Patents

Literature

174results about How to "Won't pinch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

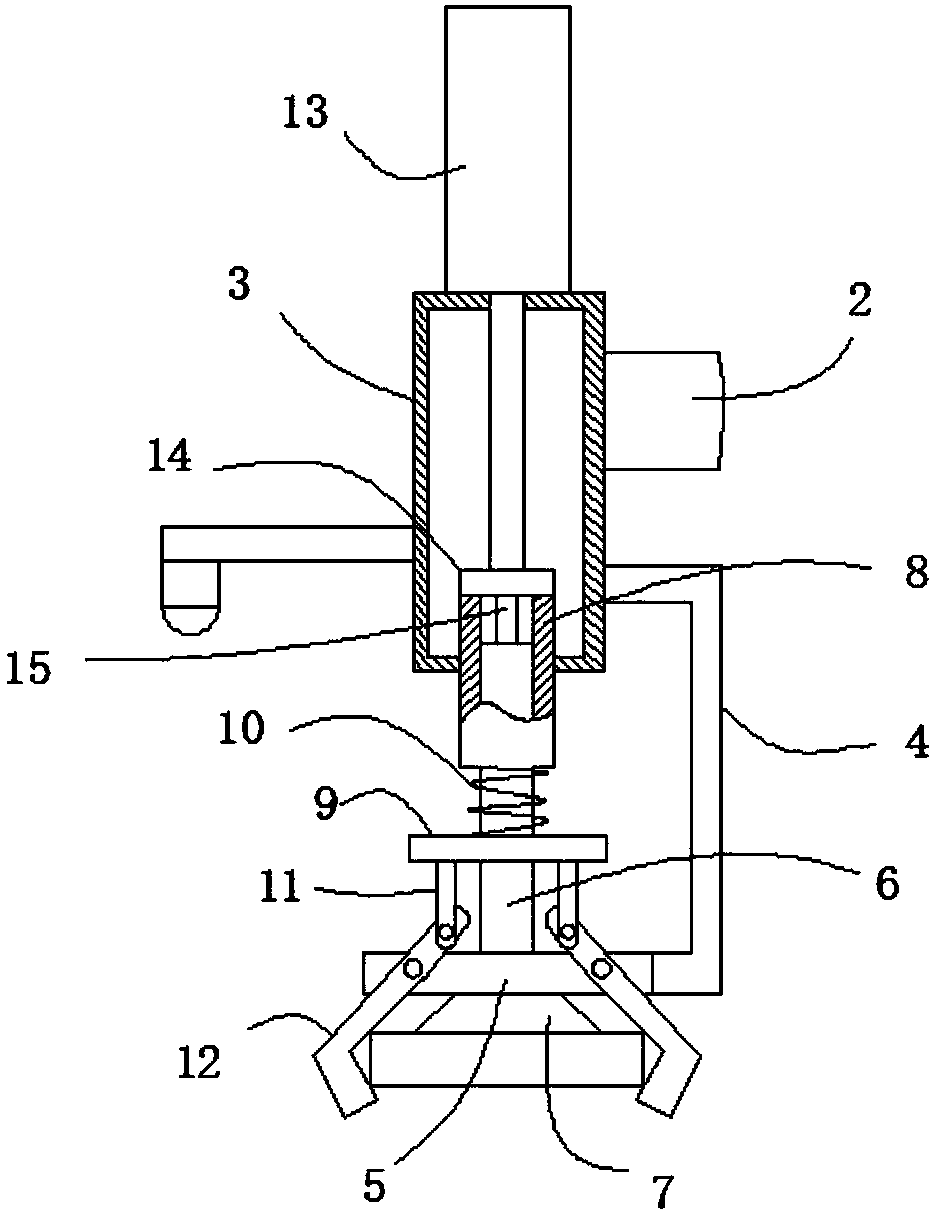

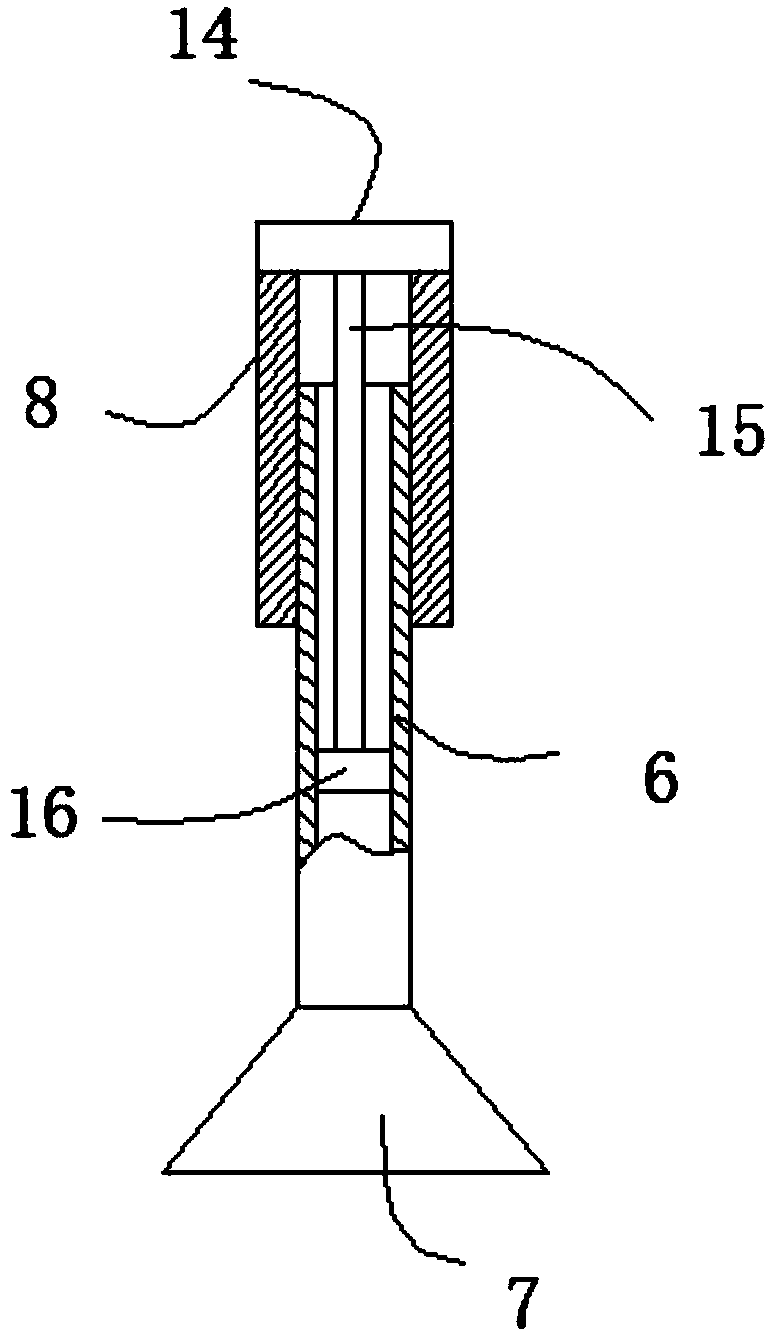

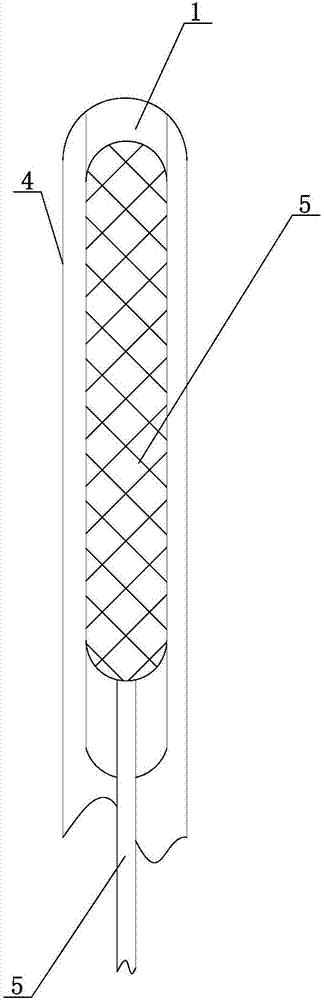

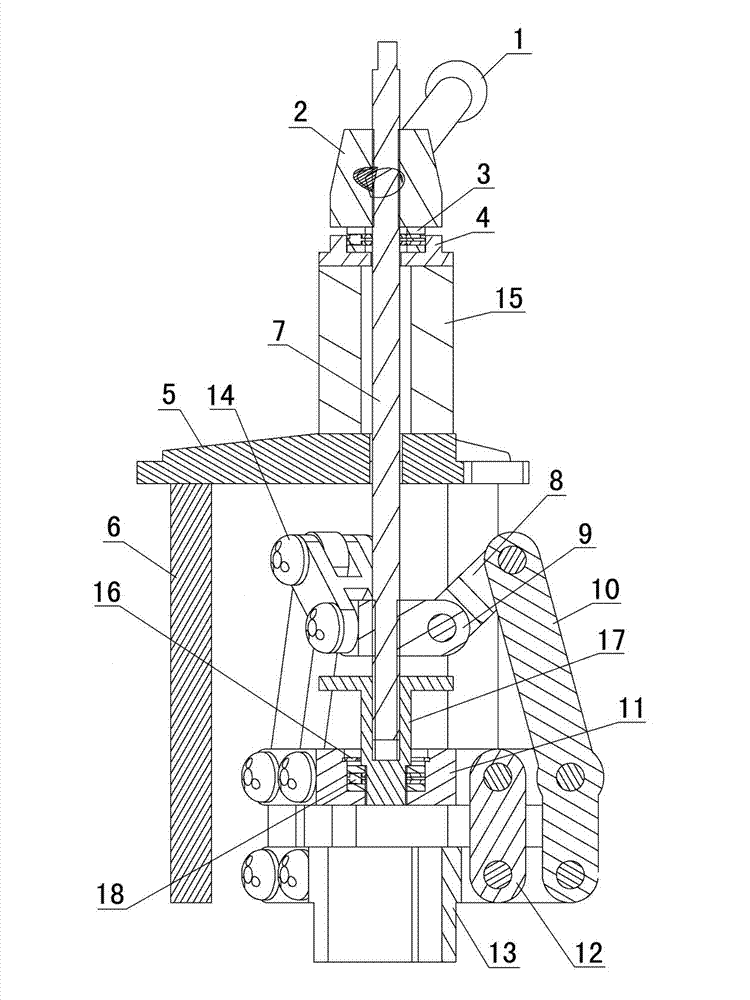

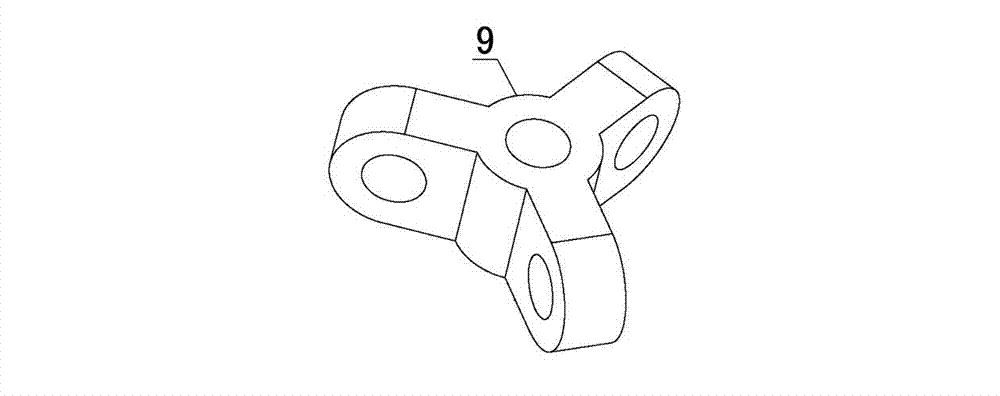

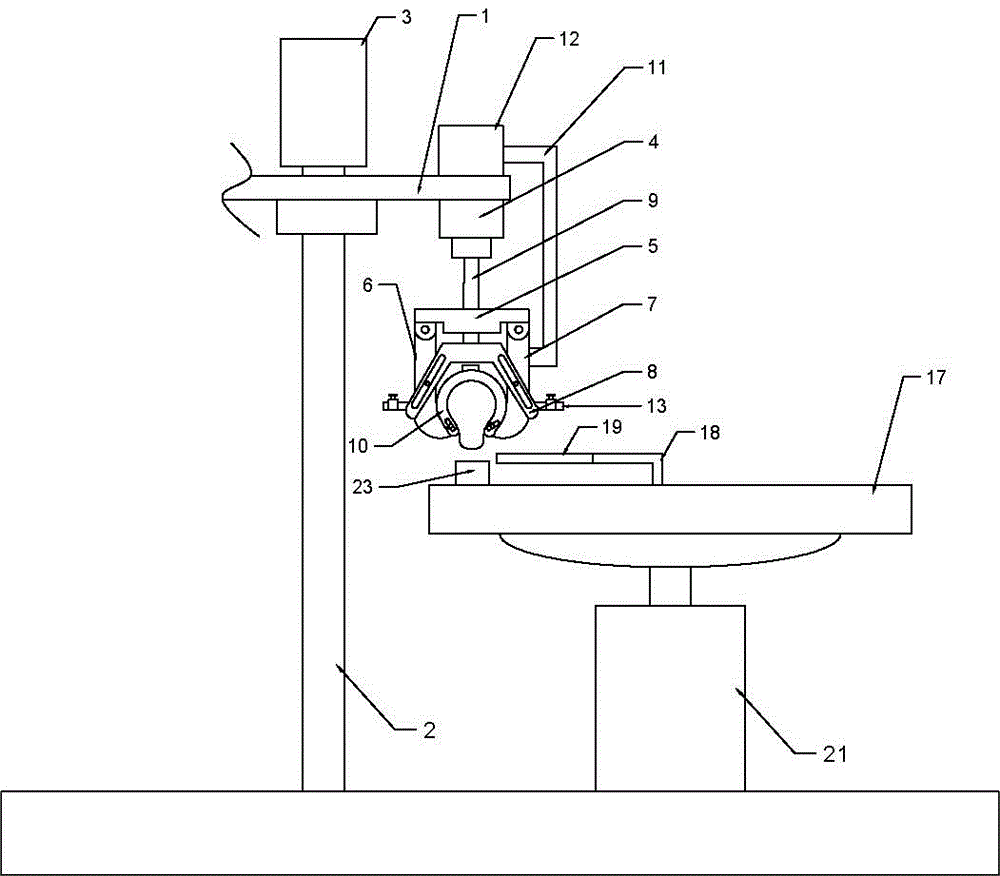

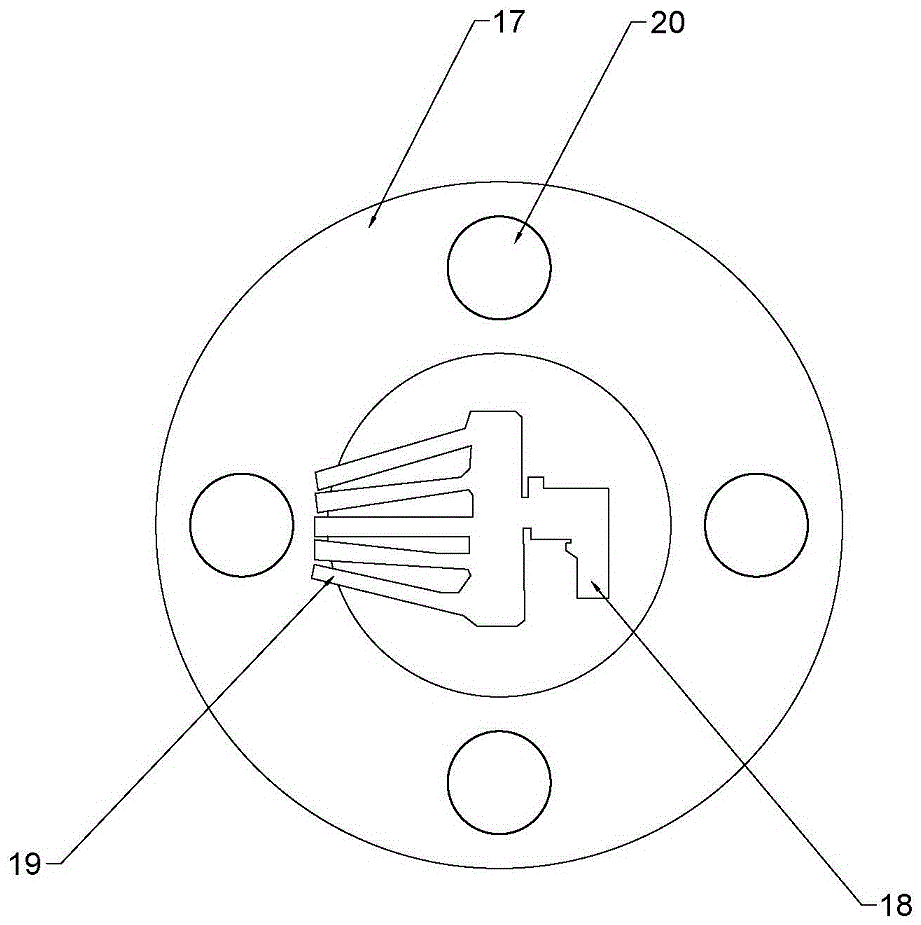

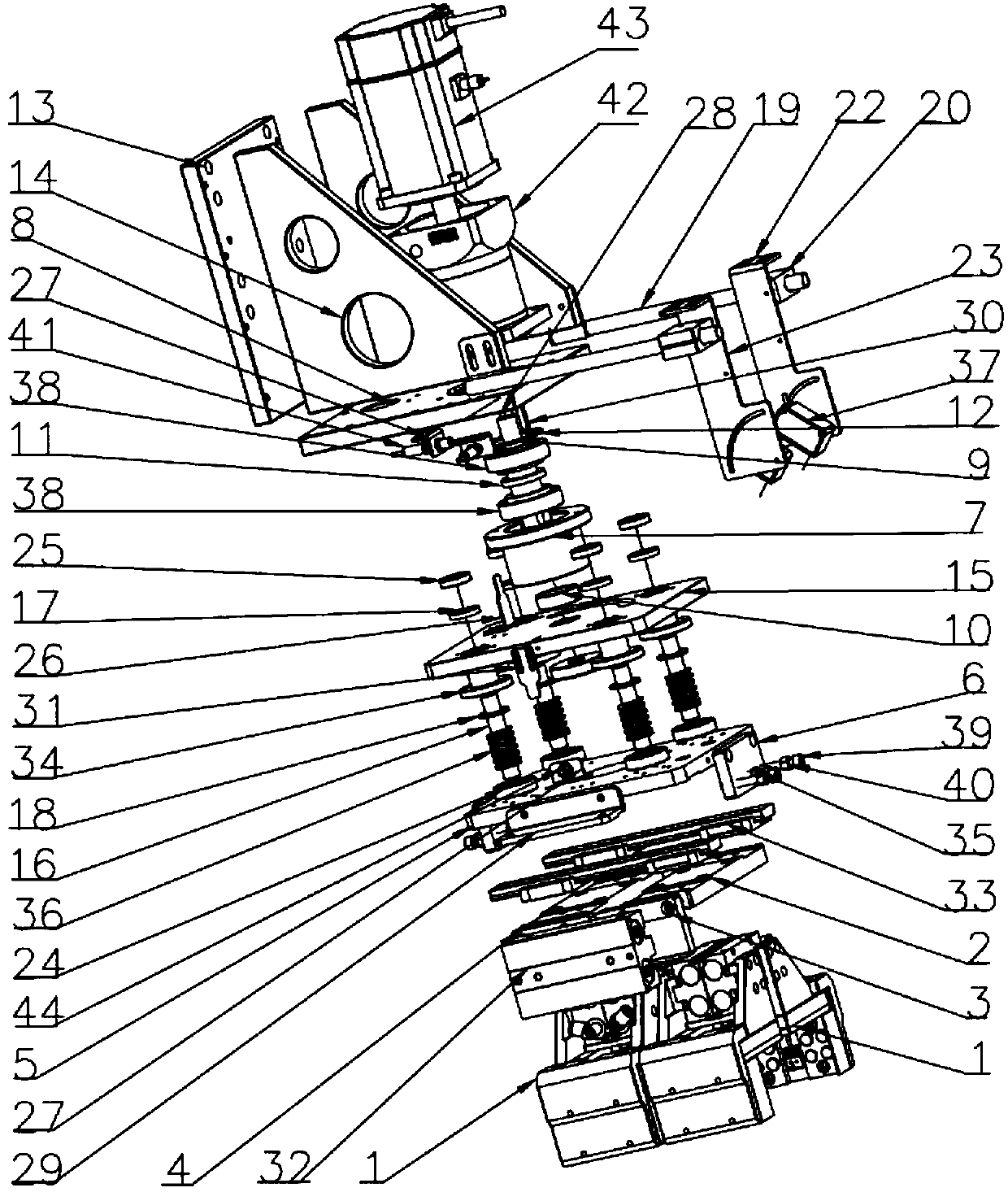

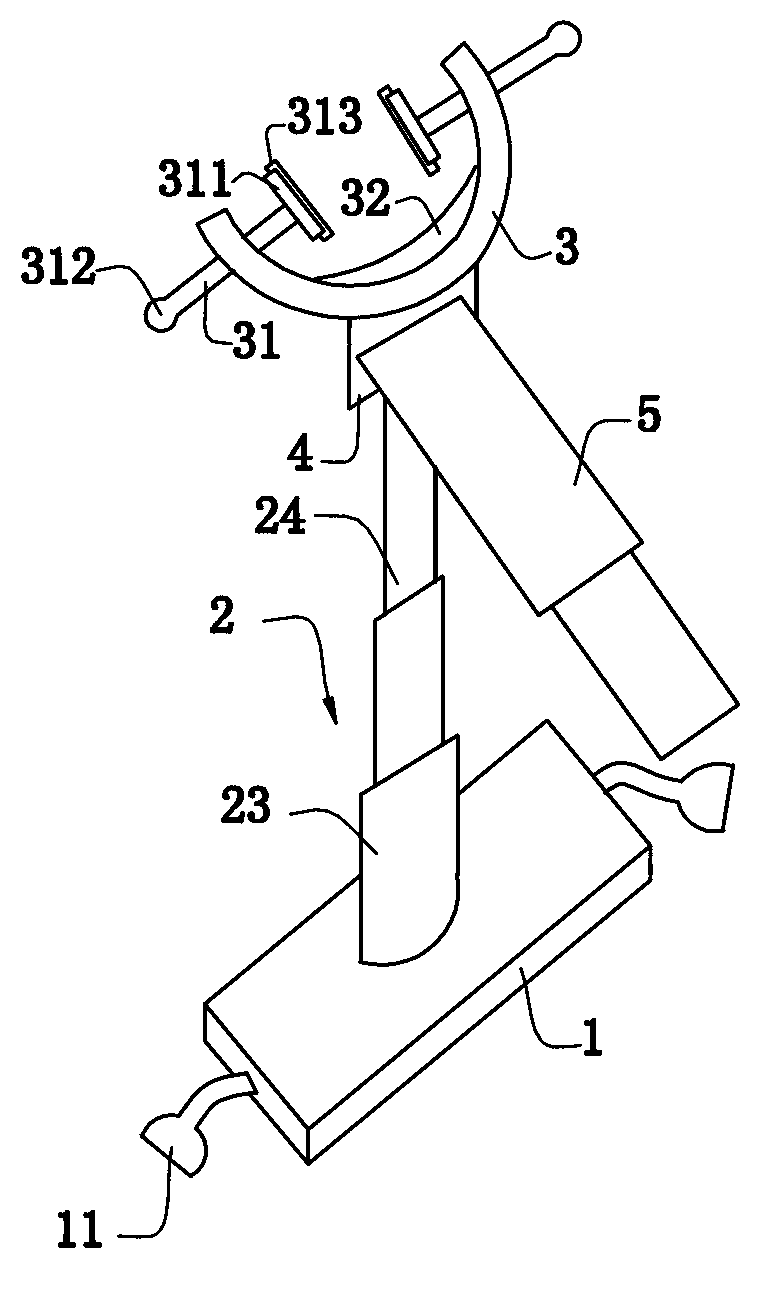

Manipulator suitable for transplanting tissue culture plantlets in culture flask

InactiveCN101416609ASimple structureFlexible structureJointsGripping headsThree degrees of freedomEngineering

