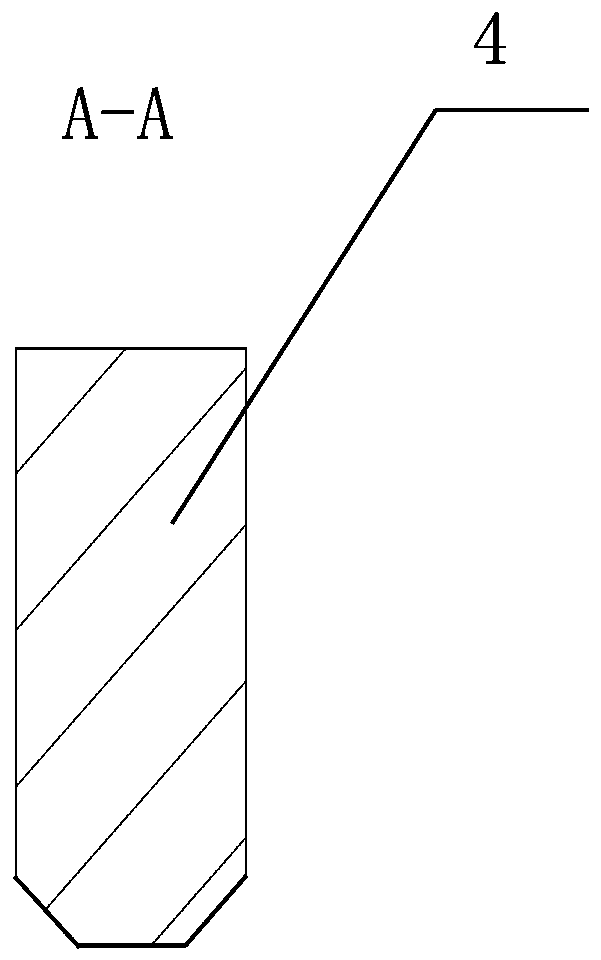

Ratchet screw driver

The invention discloses a ratchet screw driver which aims at solving the problems that the existing orienting screw driver is inconvenient to hold by hand and has a complicated structure. The ratchet screw driver comprises a handle and a driver rod and is characterized in that the front end of the handle is provided with a pawl bed, wherein the pawl bed is provided with two pendular pawls arranged in the opposite directions and a shift part for controlling the position states of the two pawls, and the shift part is provided with two shift blocks which respectively correspond to the two pawls;the tail of the driver rod is provided with a ratchet sleeve, and the ratchet sleeve is sheathed on the pawl bed and is at least meshed with one of the two pawls; and an operating part which can be positioned on the handle is arranged and is used for changing the position of the shift part. By integrating all orienting structures at the front end of the handle, the ratchet screw driver has the advantages of simple and compact structure and convenient assembly and disassembly. Since a rotating sleeve is adapted to the outline wheel of the handle, the ratchet screw driver is kept adapted to thehandle in shape in addition to facilitating gear shift, thereby facilitating being holden by hand for usage.

Owner:HANGZHOU GREAT STAR IND CO LTD

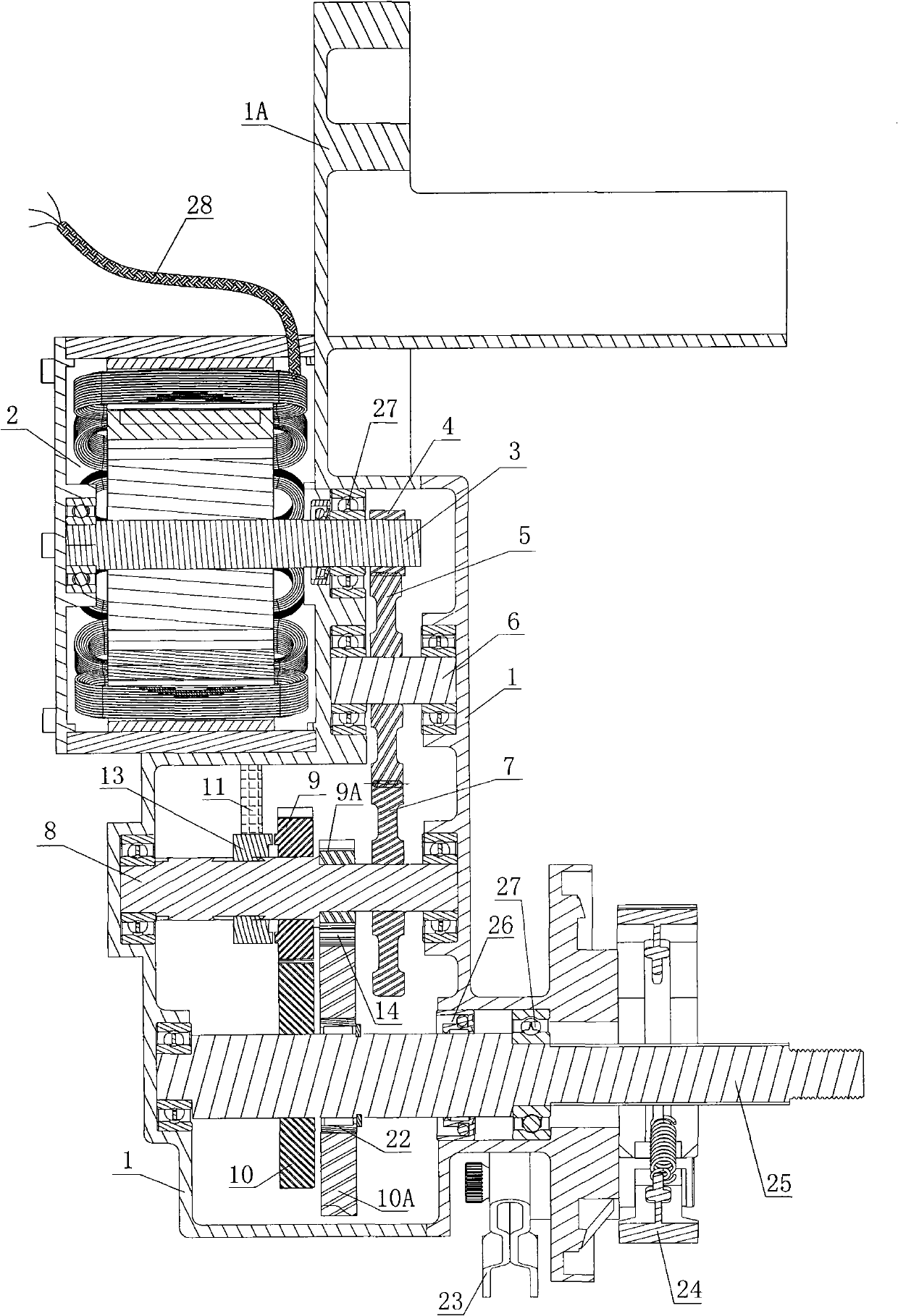

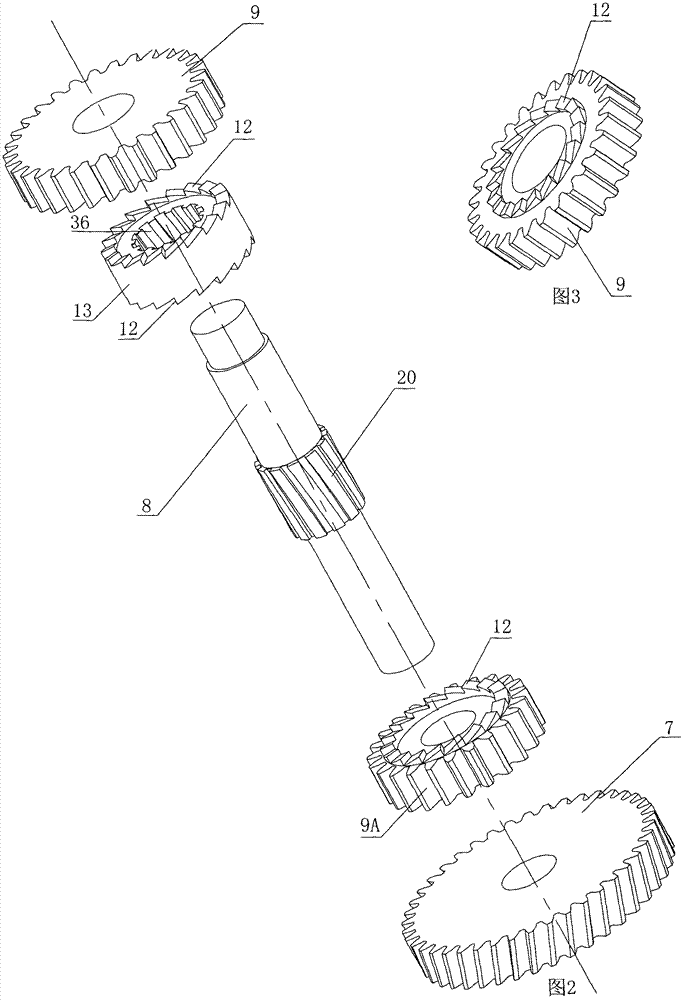

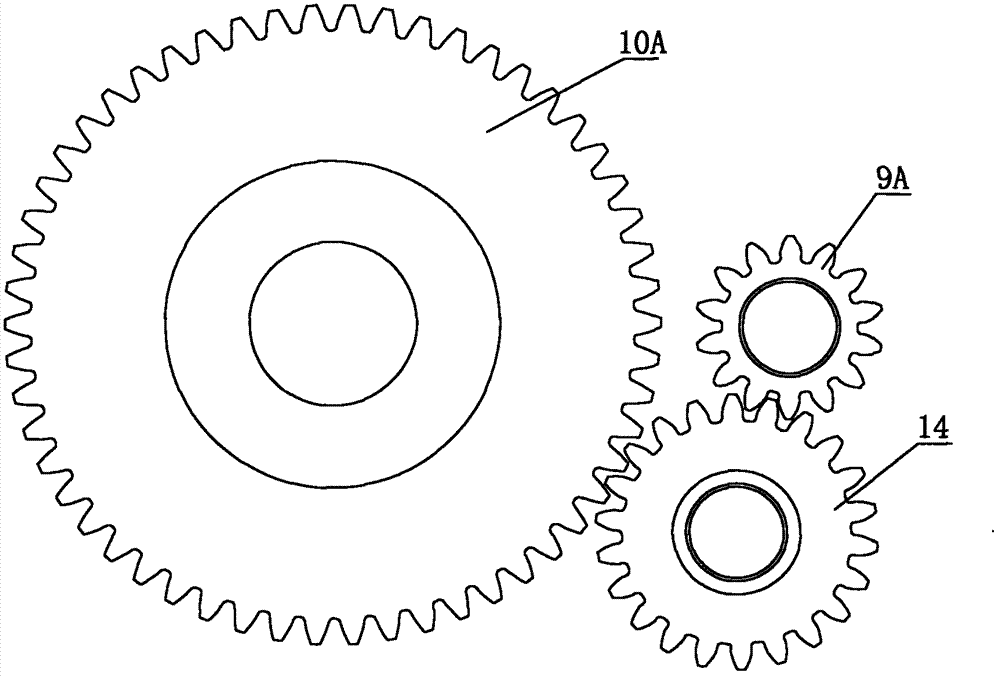

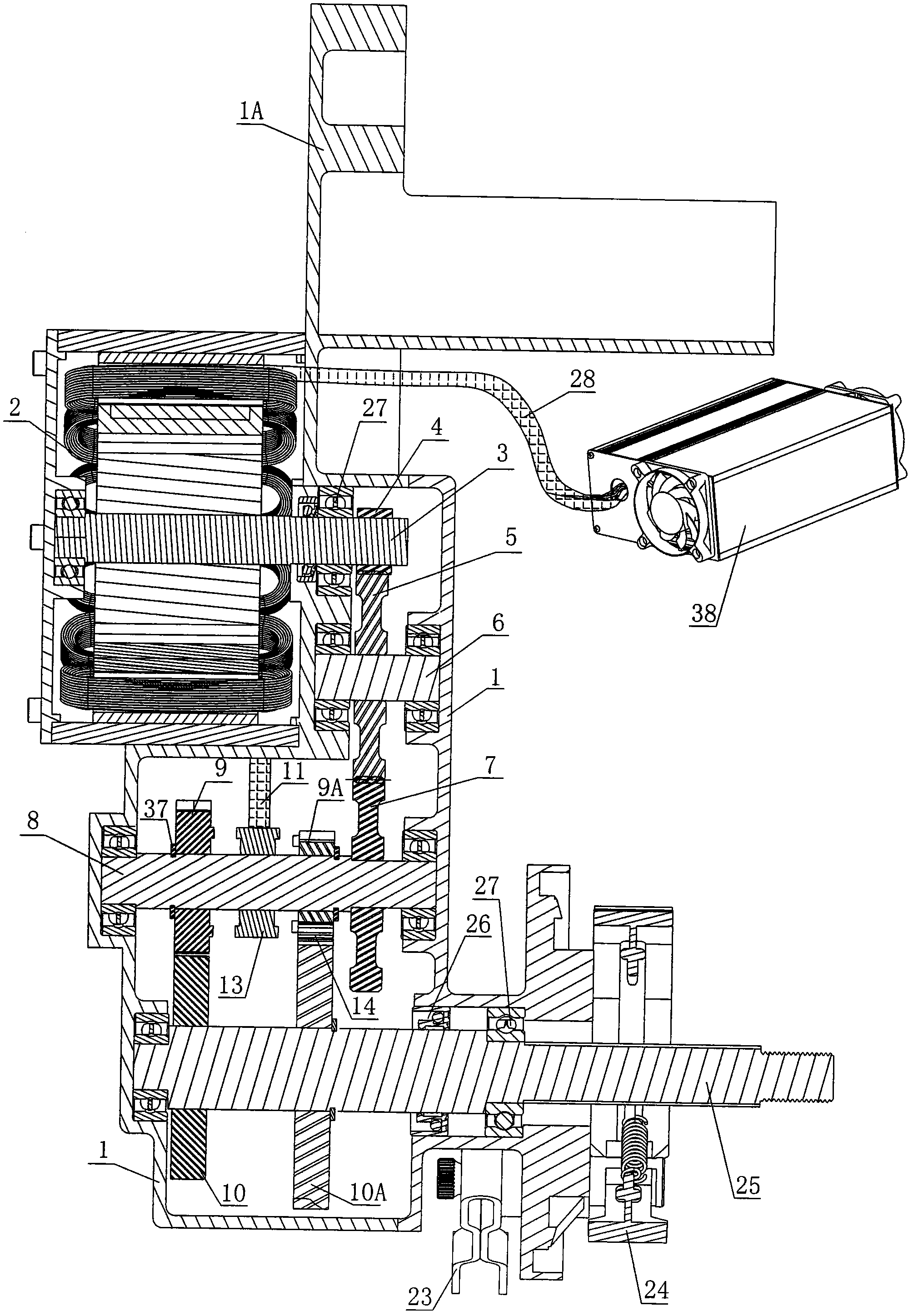

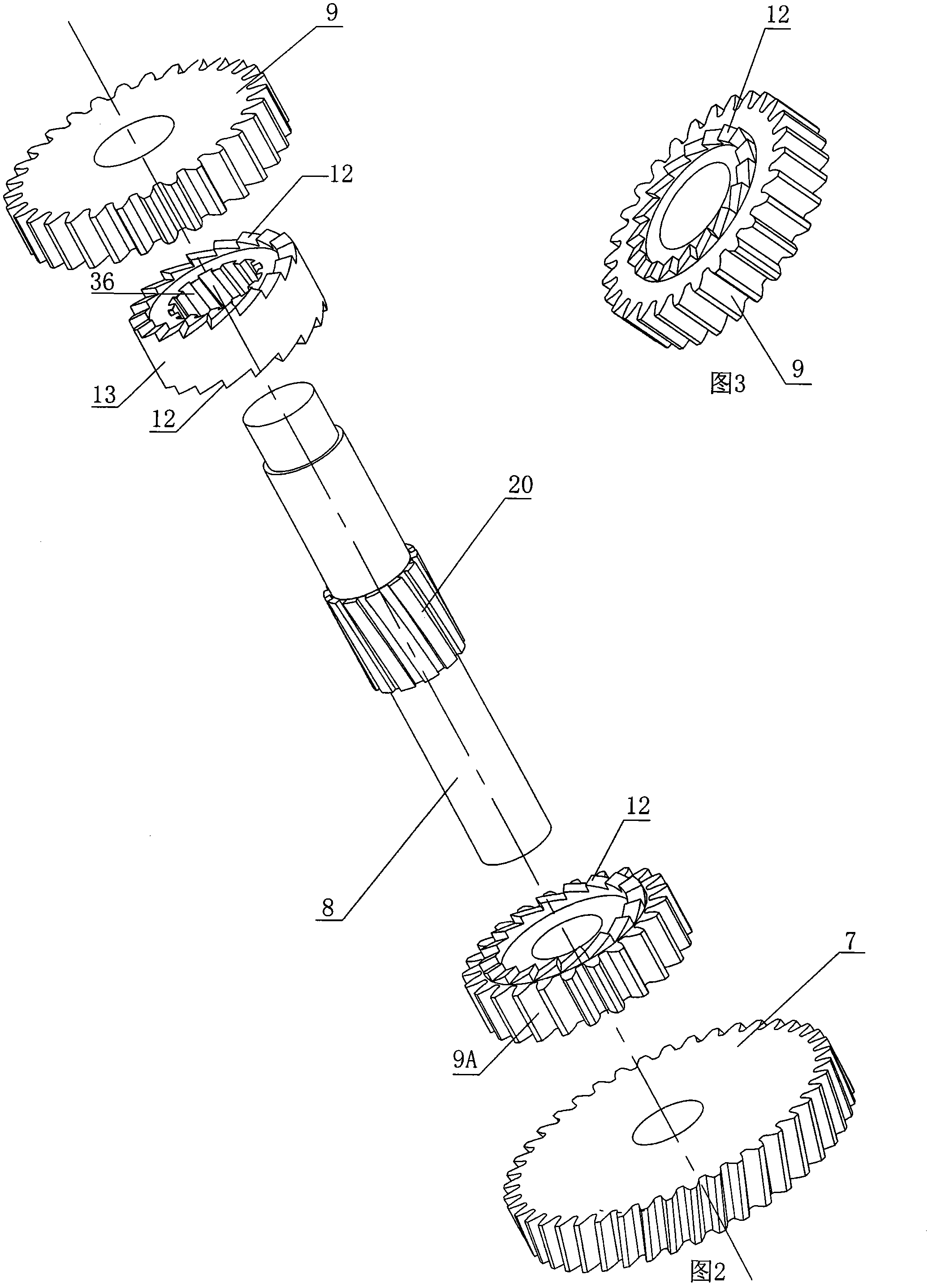

Transmission for electric vehicles

InactiveCN102562960AImprove efficiencyNot easy to get hotToothed gearingsGearing controlFluteElectric cars

The invention relates to a transmission for electric vehicles, belongs to the technical field of power transmission for electric vehicles and realizes that different speed and torque can be output on the condition of the same revolution speed of a motor. The transmission for electric vehicles comprises a case, a motor is arranged in the case and provided with a motor shaft, the motor shaft is in transmission coupling with a spindle, a drive gear is fixed on the spindle, a second-gear drive gear is in meshing transmission with an output gear sleeved on an output shaft, flutes are machined on the spindle, a slider is connected with the second-gear drive gear under action of the flutes when in rotation of the spindle, the second-gear drive gear meshes with the output gear to drive the output shaft to rotate, and a first-gear drive gear drives a first-gear output gear through a reversing gear so as to drive the output shaft to rotate.

