Self locking system of MT (Manual Transmission) gear shifting mechanism

A manual transmission and shifting mechanism technology, applied in mechanical equipment, transmission control, components with teeth, etc., can solve problems such as the inability to ensure a clear gear position, the inability to play a neutral gear and the accurate positioning of each gear position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

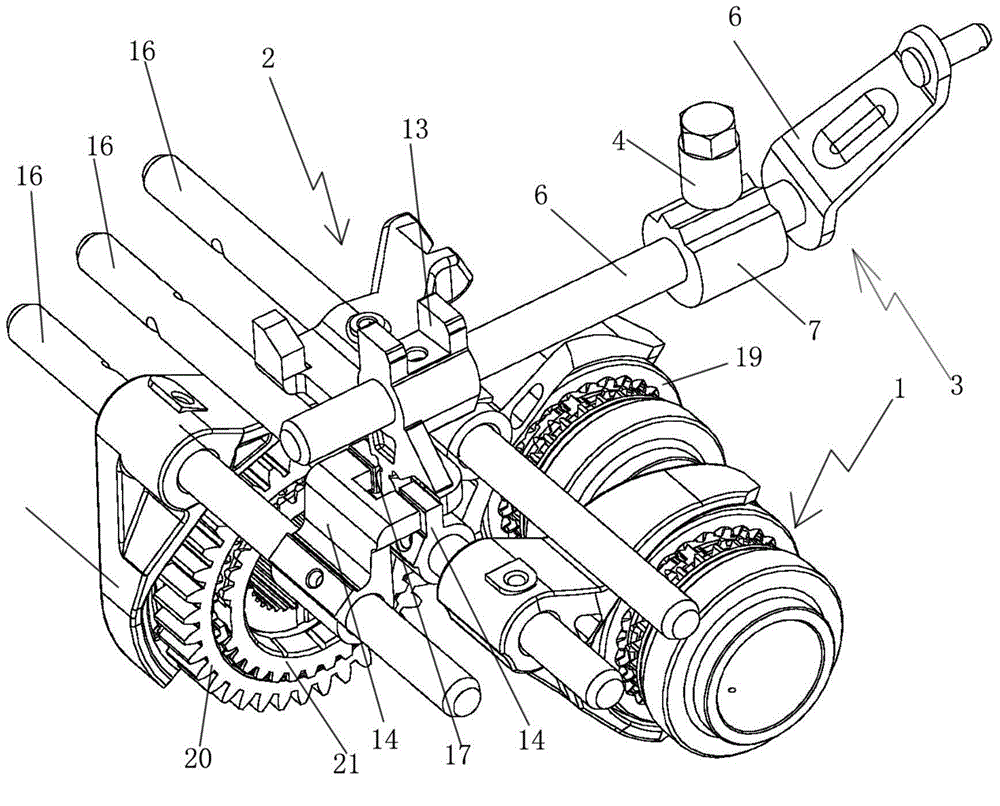

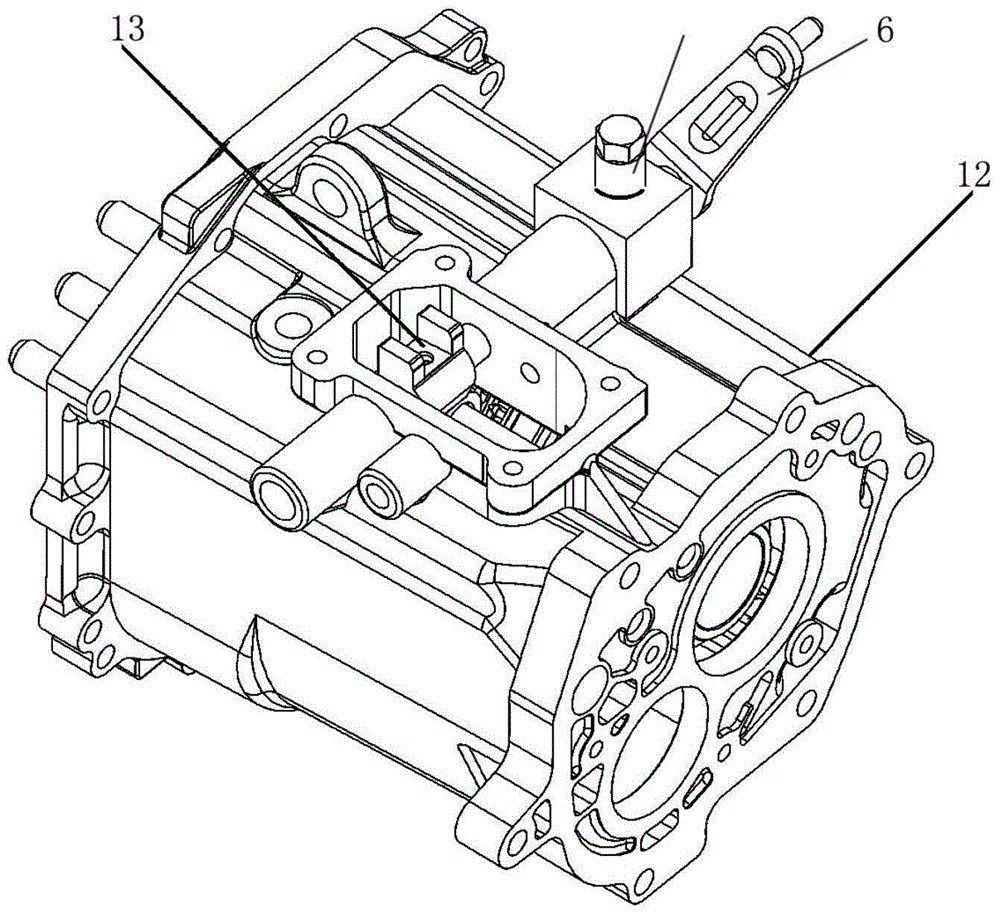

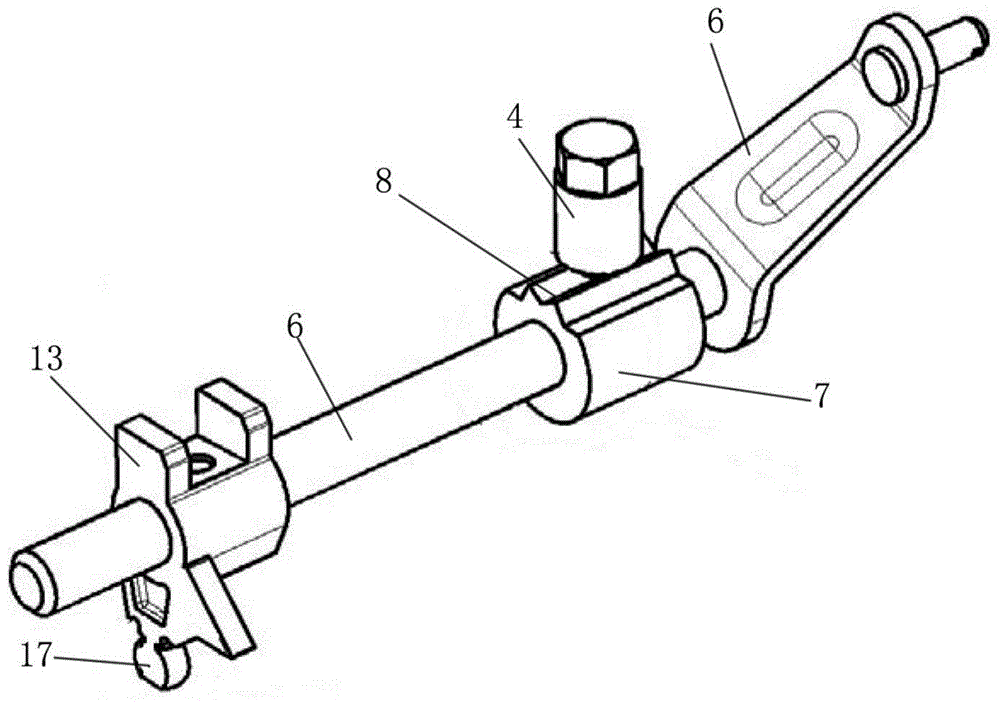

[0037] The following with attached Figure 1 to Figure 10 The manual transmission shift mechanism self-locking system of the present invention will be further described in detail.

[0038] For the self-locking system of manual transmission shift mechanism of the present invention, please refer to Figure 1 to Figure 10, including a synchronizer assembly 1, a shift fork shaft assembly 2 and a shift operation assembly 3, the synchronizer assembly 1 is set on the transmission shaft, the shift fork shaft assembly 2 and the synchronizer assembly into a sliding connection, the shift operation assembly 3 is connected to the shift fork shaft assembly 2, the shift operation system is connected with a positioning spring ball device that can lock the shift operation system, and the synchronization A self-locking device that can lock the synchronizer assembly 1 is provided in the synchronizer assembly 1, and the positioning spring ball device includes a sleeve 4 and a self-locking spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com