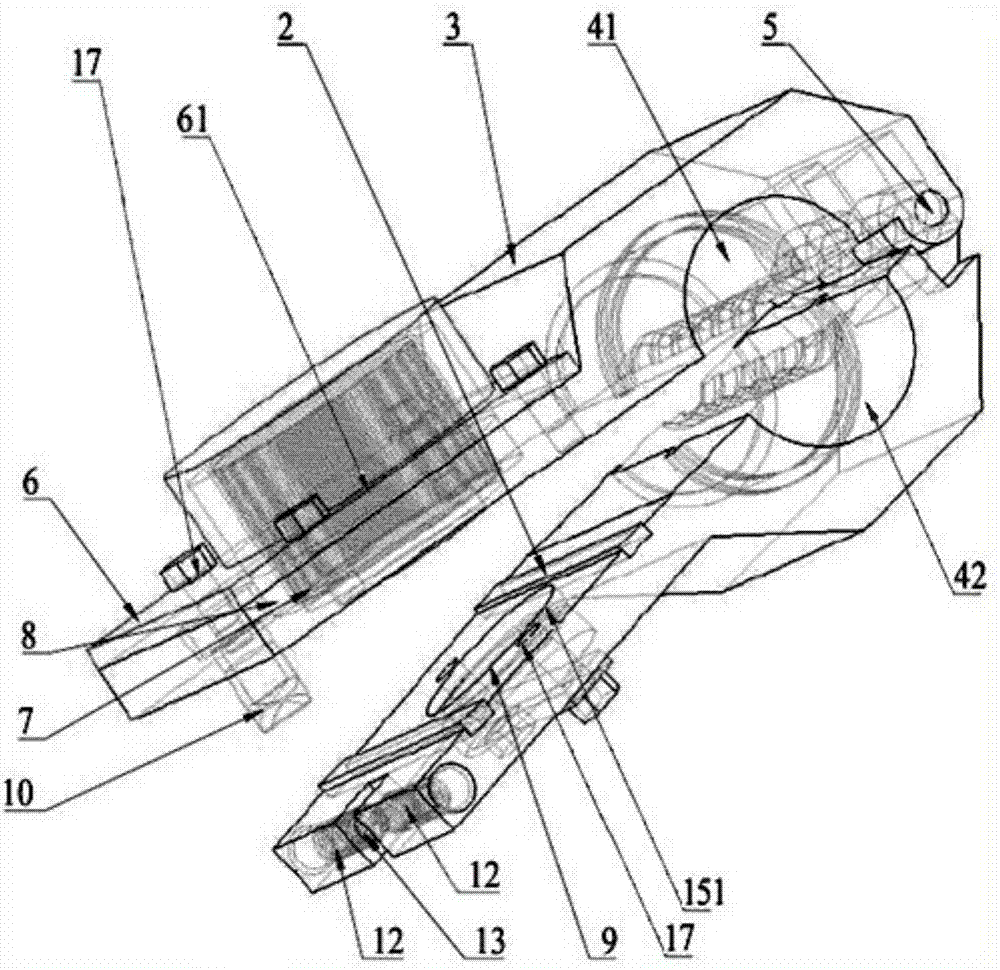

The invention relates to a manipulator for transplanting tissue culture seedling in culture flask, comprising a workbench provided with a mechanical arm having 3 freedoms and a claw mechanism having 2 freedoms; the mechanical arm has two horizontally rotary joint mechanisms in series connection and a vertically moving joint mechanism connected to the end of the horizontally rotary joint mechanism in series; the end of the vertically moving joint mechanism is connected with the claw mechanism; the claw mechanism has an openable and clo sable claw, capable of rotating around a vertical axial line in 360 degrees and turning over in horizontal and vertical directions. The invention has simple structure and accurate position. The driving mechanism of the claw can fetch seedling only by extending the claw into the culture flask without stretching into and touching flask and hurting seedling. So it is fit for small space operation.