Owner:蔡旭阳

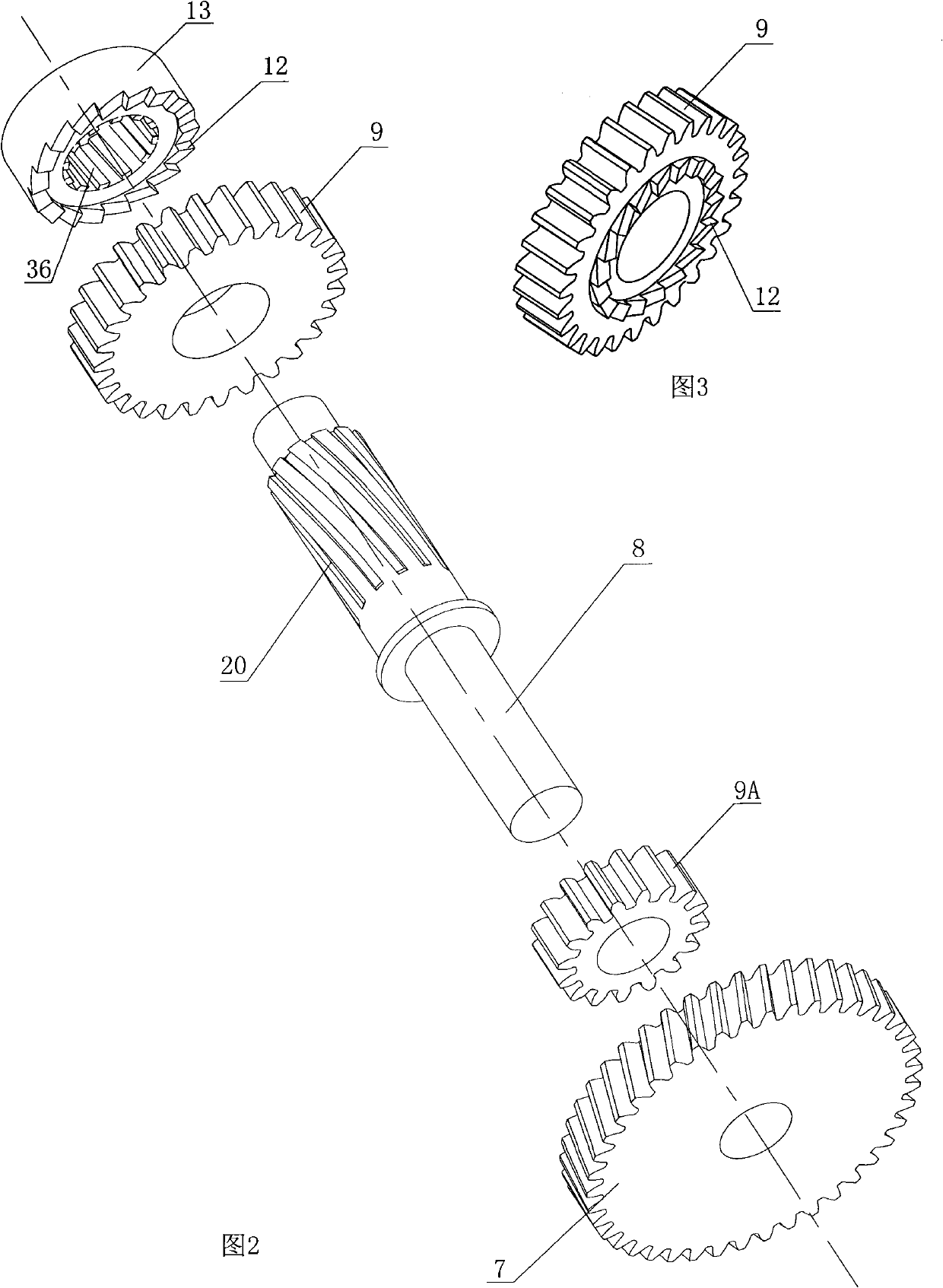

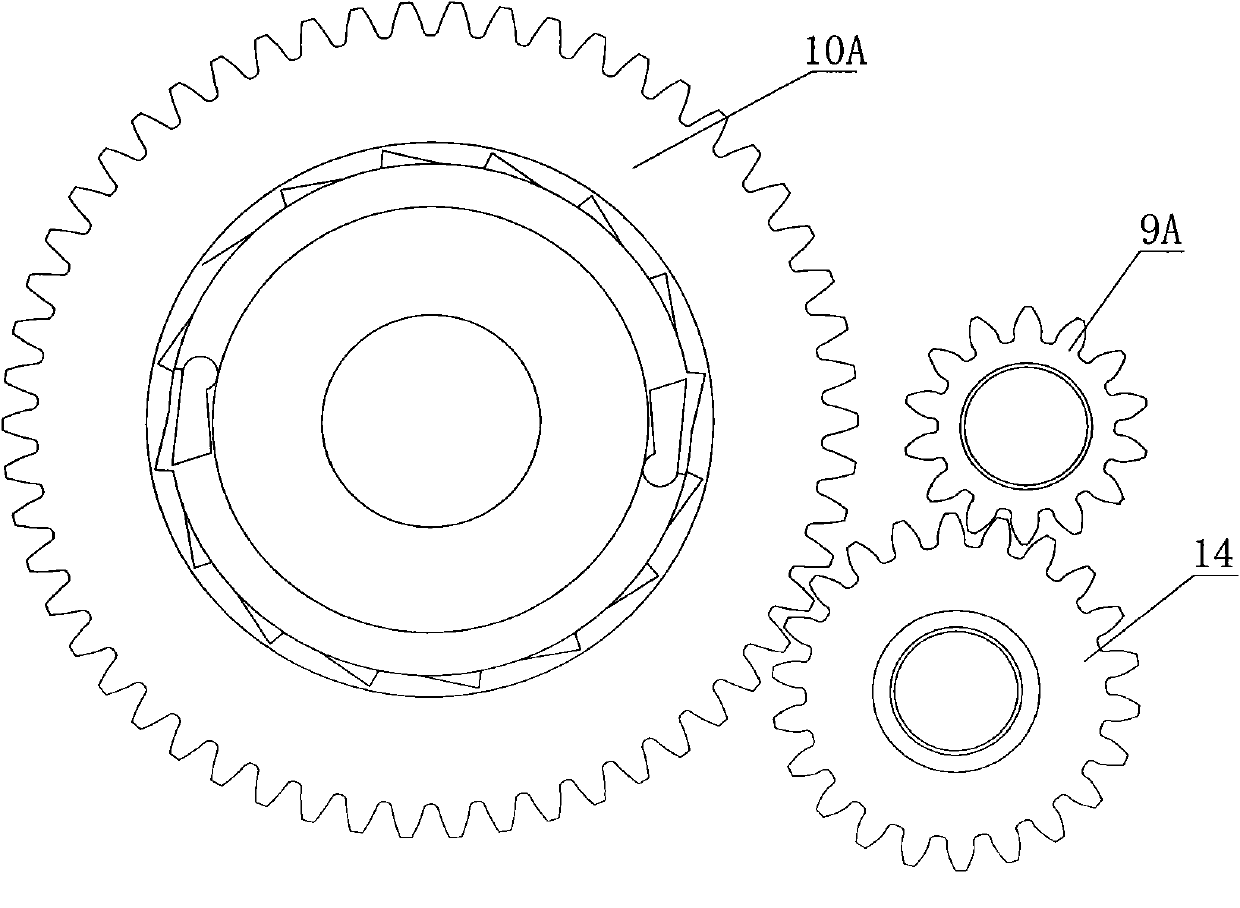

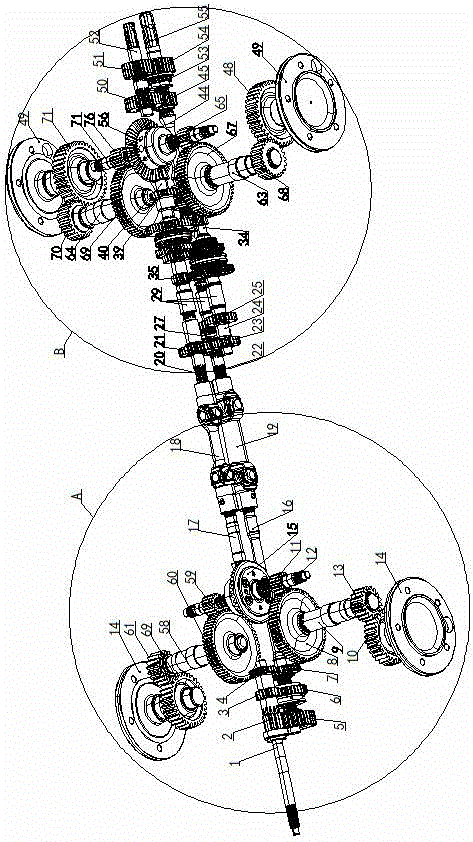

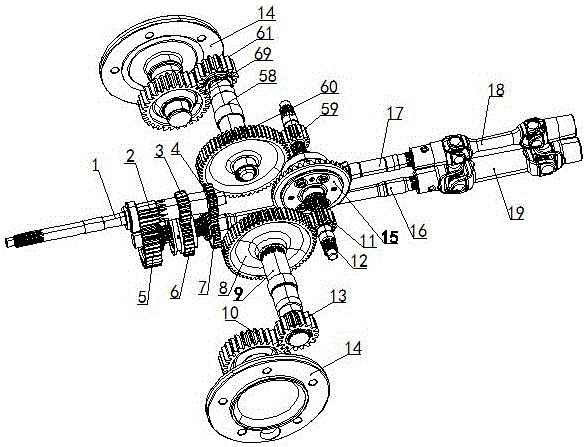

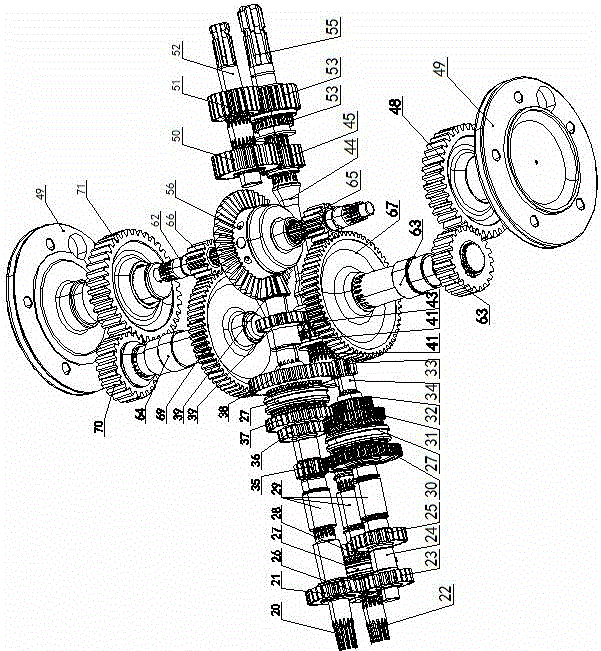

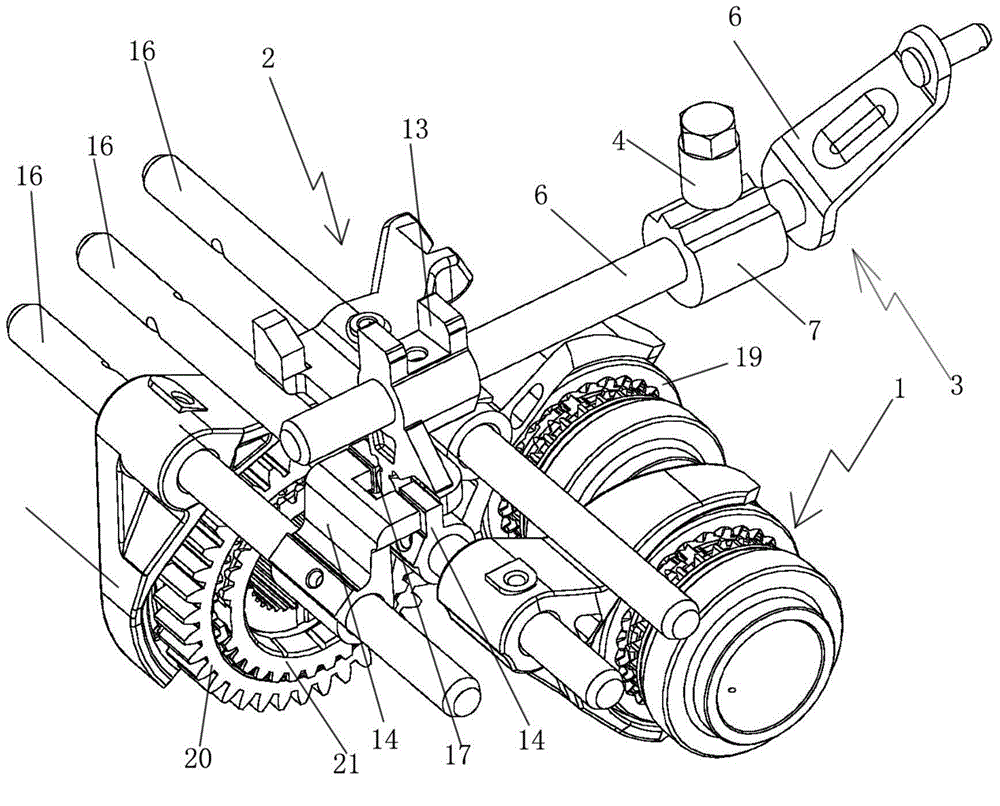

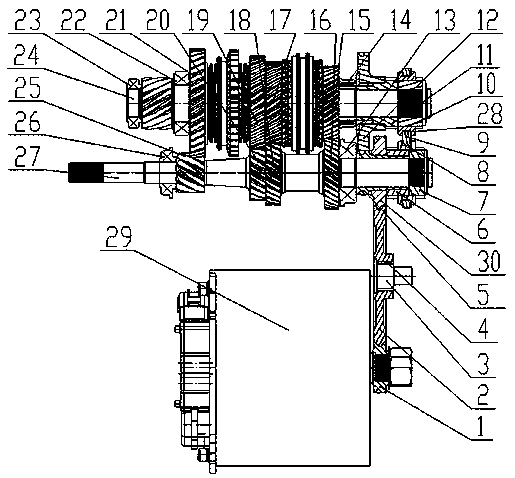

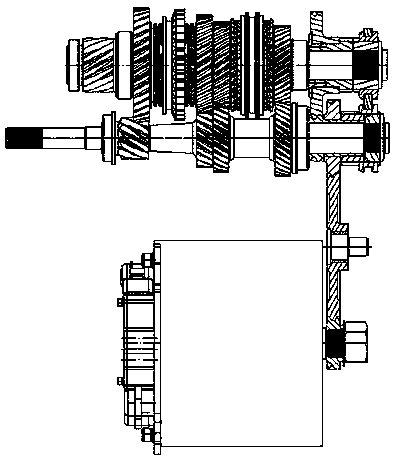

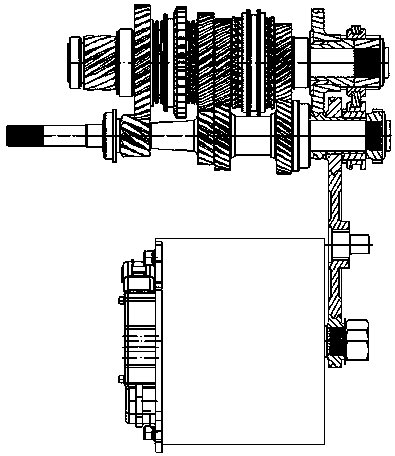

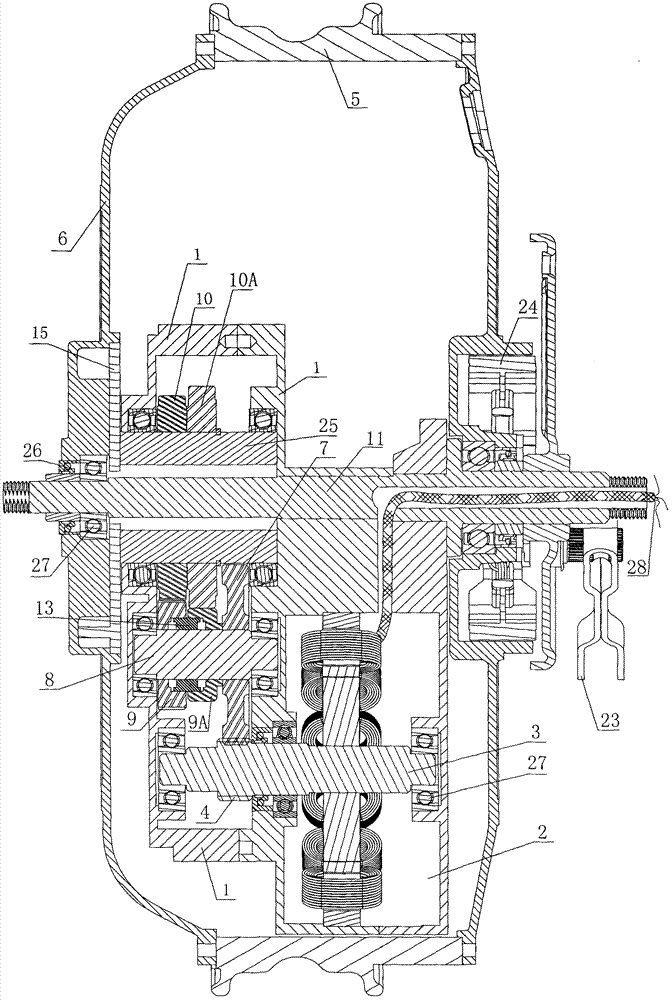

Tractor transmission mechanism

PendingCN106740078ACompact structureImprove transfer efficiencyGearing detailsControl devicesVariatorTractor

The invention discloses a tractor transmission mechanism. The tractor transmission mechanism comprises an auxiliary transmission, a universal joint assembly, a shuttle-type gear shift mechanism, a main transmission and a power output device which are sequentially connected; a front gearbox with a differential mechanism A (15) and connected with the universal joint assembly is arranged between the auxiliary transmission and the universal joint assembly, a rear gearbox with a differential mechanism B (56) and meshed with the main transmission is arranged between the main transmission and the power output device, and walking-wheel mounting flanges are respectively arranged on two sides of the front gearbox and two sides of the rear gearbox. The tractor transmission mechanism has the advantages of being compact in structure, firm and reliable, high in transmission efficiency, convenient in shift, multiple in shift and reasonable in velocity distribution; by the arrangement, a tractor has 12 forward gears, 12 backward gears, quick switching in forward and backward can be realized through an operation lever, gear speed is well matched, and the optimum operation speed can be selected according to specific resistance of different machine tools and different soil.

Owner:CHONGQING ZONGSHEN GENERAL POWER MACHINE

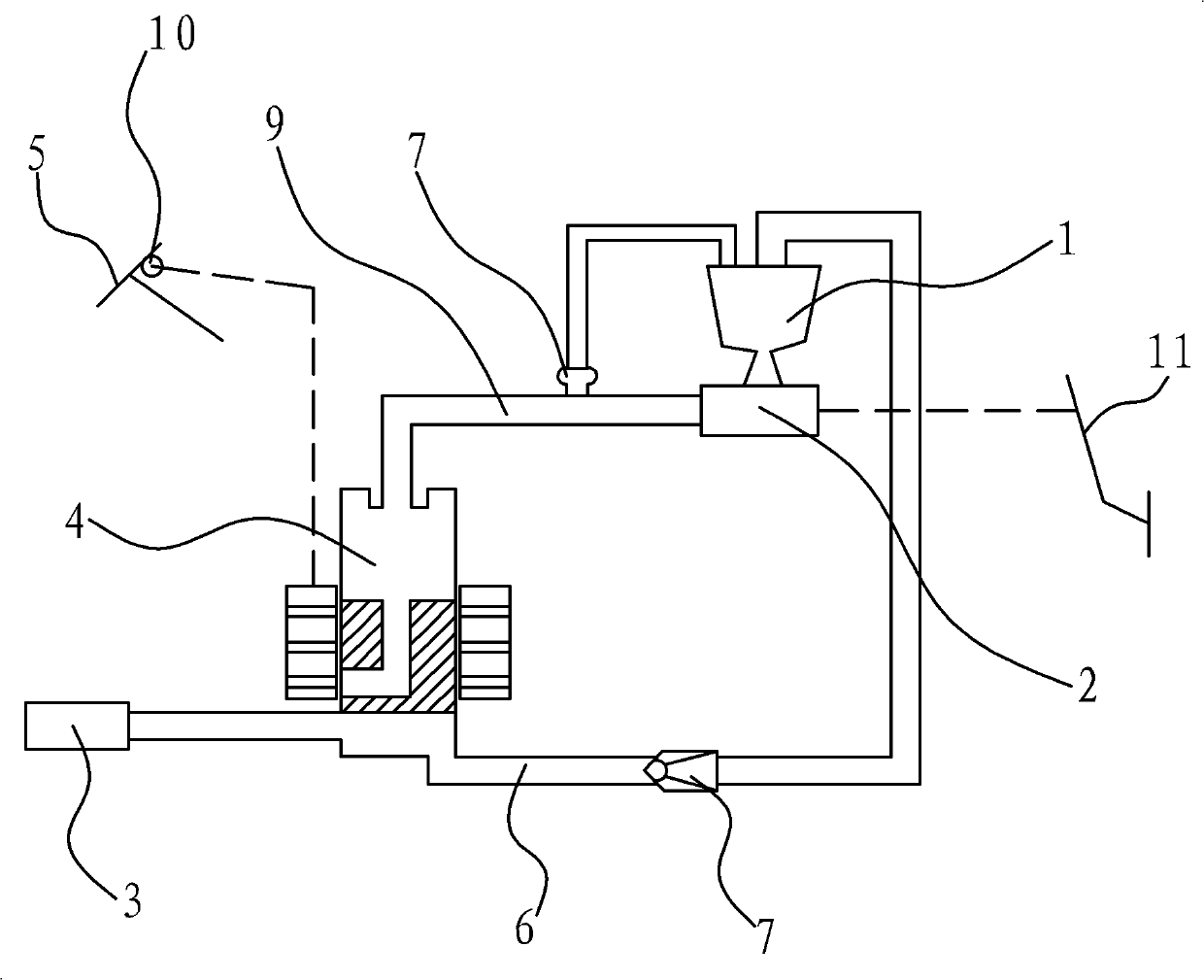

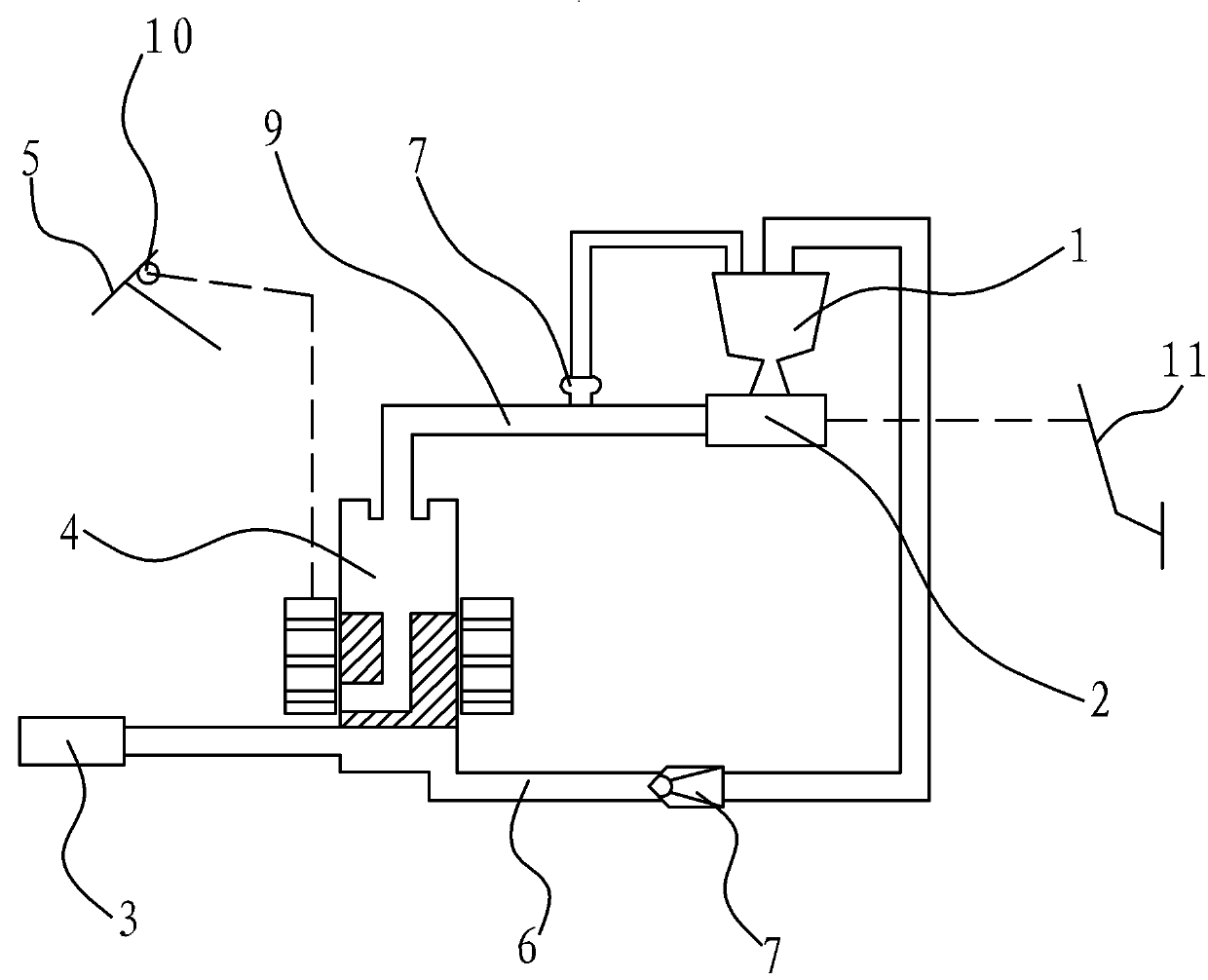

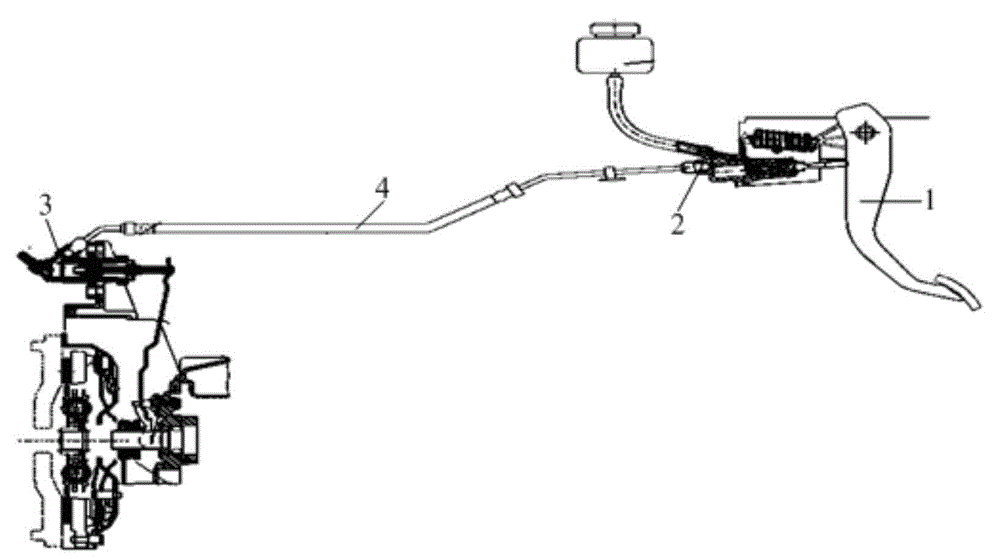

Auxiliary engagement device for clutch

The invention provides an auxiliary engagement device for a clutch and belongs to the technical field of automobiles. The problem that the clutch cannot be engaged quickly by trampling an accelerator pedal in the conventional automobile is solved. The auxiliary engagement device for the clutch is arranged in a clutch hydraulic control mechanism; the clutch hydraulic control mechanism comprises a liquid storage cylinder, a main cylinder which is communicated with the liquid storage cylinder, and a working cylinder connected with the clutch; the auxiliary engagement device for the clutch comprises a solenoid valve arranged between the main cylinder and the working cylinder, and a control circuit which can control the solenoid valve to be opened and closed when the accelerator pedal is trampled; and a one-way oil return pipeline in which oil can only flow from the working cylinder to the liquid storage cylinder is arranged between the working cylinder and the liquid storage cylinder. The auxiliary engagement device for the clutch is easy to control, the cultch can be engaged quickly by tramping the accelerator pedal, and the auxiliary engagement device is convenient to use.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

