Motor multi-gear power transmission device

A power transmission, multi-gear technology, applied in the transmission, gear transmission, transmission control and other directions, can solve the problem of not being able to adapt to the actual driving needs of the vehicle, increasing the difficulty of driving, hidden dangers of driving safety, etc. , to achieve the effect of easy setting, saving energy consumption and prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

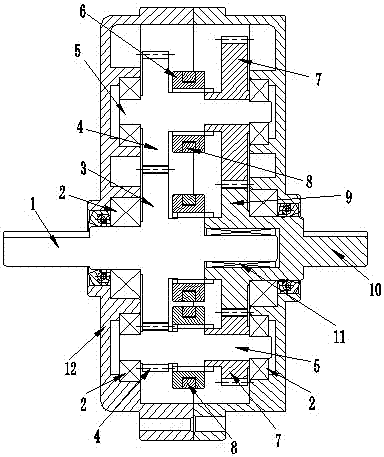

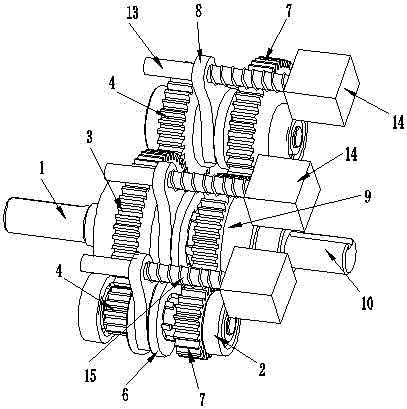

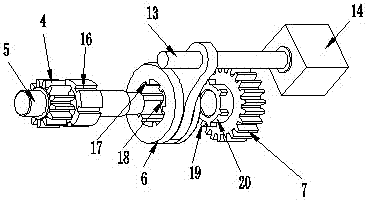

[0024] As shown in the figure, the power transmission device can be applied to electric two-wheel vehicles and electric vehicles with more than two wheels, and is used for automatic gear shifting during the running of the vehicle.

[0025] The structure of the power transmission device includes a power input shaft 10 and a power output shaft 1. The outer circumference of the power input shaft 10 is fixedly provided with a main driving gear 9, and the outer circumference of the power output shaft 1 is fixedly provided with an active and passive gear 3. A plurality of transmission pairs are arranged on the periphery of the power output shaft 1 and the power input shaft 10. The transmission speed ratios of these transmission pairs are different. Corresponding to transmission pairs with different transmission speed ratios, the power output shaft 1 outputs power at different speeds.

[0026] The transmission pair includes a transmission shaft 5 and an auxiliary driving gear 7 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com