Owner:CHINA AGRI UNIV

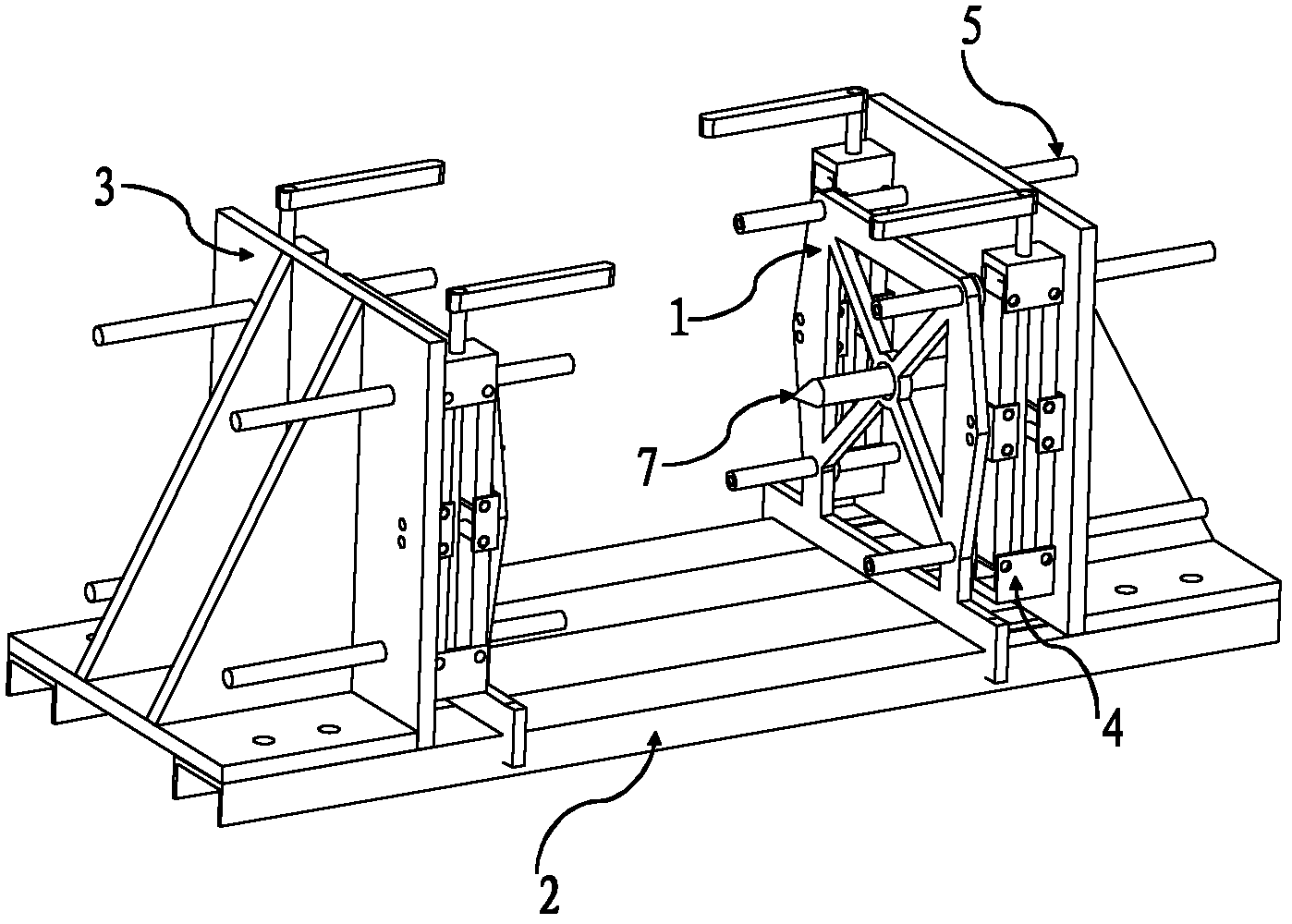

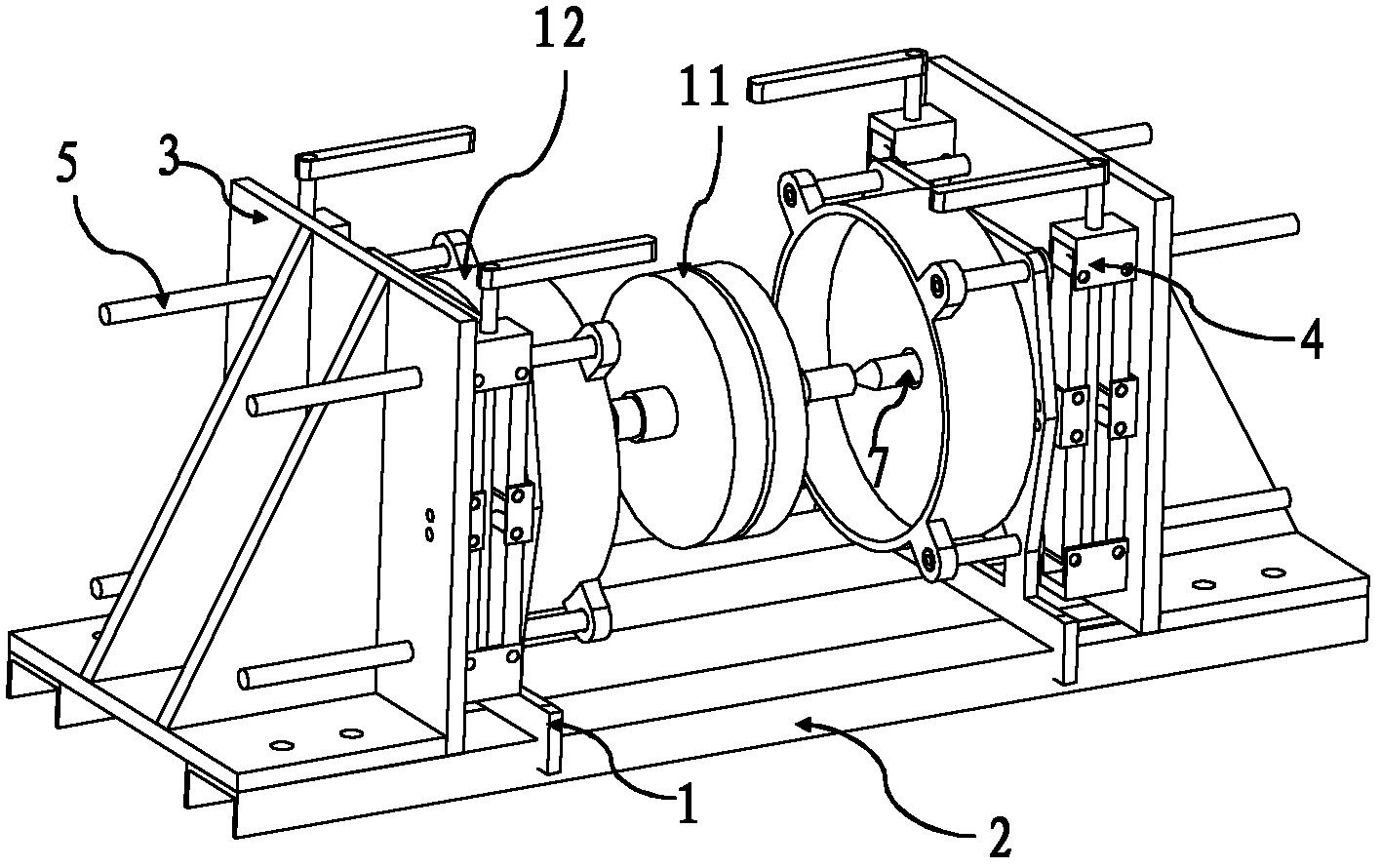

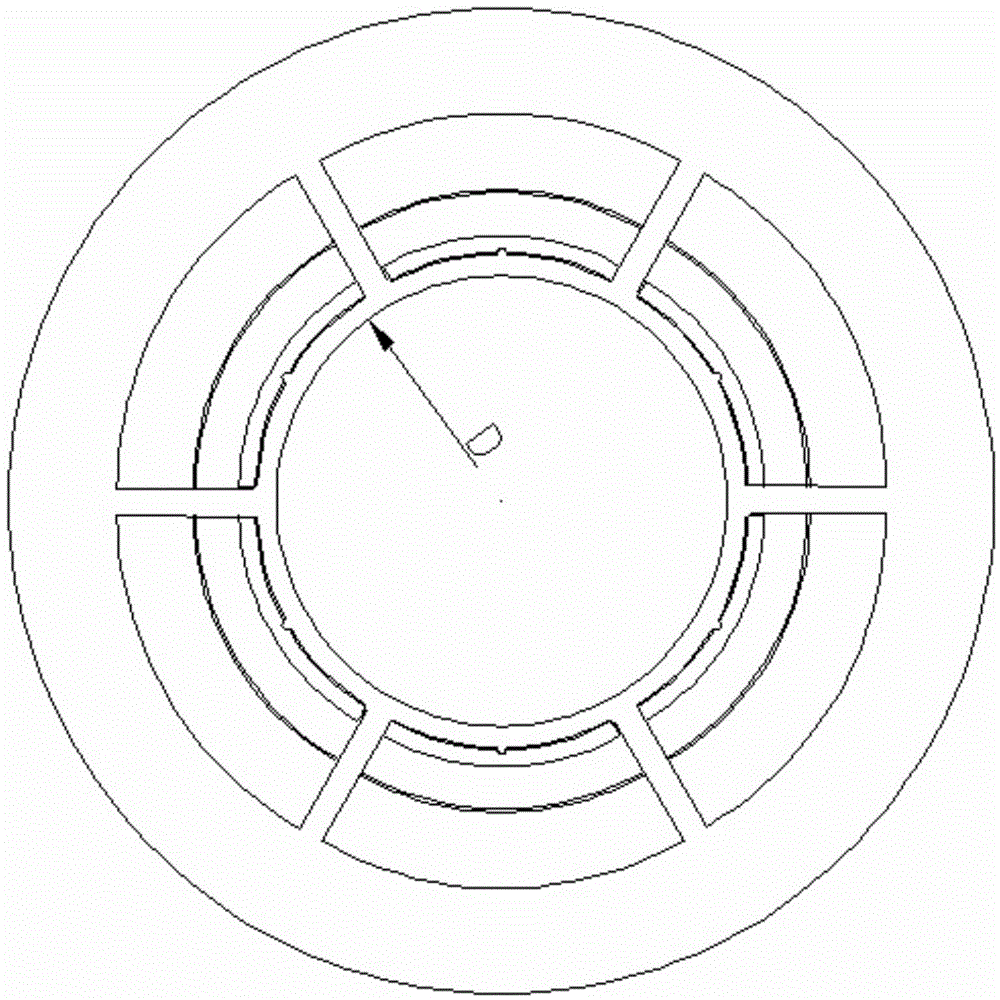

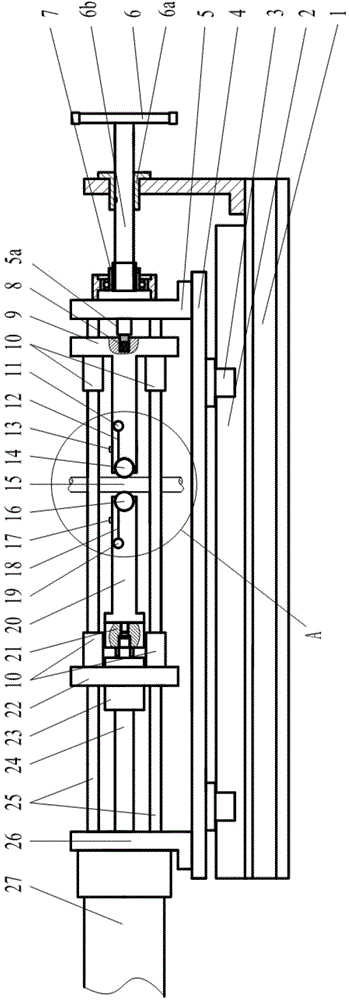

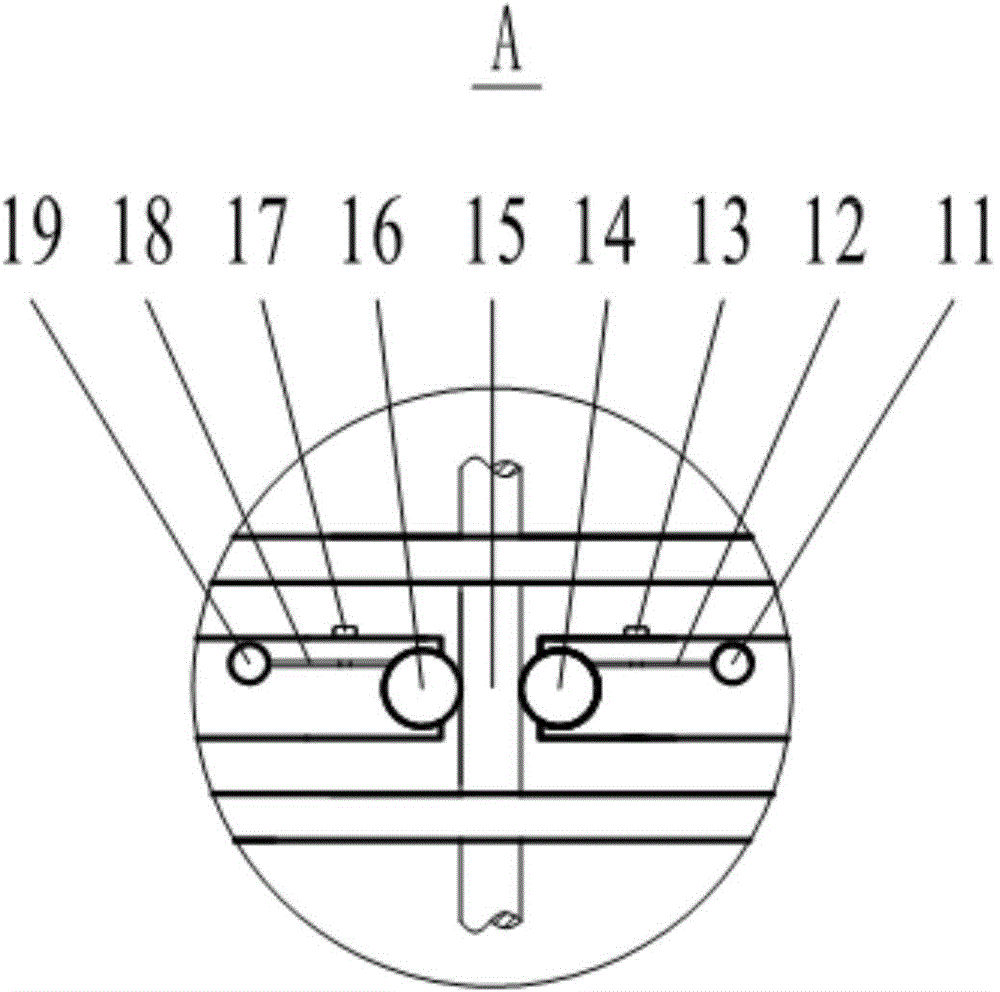

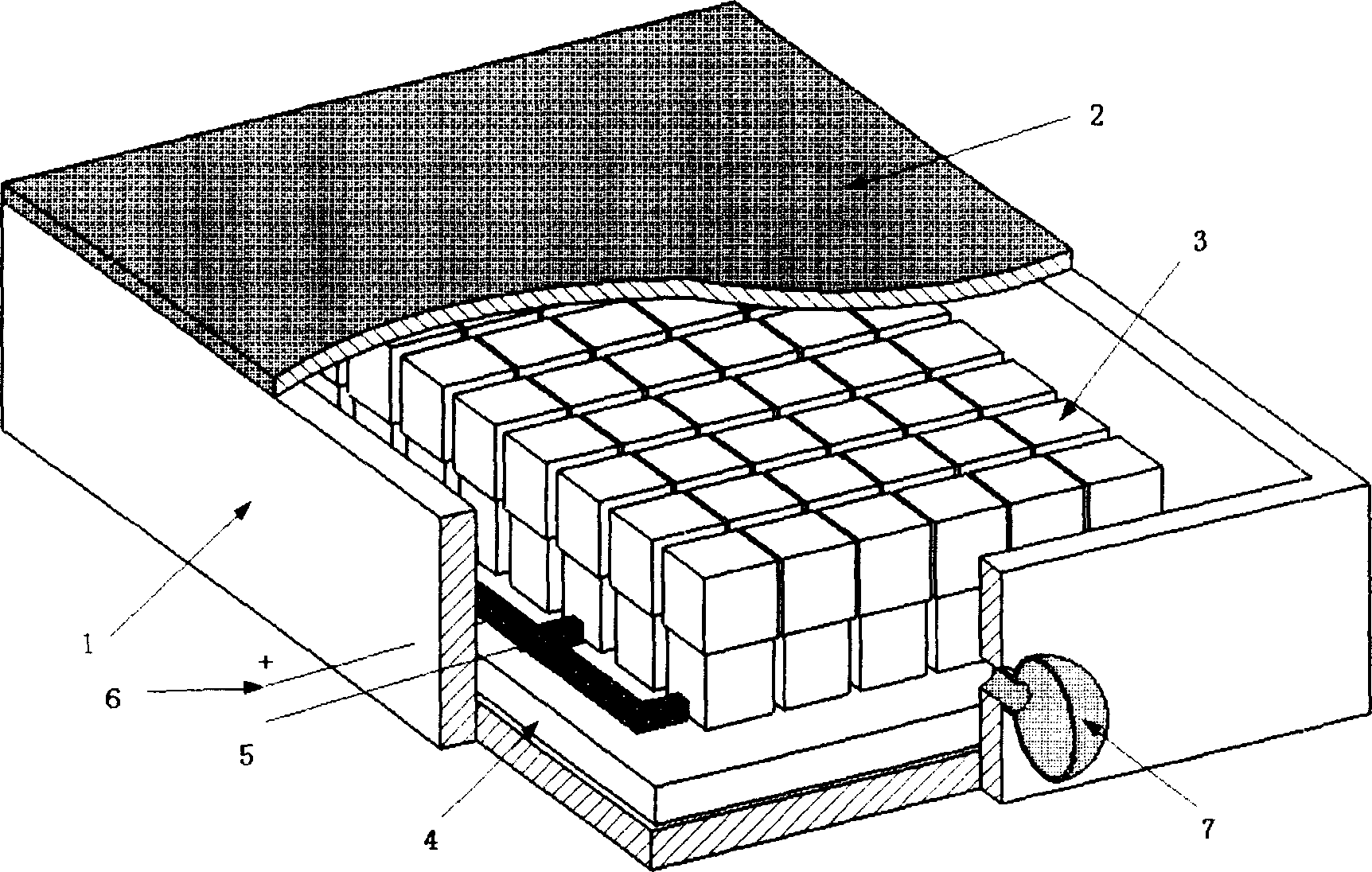

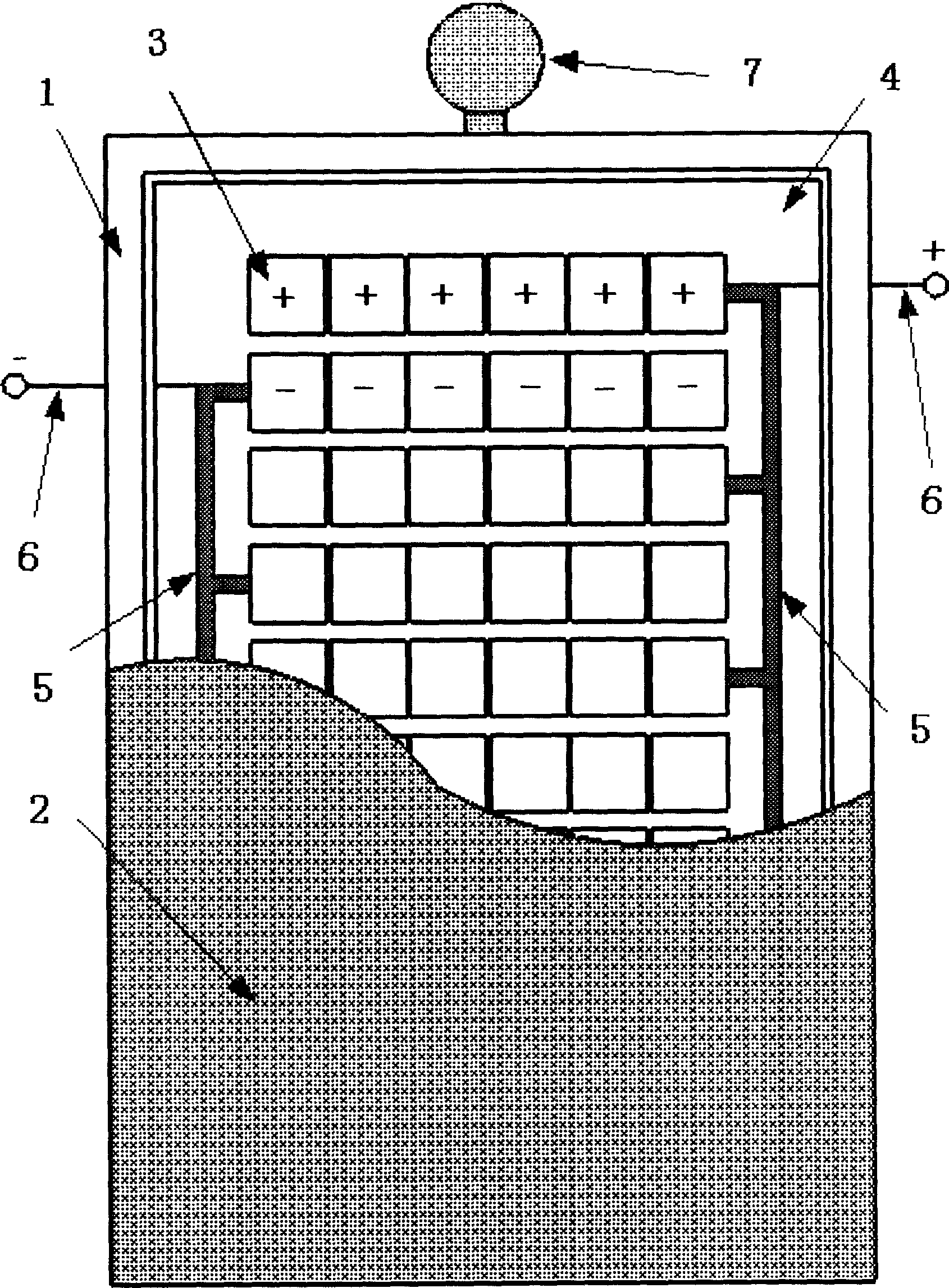

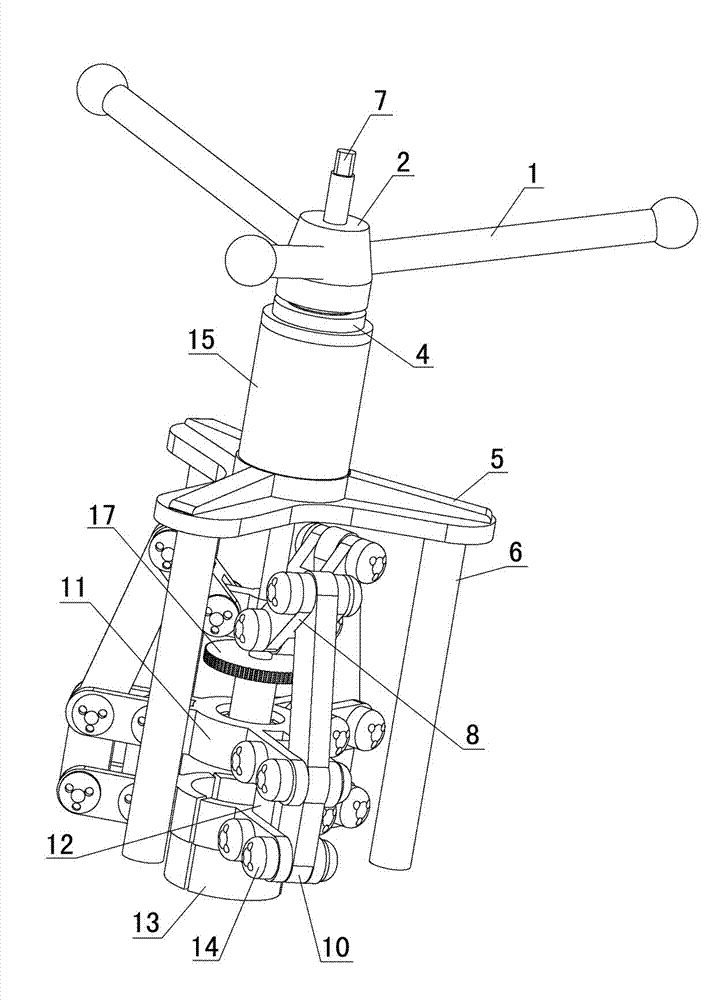

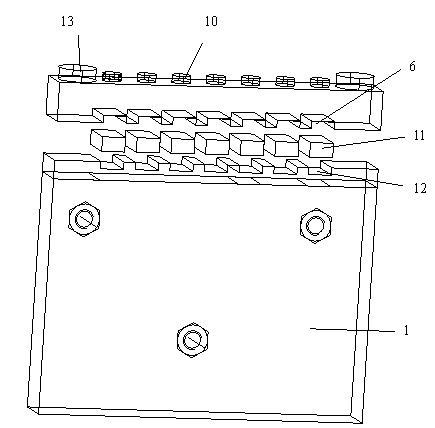

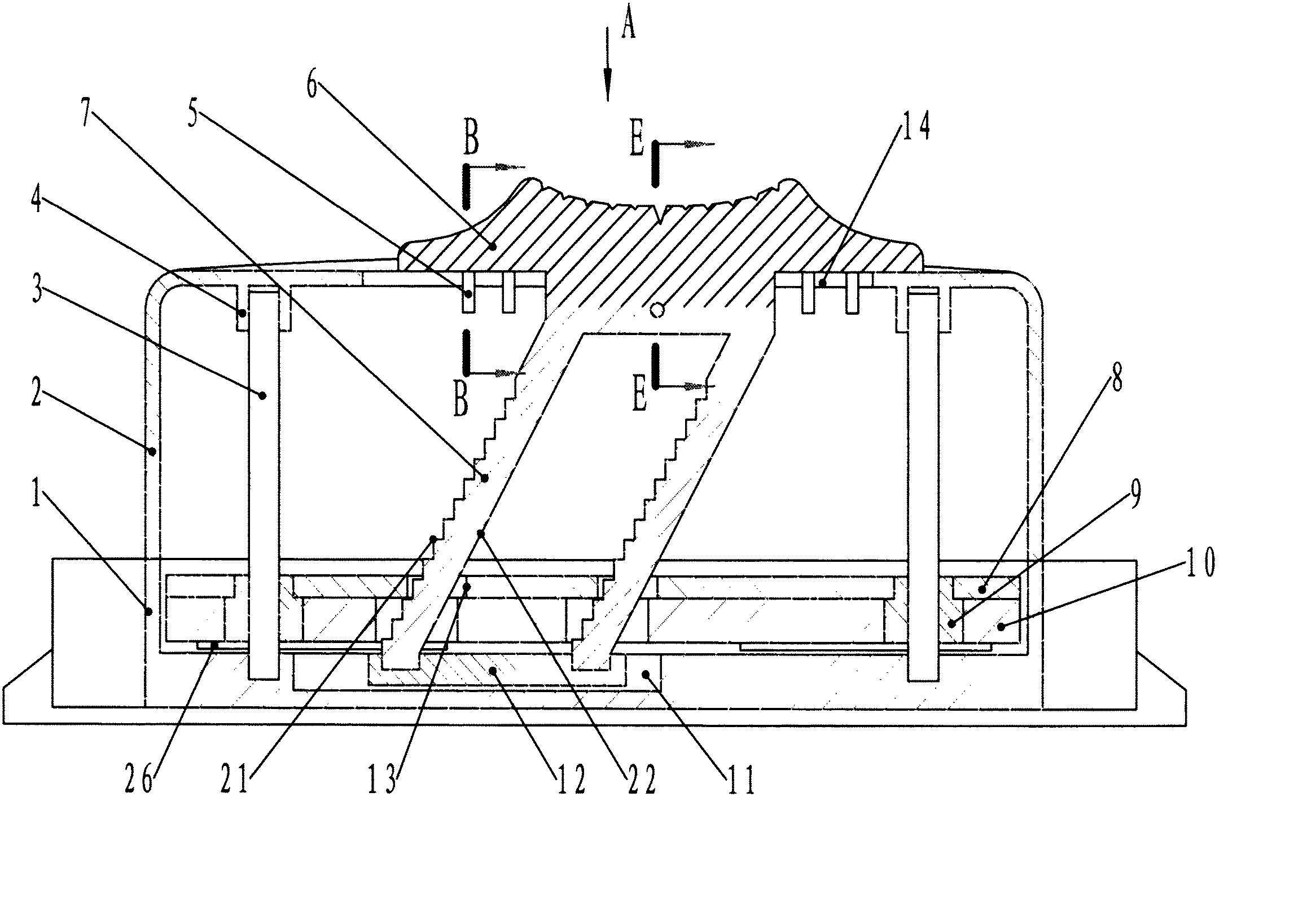

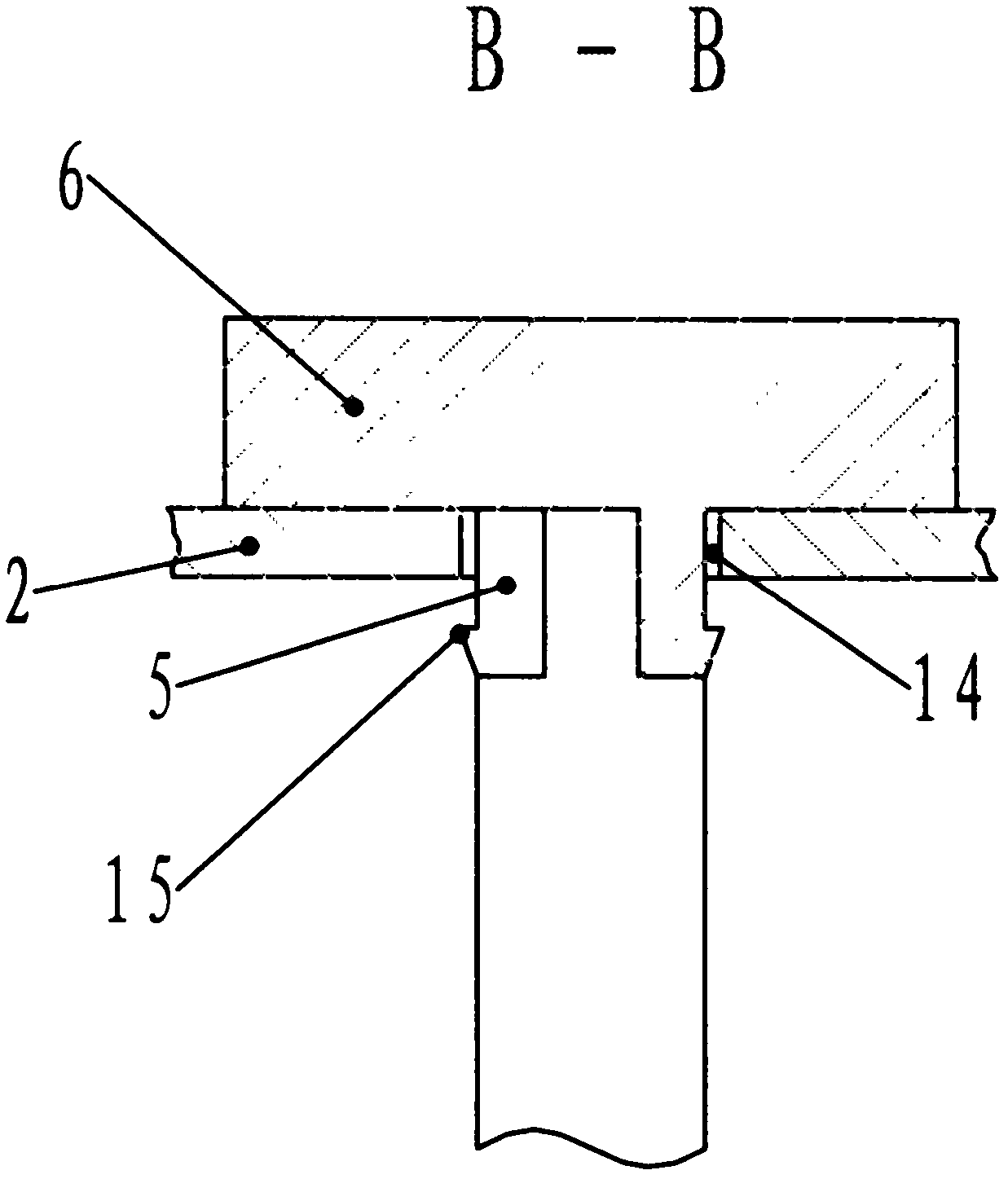

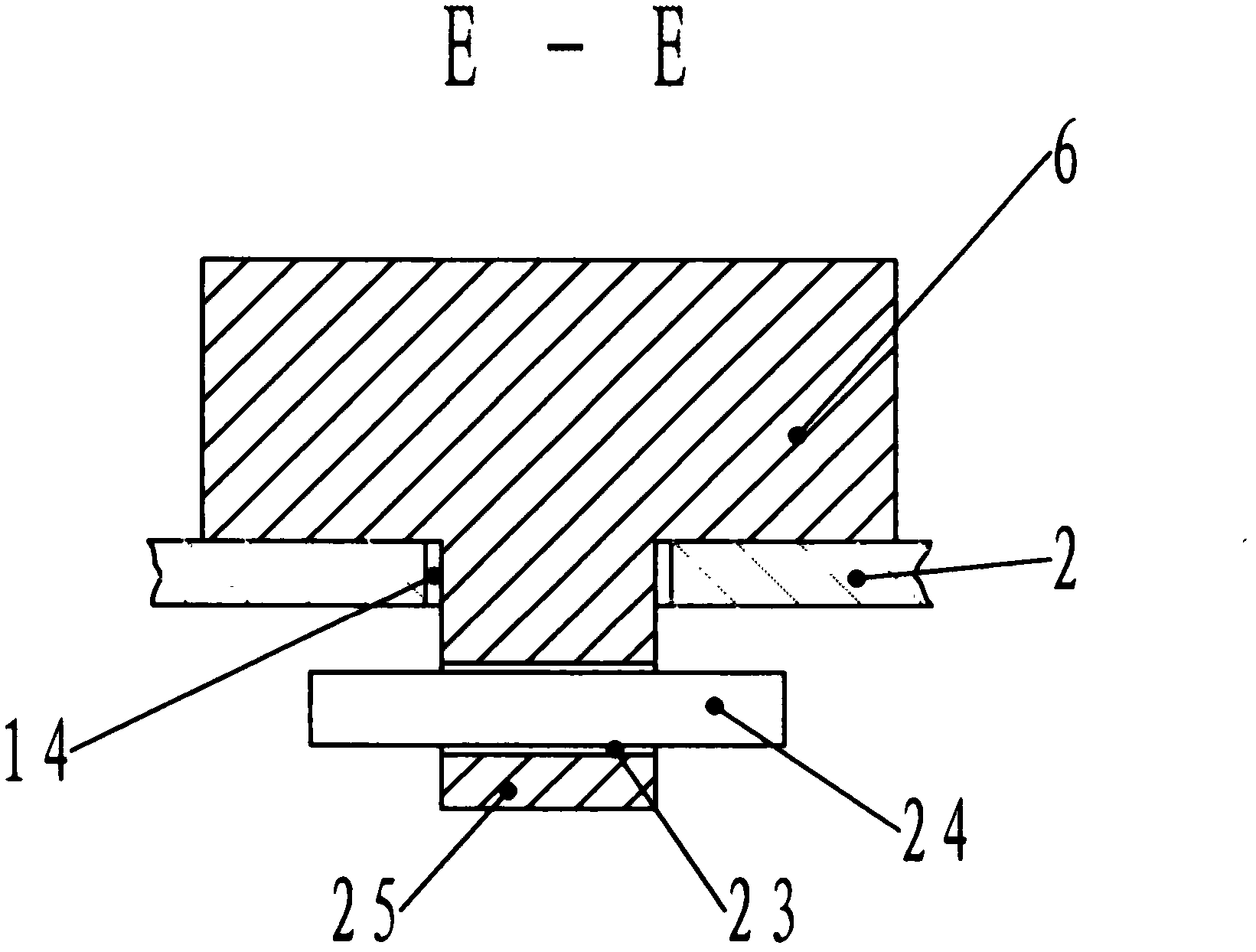

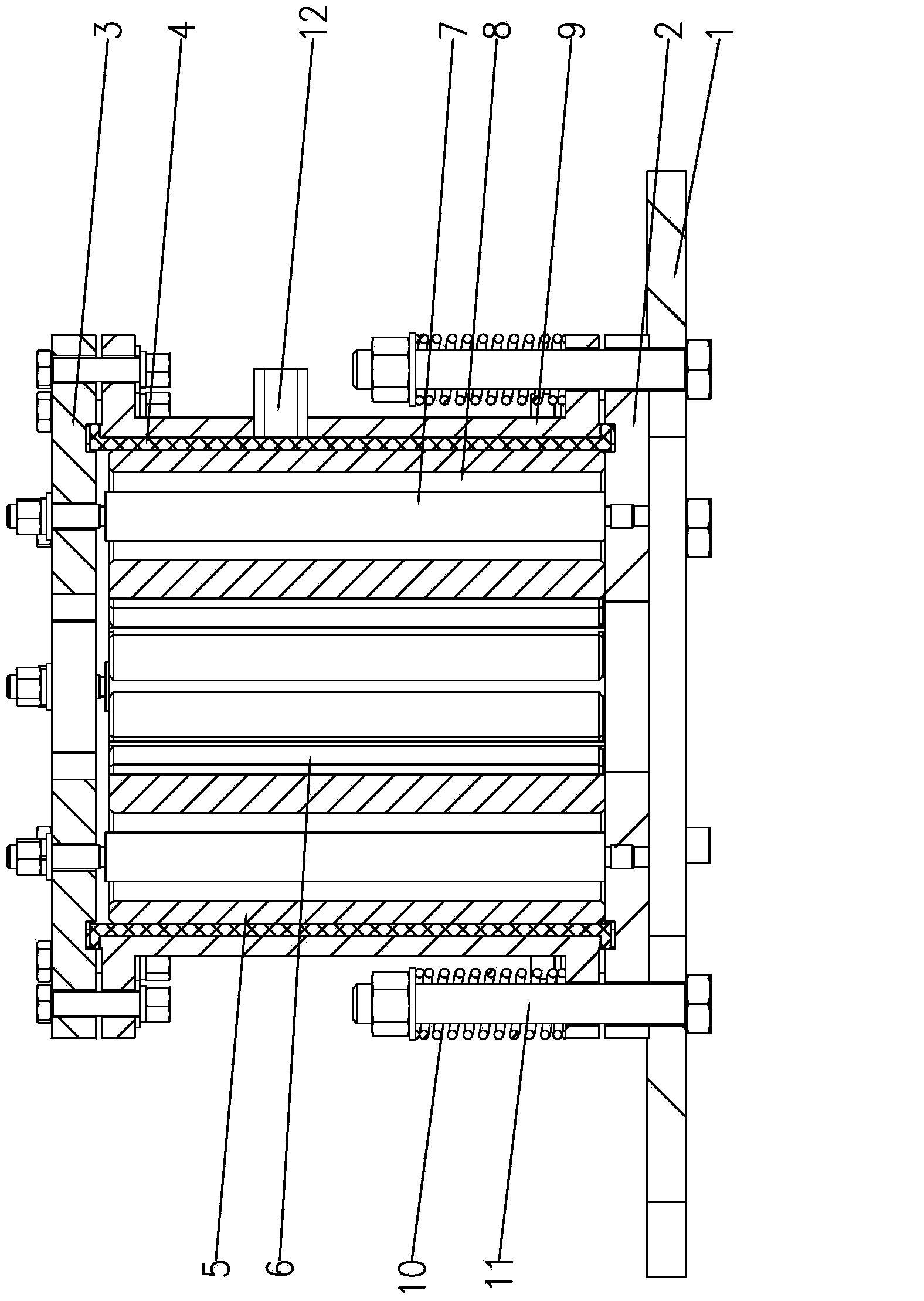

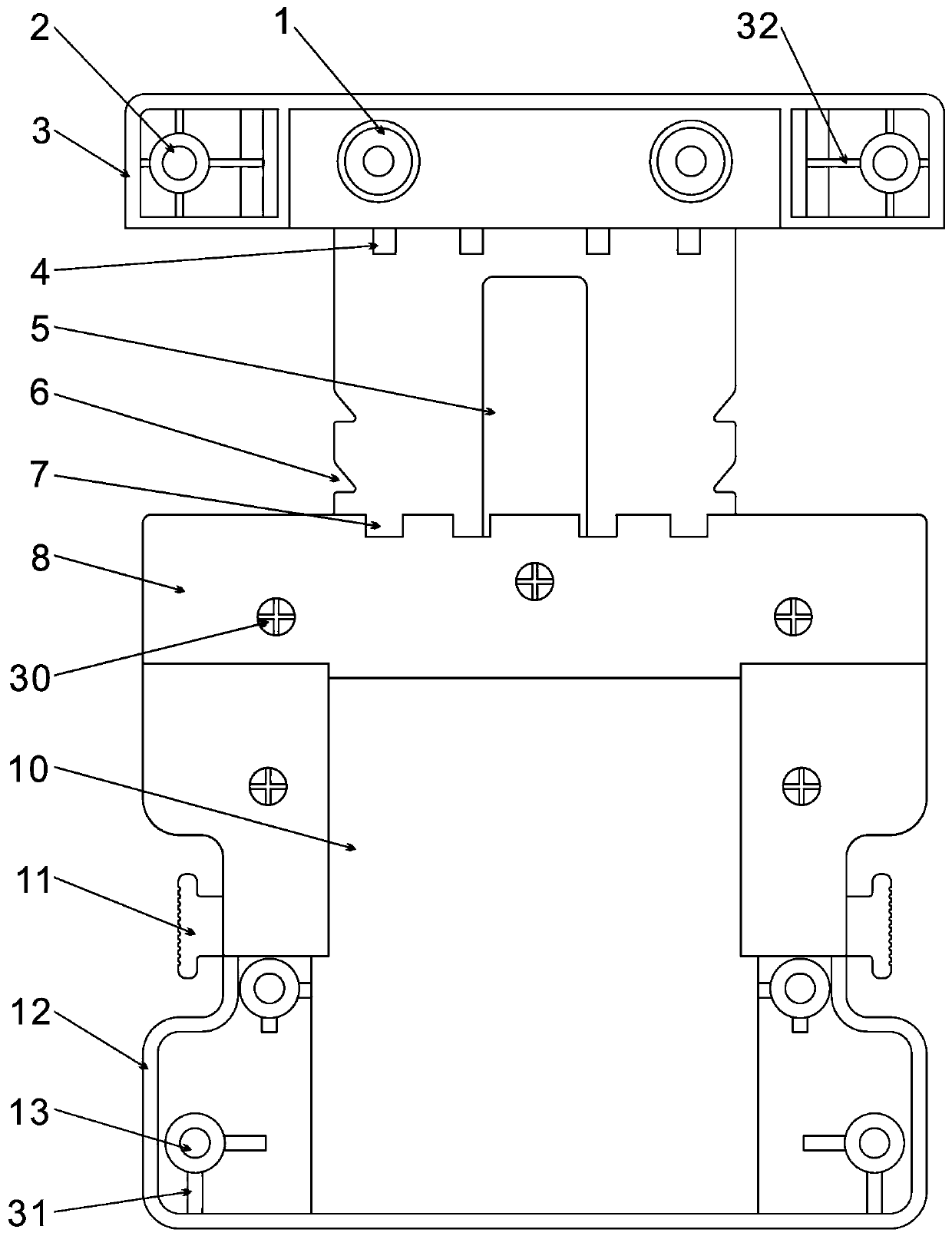

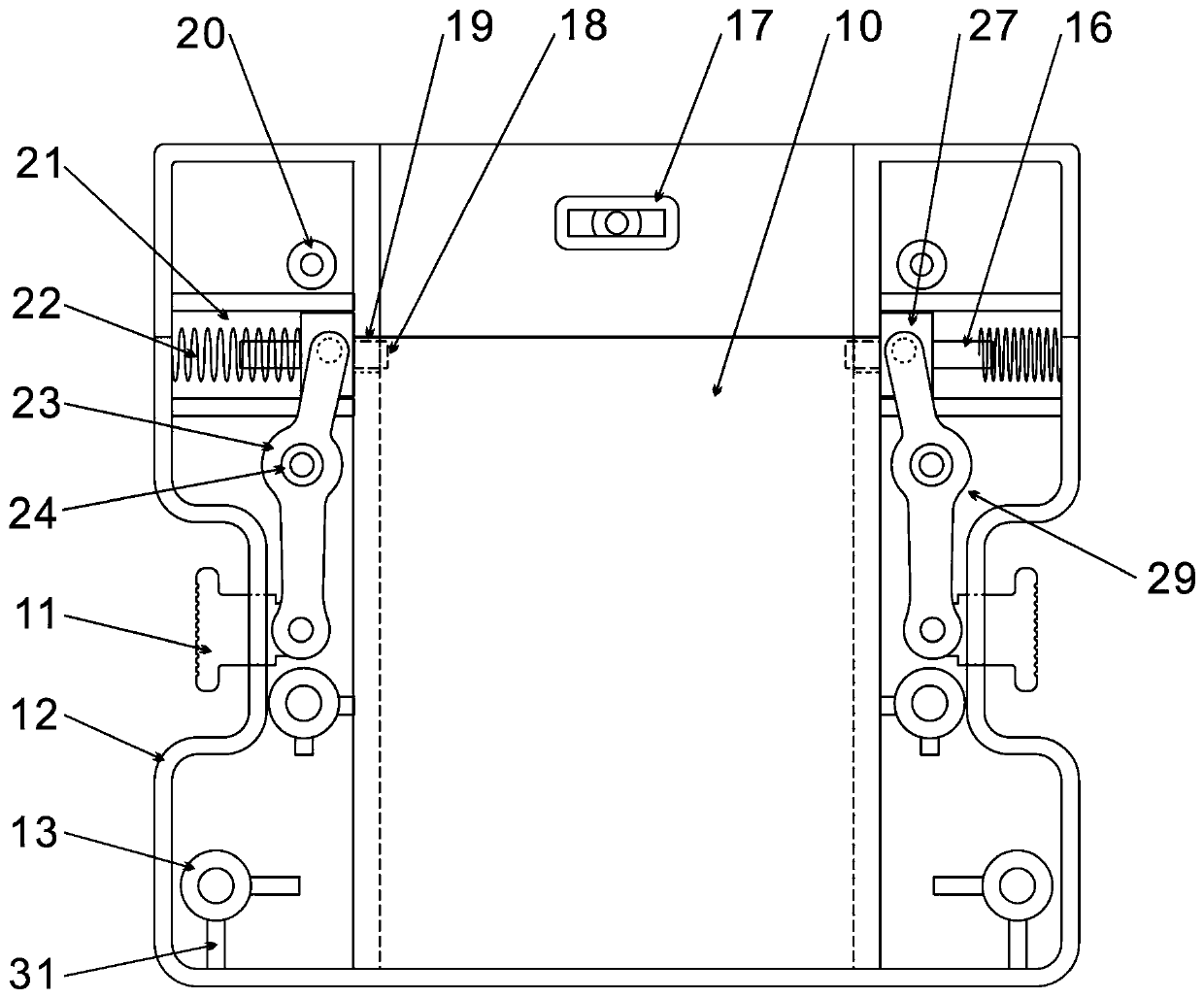

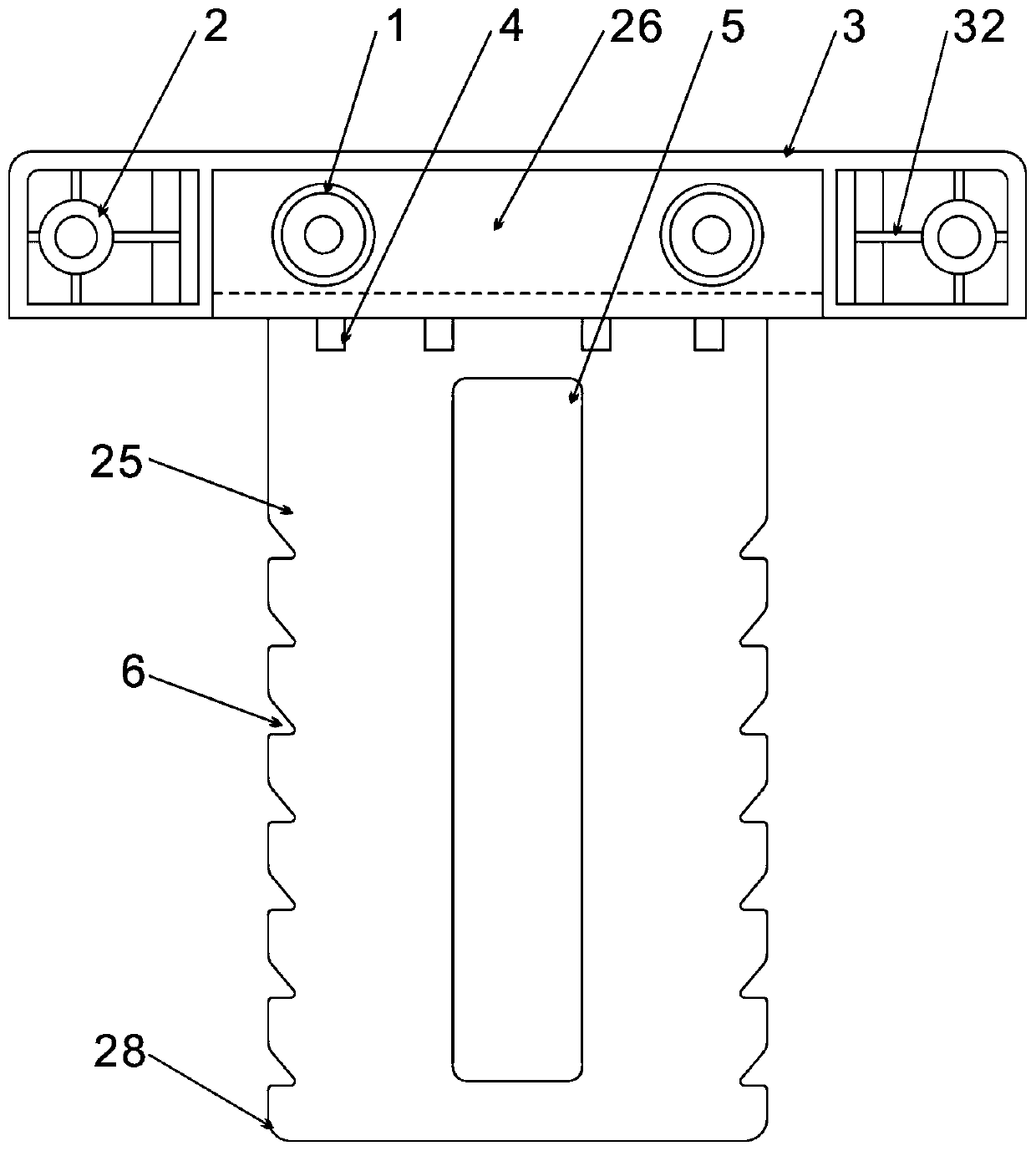

Assembling and disassembling tool for disk type permanent magnet motors and method for installing motor end covers

InactiveCN103001400AEasy to installQuick installationManufacturing stator/rotor bodiesPermanent magnet motorEngineering

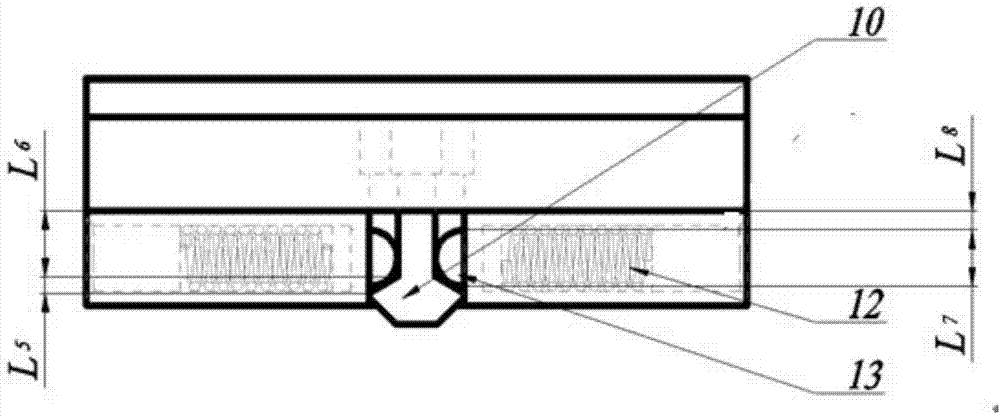

The invention discloses an assembling and disassembling tool for disk type permanent magnet motors. The assembling and disassembling tool is used in the field of disk type permanent magnet motors and comprises guide rails, two seat frames, two fixing plates and fixing devices, wherein the seat frames perpendicular to the guide rails are respectively positioned at two ends of the guide rails, the two fixing