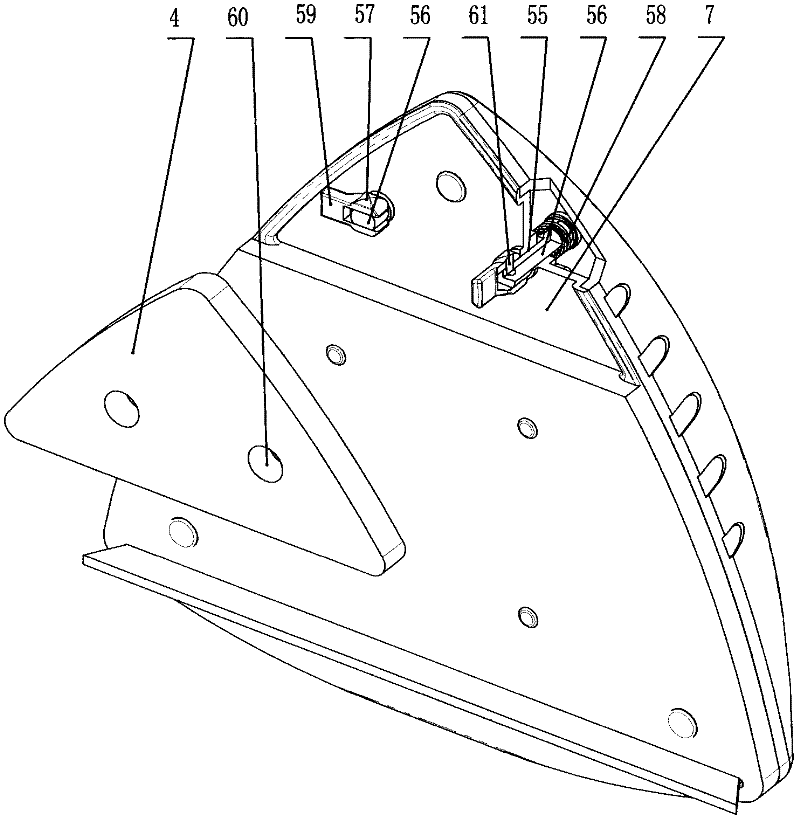

Safe multi-gear magnetic force glass-wiping device

The invention provides a safe multi-gear magnetic force glass-wiping device, which mainly comprises a casing consisting of an upper cover and a lower casing, a permanent magnet, a magnetic conducting plate, a rubber scrapping plate, hair felt, a rope and buckles. The safe multi-gear magnetic force glass-wiping device is characterized in that a jumping-off spring is arranged between the casing and the permanent magnet and the magnetic conducting plate, the permanent magnet and the magnetic conducting plate slide along a guide slide way in the casing, a trigger and a button are arranged in the casing, and the button controls the trigger to support or release the permanent magnet and the magnetic conducting plate to be far away or close to the wiping surface of the lower casing. The safe multi-gear magnetic force glass-wiping device can wipe various glass with different thickness in a double-faced mode, is rapid in gear shifting, convenient to use and very safe, and does not clamp and hurt fingers.

Owner:刘忠臣

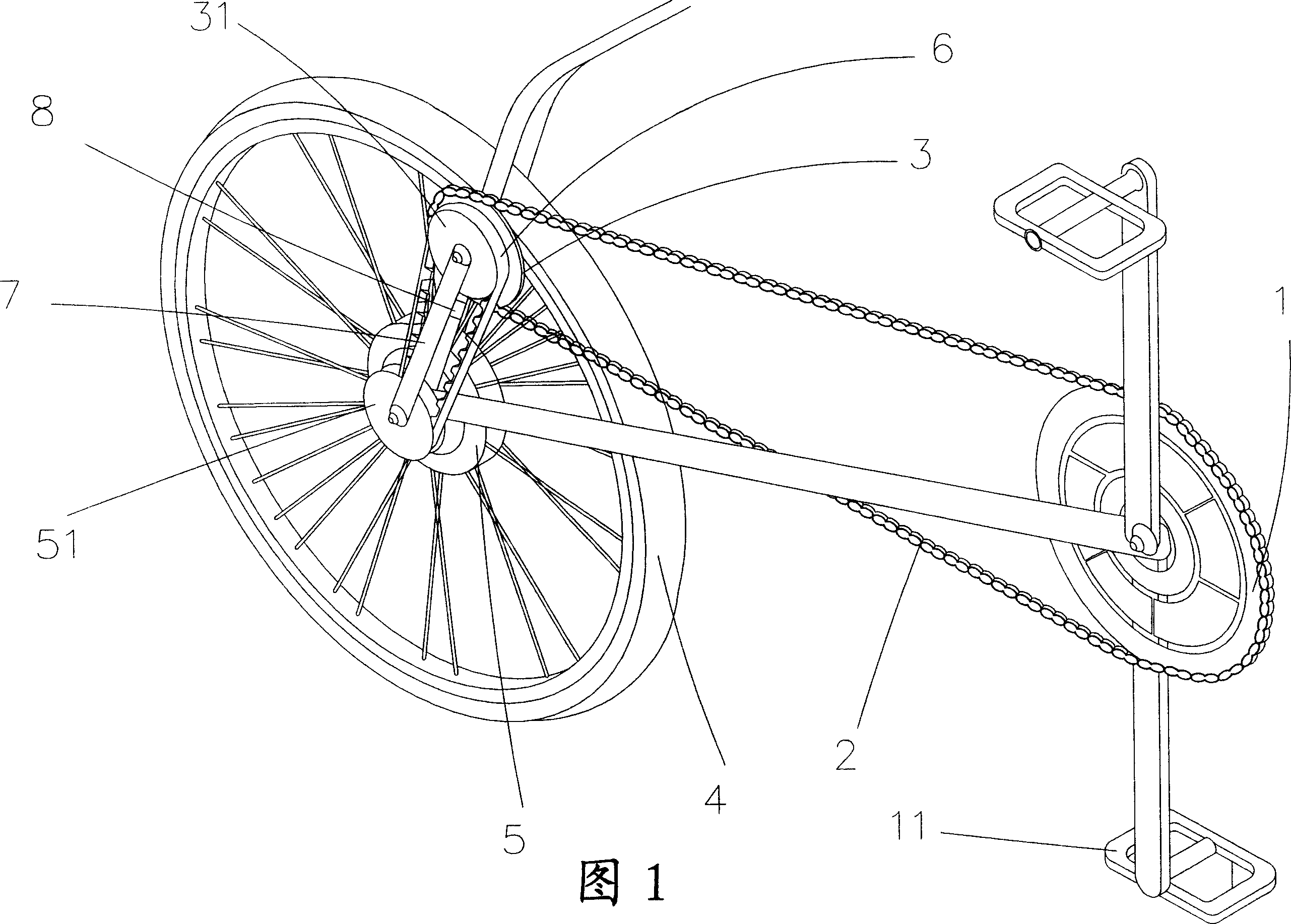

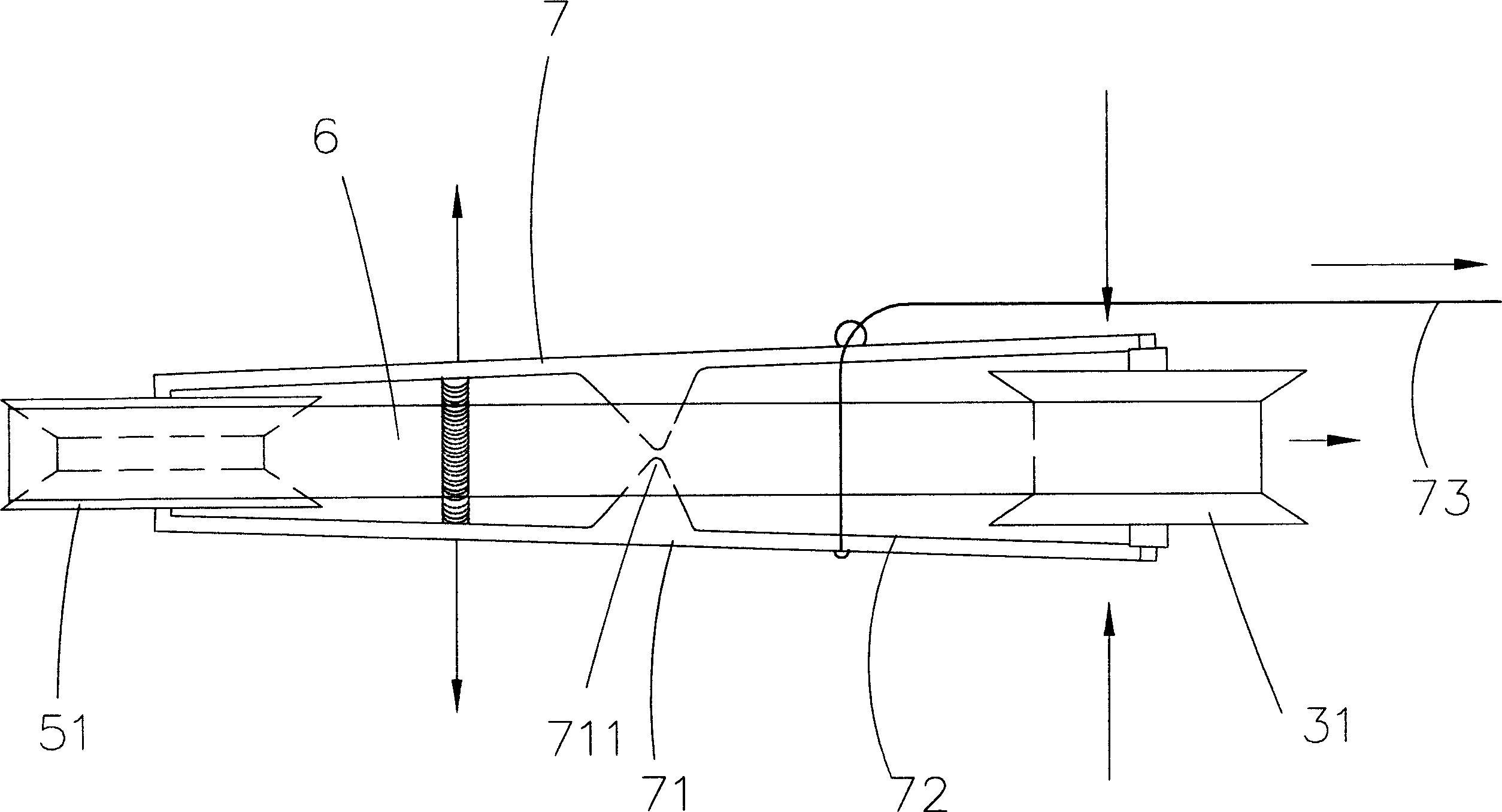

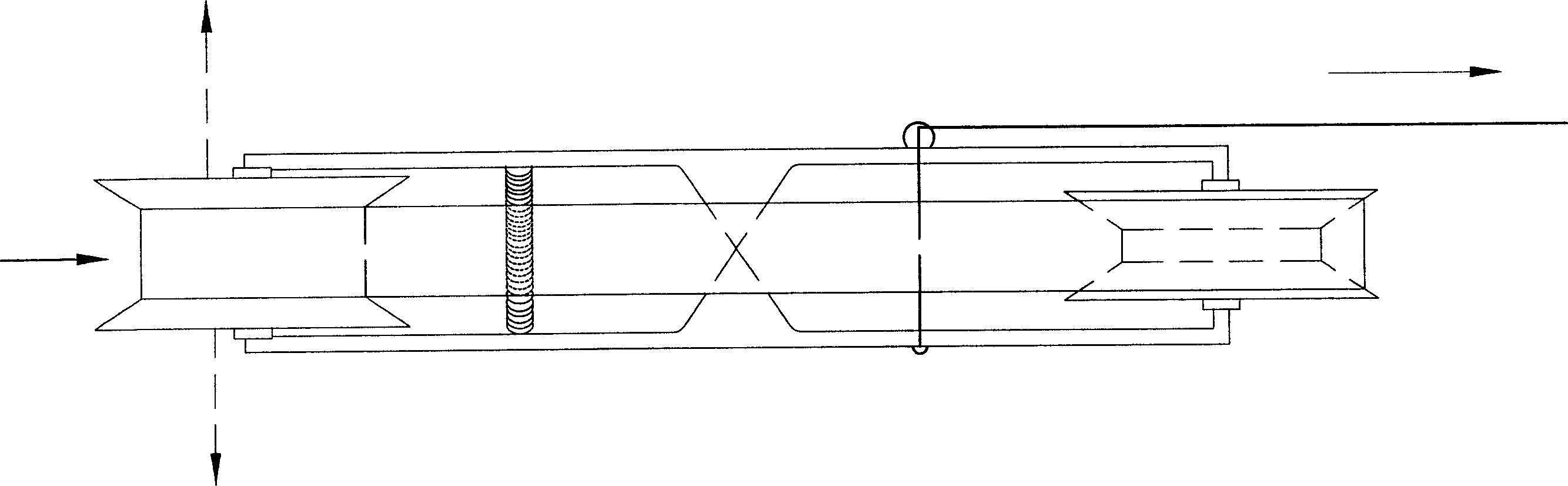

Automatic speed variator for bicycle

InactiveCN1907803ATransform smoothSimple shiftingChain/belt transmissionCycle actuatorsElectricityElectric power

The invention relates to an automatic speed changer of bicycle, wherein it is mounted on the bicycle with front tooth disc (driven by pedal), back wheel (wheel axle) and chain; it comprises a back tooth disc axially connected to the bicycle, the first and second speed-variable discs changing disc distance via the rotation speed, one generator, one sensor, one belt, and an interactive structure; the front and back tooth disc have chain sheathed between them; the first and second speed-variable discs are axially connected to the back tooth disc and back wheel; the generator is at the back wheel axle to generate via the rotation speed; the sensor with one flexible rod can control the extending of flexible rod based on the electricity of generator; the belt is sheathed between each disc distances of first and second speed-variable discs; the first and second ends of interactive structure are axially connected to the first and second speed-variable discs, while its first end via wires is connected to the flexible rod; the first end of interactive structure, via the tension of wires, controls the zoom of disc distance of first speed-variable disc, and the disc distance of second variable-speed disc of second end will be zoomed reversed.

Owner:钟志豪

Self locking system of MT (Manual Transmission) gear shifting mechanism

The invention discloses a self locking system of an MT (Manual Transmission) gear shifting mechanism. The self locking system comprises a synchronizer assembly, a shifting fork shaft assembly and a gear shifting operation assembly, wherein the synchronizer assembly, the shifting fork shaft assembly and the gear shifting operation assembly are sequentially connected; a gear shifting operation system is connected with a positioning spring ball device comprising a sleeve and a self locking spring ball which is elastically arranged in the sleeve; a self locking device is arranged in the synchronizer assembly; the gear shifting operation assembly comprises a gear shifting rocker arm which is provided with a waveform convex plate; the self locking spring ball leans against a concave part which is formed by a waveform surface of the waveform convex plate; a neutral position positioning groove is formed in the synchronizer assembly; the self locking device comprises a neutral position positioning spring; the neutral position positioning spring is arranged in the neutral position positioning groove in a clamping way or is deviated from the neutral position positioning groove. According to the self locking system of the MT gear shifting mechanism, disclosed by the invention, the structure is simple, respective and mutual non-interference self locking on the synchronizer assembly and the gear shifting operation assembly is realized, accurate positioning of the synchronizer assembly and the gear shifting operation assembly is ensured, the situation that a driver has a clear gear sense during a gear shifting process is ensured, and gear clearness is ensured.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Ratchet screw driver

InactiveCN101890688BCompact structureEasy to assembleSpannersWrenchesEngineeringMechanical engineering

