Planetary gear shift mechanism

A technology of planetary gear and speed change mechanism, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., which can solve the problems of complex structure, high manufacturing cost, and bearing damage of planetary gear transmissions, so as to improve work reliability and The effect of increasing the service life, improving the service life and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

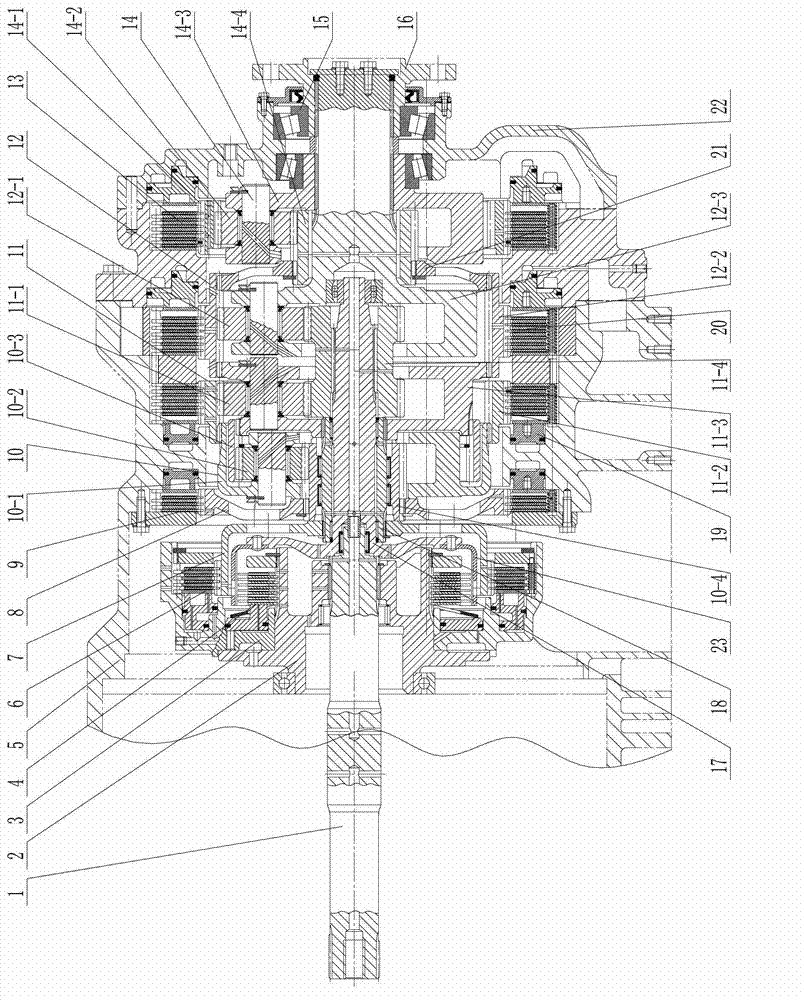

[0011] See figure 1 As shown, the planetary gear transmission mechanism of the present invention includes a casing 5, an input shaft 1 mounted on the casing 5, a clutch connected to the input shaft 1, a planetary gear row and brakes installed in the casing 5. The hydraulic torque converter is installed in the box body 5 of the present invention to provide power, the input shaft 1 is connected with the clutch oil cylinder 3 of the first clutch 4 and the second clutch 6 through the drive hub 2, and the input shaft 1 is connected with the drive hub 2 by keys , the drive hub 2 is installed on the wallboard of the box body 5 through bearings, the drive hub 2 is connected with the clutch cylinder 3 through fasteners, and the power is transmitted from the drive hub 2 to the first clutch 4 and the second clutch through the input shaft 1 The public clutch oil cylinder 3 of 6 transmits power to the first clutch 4 and the second clutch 6. The first clutch 4 and the second clutch 6 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com