plates are positioned between the two seat frames, and motor end covers can be fixed onto the fixing plates by the fixing devices; and the fixing plates at the two ends of the guide rails are connected with the seat frames by two pair of scissor jacks, apexes perpendicular to the seat frames are arranged in centers of the seat frames, through holes which are concentric with the apexes are arranged in centers of the fixing plates, and the apexes penetrate through the through holes of the centers of the fixing plates when the scissor jacks contract. The assembling and disassembling tool has the technical advantages that a rotor can be effectively prevented from being sucked onto the motor end cover on an optional side of the rotor under the action of magnetic force, and a step for adjusting a gap between each motor end cover and the rotor is omitted; the motor end covers of a disk type permanent magnet motor can be accurately and quickly installed; and collision of coils due to single-side absorption is prevented, fingers of operators cannot be pinched due to high attractive force of magnetic steel, and the safety is greatly improved during motor assembly.

Owner:SHANGHAI NANYANG ELECTRICAL MACHINERY

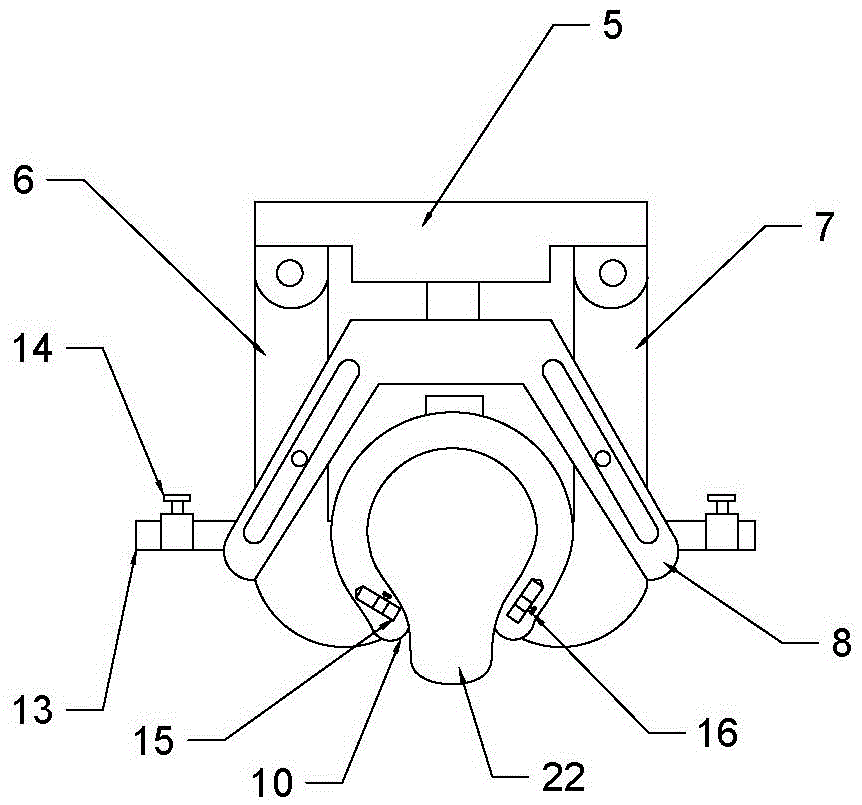

Clamping mechanism

InactiveCN104552076AWon't shakeEven by forceWork holdersPositioning apparatusDevices fixationEngineering