Owner:HANGZHOU GREAT STAR IND CO LTD

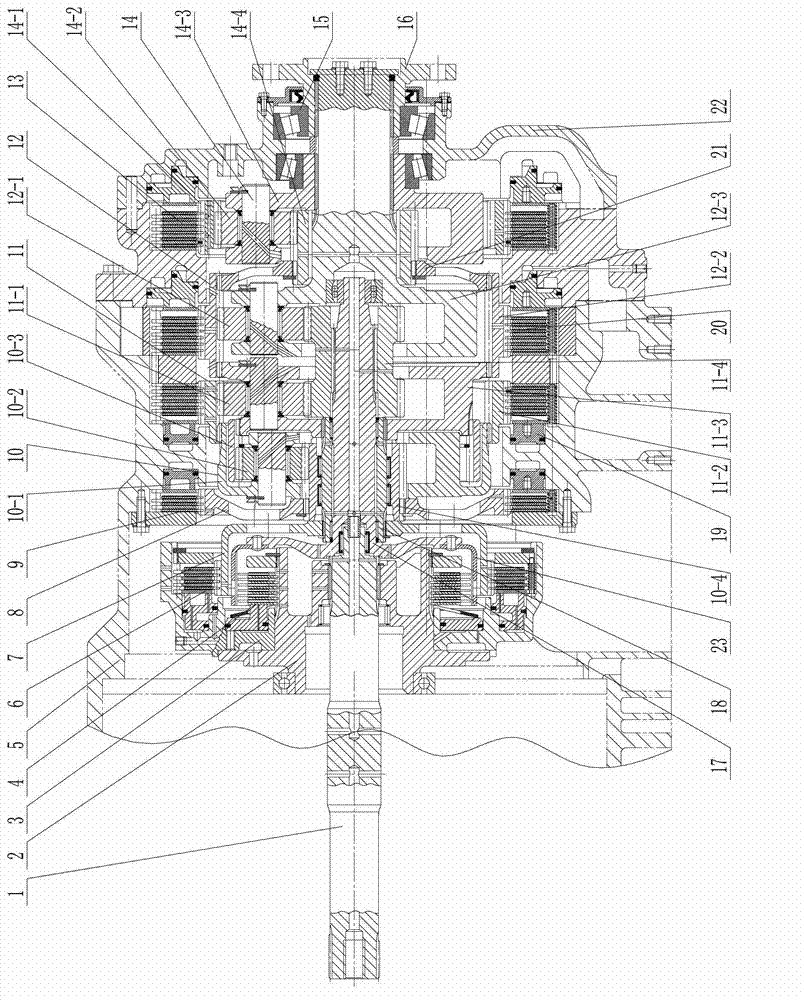

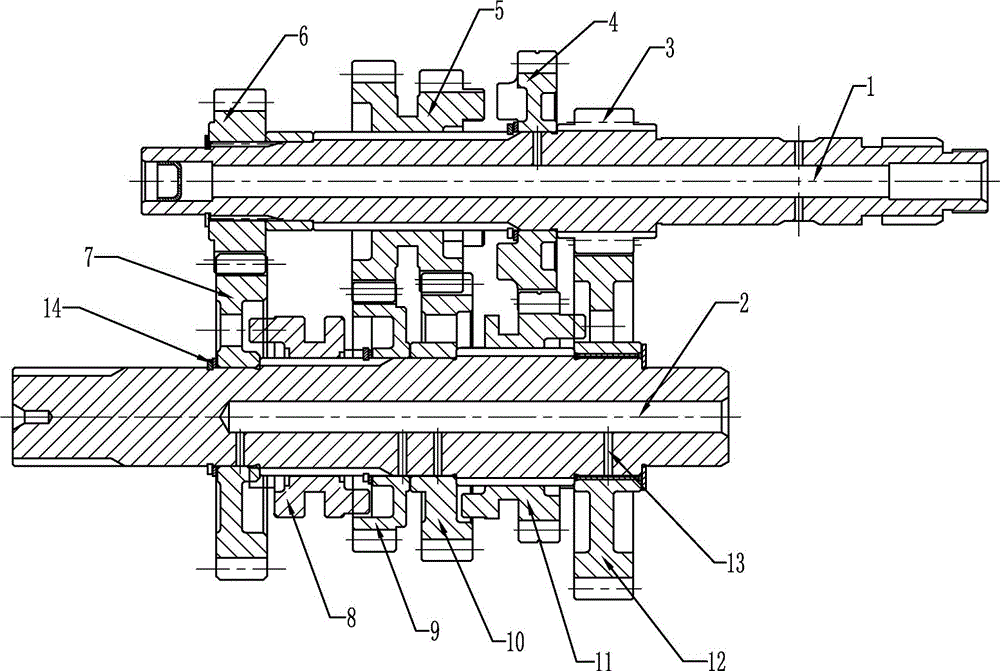

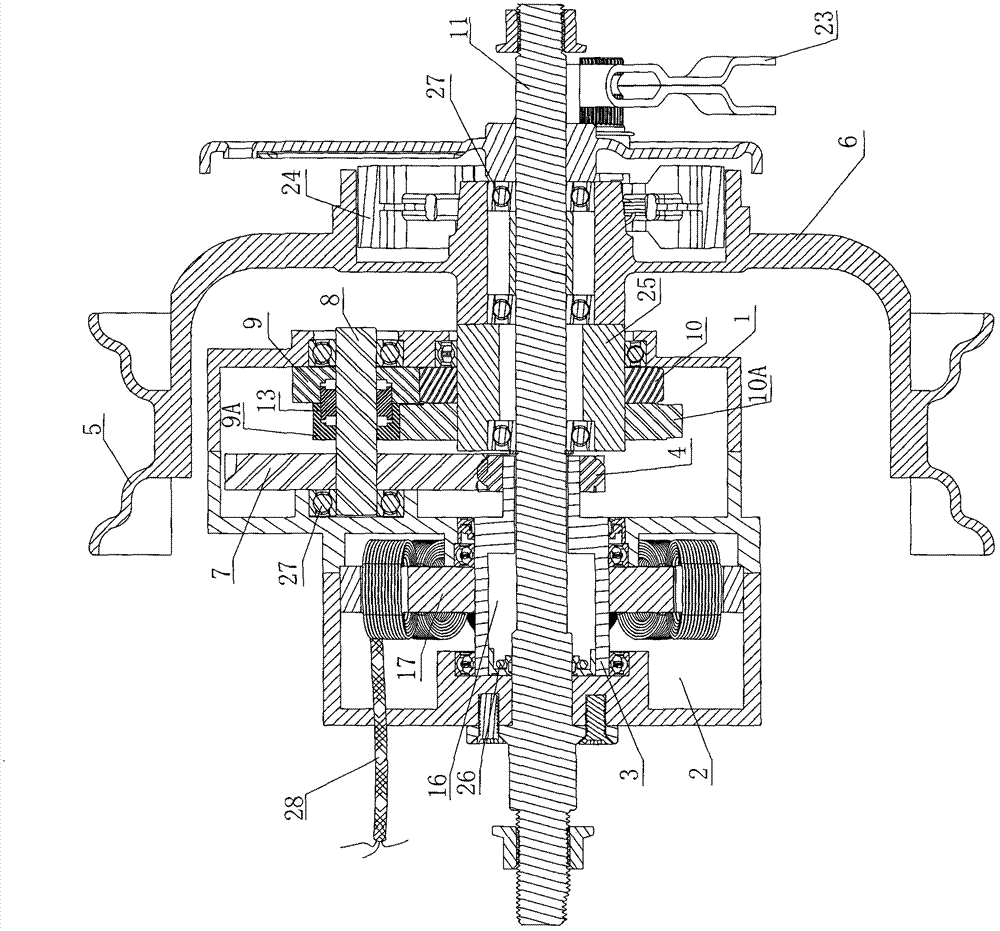

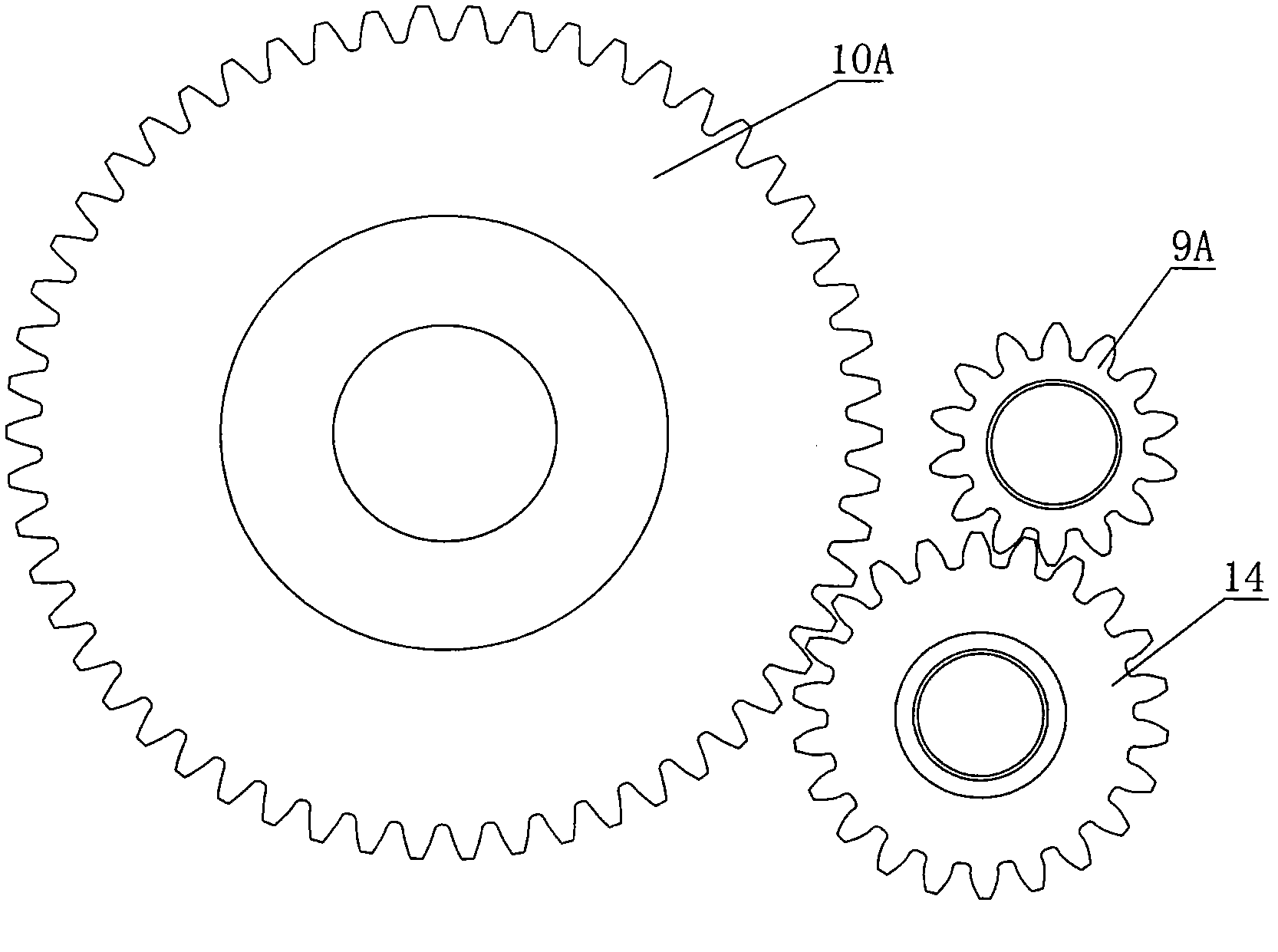

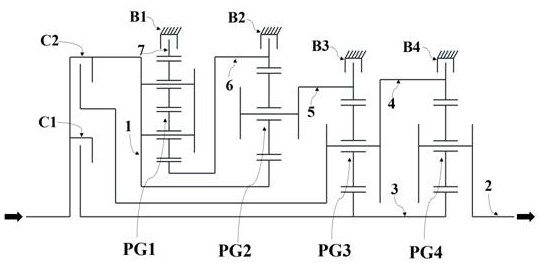

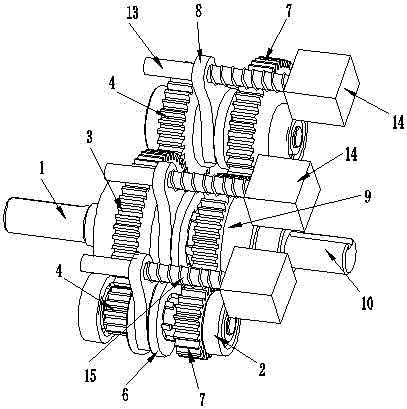

Planetary gear shift mechanism

The invention relates to a planetary gear shift mechanism. An input shaft is connected with a common clutch cylinder through a drive hub. A first clutch is connected with a first shaft. Two sides of the first shaft are supported on the input shaft and a third planet carrier respectively. The first shaft is connected with a common sun gear for a second planet row and a third planet row. A second shaft connected with a second clutch is connected with a second planet carrier through the first shaft. The second planet carrier is respectively connected with a first gear ring row and a third gear ring row. Two ends of a front brake component are connected with a first brake and a first sun gear respectively. A first planet carrier is connected with a second gear ring row of the second planet row. A fourth sun gear is sleeved on an output shaft of the third planet carrier idly. Two ends of a rear connector are connected with the third gear ring row and a fourth sun gear respectively. A fourth planet carrier is connected to an output shaft of the third planet carrier connected with an output disk. The planetary gear shift mechanism is reasonable in layout, compact and simple in structure and convenient to operate and has six forward gears and one reverse gear.

Owner:邓亚民

Motorcycle gear shift transmission mechanism

InactiveCN105202129AReduce settingsFlexible transformationToothed gearingsMechanical engineeringEngineering

Owner:CHONGQING HUALING IND CO LTD

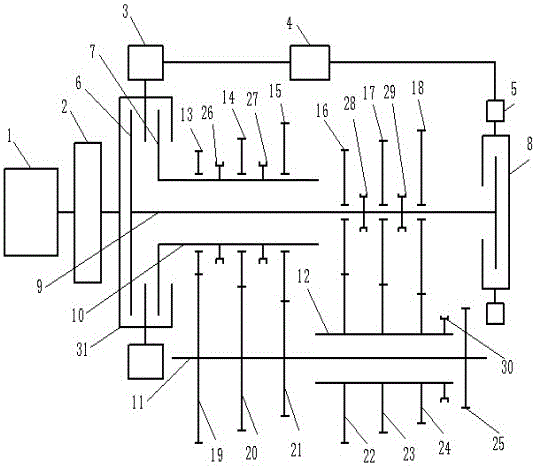

Automotive three-clutch hybrid power transmission system

InactiveCN106347096AMeet power needsImprove powerGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingFreewheelGear wheel

An automotive three-clutch hybrid power transmission system is composed of an engine, a dual mass flywheel, a generator, an energy storage device, a motor, three clutches, two input shafts, two output shafts, six idler gears, seven fixed gears and five synchronizers. The automotive three-clutch hybrid power transmission system is characterized in that the engine is connected with the double clutch through the dual mass flywheel, the generator is connected with the double clutch and the energy storage device, and the motor is connected with the energy storage device and the third clutch; the first input shaft is connected with the first clutch and the third clutch, the second input shaft is connected with the second clutch, the second input shaft and the second output shaft are both hollow shafts and are arranged on the first input shaft and the first output shaft respectively in a nested mode, and the first input shaft and the first output shaft are arranged in a spatially parallel mode. The automotive three-clutch hybrid power transmission system has the advantages that gear shifting is convenient, power failure is avoided, the hybrid power transmission path is clear, the structure is compact, multiple work modes can be achieved, energy utilization efficiency is high, and good comprehensive performance is achieved.

Owner:SICHUAN UNIV

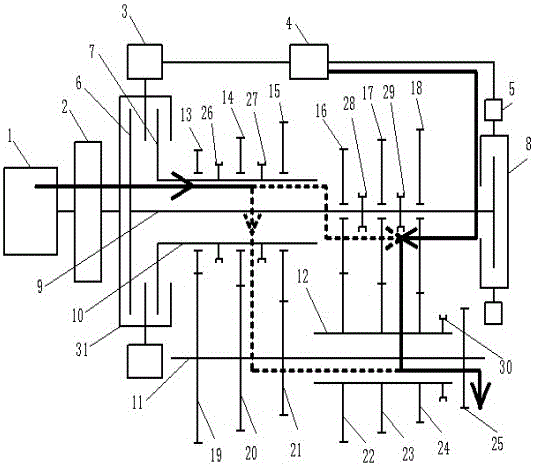

Automobile hybrid power structure based on AMT capable of adapting to speed change requirements of different vehicle types

PendingCN109878322ASimple structureLow costGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingVariatorMotor drive

The invention discloses an automobile hybrid power structure based on AMT capable of adapting to speed change requirements of different vehicle types, wherein a transmission input shaft is provided with a driving tooth, a driving-driven combined tooth and a mode switching combined tooth sleeve; the driving tooth and the driving combined tooth are fixedly connected with and sleeve the input shaft in a hollow manner; a driven combined tooth is arranged on the input shaft; the mode switching combined tooth sleeve can slide on the driving combined tooth and the driven combined tooth to be meshed with the driving combined tooth or the driven combined tooth independently or both simultaneously. The output shaft is provided with a tooth part similar to the input shaft. When the two modes are switched and combined with the synchronous sliding of the tooth sleeves, only one tooth sleeve of the two tooth sleeves is simultaneously meshed with the driven combined teeth and the driving combined teeth, or the two tooth sleeves are not simultaneously meshed with the driven combined teeth and the driving combined teeth. The motor driving teeth are meshed with the input shaft driving teeth. The automobile hybrid power structure overcomes the problem of power interruption during gear shifting of the AMT transmission, can automatically switch among a pure oil mode, a P2 mixed mode and a P3 mixedmode, and meets the requirements of different driving conditions.

Owner:力帆科技(集团)股份有限公司

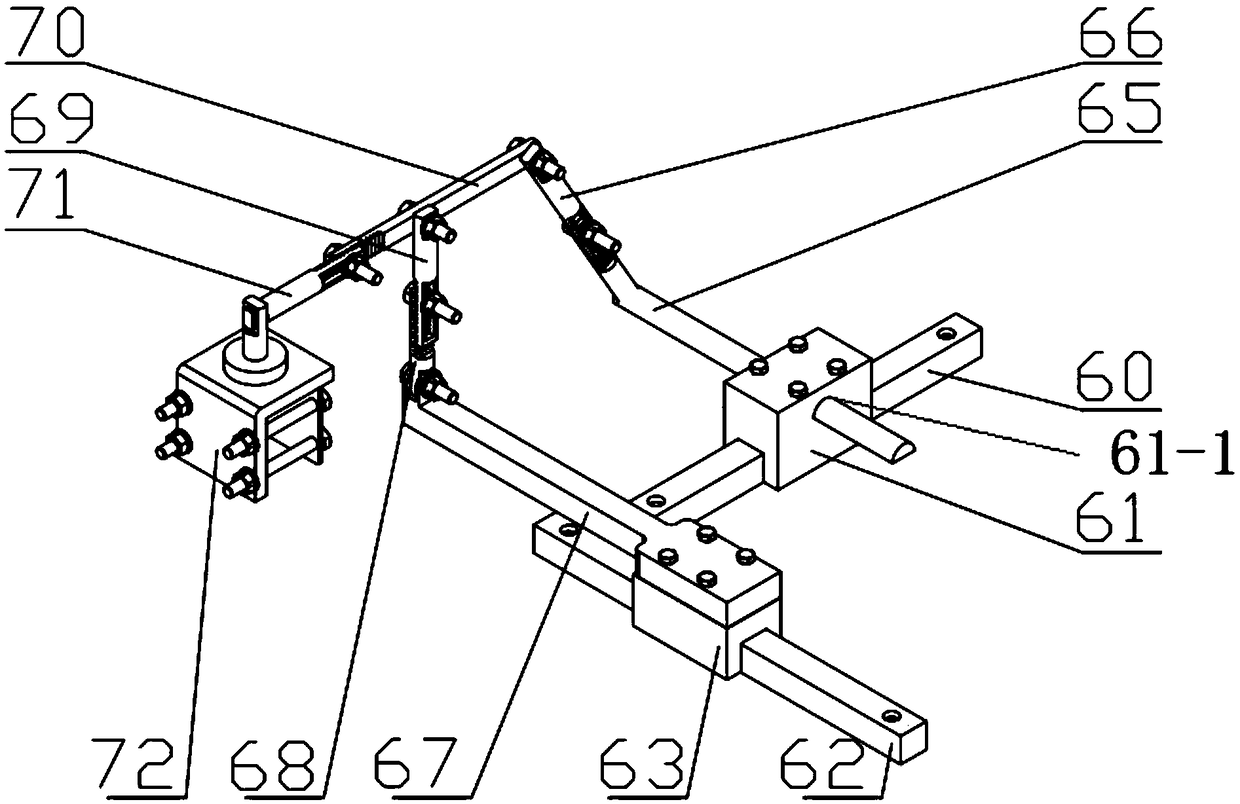

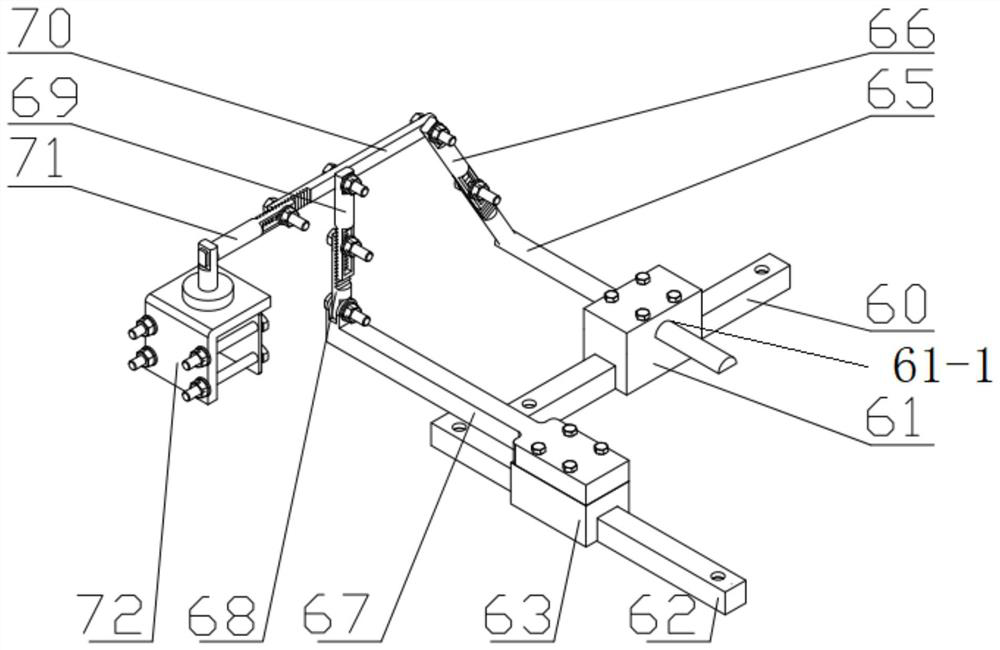

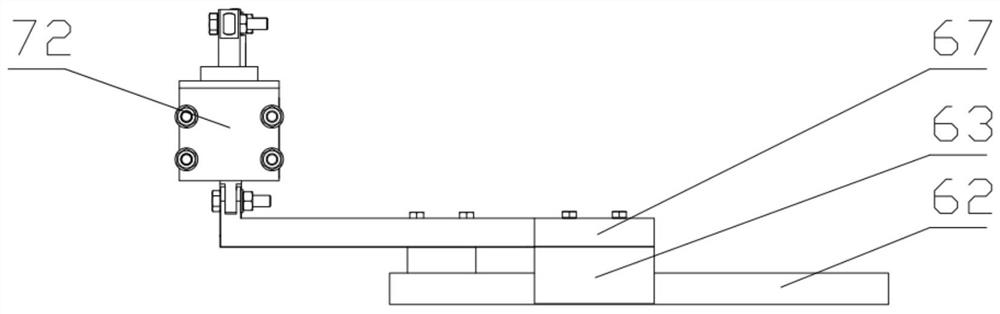

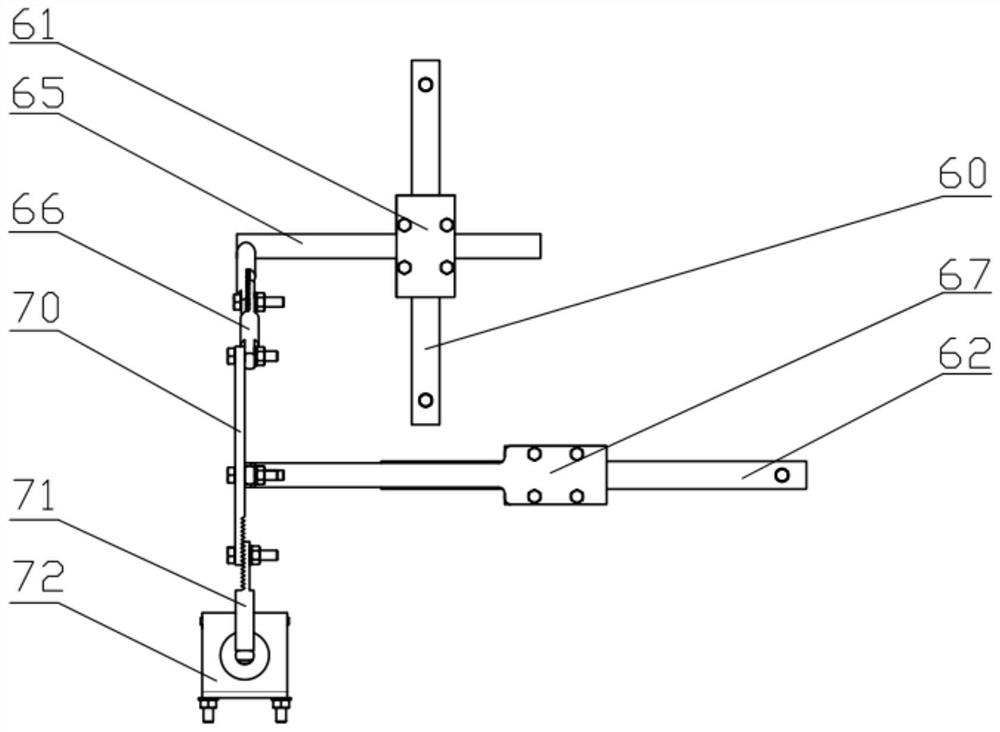

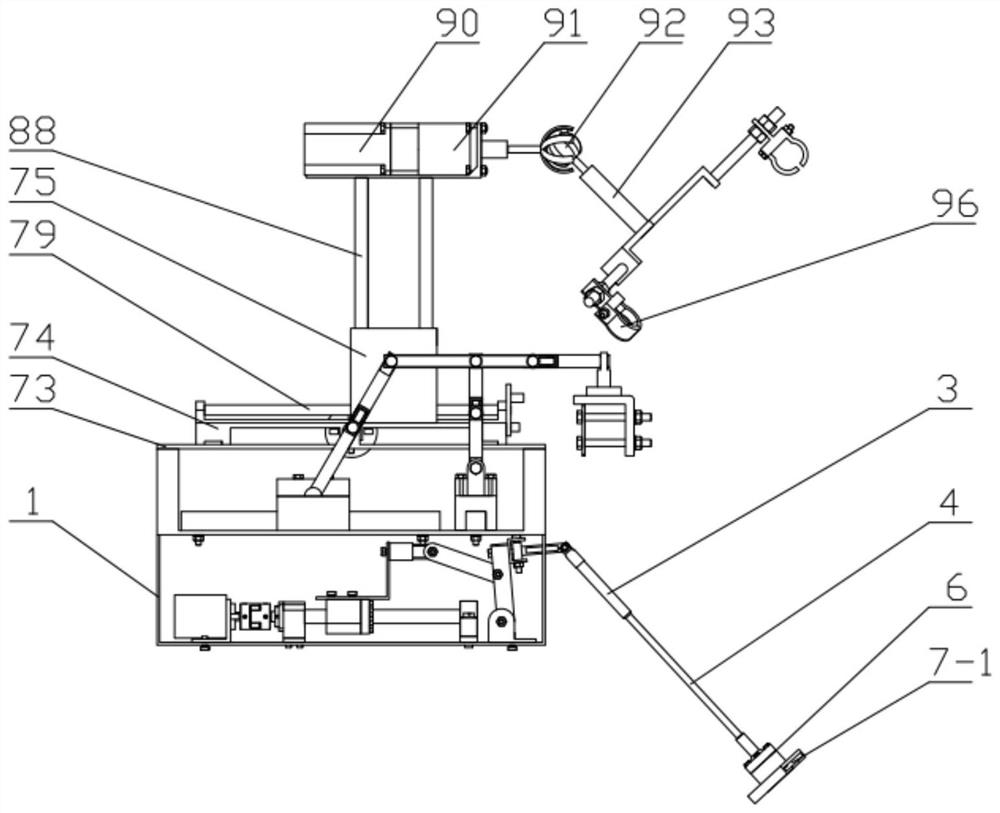

Gear-shifting manipulator of autopilot robot

The invention provides a gear-shifting manipulator of an autopilot robot, which comprises a first stepping motor, a first slider, a first slide rail, a first link, a second link, a first swing bar, agripper, a second stepping motor, a second slider, a second slide rail, a third link, and a fourth link; The first stepping motor, the second stepping motor, the first slide rail and the second sliderail are fixed on the upper end of the box body; The first stepping motor drives the first slider to move forward and backward along the first slide rail; The third connecting rod is matched with thesliding groove in the first slider and is perpendicular to the sliding direction of the first slider; The lower end of the second connecting rod is connected with the third connecting rod; An upper end of the second connecting rod and a rear end of the first swing rod are connected with each other through a pin shaft; The front end of the first swing lever is connected with the grip; The second stepping motor drives the second slider to slide along the second sliding rail, and the sliding direction is perpendicular to the first slider; The third connecting rod is connected with the second slider; The lower end of the fourth connecting rod is connected with the third connecting rod; An upper end of the fourth connecting rod is connected with the first swing rod through a pin shaft; The manipulator can be adapted to different types of cab and shifting mode.

