Automotive hybrid power structure based on AMT

A technology of hybrid power and automobiles, which is applied in the field of hybrid power structures of automobiles and new energy vehicles, and can solve problems such as power interruption, reduced reliability, and high gear transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

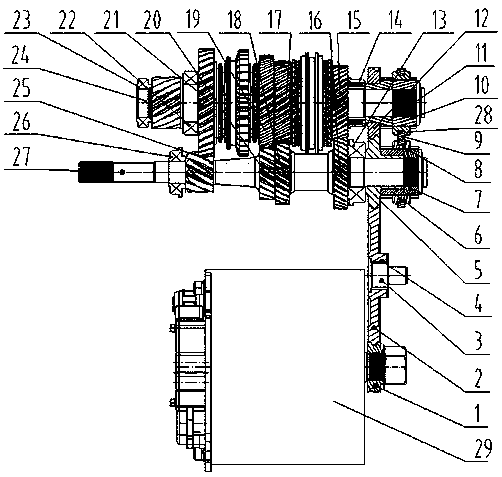

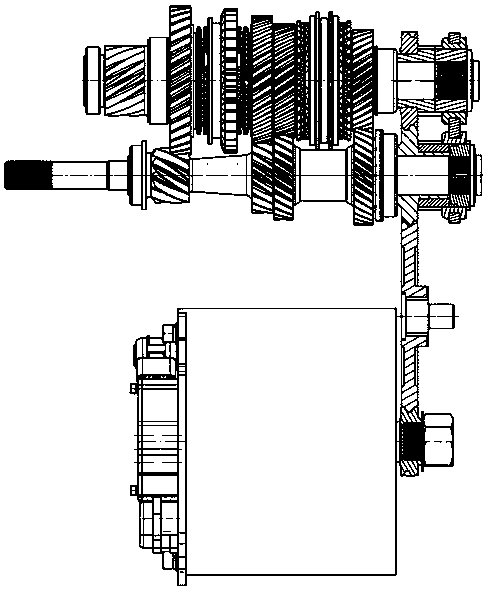

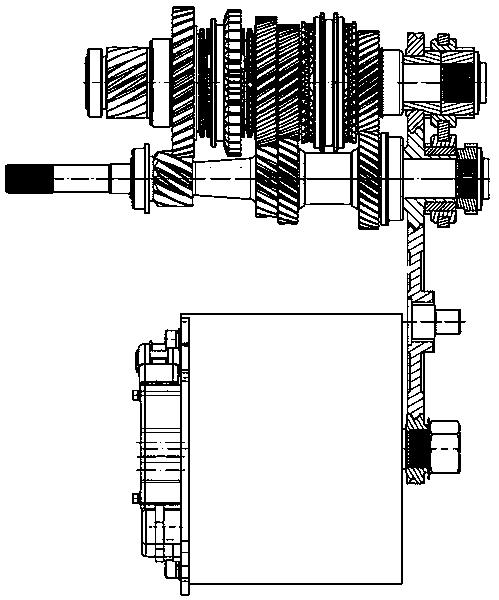

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] see Figure 1-Figure 4 , as can be seen from the figure, the present invention is based on the automobile hybrid structure of AMT, comprises engine, automatic clutch, drive motor 29, motor controller and automatic mechanical transmission, the output of motor controller connects drive motor, and automatic mechanical transmission comprises input Shaft 27, each gear driving gear arranged on the input shaft, output shaft 24 and each gear driven gear corresponding to each gear driving gear arranged on the output shaft, the output shaft of the engine is connected to the input shaft 27 of the automatic mechanical transmission through an automatic clutch . The improvement of the present invention is on working mode switching, engine, clutch and motor controller etc. belong to prior art, so do not show on the figure.

[0033] The input shaft 27 of the automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com