Owner:浙江和良智能装备有限公司

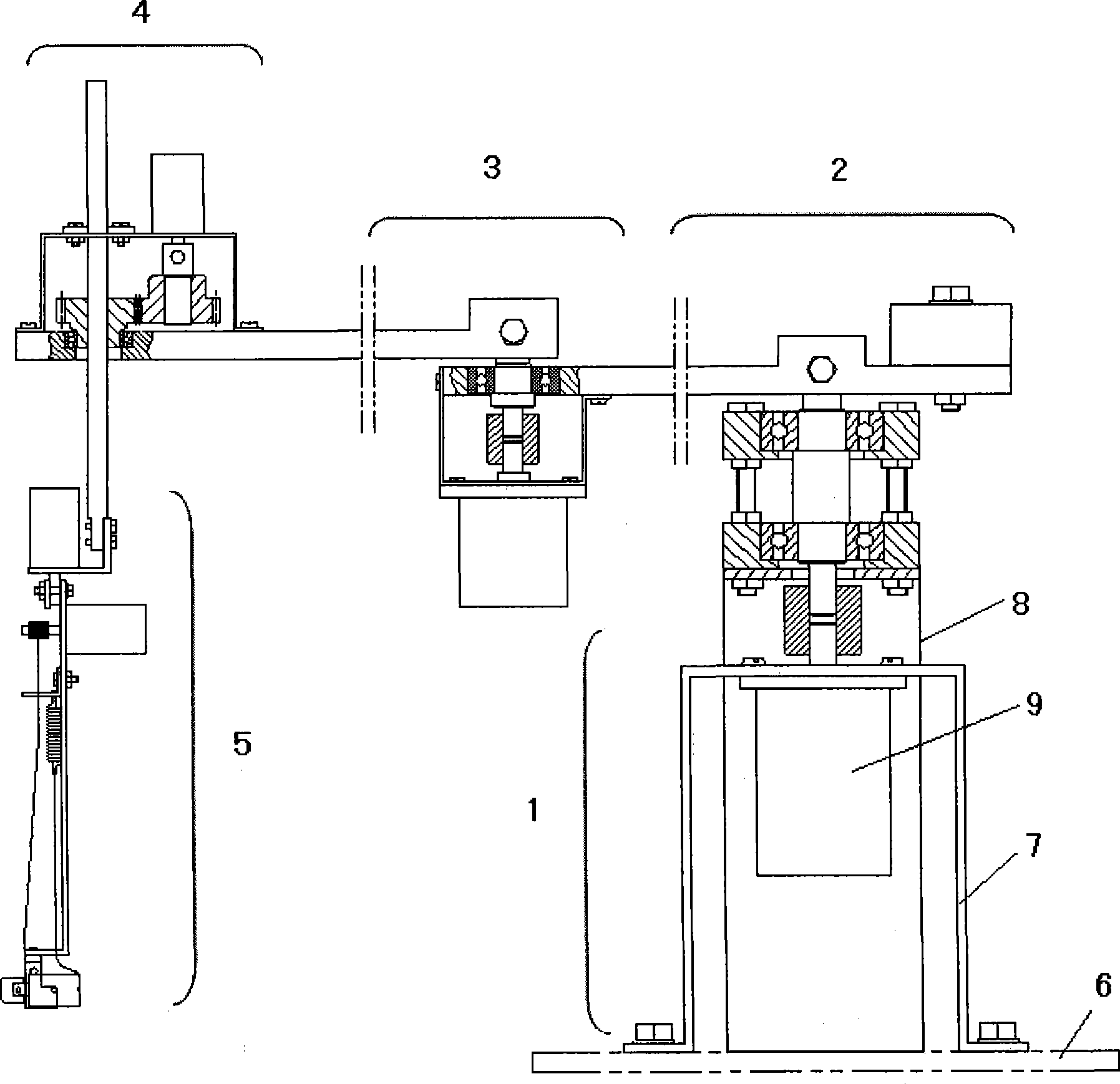

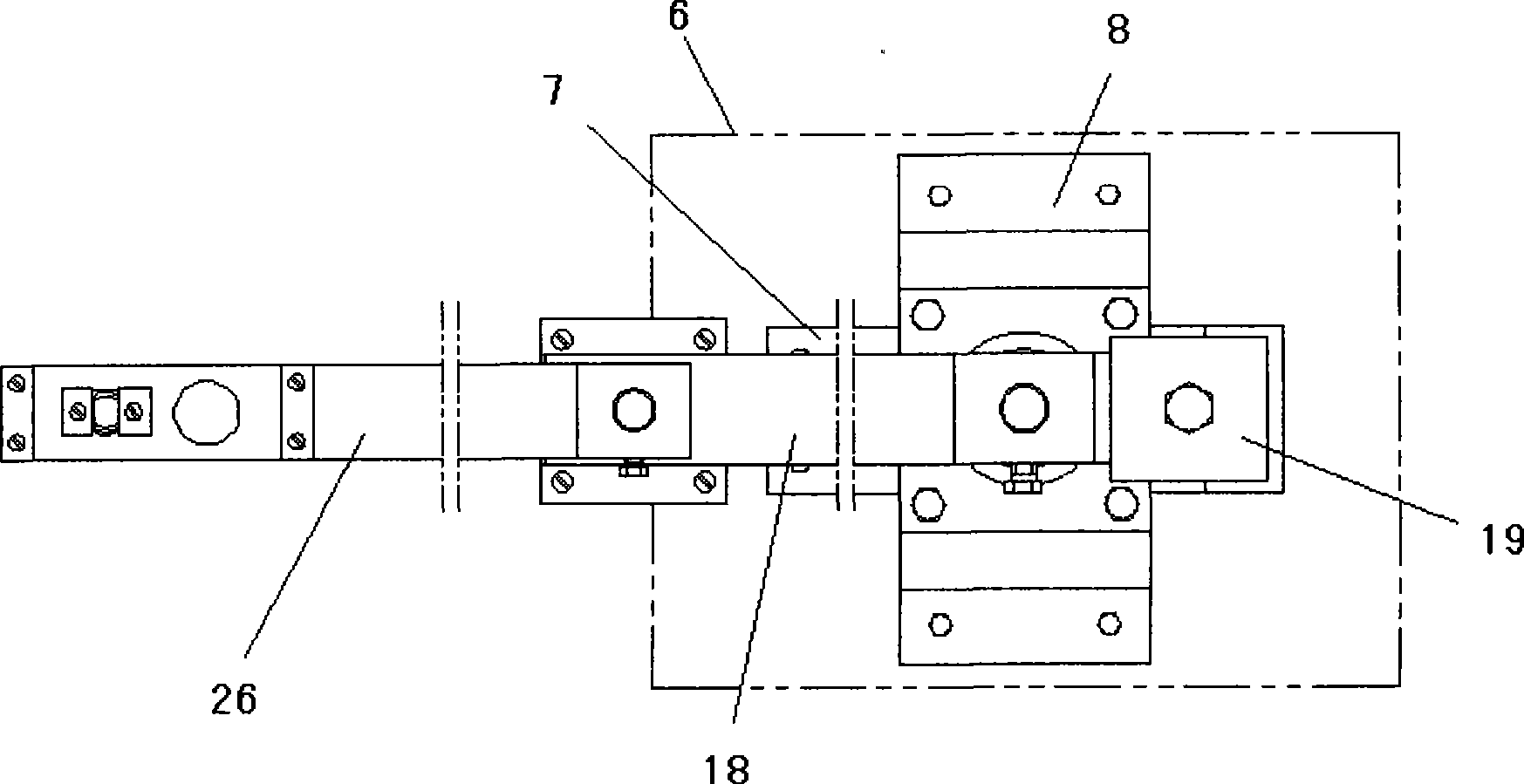

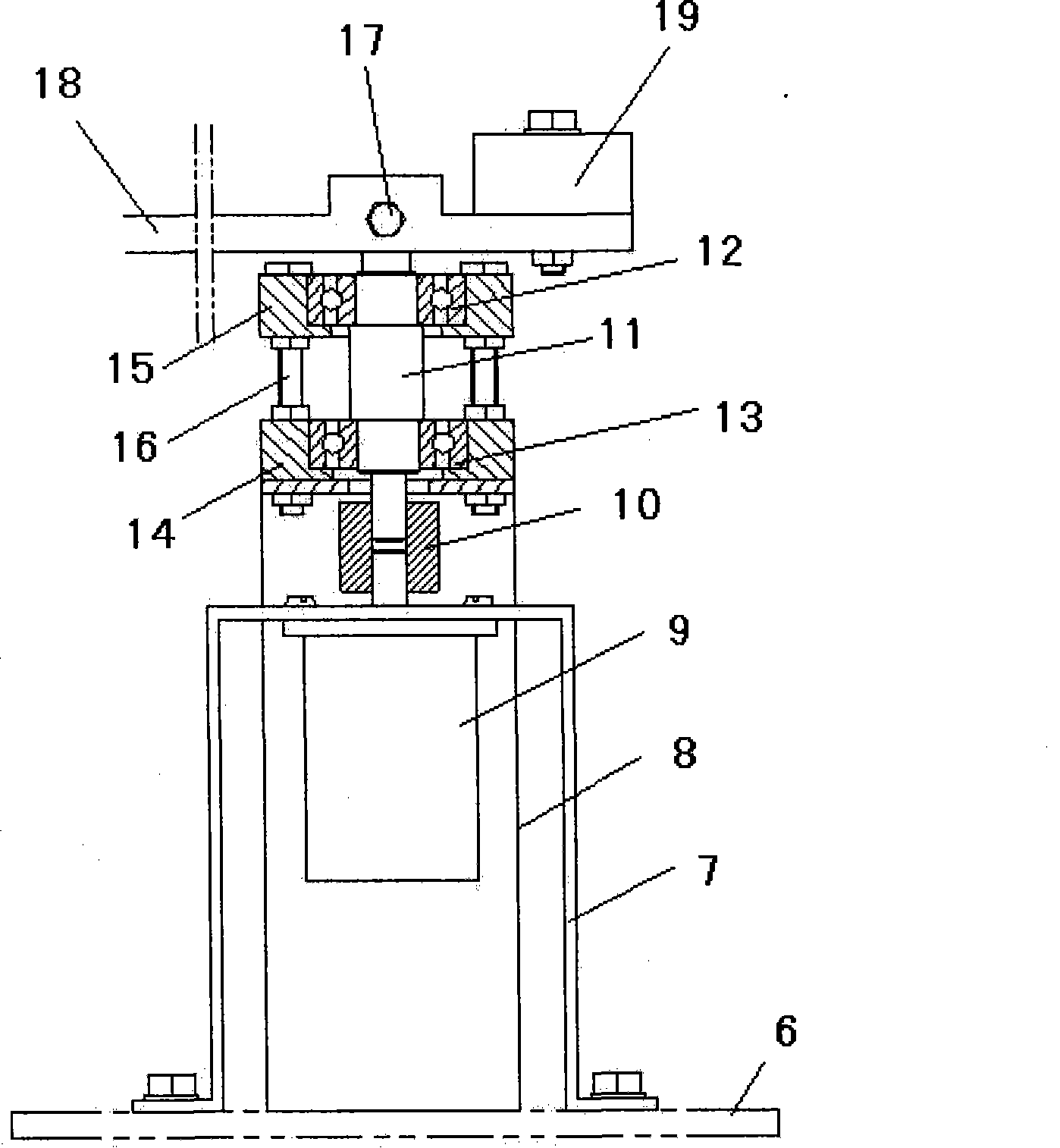

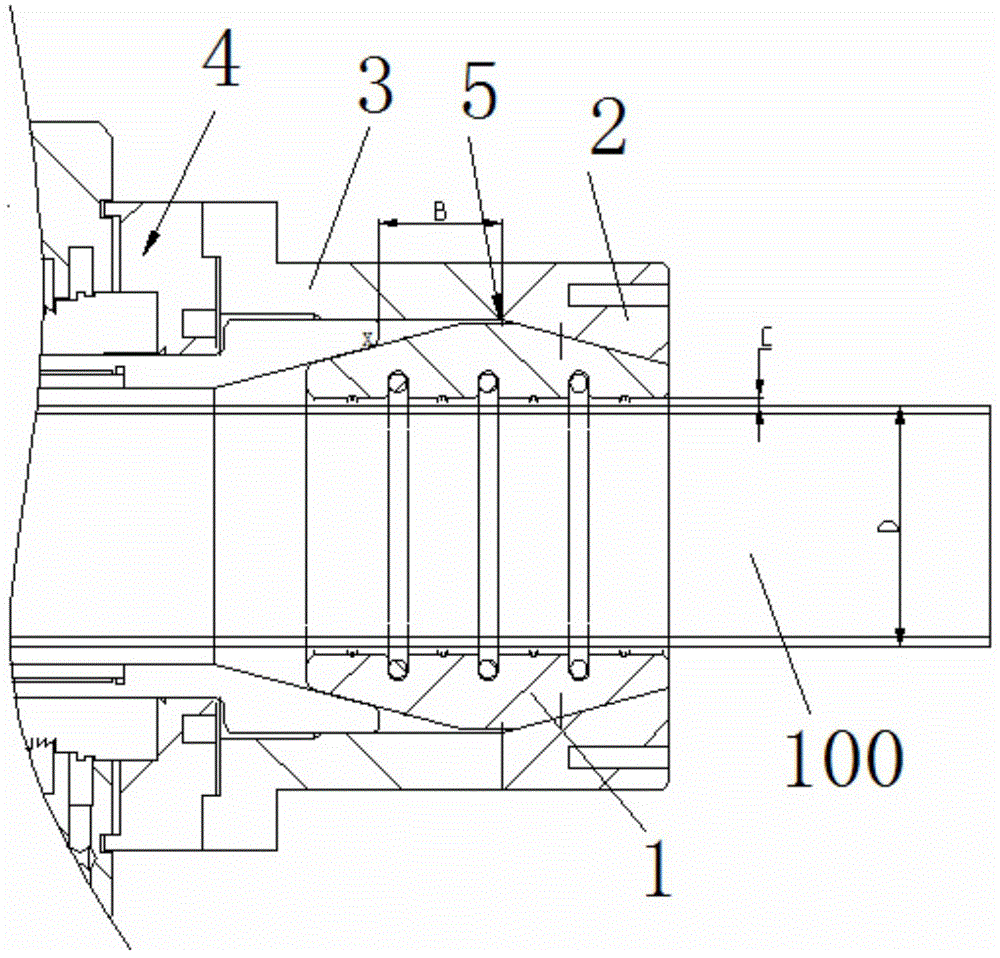

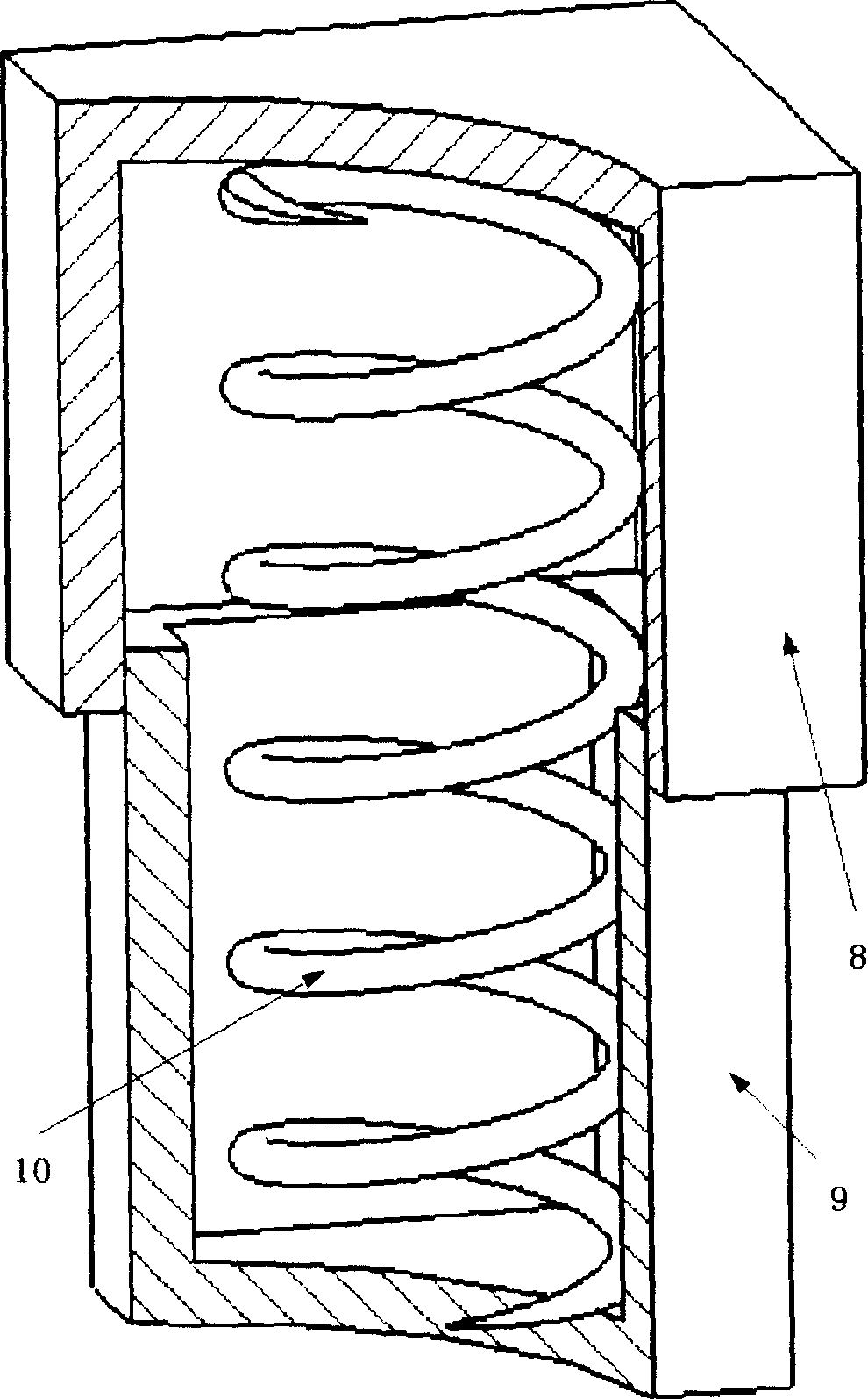

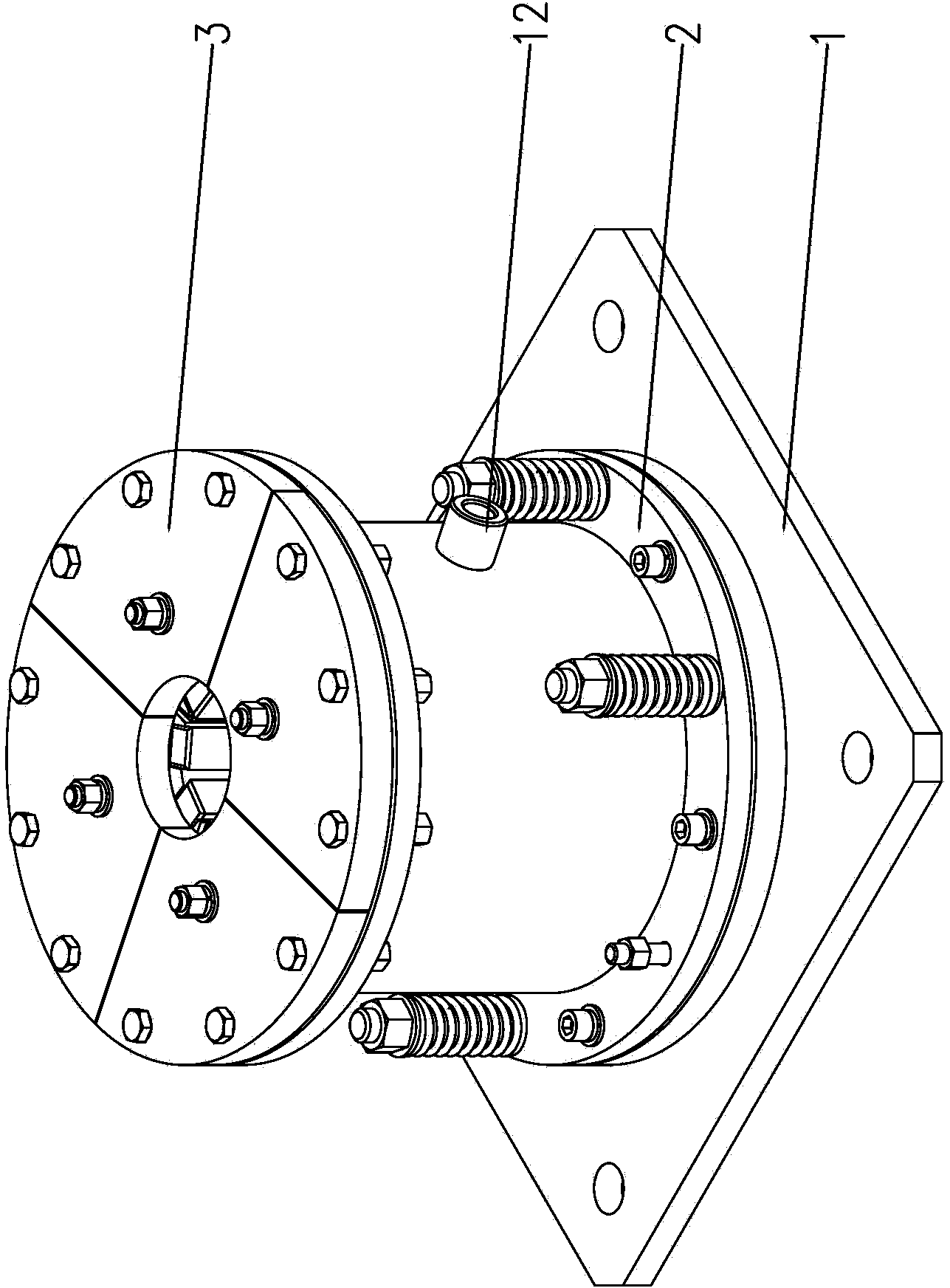

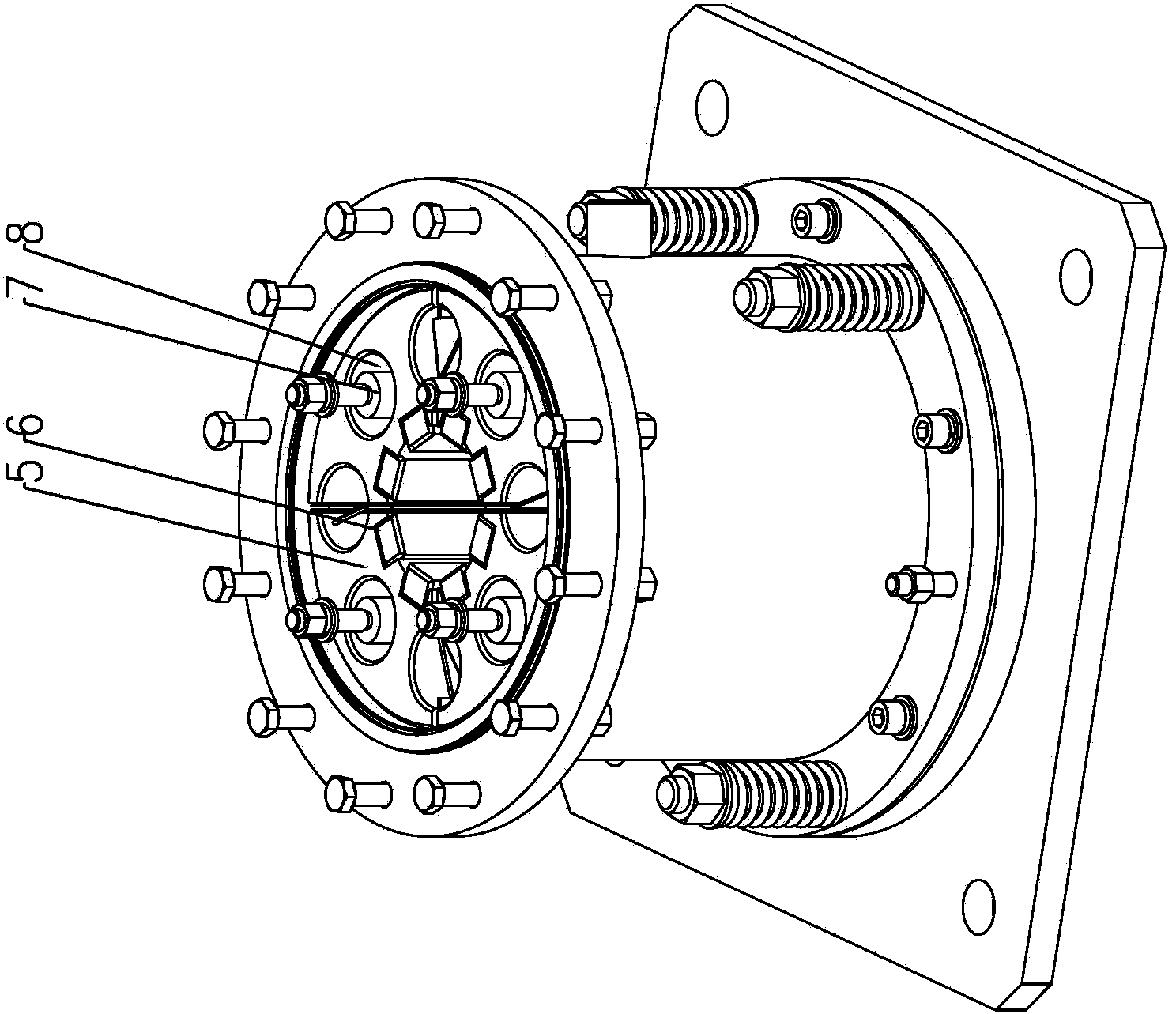

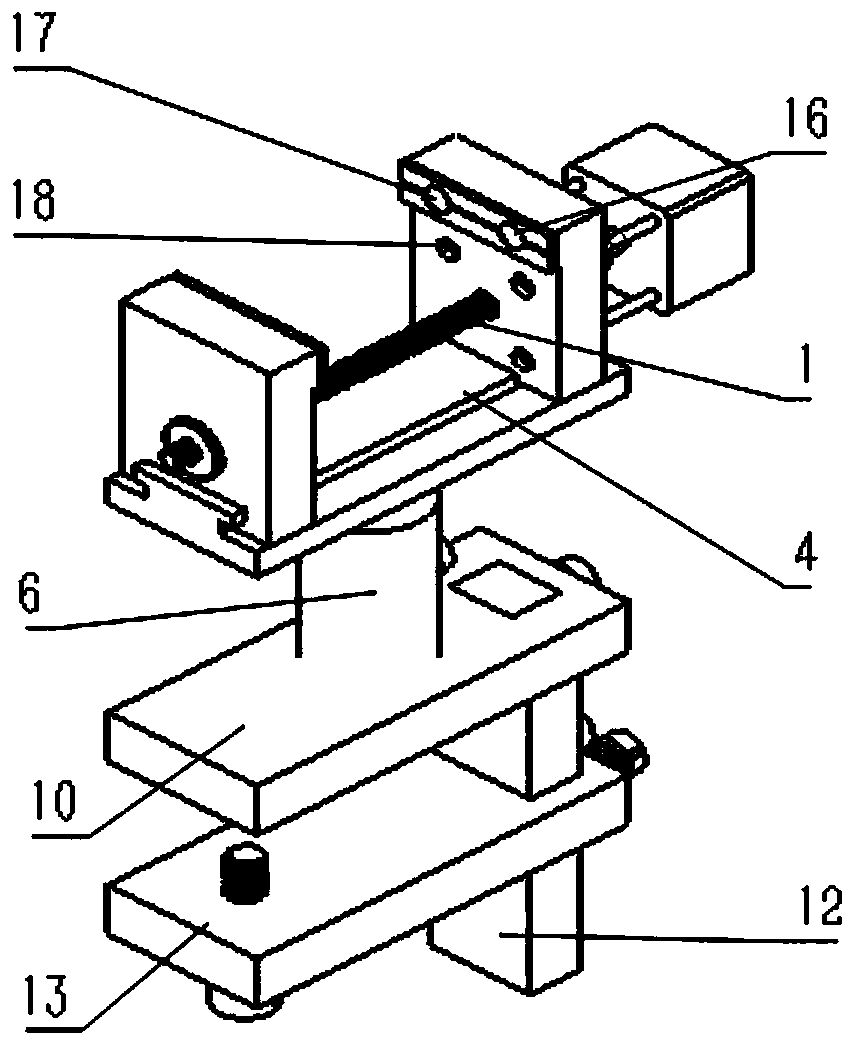

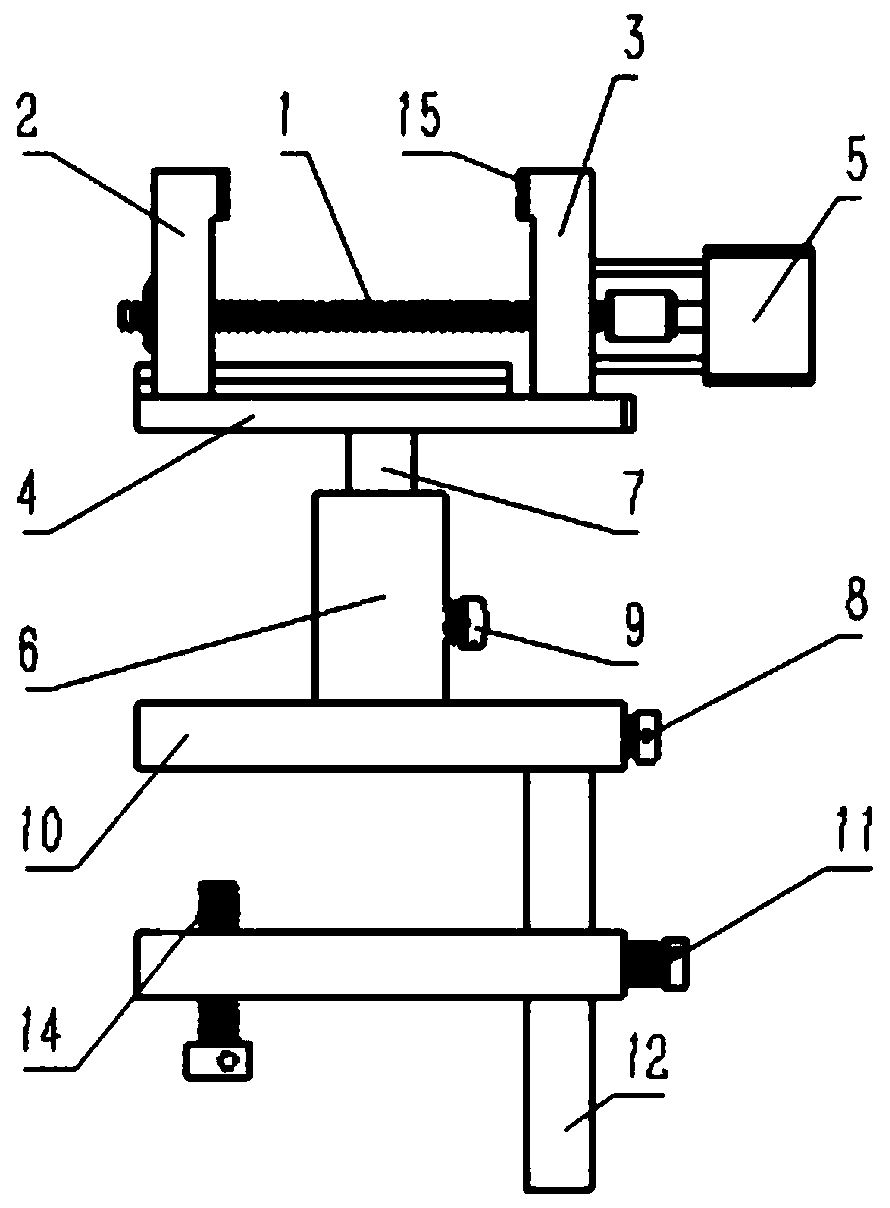

Normal loading device of fretting fatigue test system

InactiveCN104568619ASmall volume changeSmall pressure changeMaterial strength using repeated/pulsating forcesNormal loadEngineering