Owner:NANJING UNIV OF SCI & TECH

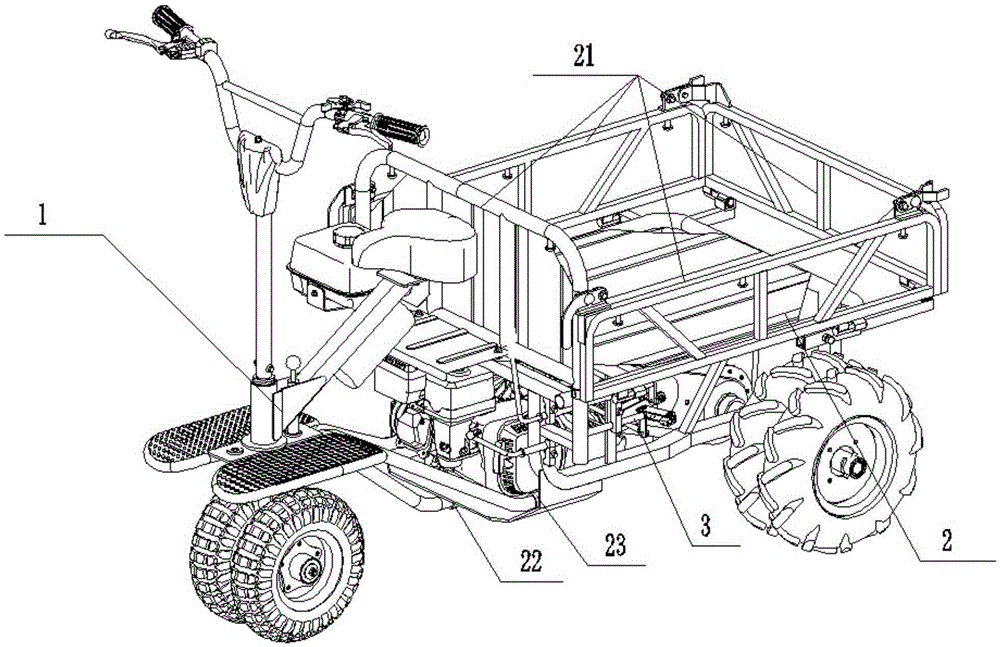

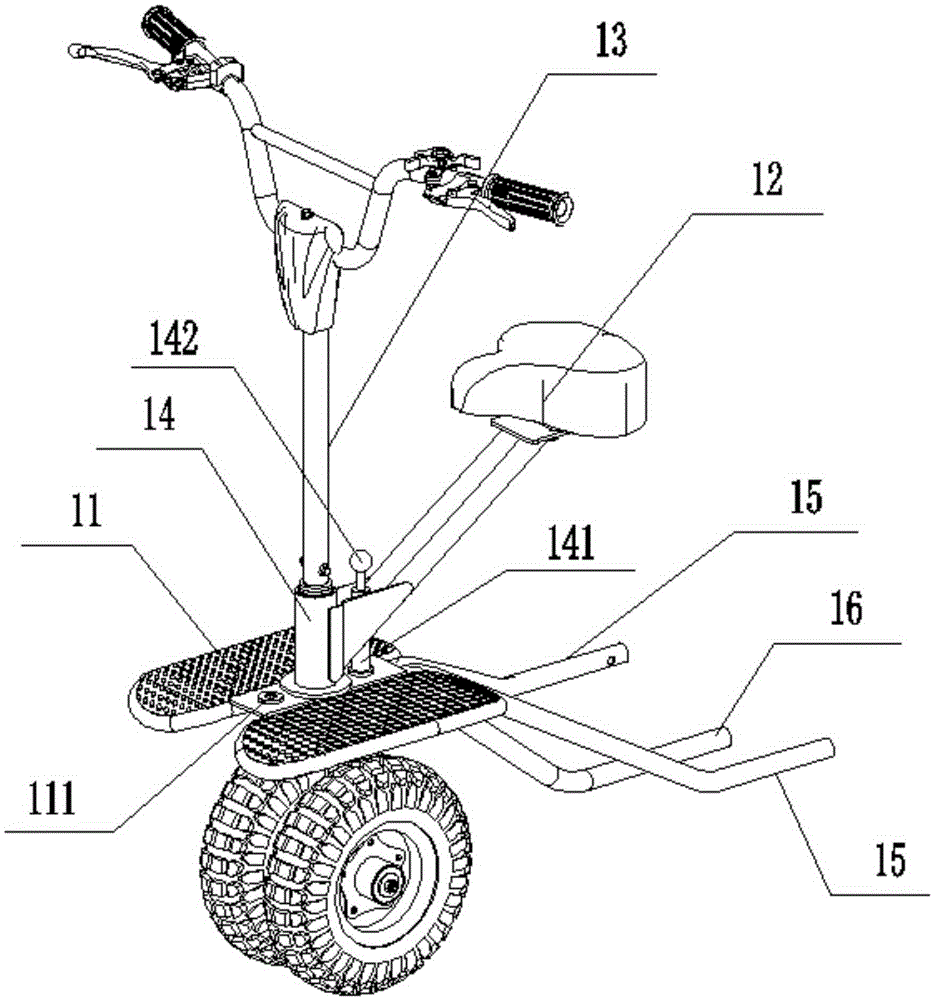

Riding transfer vehicle

The invention in particular relates to a riding transfer vehicle, which belongs to the field of transporting equipment. The riding transfer vehicle comprises a vehicle main body and a rotatable riding frame, wherein the riding frame is tightly connected with the front end of the vehicle main body; a power mechanism and a gear shifting mechanism are arranged under the vehicle main body; one end of the gear shifting mechanism is connected with the power mechanism; the other end of the gear shifting mechanism extends out of the vehicle main body and is arranged close to the riding frame; and a detachable turnover protective frame is arranged on the vehicle main body. The riding transfer vehicle provided by the invention is beneficial for reversing in a reverse direction through the rotatable riding frame, has the advantages of wide vision, high safety performance, simple structure, compact layout and convenient operation and is convenient to shift gears and do reversing operation in the operation process.

Owner:CHONGQING HWASDAN MACHINERY MFG

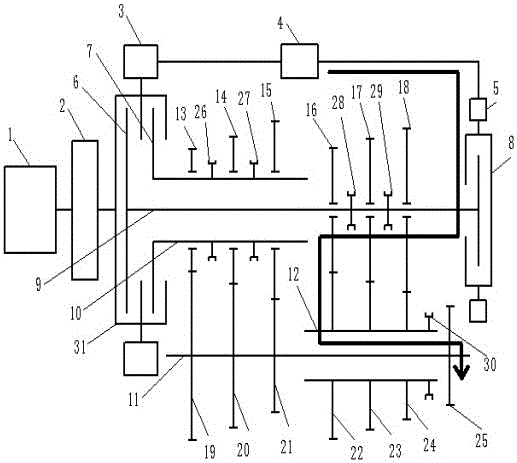

Automotive hybrid power structure based on AMT

PendingCN109878320ASimple structureLow costGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingEngineeringMode switch

The invention discloses an automotive hybrid power structure based on AMT (automatic mechanical transmission). A transmission input shaft is provided with a driving tooth, driving and driven combinedteeth and mode-switching combined tooth sleeves, the driving tooth and the driving and driven combined tooth are fixedly connected together and sleeve the input shaft in a spaced way, the driven combined tooth is installed on the input shaft, and the mode-switching combined tooth sleeve can slide on the driving combined tooth and the driven combined tooth to be separately engaged with driving combined tooth or the driven combined tooth or to be simultaneously engaged with the teeth. An output shaft is provided with tooth parts similar to the input shaft, and the teeth have a similar connectionrelationship. The two mode-switching combined tooth sleeves slide synchronously, and when the two tooth sleeves slide synchronously, only one tooth sleeve is engaged with the driven combined tooth and the driving combined tooth simultaneously or the tooth sleeves are not engaged with the teeth simultaneously. A driving tooth of the motor is engaged with the driving tooth of the input shaft. The automotive hybrid power structure overcomes the problem of power interruption during shifting of an AMT transmission, can be automatically switched among a pure oil mode, a P2 hybrid mode and a P3 hybrid mode, and meets the requirements of different driving conditions.

Owner:力帆科技(集团)股份有限公司

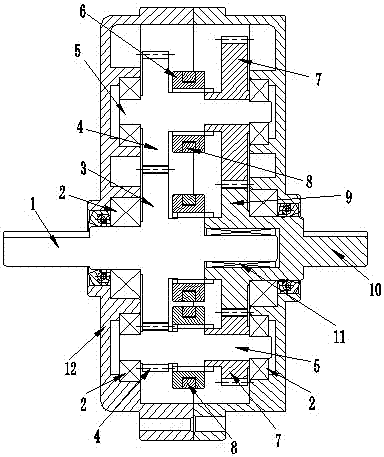

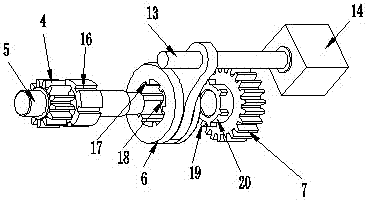

Forward-and-backward rotation variable-speed hub motor

InactiveCN102957262AImprove efficiencyNot easy to get hotToothed gearingsMechanical energy handlingGear driveClamp connection

The invention belongs to the technical field of electric vehicle power transmission, and aims at solving the problem that a motor can not output different vehicle speeds and different torques at the same rotation speed. A forward-and-backward rotation variable-speed hub motor comprises a hub ring, an end face and a case body, wherein the case body and the motor are fixed on a fulcrum shaft; the motor is provided with a motor shaft which is in transmission connection with a main shaft; driving gears are flexibly sleeved on the main shaft; a second-gear driving gear is in engaged transmission with an output gear fixed on an output shaft; a skewed slot is formed on the main shaft; when the main shaft rotates, under the action of the skewed slot, a sliding piece is in clamped connection with the second-gear driving gear or a first-gear driving gear and rotates, and the first-gear driving gear drives a first-gear output gear through a reversing gear, thereby driving the output shaft to rotate; and through forward and backward rotation of the main shaft, the sliding piece is coupled with or separated from the second-gear driving gear or first-gear driving gear, thereby switching to first-gear or second-gear power output.

Owner:蔡旭阳

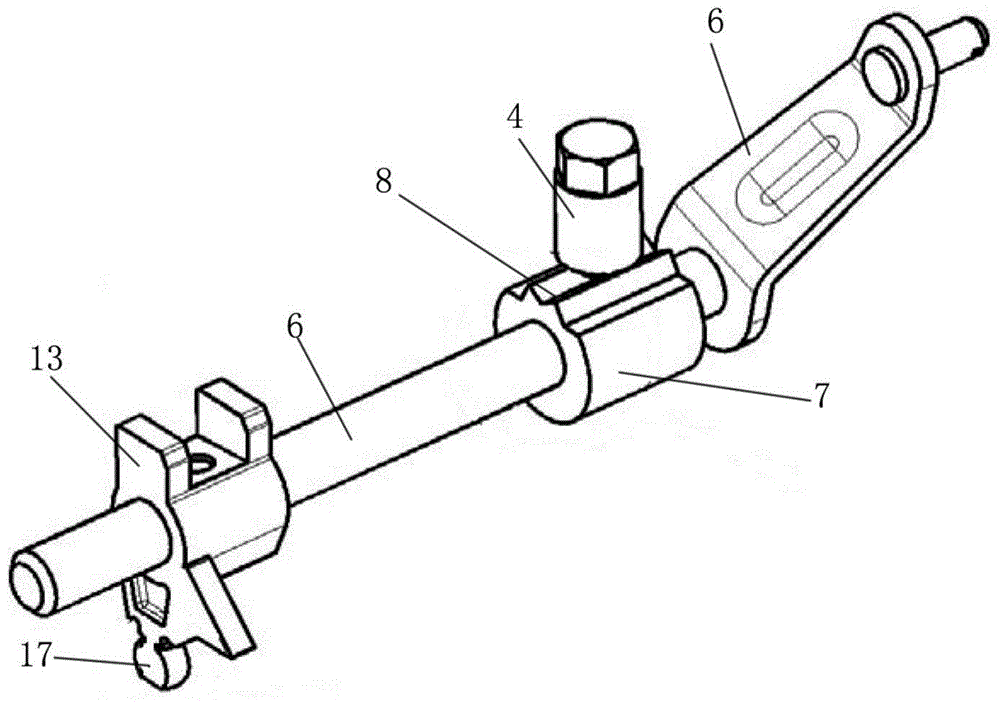

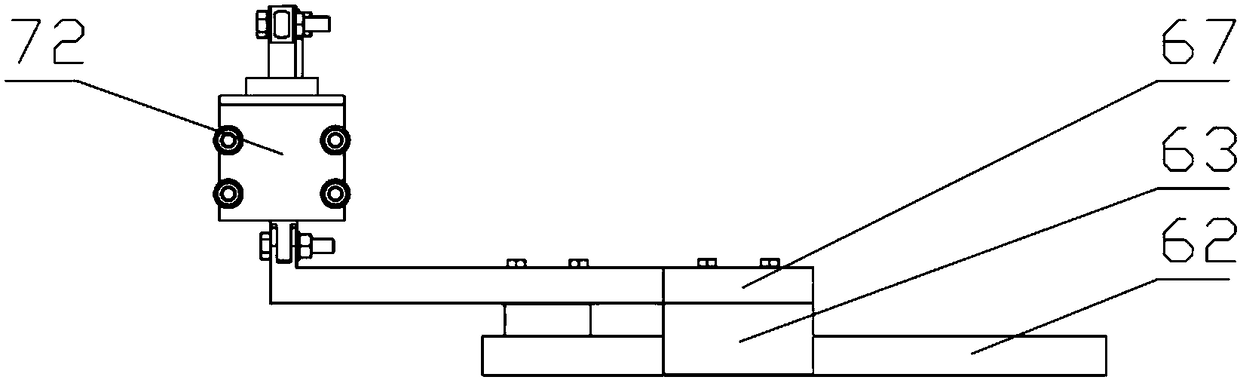

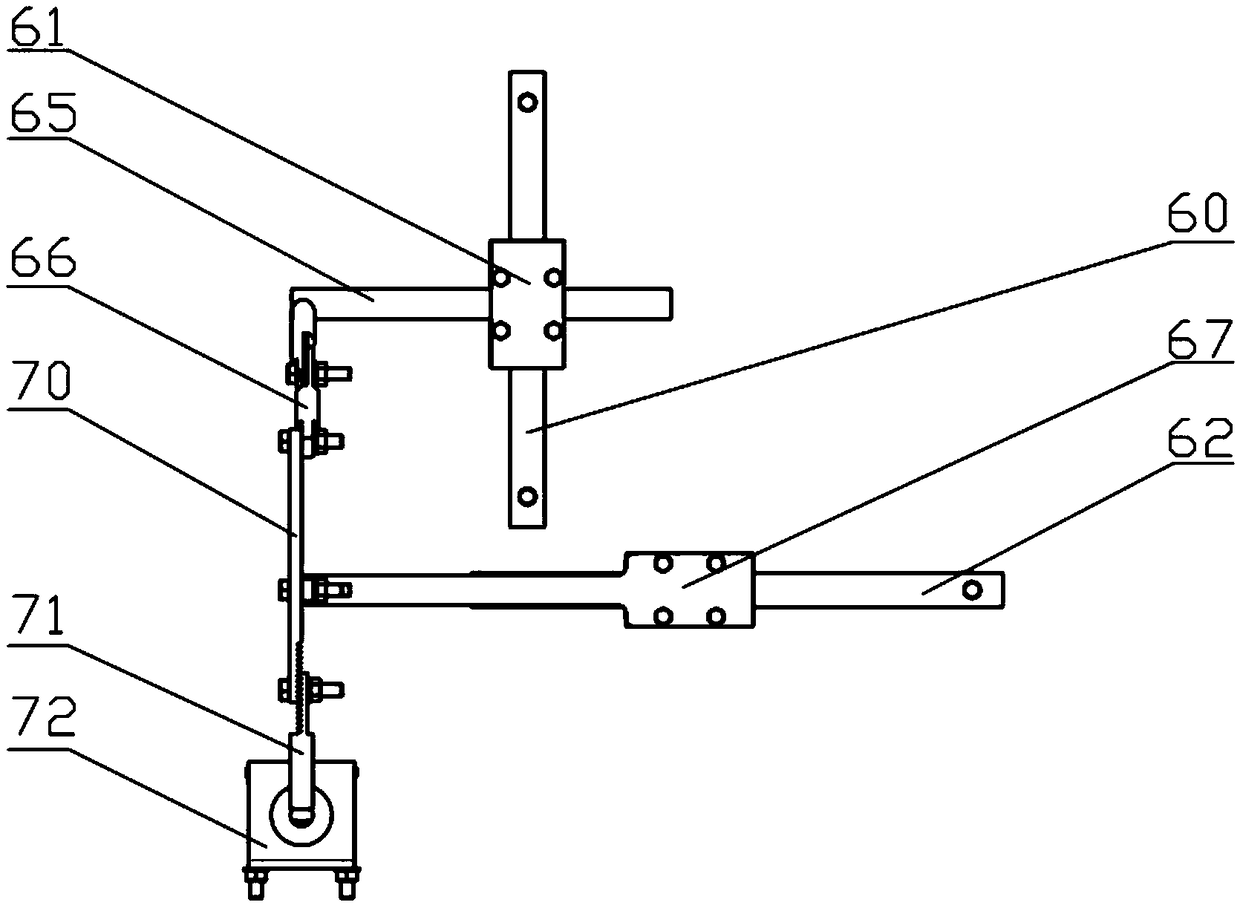

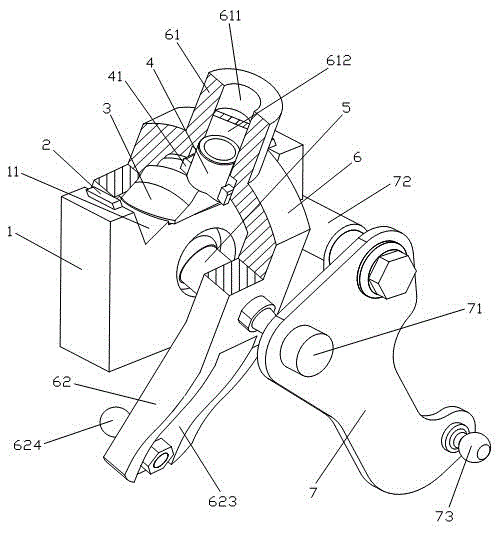

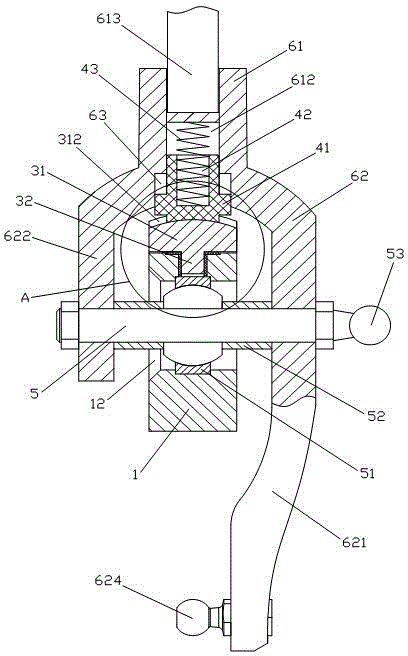

Gear shifting manipulator

ActiveCN104696506AAvoid problems that cannot be correctedAvoid interferenceGearing controlManipulatorRocker arm

The invention relates to a gear shifting manipulator. The gear shifting manipulator comprises a manipulator support, a gear-shifting limit block, a limit bolt, a gear shifting shaft, a gear-shifting rocker arm and a shift-selecting rocker arm, wherein the gear-shifting limit block is movably mounted at the top end of the manipulator support, and consists of a transverse limit part and a longitudinal limit shaft; the gear-shifting rocker arm comprises a basis part and a connecting arm; a gear lever is arranged at the top end of the basis part in a penetrating manner; a bolt clamping groove is formed in the connection position of the basis part and the connecting arm; the limit bolt is provided with a cylindrical cavity, and the other end of the limit bolt is in contact connection with a neutral limit groove in a movable manner; a spring is embedded in the cylindrical cavity; one or more pairs of anti-rotation blocks are arranged on the limit bolt; the gear-shifting limit block collides with a gear-shifting limit blocking pad during forward shifting and backward shifting; one side of the upper end of the shift-selecting rocker arm is connected with a shaft body at one end of the gear shifting shaft in an assembled manner, and a rotating shaft of the gear-selecting rocker arm is fixedly arranged on the other side of the upper end of the shift-selecting rocker arm. The gear shifting manipulator disclosed by the invention has the advantages that the structural design is reasonable, the operation and the use are simple, the feeling of manipulation is good, gear selection and shifting are convenient and reliable, the out-of-gear problem after engagement of gears can be effectively avoided.

Owner:SHIYAN DAFENG FLEXIBLE CONTROL CABLES

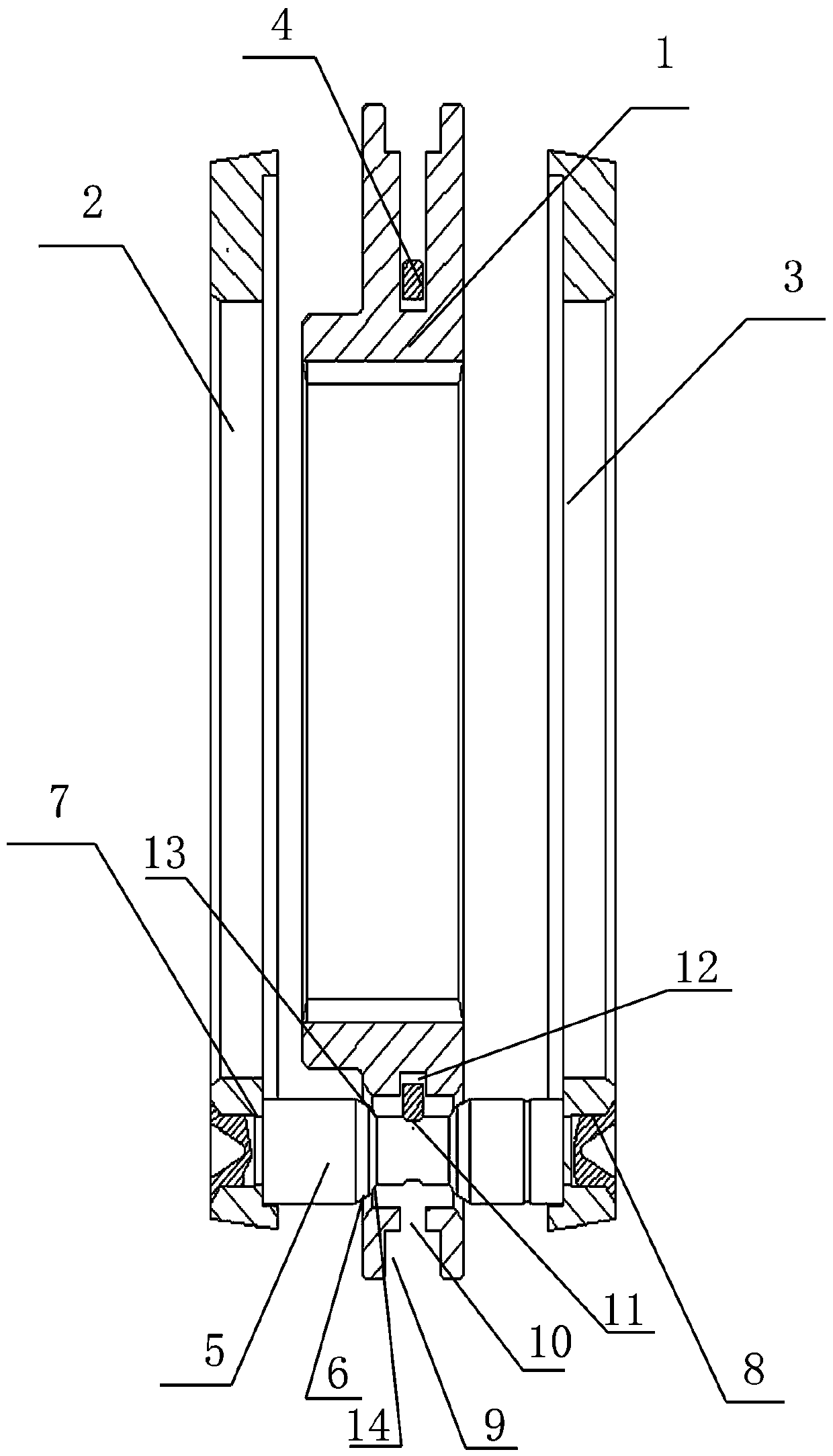

Automobile synchronizer

The invention discloses an automobile synchronizer. Positions of locking pin holes (6) correspond to those of first locking pin holes (7) and those of second locking pin holes (8), and a sliding gearsleeve (1), a first synchronous conical ring (2) and a second synchronous conical ring (3) are connected into a whole by inserting locking pins (5) into the locking pin holes (6), the first locking pin holes (7) and the second locking pin holes (8); multiple locating ring slots (10) are formed in the groove bottom of a shifting fork groove (9) in the radial direction, and each locating ring slot (10) corresponds to one locking pin hole (6) of the sliding gear sleeve (1); a locating slot (11) is formed in the middle of each locking pin (5), and each locating slot (11) corresponds to one locating ring slot (10); and locating clamping slots (12) are formed in the groove bottom of the shifting fork groove (9), each locating snap spring (4) is embedded into the corresponding locating clamping slot (12), the outer side of each locating snap spring (4) is located in the corresponding locating slot (11), and a locking surface (14) of each locking pin (5) corresponds to one locking angle (13) of the corresponding locking pin hole (6).

Owner:江苏追日汽车同步器有限公司

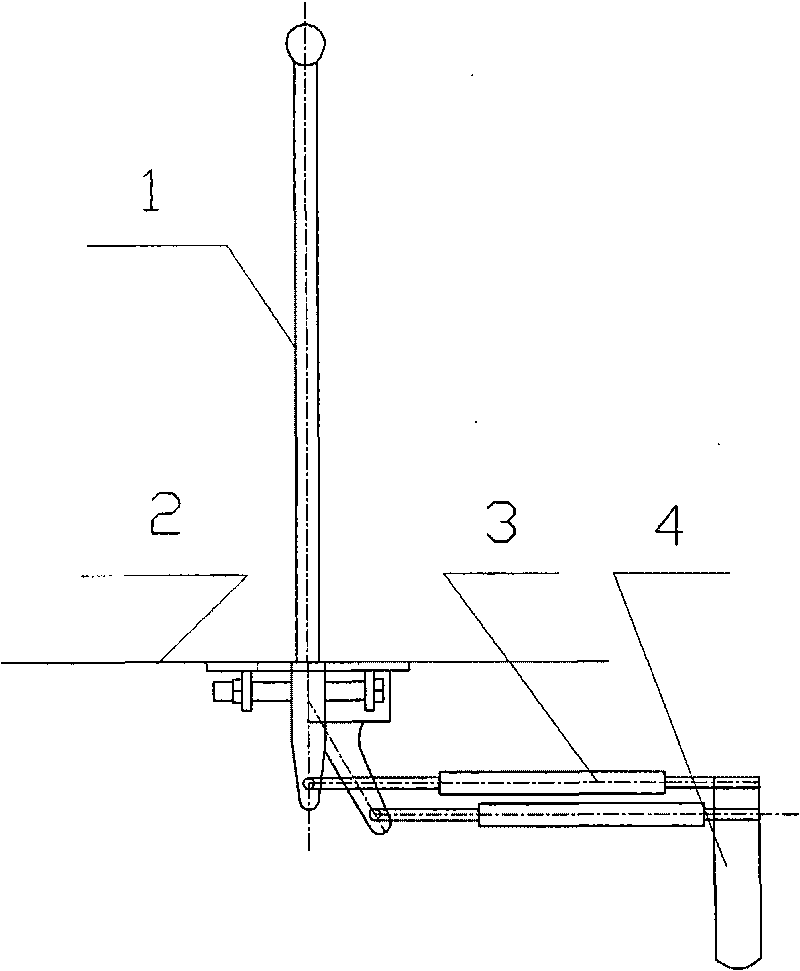

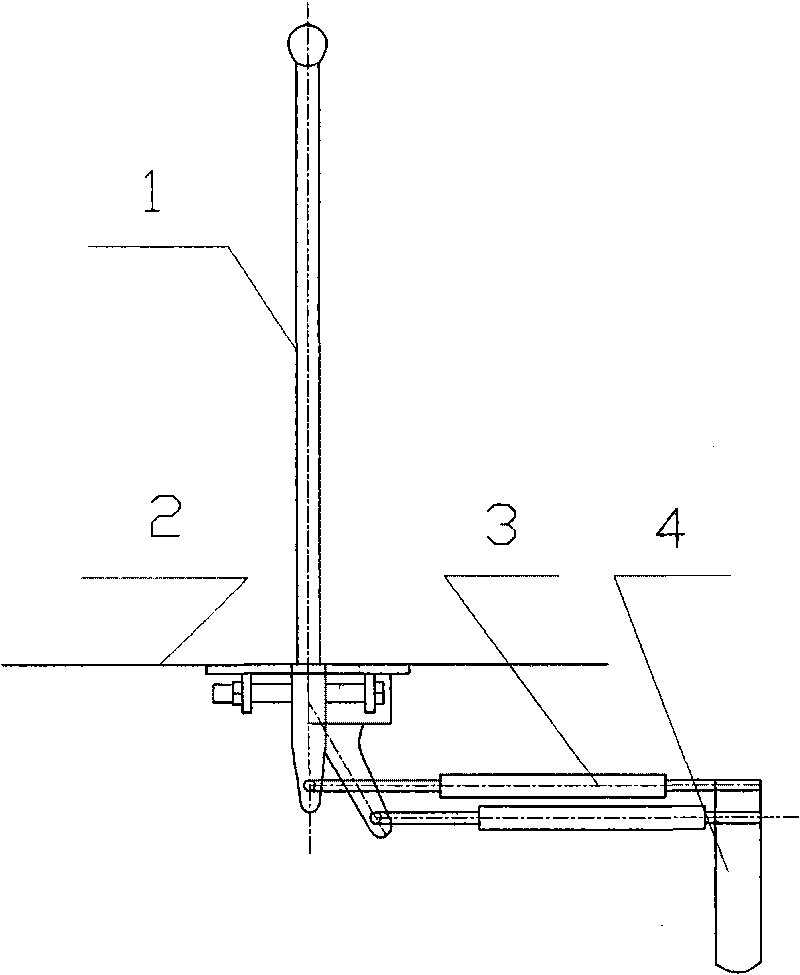

Gear shifting mechanism of harvester

The invention discloses a gear shifting mechanism of a harvester. The purpose of the invention is to provide a gear shifting mechanism of a harvester with convenient and easy gear shifting. The technical scheme of the invention includes that: the gear shifting mechanism of the harvester comprises a gear shifting assembly, a gear shifting pull rod and a gear shifting rotary arm, the gear shifting assembly is movably connected with one end of the gear shifting pull rod, while the other end of the gear shifting pull rod is movably connected with the gear shifting rotary arm. The gear shifting mechanism has the technical effects that: as only the gear shifting pull rod is arranged between the gear shifting assembly and the gear shifting rotary arm, the intermediate power conversion steps are reduced, the gear shifting assembly can easily transfer the gear shifting power to the gear shifting pull rod and the gear shifting rotary arm, thereby ensuring more convenient and easier gear shifting.

Owner:河南蛮牛农机制造有限公司

Forward-and-backward rotation variable-speed hub motor

InactiveCN102951009AImprove efficiencyNot easy to get hotElectric machinesMotor depositionGear driveControl theory

The invention belongs to the technical field of electric vehicle power transmission, and aims at solving the problem that a motor can not output different vehicle speeds and different torques at the same rotation speed. A forward-and-backward rotation variable-speed hub motor comprises a hub ring, an end face and a case body, wherein the case body and the motor are fixed on a fulcrum shaft; the motor is provided with a motor shaft which is in transmission connection with a main shaft; driving gears are flexibly sleeved on the main shaft; a second-gear driving gear is in engaged transmission with an output gear fixed on an output shaft; a skewed slot is formed on the main shaft; when the main shaft rotates, under the action of the skewed slot, a sliding piece is in clamped connection with the second-gear driving gear or a first-gear driving gear and rotates, and the first-gear driving gear drives a first-gear output gear through a reversing gear, thereby driving the output shaft to rotate; and through forward and backward rotation of the main shaft, the sliding piece is coupled with or separated from the second-gear driving gear or first-gear driving gear, thereby switching to first-gear or second-gear power output.

Owner:蔡旭阳

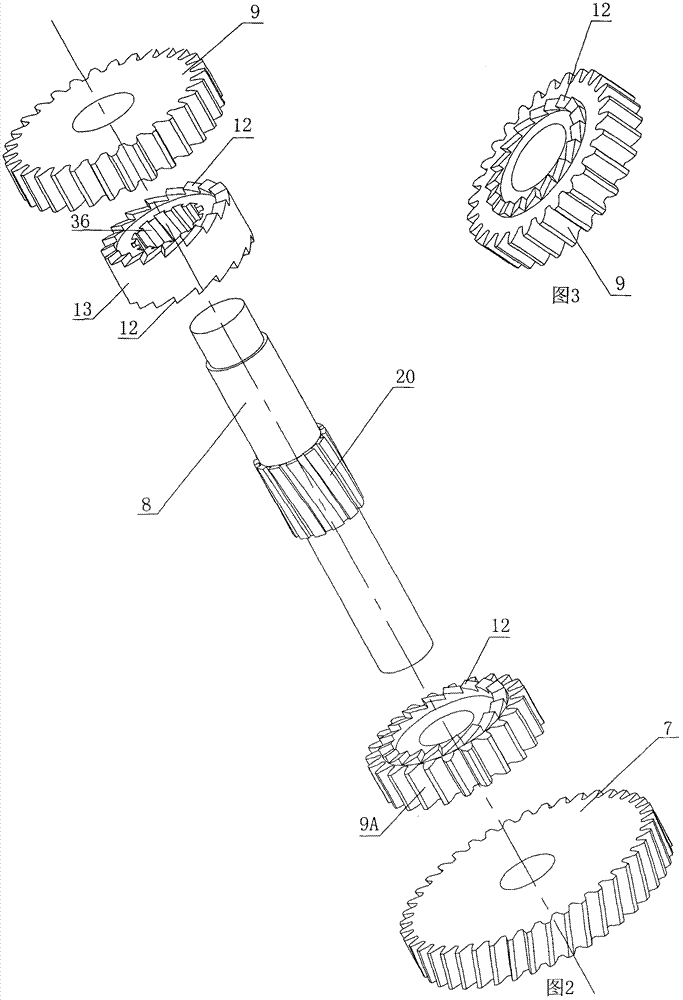

Transmission of electromobile motor

InactiveCN102931763AImprove efficiencyNot easy to get hotMechanical energy handlingControl devicesVariatorMotor shaft

The invention discloses the technical field of power transmission of electromobile motors and solves the problem that a motor can not output different speeds and different torques under same rotating speed. A transmission of an electromobile motor comprises a box body, wherein the box body is provided with a motor, the motor is provided with a motor shaft, the motor shaft is in transmission connection with a main shaft, a drive gear is sleeved on the main shaft, a two-gear drive gear is in meshing transmission with an output gear fixed on an output shaft, a chute is processed on the main shaft, a sliding member is connected with a one-gear drive gear or two-gear drive gear under the action of the chute when the shaft rotates, the one-gear drive gear drives a one-gear output gear through a reversing gear so as to drive an output shaft to rotate; and the sliding member is combined or separated from the two-gear drive gear or one-gear drive gear through positive or negative rotation of the main shaft, therefore, one-gear or two-gear power output is switched.

Owner:蔡旭阳

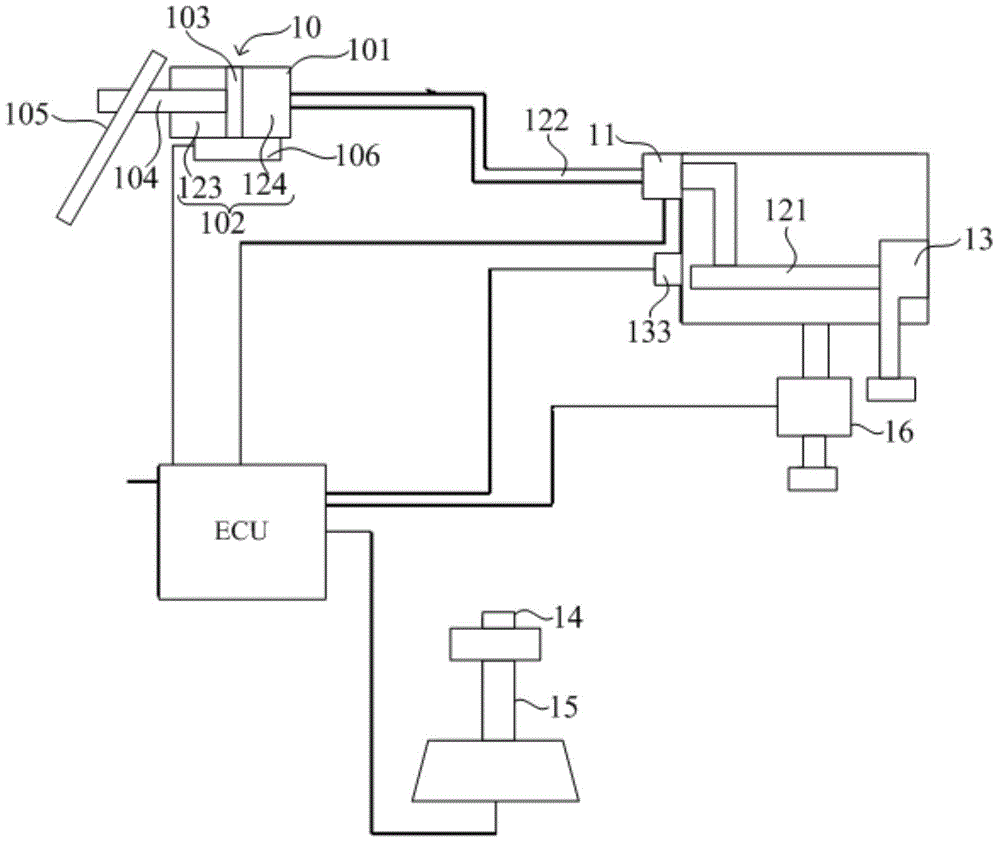

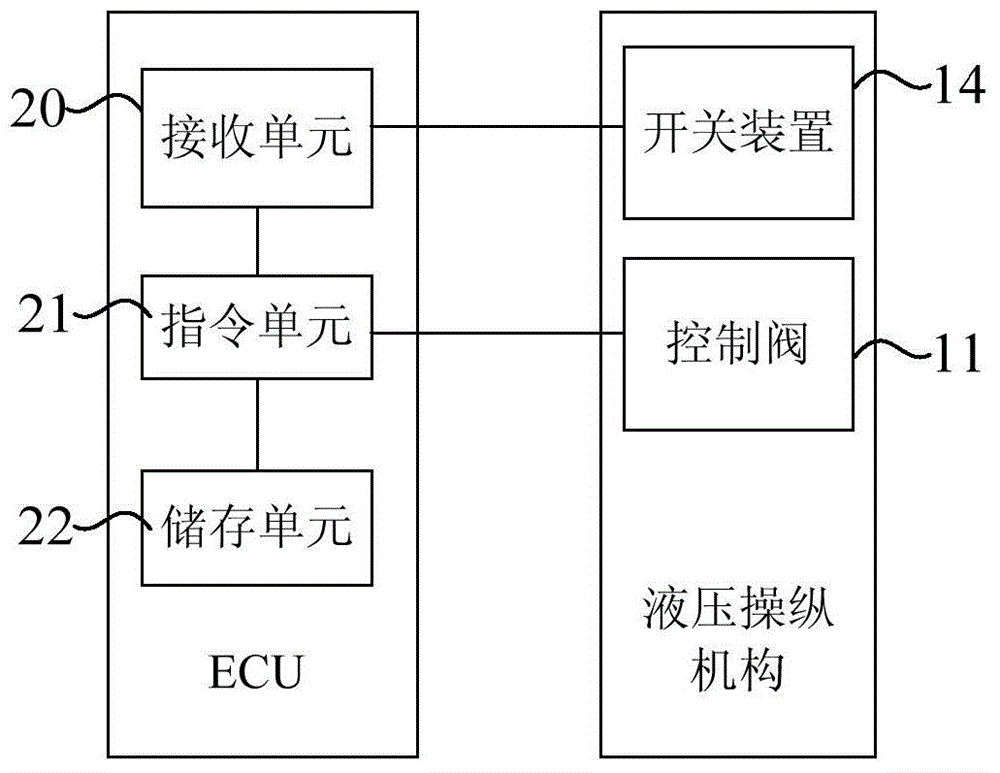

Hydraulic operating mechanism, ECU, clutch system and car

InactiveCN106151310AReduce labor intensityEase of shiftingClutchesGearing controlEngineeringControl valves

The invention discloses a hydraulic operating mechanism, an ECU, a clutch system and a car. The hydraulic operating mechanism comprises a clutch separation assistant cylinder, a control valve and a switch device. The control valve is provided with an oil inlet, an oil outlet and an oil discharging hole, the oil inlet communicates with an engine oil pump, and the oil outlet communicates with the clutch separation assistant cylinder. The switch device is used for controlling the oil outlet and the oil inlet of the control valve to communicate through the ECU so that the clutch separation assistant cylinder can be filled with oil, and controlling the oil outlet and the oil discharging hole to communicate so that oil can be discharged from the clutch separation assistant cylinder. The hydraulic operating mechanism controls a clutch to be disengaged and engaged through the switch device in cooperation with the control valve. In addition, during gear shifting each time, a driver can control disengagement of the clutch by operating the switch device, foot action is avoided, the gear shifting operation is convenient, and the labor intensity of the driver is relieved.