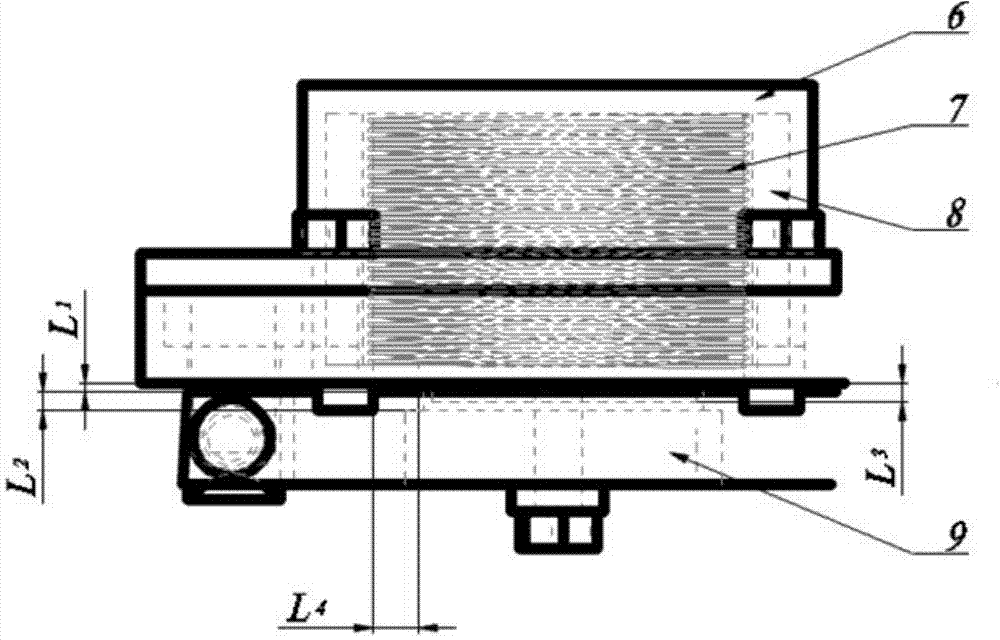

The invention discloses a normal loading device of a fretting fatigue test system. The device adopts the scheme that a base is fixed on the table board of a tension torsion multi-axial fatigue tester through a thread; two transverse guide rails are fixed on the base; a nut of a lead screw is mounted at the right end of the base; a screw of the lead screw is connected with a right baffle plate of a clamping mechanism; the clamping mechanism is characterized in that a sliding block on the bottom surface of a bottom plate is matched with the guide rails on the base; a left baffle plate and a right baffle plate connected through four guide rods are fixed at the left and right ends of the bottom plate; a pressure sensor which is opposite to a pressure head of the right baffle plate is mounted in a groove on the right side of a right chuck; a right inching pad is arranged in an arc-shaped groove of the right chuck; an air cylinder is fixed on the left side of the left baffle plate; a piston rod of the air cylinder penetrates through the left baffle plate to be connected with a buffer block; the right side surface of the buffer block is opposite to the left side surface of a movement plate; the right side of the movement plate is connected with a left chuck through a three-dimensional sensor; a left inching pad is arranged in an arc-shaped groove of the left chuck. The normal load loaded by the test deice can preferably keep constant and the test result is more correct and reliable.

Owner:SOUTHWEST JIAOTONG UNIV

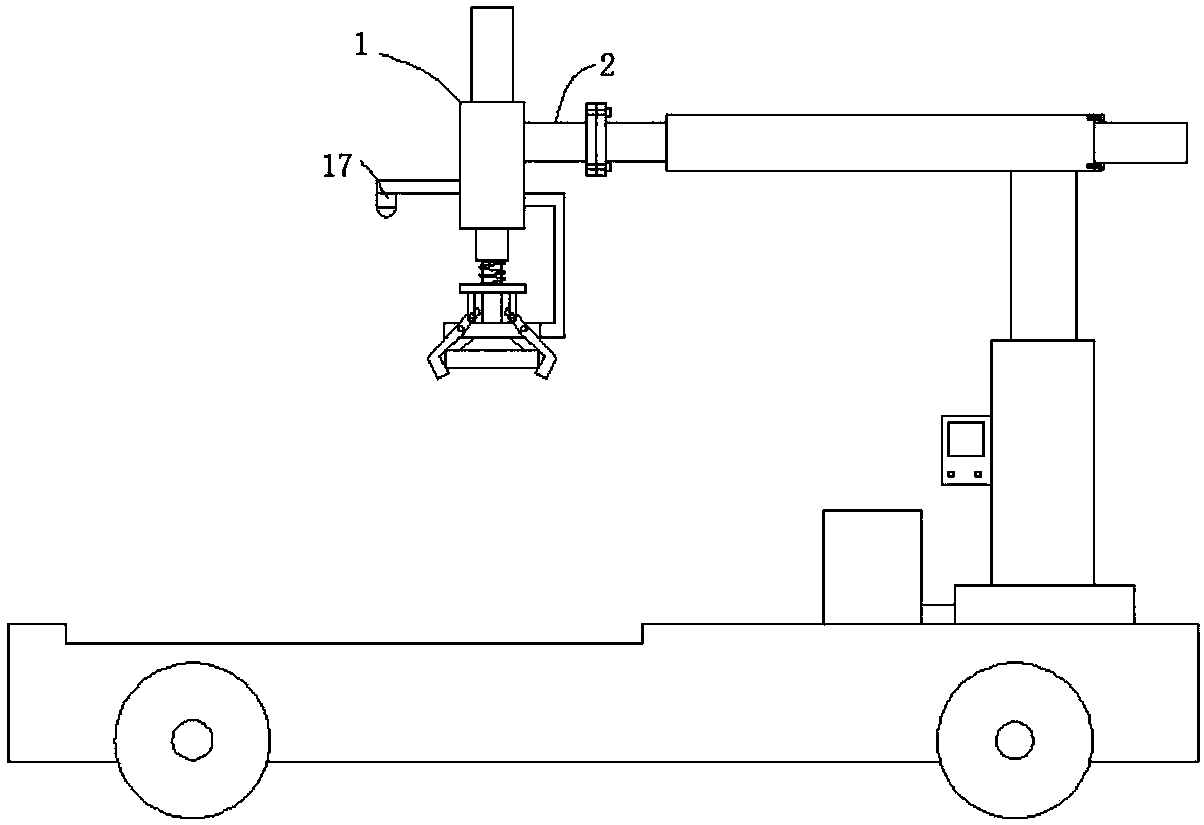

Mobile warehousing robot mechanical arm

The invention discloses a mobile warehousing robot mechanical arm. The mobile warehousing robot mechanical arm comprises an object grabbing portion and a fixed arm. The object grabbing portion comprises an installation pipe vertically welded to the fixed arm, the top of the installation pipe is fixedly provided with an electric cylinder, one side of the installation pipe is fixedly provided with aU-shaped fixing rod, and the end, away from the installation pipe, of the U-shaped fixing rod is fixedly provided with an installation plate located below the installation pipe. The installation plate is fixedly provided with a guide plate in an embedded manner, the bottom end of the guide pipe is fixedly provided with a sucking cup, and the inner side of the guide pipe is slidably connected witha piston in a sleeved manner. Through the electric cylinder, a pull rod, the piston, a fixing disc and the sucking disc, an object can be adsorbed under the sucking disc through the atmospheric pressure for secondary fixing, therefore the object is clamped quite firmly, and falling of the object is avoided; and primary fixing and secondary fixing can both be completed through drive of one electric cylinder, therefore the number of drive equipment is reduced to a certain degree, the installation cost is saved, and the mobile warehousing robot mechanical arm is quite suitable for being appliedand popularized.

Owner:FUYANG SHENGDONG INTELLIGENT MFG TECH DEV CO LTD

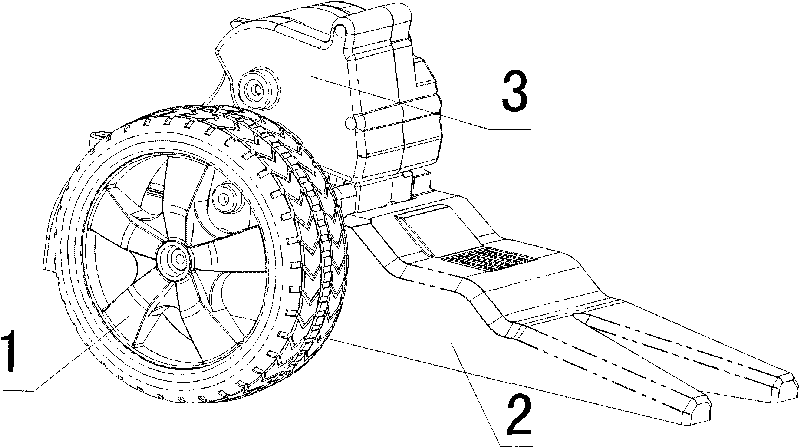

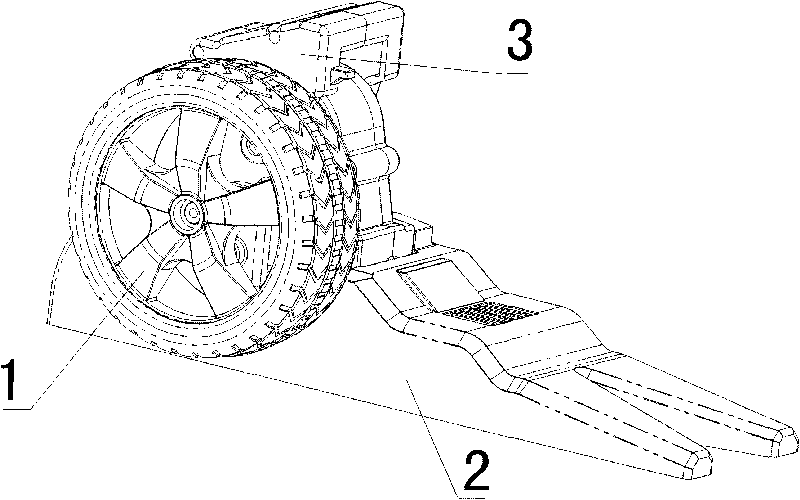

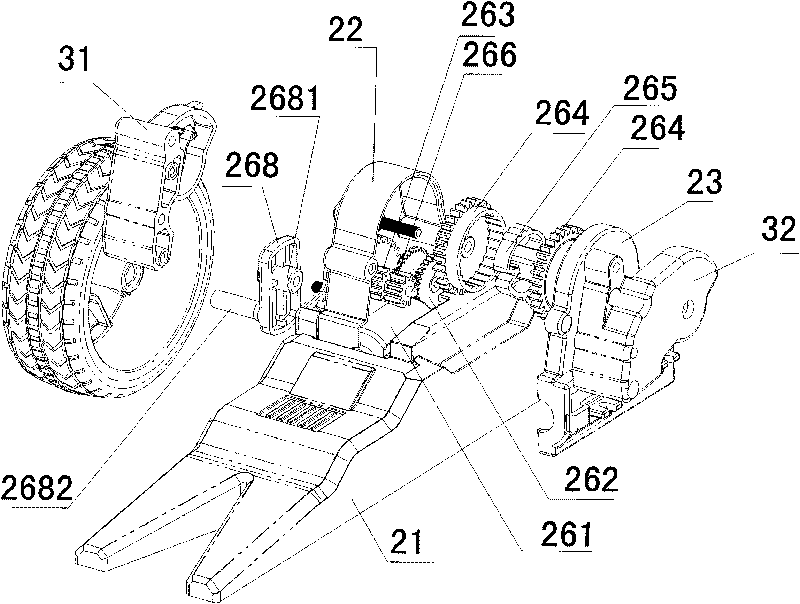

Automobile/robot foot structure

The present invention provides an automobile / robot foot structure. The foot structure comprises wheels, a foot assembly and a foot connecting assembly. The foot assembly comprises one group of power drive mechanism. The wheels are arranged outside the foot assembly, and are in drive connection with the power drive mechanism. The wheels can be driven by the power drive mechanism to rotate upward to positions higher than the foot bottom, and the transformation from an automobile to a robot is realized. Otherwise, the wheels can be driven by the power drive mechanism to rotate downward to positions lower than the foot bottom, and the transformation from the robot to the automobile is realized. The foot connecting assembly is covered on the foot assembly, and is in drive connection with the power drive mechanism. The foot connecting assembly can be driven by the power drive mechanism to rotate upward to a vertical position for realizing the transformation from the automobile to the robot. Otherwise, the foot connecting assembly can be driven by the power drive mechanism to rotate downward to a horizontal position for realizing the transformation from the robot to the automobile. Only one motor is arranged in each foot structure, and the wheels and the foot connecting assembly can be simultaneously driven by the motors to rotate. The present invention has the advantages of simple and compact structure, accurate action and stable properties.

Owner:SHANGHAI JINGYI ELECTRICAL APPARATUS FACTORY CO LTD +1

Mechanical claw with rigidity controllable flexible surface

The invention relates to a method for producing robot, mechanical arm or mechanical clamp, and the application technique of current flowing deformation liquid. It comprises a finger and a flexible surface formed by flexible film. Wherein, the finger comprises a container with a open while expansion flexible electrodes in array are arranged in the chamber of said container; said flexible surface is fixed on the open of container and connected to the upper surface of each electrode; the polarities of the electrodes in one group are same while they are parallel; the electrodes of nearby groups have reverse polarities; the groups in same polarity are paralleled and connected to a outer circuit via lead; the space between each group is filled by current flowing deformation liquid. The invention can realize the deformation of current flowing deformation and the flowing property via regulating the strength of electric field, therefore, it can non-stepped adjust the rigidity of flexible surface to apply the clamped matters in different rigidities and shapes and confirm the clamping stability, without hurting clamped matters.

Owner:UNIV OF SCI & TECH OF CHINA

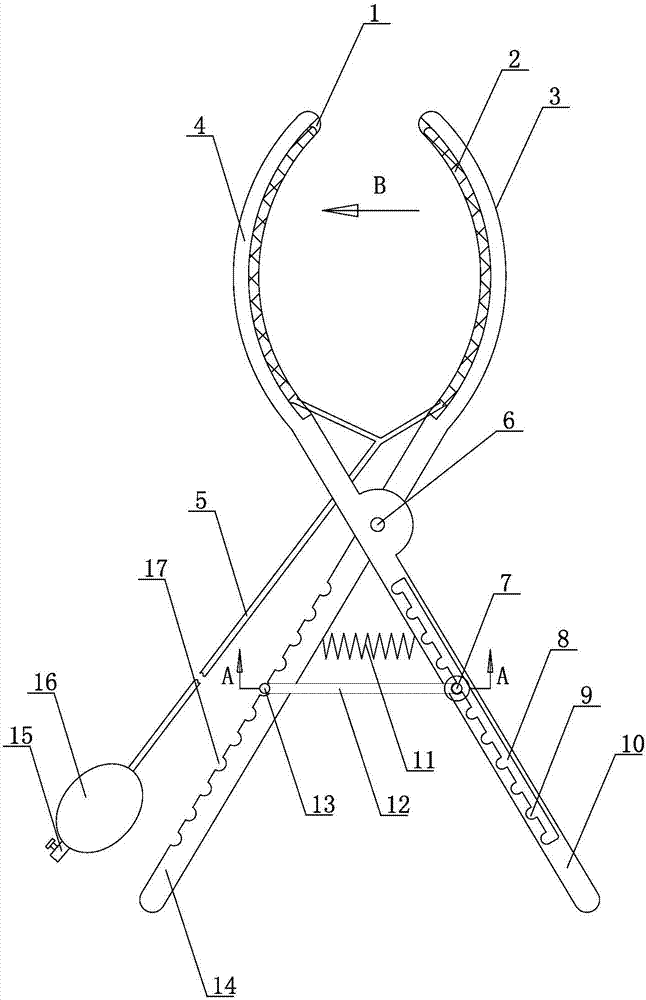

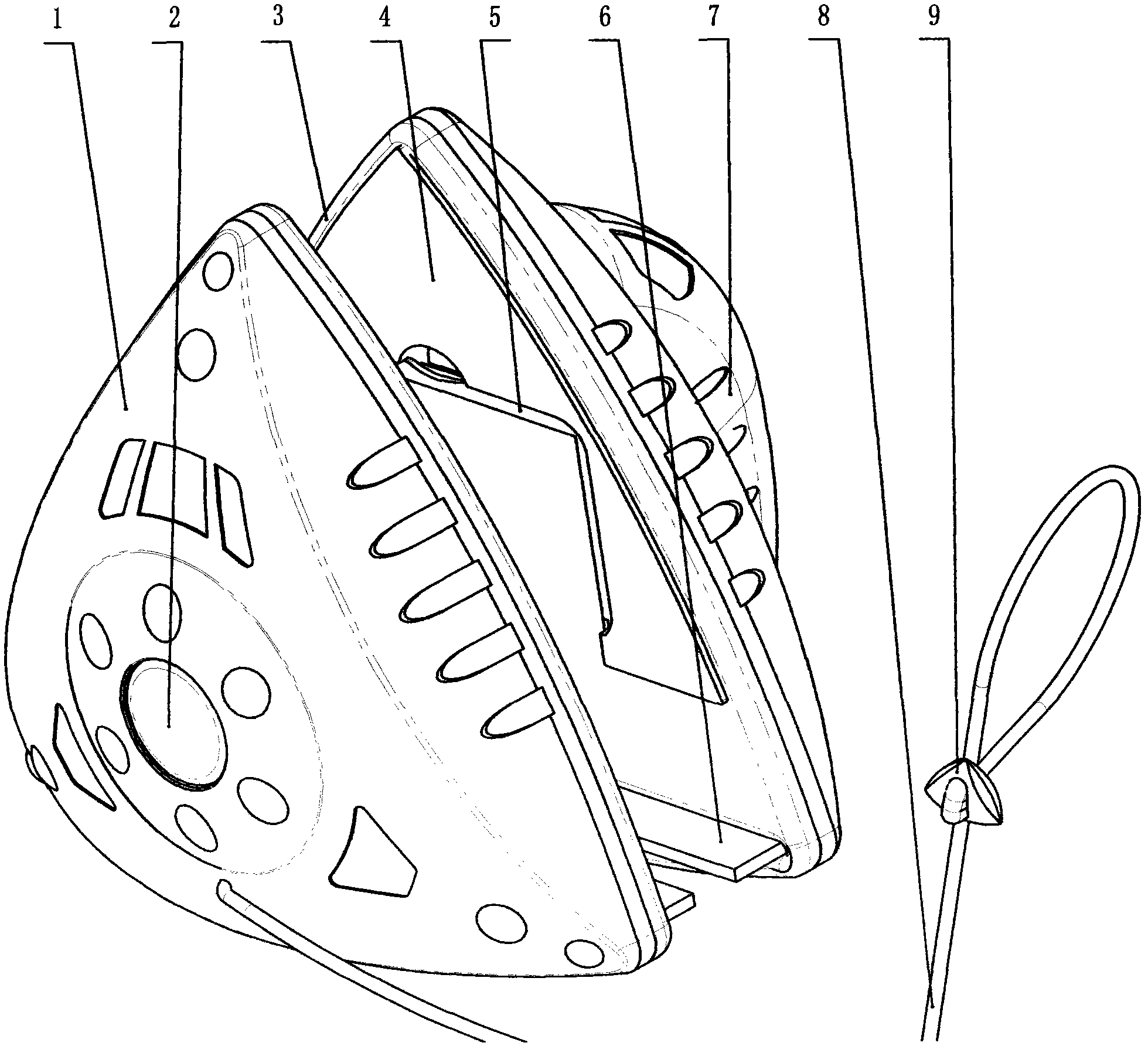

Midwifery forceps for gynecology and obstetrics

InactiveCN107411807AIncrease elasticityImprove buffering effectObstetrical instrumentsObstetric historyForceps

The invention discloses a midwifery forceps for gynecology and obstetrics. The midwifery forceps comprises a first clamp body and a second clamp body, a first clamp handle is fixedly connected with the end of the first clamp body, a second clamp handle is fixedly connected with the end of the second clamp body, the first clamp handle is connected with the second clamp handle in a hinged mode, grooves are formed in the inner walls of the first clamp body and the second clamp body, an inflatable airbag is embedded in each groove, a trachea is connected with the end of the inflatable airbag, an inflatable device is connected with the end of the trachea, a long groove is formed in the first clamp handle, several locating holes are uniformly distributed on the inner side of the long groove, several locking holes are uniformly distributed on the outer side of the second clamp handle, a sliding shaft is inserted in the locating holes, a locking rod is fixed on the top end of the sliding shaft, a locking shaft arranged vertically and downward facing is fixed on the top end of the locking rod, and a locking sleeve which can rotate along the locking shaft is connected with the locking shaft in a sleeving mode. The midwifery forceps for gynecology and obstetrics has the advantages that 1, the structure is simple, 2, the elasticity is good and the angle of the clamp bodies is conveniently locked.

Owner:济南富安机械设计有限公司

Pull type direct pulling device

The invention relates to a pull type direct pulling device which comprises a direct pulling head, a reaction rack, a pressure sensor and a stress application mechanism, wherein the direct pulling head comprises a pull rod and a pull head connected with the lower part of the pull rod; the pull head comprises a hoist block, a jacking thread sleeve, a fixed plate, claws and a link mechanism, the hoist block is in threaded connection with the pull rod, the jacking thread sleeve is in threaded connection with the pull rod under the hoist block, the fixed plate is sheathed outside the jacking thread sleeve through a first bearing bush, the fixed plate is uniformly provided with at least three fixed plate connecting rods, the claws are positioned under the fixed plate, and the number of the claws is the same as the number of the fixed plate connecting rods. The fastening force is enhanced along with the enhancement of the pull force when a concrete core sample is pulled by the pull type direct pulling device, so that the situations that the concrete core sample is smashed by clamping, or is slipped out and fall off from a mechanical direct pull head cannot happen. The pull type direct pulling device is formed by adopting rods, the weight of the pull type direct pulling device can be reduced, and the pull type direct pulling device is more convenient to use.

Owner:CABR TECH CO LTD

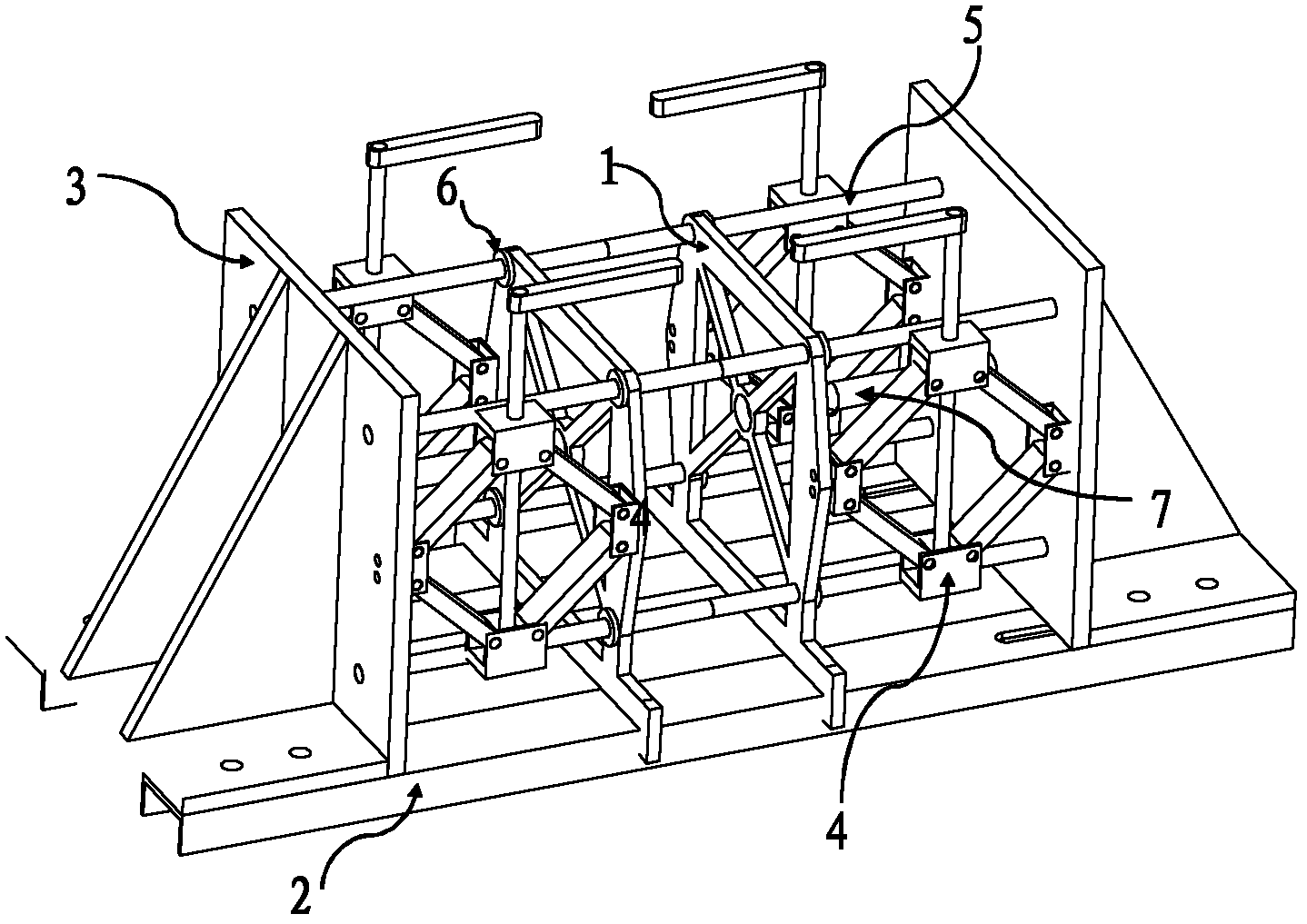

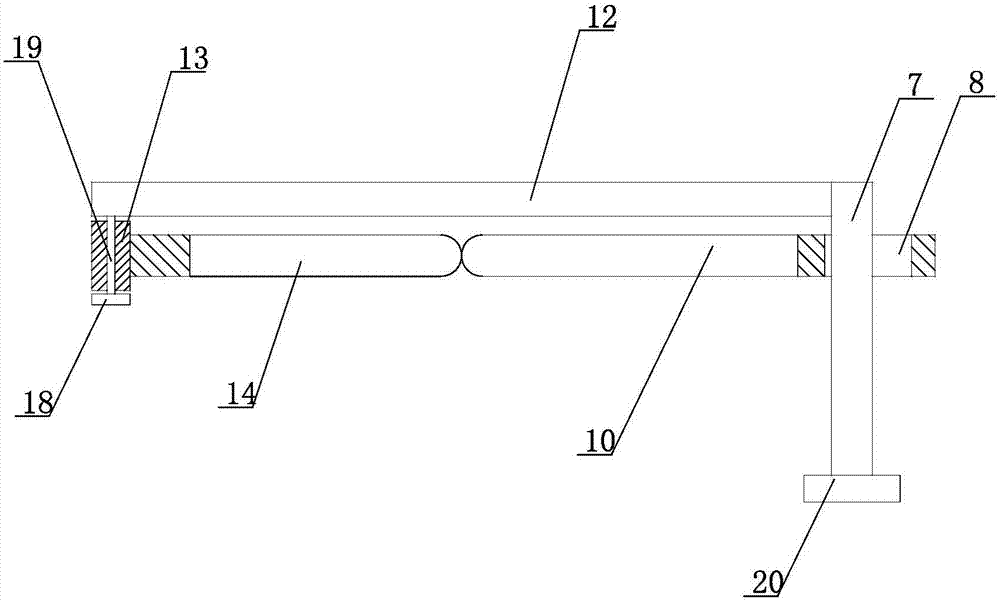

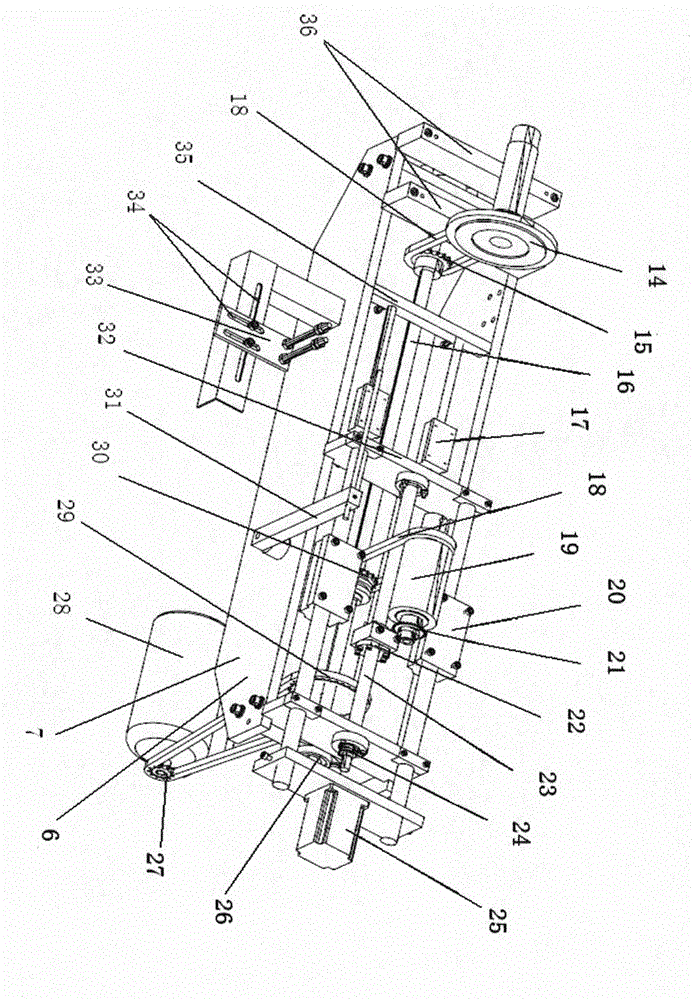

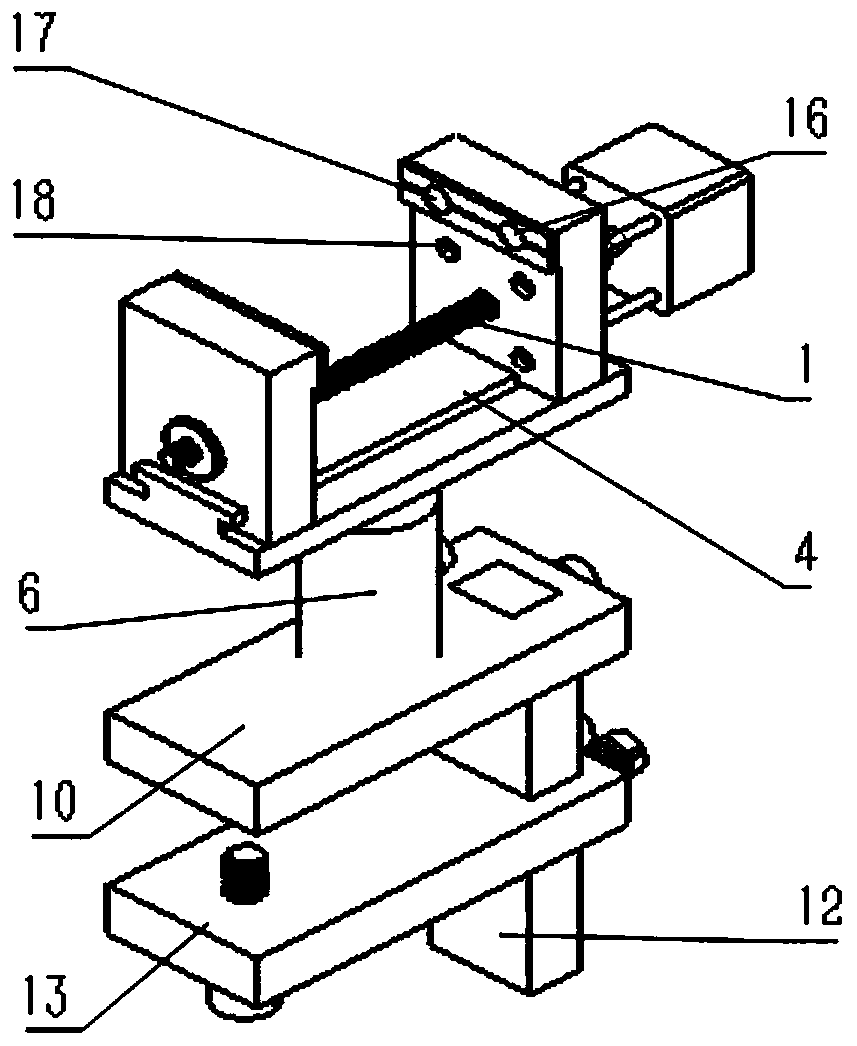

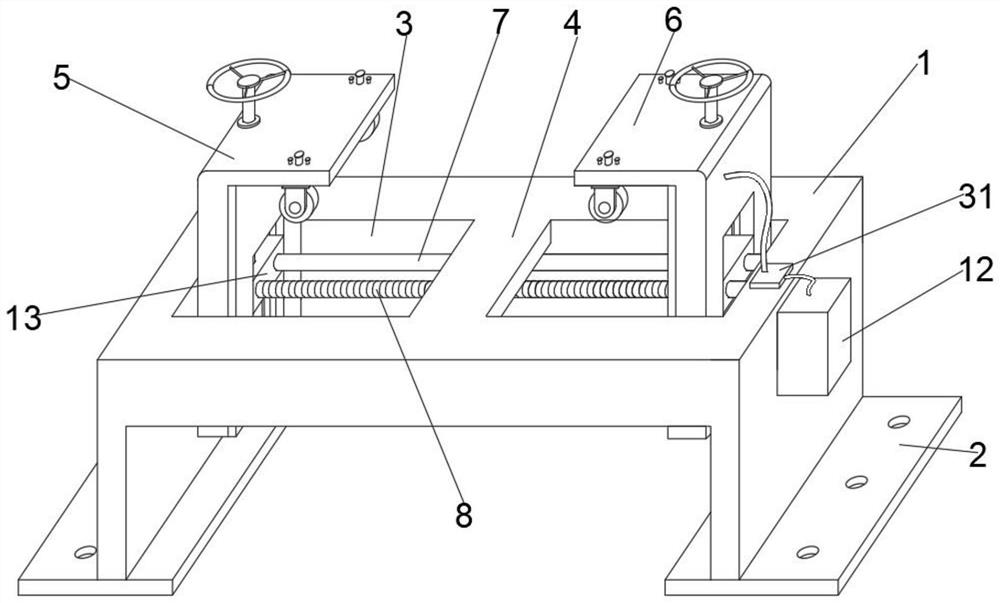

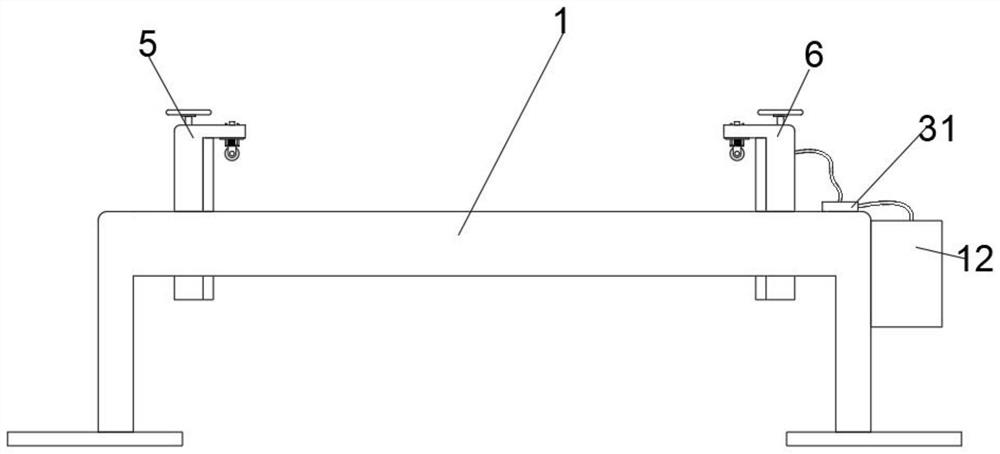

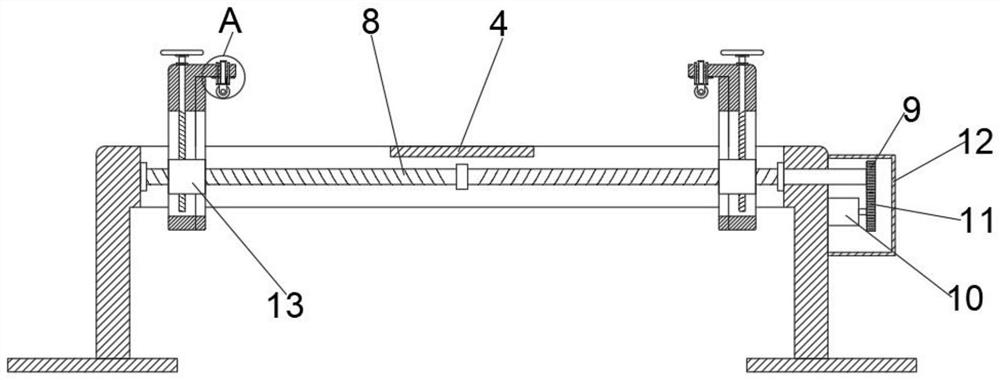

Long-gauge-distance strain sensor high-precision calibration frame

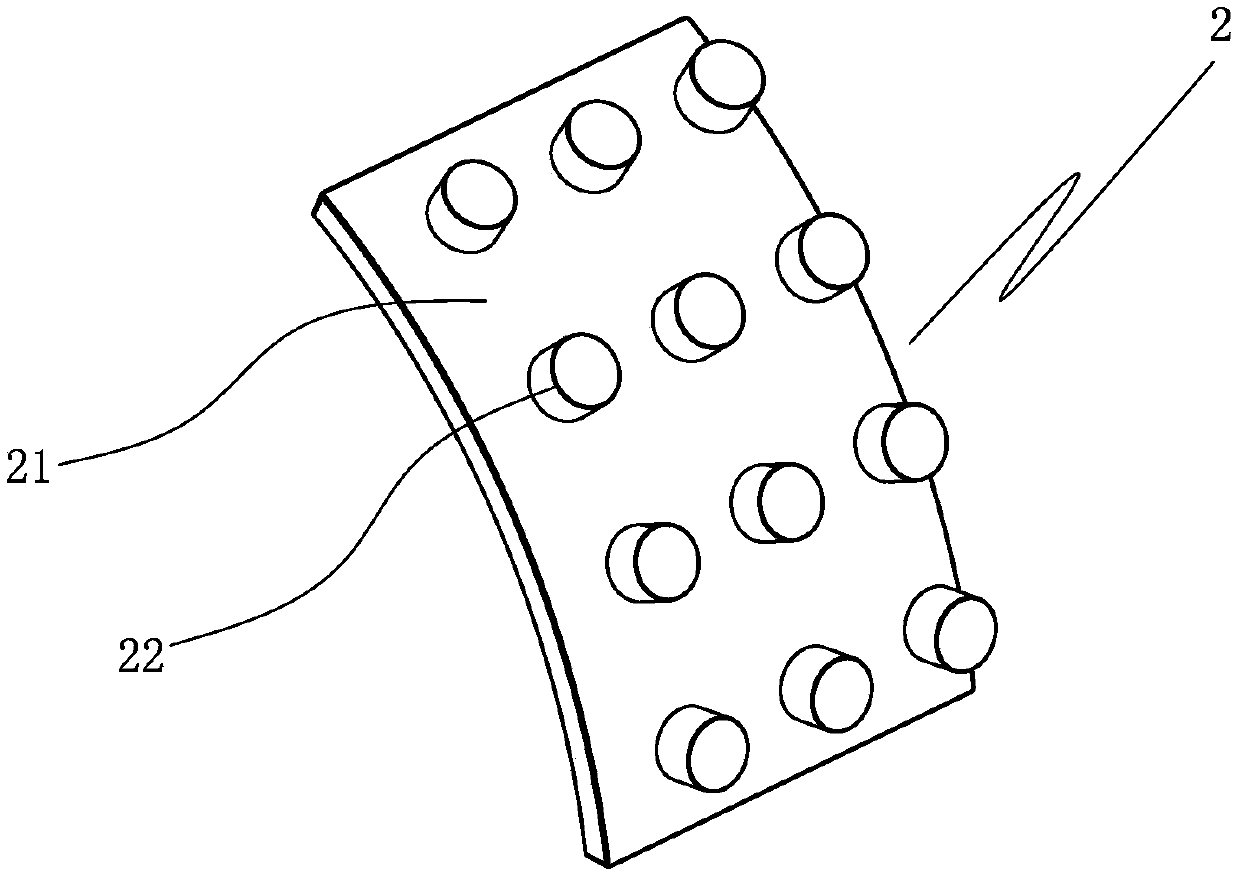

ActiveCN103424081AWon't pinchMeet the calibration needsUsing optical meansFixed frameDifferential screw

The invention discloses a long-gauge-distance strain sensor high-precision calibration frame which is composed of a front end plate, a back end plate and a middle fixing frame, wherein the front end plate and the back end plate are connected through the middle fixing frame. A fixing frame is arranged between the front end plate and the back end plate in a sliding mode. The fixing frame comprises a first dragging plate and a second dragging plate. A fixing rod is sleeved with the first dragging plate and the second dragging plate, and the first dragging plate is fixedly connected with the second dragging plate. A differential screw rod is connected with the second dragging plate. The other end of the differential screw rod is connected with a circular handle which is connected to the back end plate. Dial gauges and two clamps are arranged on the front end plate and the first dragging plate. 3 to 20 cushion block grooves are formed in the opposite surfaces of the two clamps. A sensor clamping cushion block is arranged in each cushion block groove, and each cushion block is a soft metal block. The long-gauge-distance strain sensor high-precision calibration frame has the advantages of being reasonable in structure arrangement, large in stiffness, adjustable in differential screw rod screw-in speed, high in control precision, firm and durable.