Owner:SAIC MOTOR

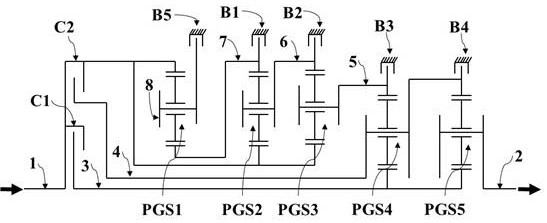

A Longitudinal Rear Drive Planetary Gear Automatic Transmission

ActiveCN112984059BMany gearsEasy to controlToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The invention discloses a longitudinal rear drive planetary gear automatic transmission, which adopts 5 negative sign planetary gear sets, 8 rotating shafts, 7 shift elements, including 2 clutches, 5 brakes, and 5 brakes nested Planetary gear set arrangement, 2 clutches are located at the front of the transmission, and the structural layout is more compact. In the present invention, each gear position closes 2 shifting elements, 11 forward gears and 2 reverse gears can be realized, and as the number of gears increases, a wider speed ratio range and a more uniform transmission step ratio can be obtained .

Owner:BEIHANG UNIV

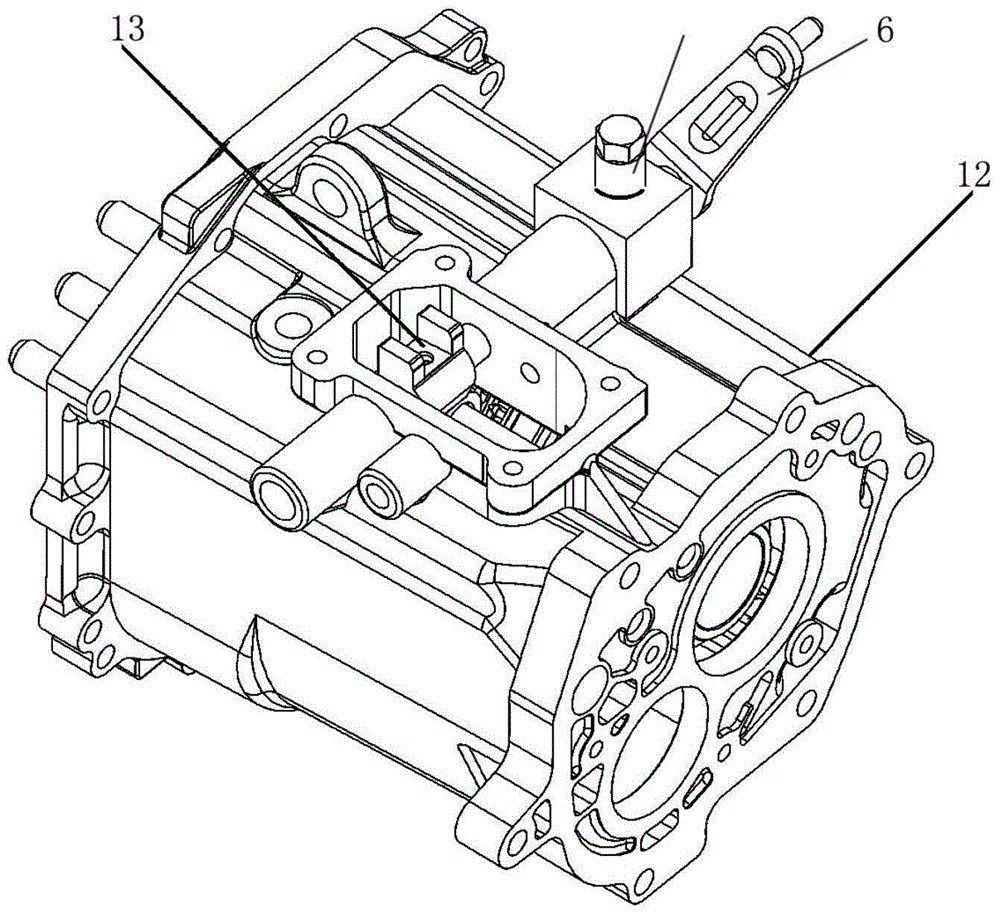

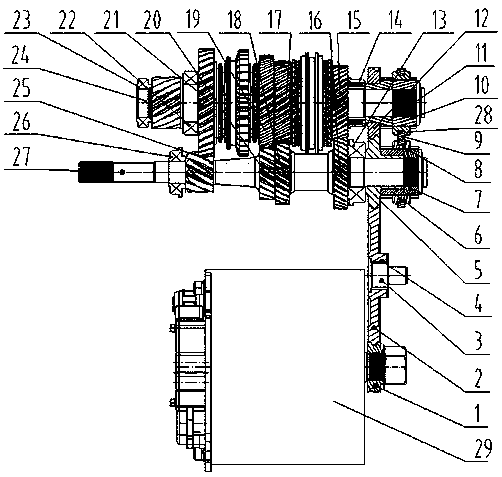

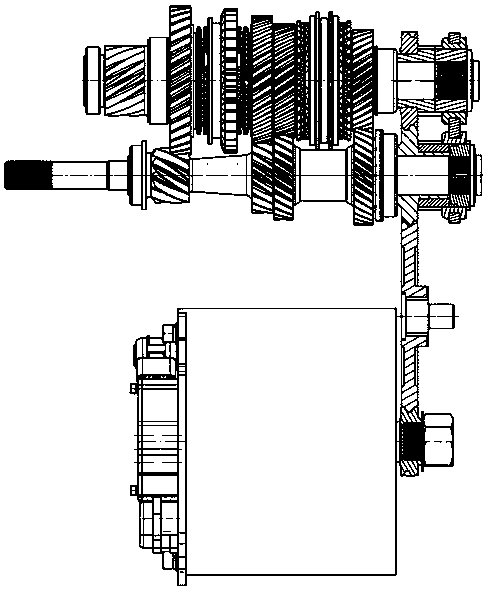

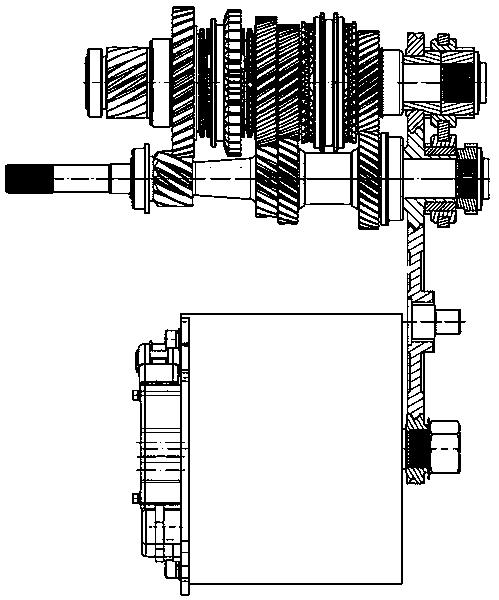

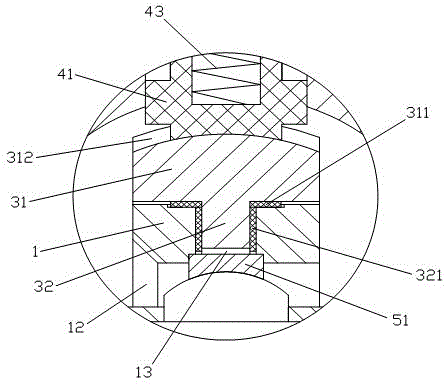

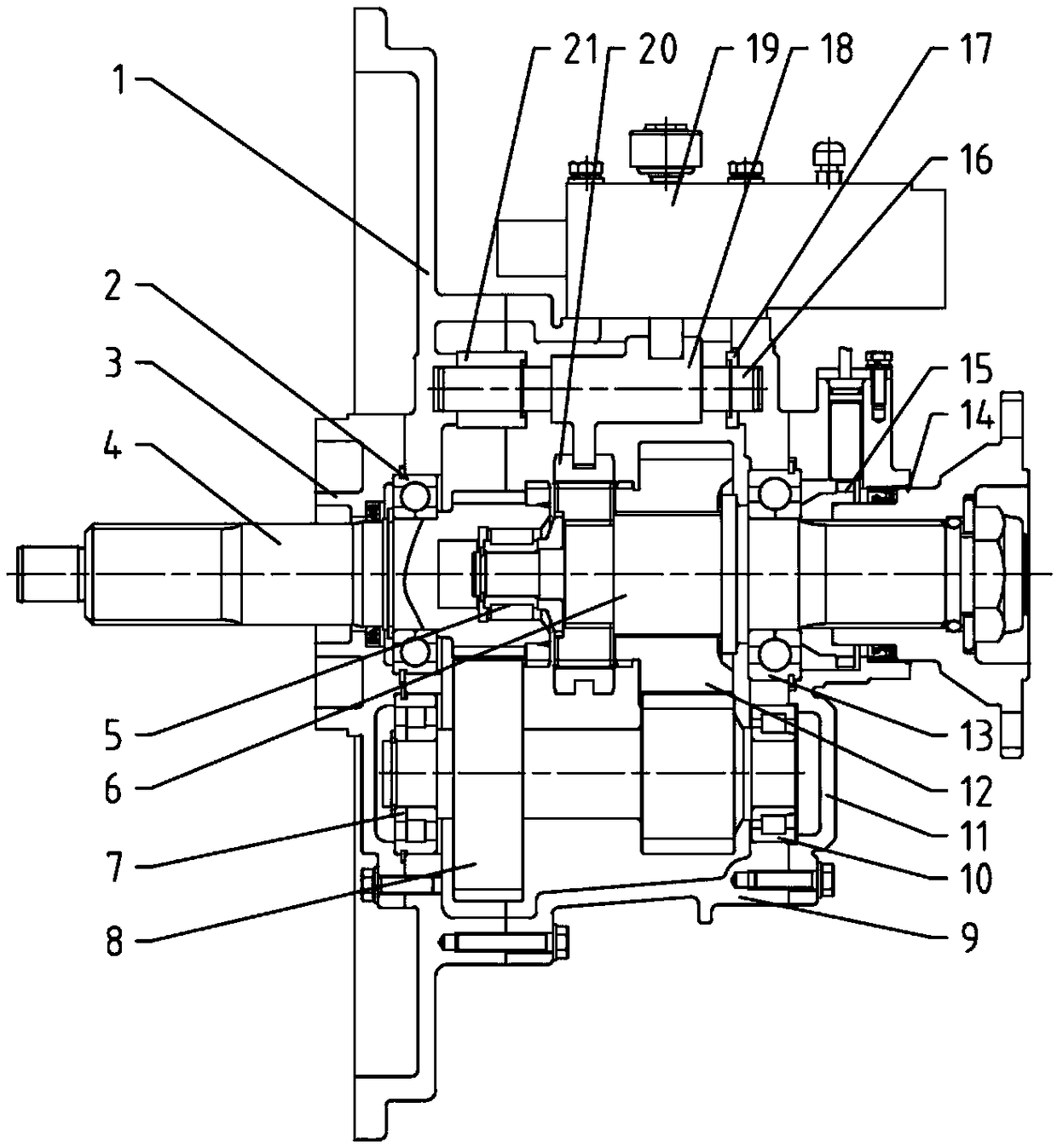

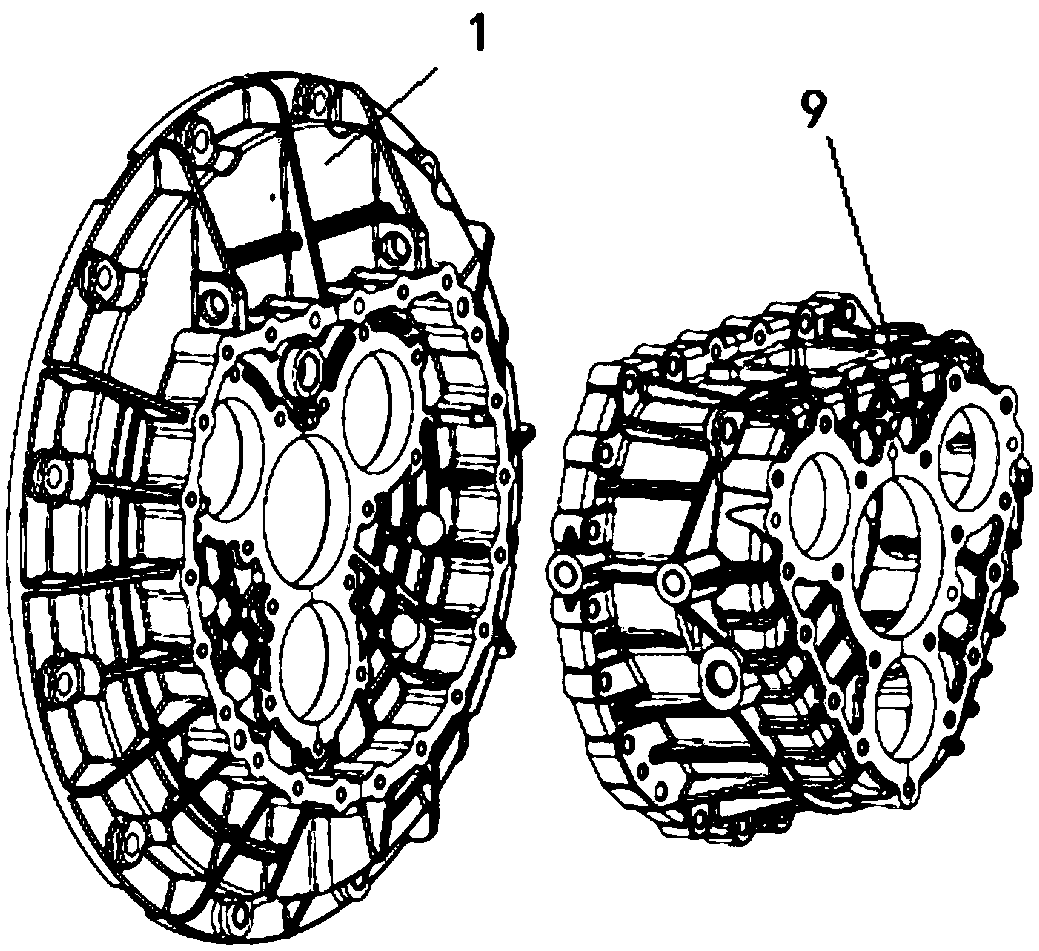

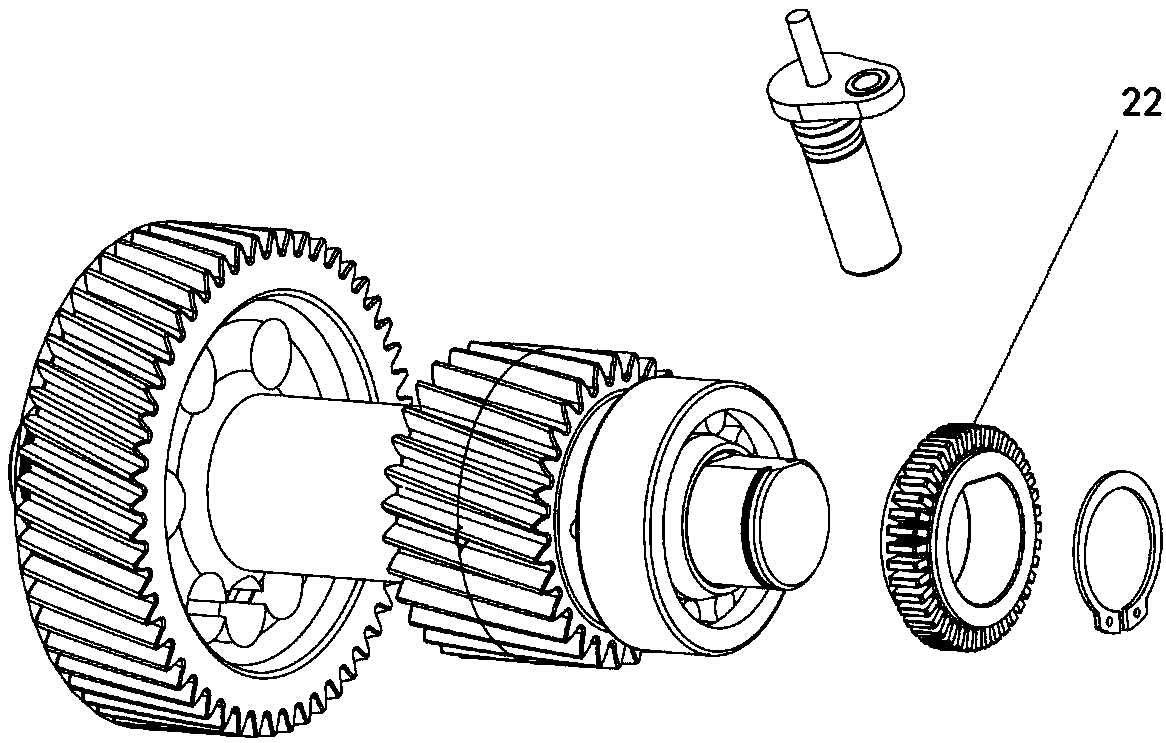

Two-speed pure electric transmission

The invention discloses a two-speed pure electric transmission. The transmission comprises a front shell, a front bearing cover connected with the front shell, an input shaft assembly, an output shaftassembly, a transmission shell and a rear bearing cover connected with the transmission shell. The input shaft assembly is supported on the front shell. The two ends of the output shaft assembly aresupported on an inner ring of the input shaft assembly and the transmission shell correspondingly. An output shaft first-speed gear is arranged on the output shaft assembly. A sliding sleeve is arranged between the output shaft first-speed gear and the input shaft assembly. A shifting fork is arranged above the sliding sleeve and sleeves a shift rail in an idling mode. A transmission control device is arranged above the shifting fork. Three counter shafts are uniformly distributed on the periphery of the output shaft assembly. The two ends of each counter shaft are supported on the front shelland the transmission shell correspondingly. According to the two-speed pure electric transmission, the technical route of the three counter shafts is adopted, the center-to-center distance is reduced, and the transmission is small in size, light in weight and compact in structure; and meanwhile, the three counter shafts adopt the symmetric distribution structure of two up and one down, lubrication is guaranteed, the churning loss can be further reduced as much as possible, and the transmission efficiency is improved.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

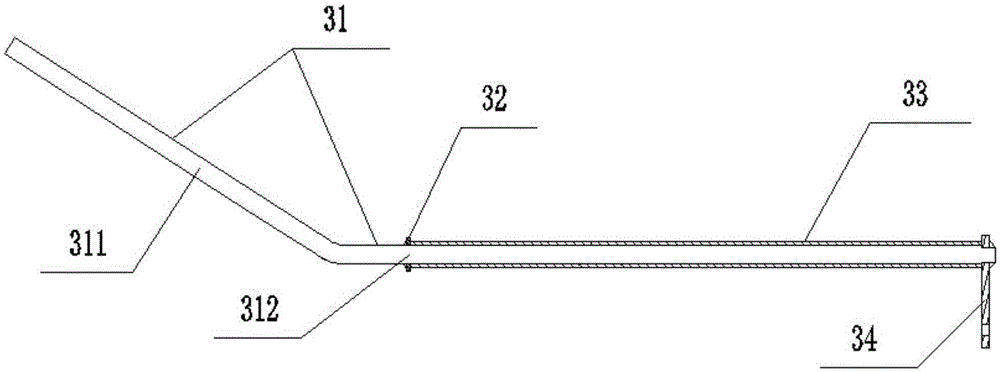

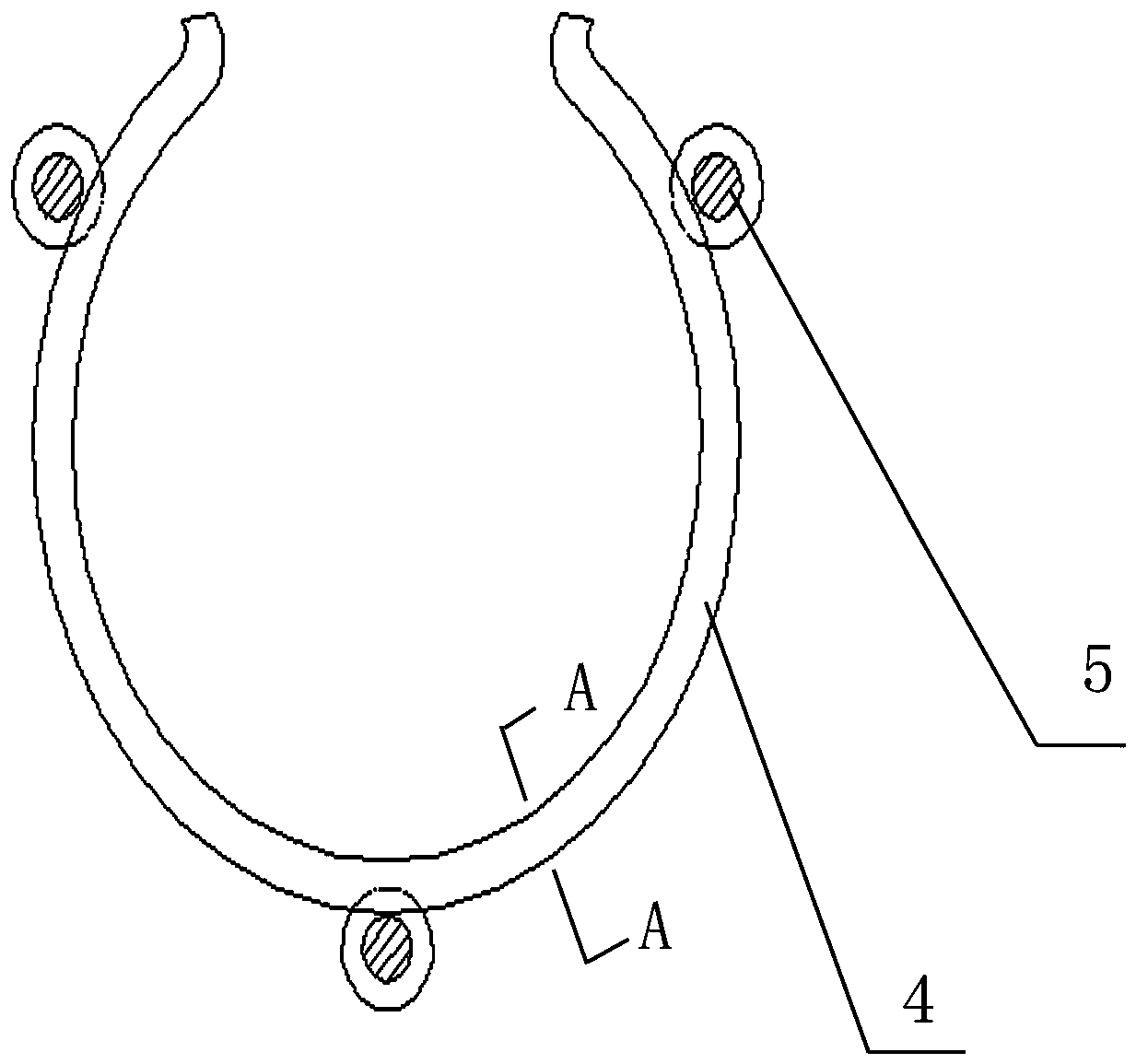

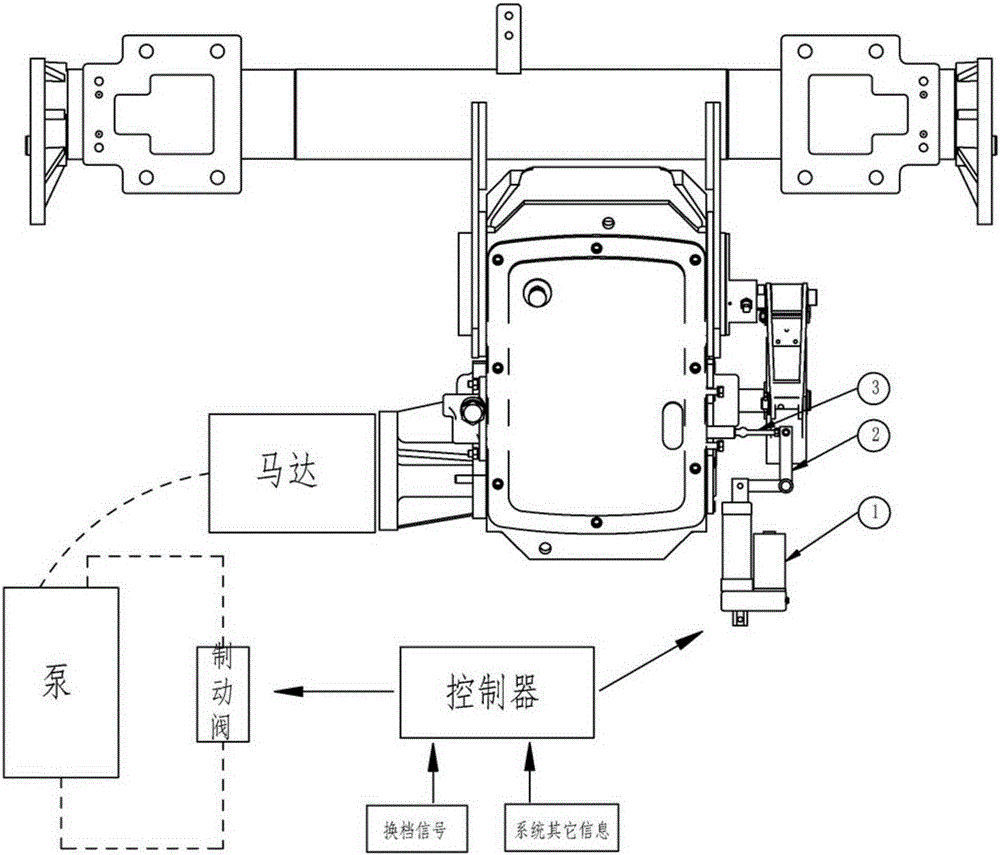

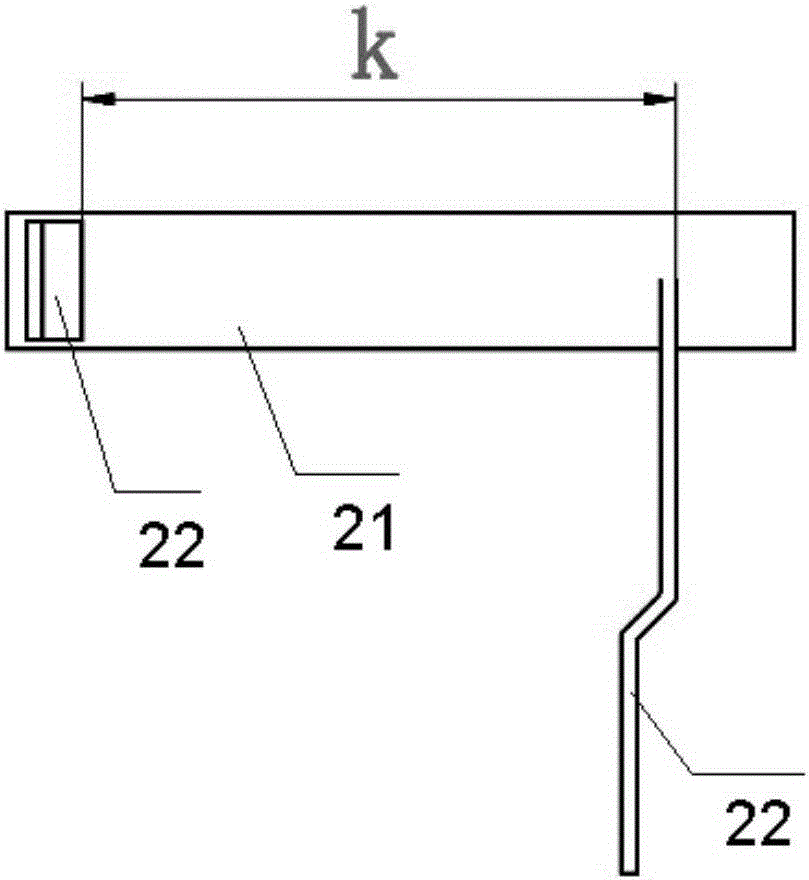

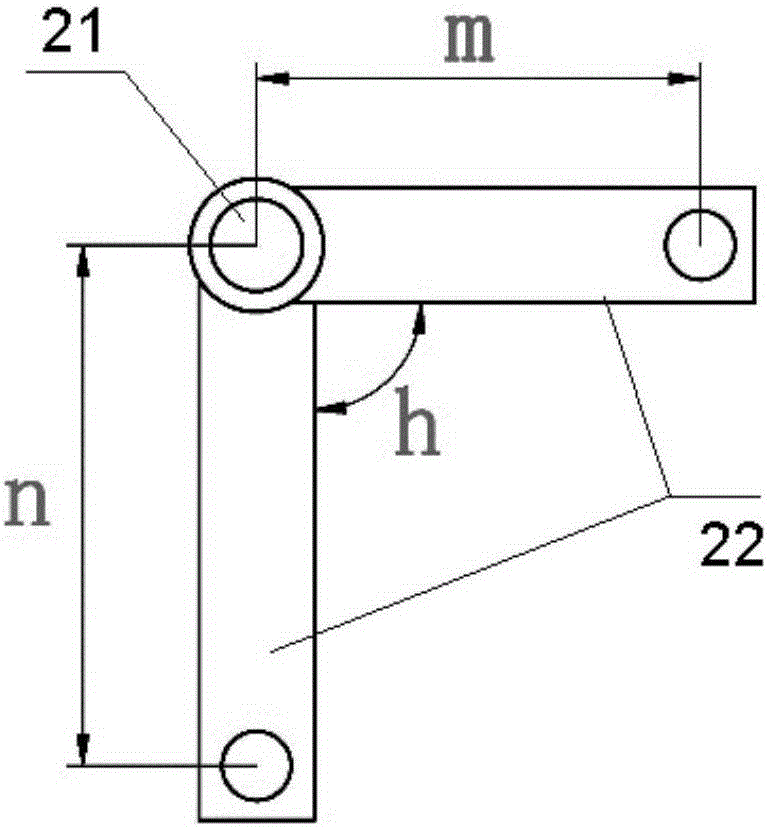

Gearshift mechanism of harvesting machine, gearshift control system and harvesting machine with gearshift mechanism

The invention discloses a gearshift mechanism of a harvesting machine, a gearshift control system and a harvesting machine with the gearshift mechanism. The gearshift mechanism is provided with a shift lever (2), a driving component and a connecting rod (3), wherein the nearby part of the middle part of the shift lever (2) is rotatablely sheathed on the shaft of a machine body; the driving component is controlled by a controller; the end of the driving component is hinged with a first end of the shift lever (2); a first end of the connecting rod (3) is hinged with a second end of the shift lever (2); and a second end of the connecting rod (3) is connected with a transmission case gearshift point of the machine body. The driving component drives one end of the shift lever (2), so that the shift lever (2) rotates around the shaft, the other end of the shift lever (2) drives the connecting rod (3) to move, and the connecting rod (3) is connected with the transmission case gearshift point, thereby changing the position of the transmission case gearshift point and achieving the goal of gearshift. The motion of the driving component is controlled to implement gearshift, and the driving component is automatically controlled by the controller, so that the gearshift is convenient, reliable and intelligent, thereby lowering the driving fatigue.

Owner:ZOOMLION HEAVY MASCH CO LTD

A self-driving robot shifting manipulator

An automatic driving robot gear shifting manipulator, comprising a first stepping motor, a first slider, a first slide rail, a first connecting rod, a second connecting rod, a first swing rod, a gripper, a second stepping motor, The second slider, the second slide rail, the third connecting rod, and the fourth connecting rod; the first stepping motor, the second stepping motor, the first sliding rail, and the second sliding rail are all fixed on the upper end of the box; the first The stepping motor drives the first slider to move back and forth along the first slide rail; the third connecting rod cooperates with the chute in the first slider and is perpendicular to the sliding direction of the first slider; the lower end of the second connecting rod is connected to the third connecting rod. The upper end of the second connecting rod is connected with the rear end of the first swing rod through a pin shaft; the front end of the first swing rod is connected with the gripper; the second stepper motor drives the second slider to slide along the second slide rail, and the sliding direction perpendicular to the first slider; the third connecting rod is connected with the second slider; the lower end of the fourth connecting rod is connected with the third connecting rod; the upper end of the fourth connecting rod is connected with the first swing rod through a pin shaft; Type of cab and gear shifting.

Owner:NANJING UNIV OF SCI & TECH

A planetary gear transmission mechanism

The invention discloses a planetary gear transmission mechanism, which adopts 4 planetary gear sets, including 1 positive sign planetary row, 3 negative sign planetary rows, 7 transmission components, 6 shifting elements, including 2 clutches, 4 There are 1 brake, 4 brakes nested planetary arrangement, 2 clutches are located at the front of the transmission, and the structure layout is more compact. In the present invention, each gear position closes two shifting elements, which can realize 9 forward gears and 1 reverse gear, and as the number of gears increases, a wider speed ratio range and a more uniform transmission step ratio can be obtained .

Owner:BEIHANG UNIV

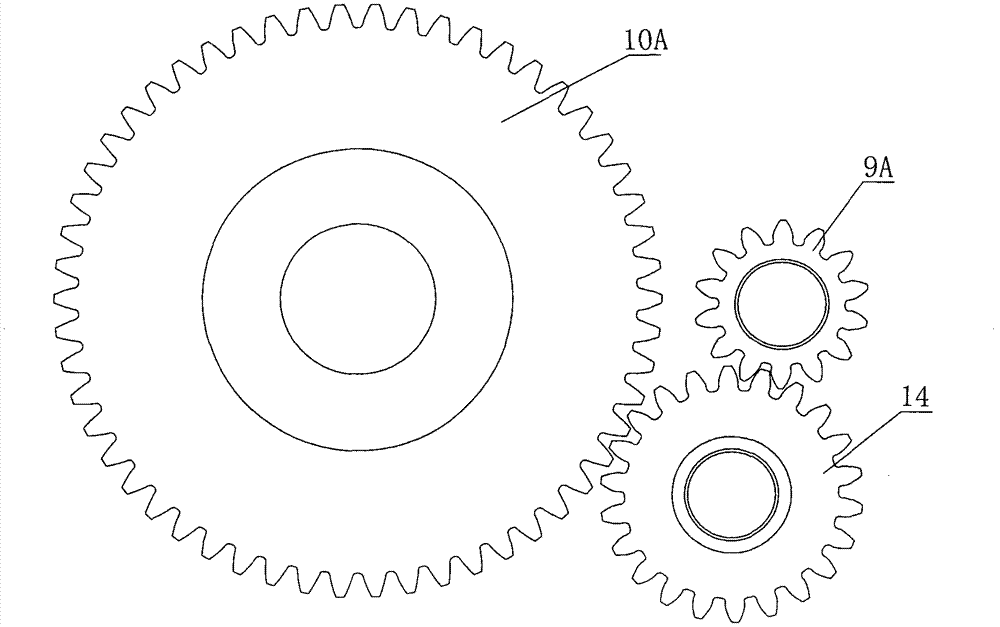

Motor multi-gear power transmission device

PendingCN106917848AEasy to controlExtended use timeToothed gearingsGearing controlElectric power transmissionElectricity

The invention discloses a motor multi-gear power transmission device, and solves the problem that safety cannot be guaranteed because a conventional electric vehicle is complicated in gear shift. The motor multi-gear power transmission device comprises a power output shaft and a power input shaft, wherein a plurality of transmission pairs comprising transmission shafts are arranged at the peripheries of the two shafts in a planetary shape; the transmission pairs have different transmission speed ratios; and a synchronizing ring in each transmission pair can axially slide on the corresponding transmission shaft through a corresponding electric driver, so that power transmission between gears which are movably connected to each transmission shaft in a sleeving manner and the corresponding transmission shaft is realized. For the electric drivers, target control is realized by a vehicle-mounted controller according to a signal of a speed sensor, so that the transmission of large torque and low rotating speed or the transmission of small torque and high rotating speed can be realized when a vehicle runs, advancing demands of the vehicle can be well met, and energy consumption is effectively reduced.

Owner:LIMA VEHICLE IND GRP

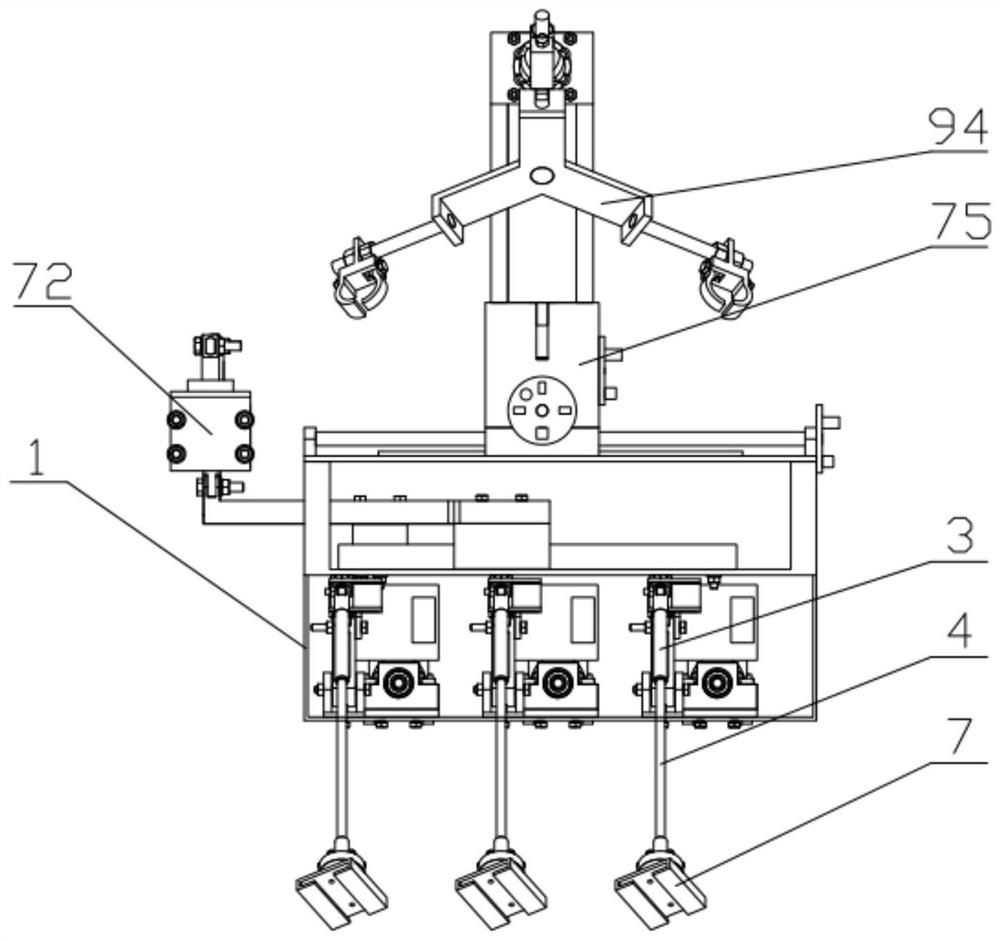

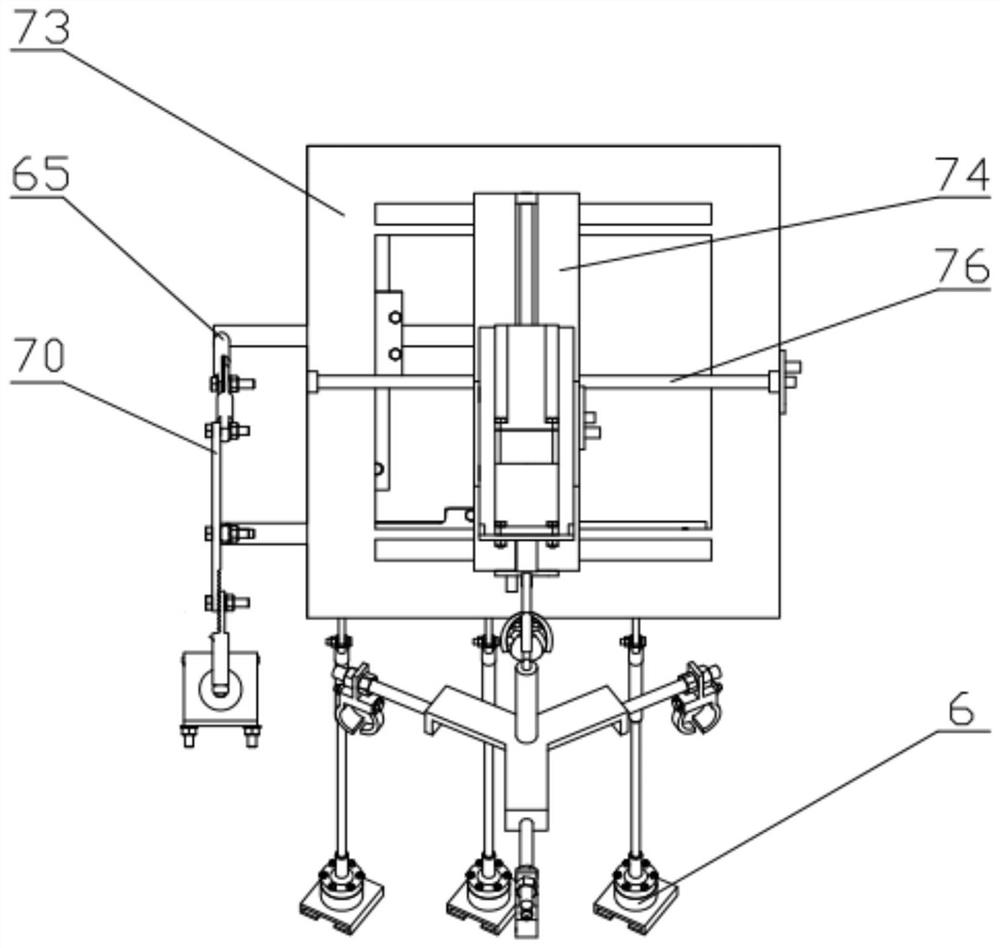

A general-purpose unmanned robot

ActiveCN109094678BCompact structureFit closelyProgramme-controlled manipulatorVehiclesSteering wheelRobot hand

The invention discloses a universal unmanned robot, which comprises a box body, three mechanical legs arranged side by side, a shift manipulator and a steering manipulator. The mechanical leg comprises a driving mechanism, a fixing plate, a first push rod, a second push rod, a third swing rod, a first fixing seat, a sixth connecting rod, a second connecting rod and a pedal clip; The driving mechanism is fixed inside the box body and is connected with the fixing plate. The fixing plate is fixedly connected with the first push rod; The first push rod is connected with the second push rod; The second push rod is connected with the third swing rod; The third swing lever is connected with the first fixing seat; The first fixing seat is fixedly connected with the box body; One end of the sixth connecting rod is connected with the third swing rod, and the other end is connected with the second connecting rod; A low end of that second connecting rod is connecte with the pedal clamp; At that upper end of the shift manipulator box, the shift lever is driven to be in gear; The steering manipulator is fixed on the box body through the bottom plate for clamping the steering wheel; The robot ofthe invention can be adapted to most of the cab, and the cab does not need to be retrofitted.

Owner:NANJING UNIV OF SCI & TECH

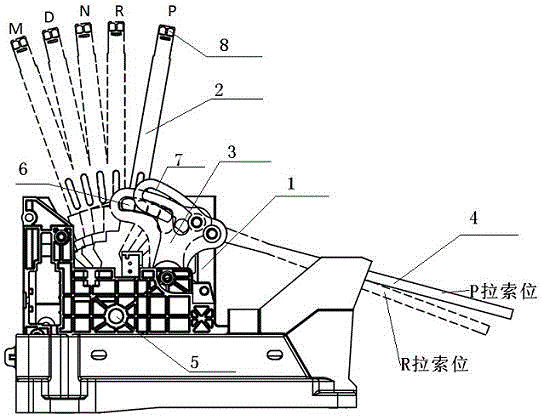

Manual electronic shifter assembly with led indication function

ActiveCN103939596BImprove adaptabilityImprove reliabilityGearing controlCar manufacturingEngineering

The invention discloses a manual and automatic integrated electronic shifter assembly with the LED indicating function. The manual and automatic integrated electronic shifter assembly comprises a support, a gear shifting lever, a gear shifting rocker arm, a gear shifting inhaul cable, an LED, a magnet spindle, a sensor and a circuit board. The gear shifting lever is arranged on the support, the magnet spindle is arranged at the lower end of the gear shifting lever, the gear shifting rocker arm is arranged on the support, the front end of the gear shifting rocker arm is connected with the gear shifting inhaul cable, the rear end of the gear shifting rocker arm is connected with the gear shifting lever, the LED is arranged below the top of the support, and the sensor and the circuit board are arranged on the side face of the support. By the adoption of the mode, the manual and automatic integrated electronic shifter assembly with the LED indicating function has the advantages of being high in reliability, accurate in positioning, compact in structure, low in manufacturing cost, good in automobile model adaptability, light in weight and the like, gear shifting is convenient, fuel economy is remarkably improved, and meanwhile the manual and automatic integrated electronic shifter assembly has wide market prospect on a light-weight automobile manufacturing market.

Owner:FICOSA INTERNATIONAL (TAICANG) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com