Owner:SOUTHEAST UNIV

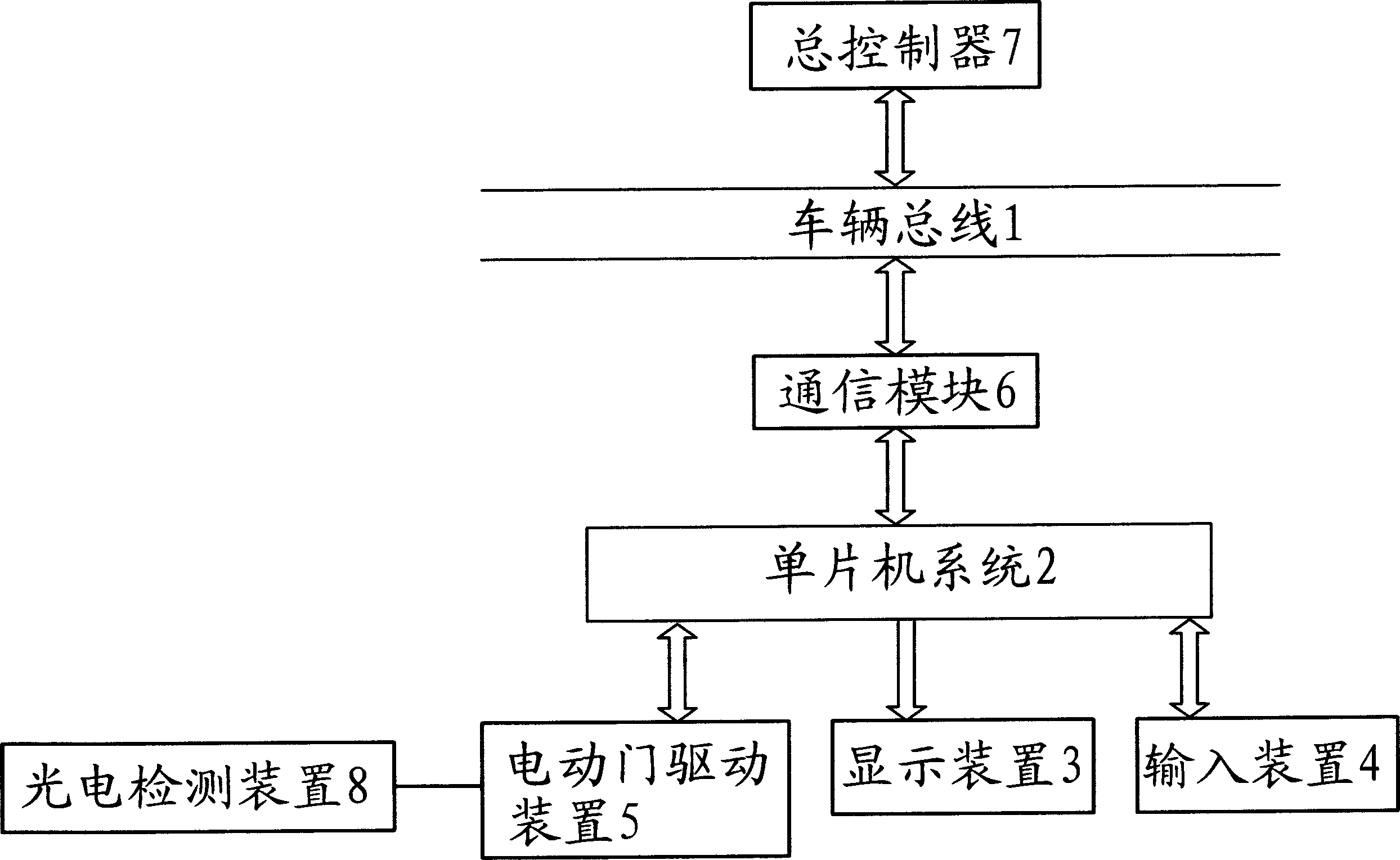

Control sub system for carriages in overhead subminiature rail train

The control sub system includes following parts: vehicle bus; several single chip systems corresponding to each carriage connected to vehicle bus; each single chip system connected to display device corresponding to each carriage; input unit in use for inputting control signal for corresponding carriage; each single chip connected to motor-driven door drive, which is connected to electromotor of controlling open and close of carriage door. Through communication module, vehicle bus carries out information exchange with each single chip system respectively. Comparing with prior art, the invention solves issues of high price of equipment, high operating cost, unstable signal transmission, and longer time delay. Advantages of the control sub system are: reasonable design, easy of implementation, stable signal transmission and safety.

Owner:杨宗林

LED lamp production device

The present invention relates to the field of illuminating lamp production and discloses an LED lamp production device. The device comprises a frame, a gas pipe, and a sintering mouth. The frame is provided with a rotating disk which is provided with a plurality of wick seats. The device also comprises a cylinder which is connected to a manipulator which comprises a clamping arm frame, a first clamp finger, a second clamp finger, and a splayed sliding block. The clamping arm frame is provided with a through hole. A piston rod goes through the through hole in a sliding way. One end of the piston rod is connected to a cylinder, and the other end of the piston rod is connected to the splayed sliding block. The first clamp finger and the second clamp finger are hinged to two ends of the clamping arm frame. A water belt is connected between the first clamp finger and the second clamp finger. The water belt is connected to the inner sides of the first clamp finger and the second clamp finger. The top end of the water belt is provided with a water inlet pipe which is connected to a constant pressure water supply device. Two sides of the water belt are connected to a water-spraying pipe which goes through the clamp fingers to be connected to a first valve. Compared with the prior art, the splash of high temperature residue to a lamp cover to cause lamp cover burst can be prevented.

Owner:遵义市义阳光电有限公司

Leech fry breeding method

InactiveCN107711635AImprove survival rateIncrease productionFood processingClimate change adaptationPutrefactionBran

The invention discloses a leech fry breeding method and relates to the technical field of leech breeding. The leech fry breeding method comprises the following steps: arranging a breeding pond, putting breeding water nutrients into the breeding pond, putting leech fries into the breeding pond, putting feed into the breeding pond, performing breeding observation, transferring leeches into differentbreeding ponds, and the like. Certain amounts of tea bran and insecticides for sterilization are put into the breeding pond after water is fed into the breeding pond, the problem of natural enemies is solved, water spinach is further planted, and thus a natural, ecological, healthy and appropriate growth environment is established; and the feed is put into sausage casings and is fed to the leechfries as a whole, then no residues, blood coagulation wastes or putrefaction is generated, water bodies are not polluted, and the feed is also prevented from being hurt or killed by pinching of snails, so that the survival rate and the yield of the leech fries are increased. By adopting the method, the problems that the survival rate and the yield of leech fires are low as water bodies can be easily polluted in the leech fry breeding process, and the feed is hard to take and utilize by the leech fires, are solved.

Owner:广西鹿帅仁生物科技有限公司

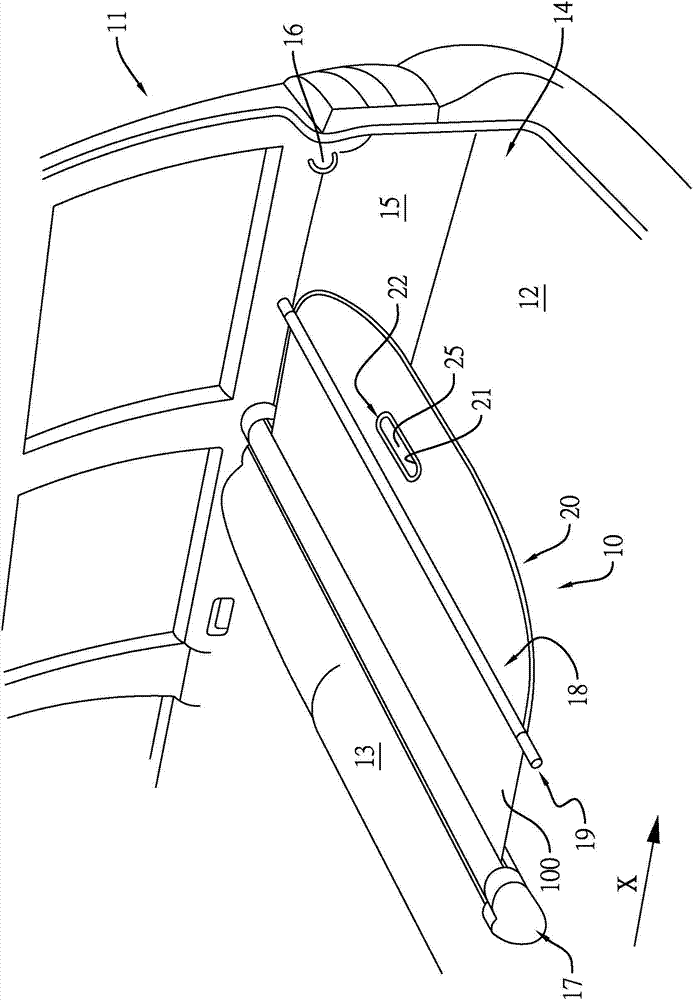

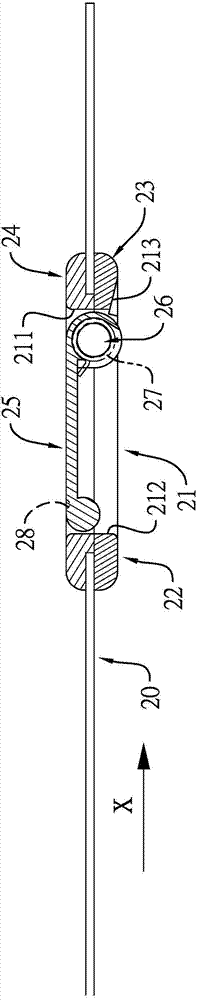

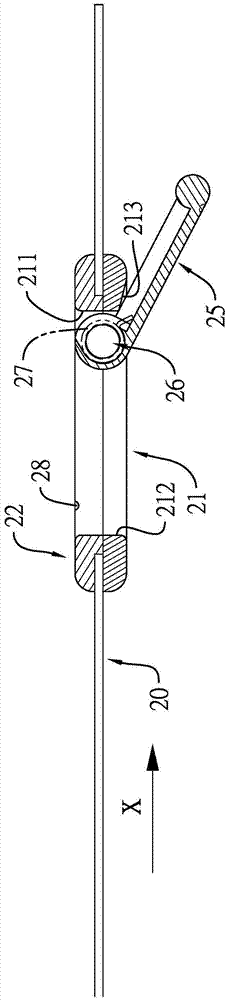

COVERING CURTAIN for motorvehicle

Owner:MACAUTO IND CO LTD

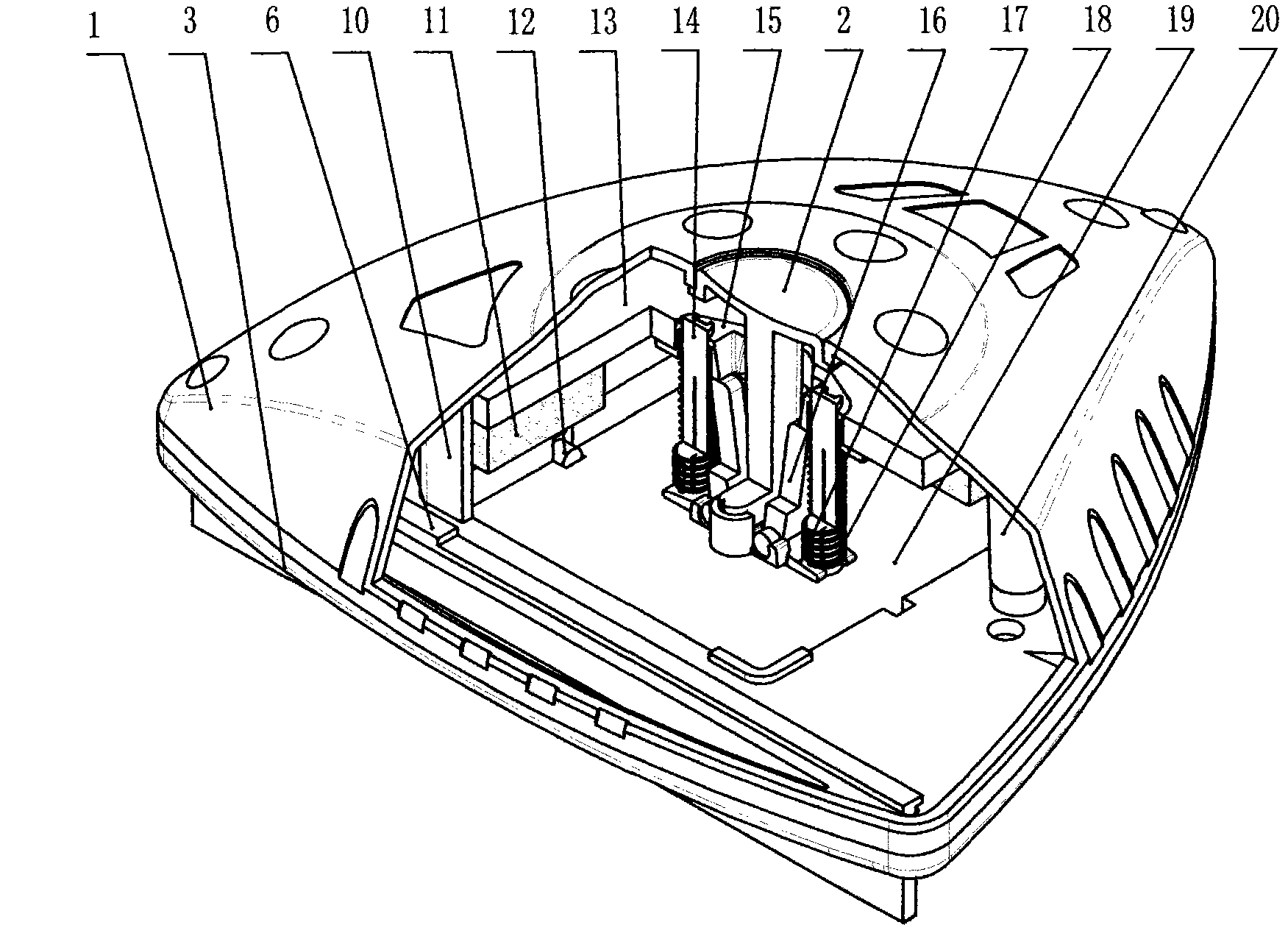

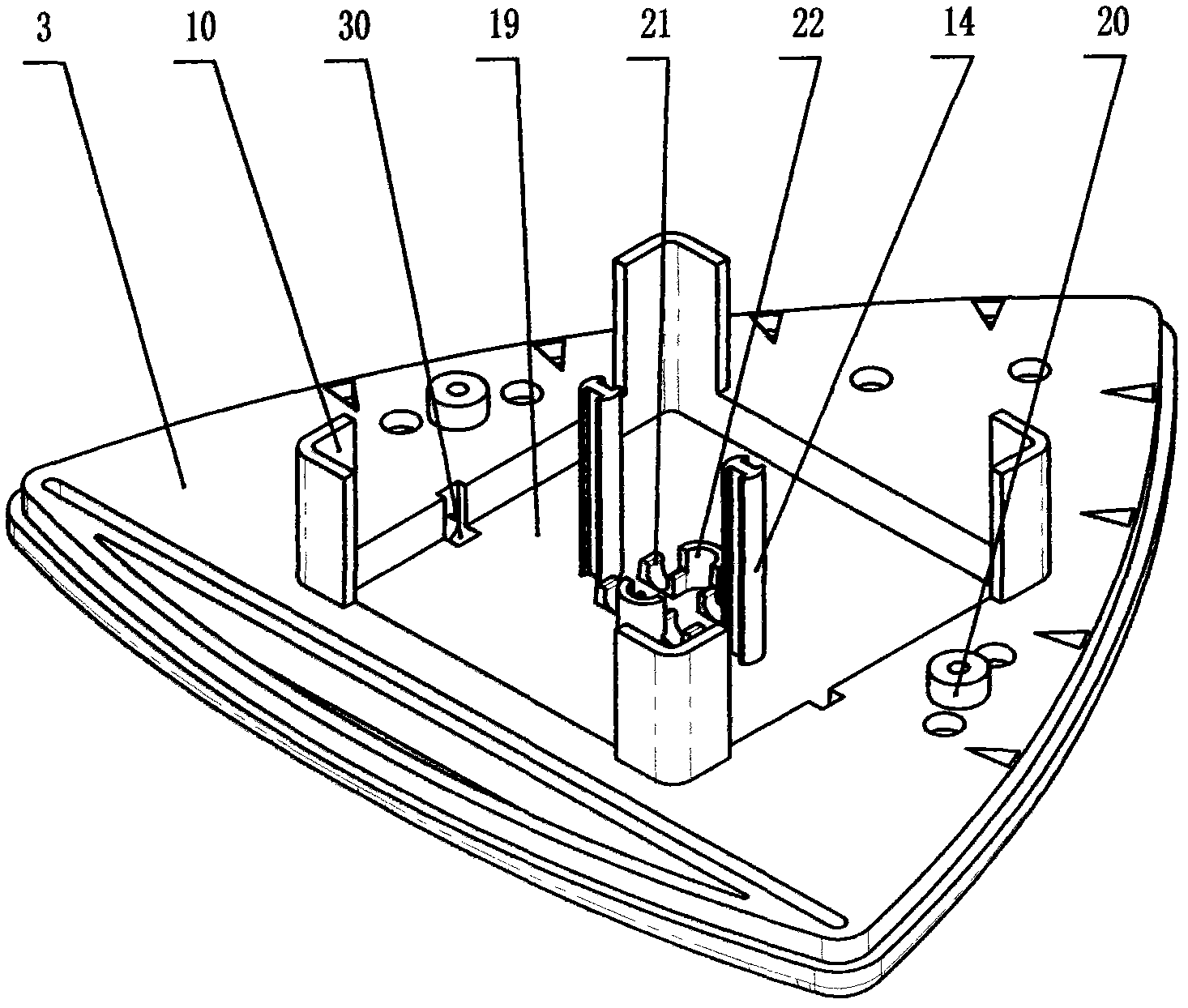

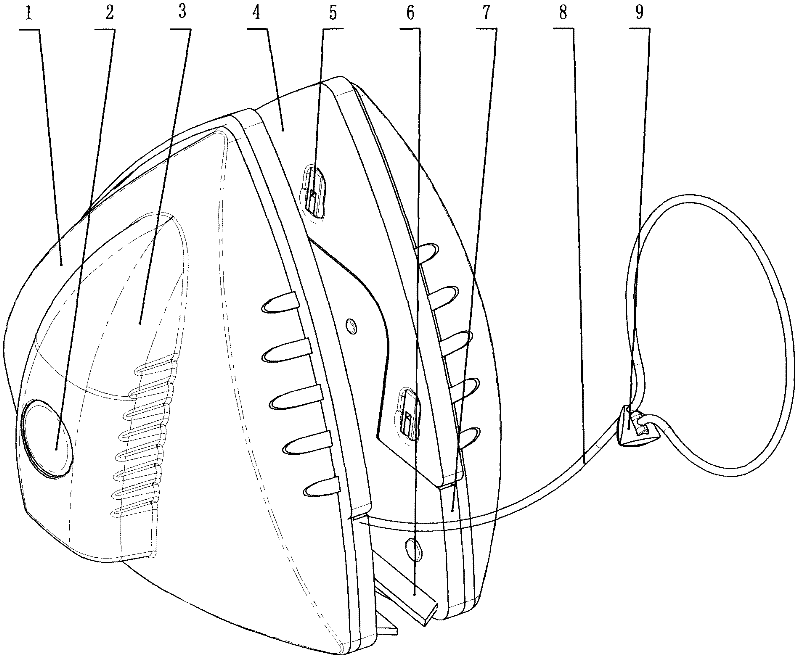

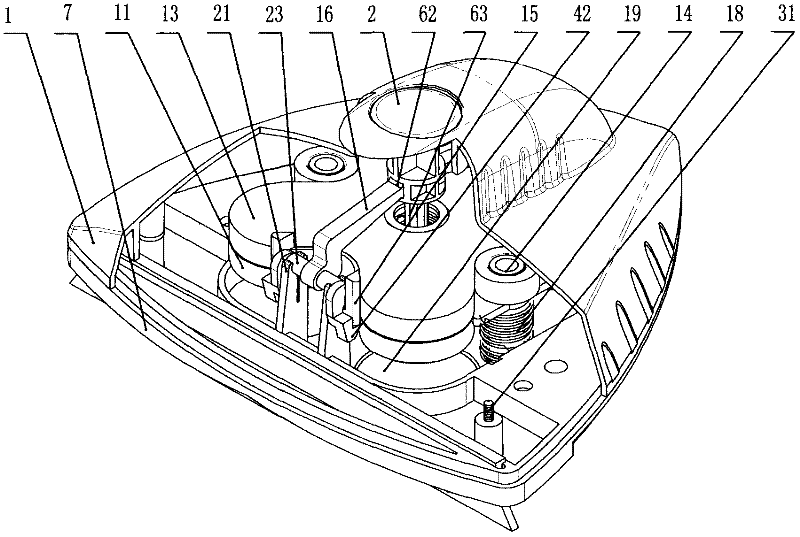

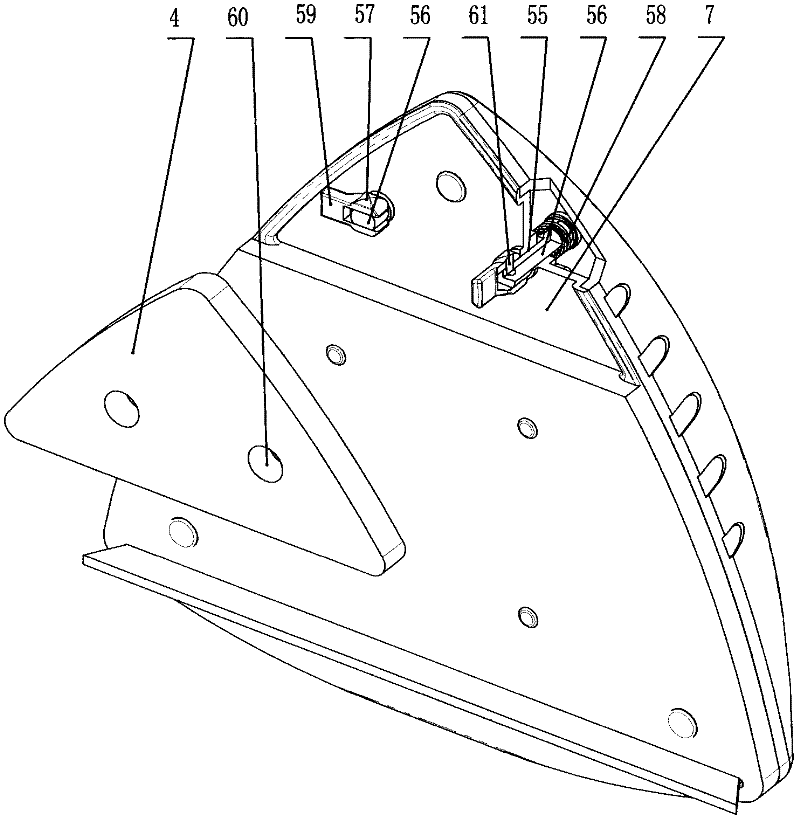

Magnetism adjusting device mounted on body of magnetic glass wiper

The invention discloses a magnetism adjusting device mounted on a body of a magnetic glass wiper. The device comprises a body bottom housing, a rear cover and a magnet, a magnet holder and an iron sheet which are arranged inside the bottom housing, wherein the bottom housing and the rear cover form a chamber; a guide column is arranged in the chamber which is formed by the rear cover and the bottom housing and used for moving the magnet, the magnet holder and the iron sheet up and down in a balanced manner; a shifting key is arranged on the upper end surface of the rear cover; a stepped adjusting rod is arranged below the shifting key; a slider is fixed at the lower end of the stepped adjusting rod; the slider is arranged on the bottom housing on which a sliding chute is formed; and notches through which the stepped adjusting rod passes are formed the magnet holder and the iron sheet. The magnetism adjusting device has a simple structure, is convenient to operate, keeps the magnet holder and the iron sheet in balance and smooth during motion, and prevents the problems of warping and turning. Besides, the range of adjusting the magnetic attraction force is large and the operation is safe.

Owner:张钠

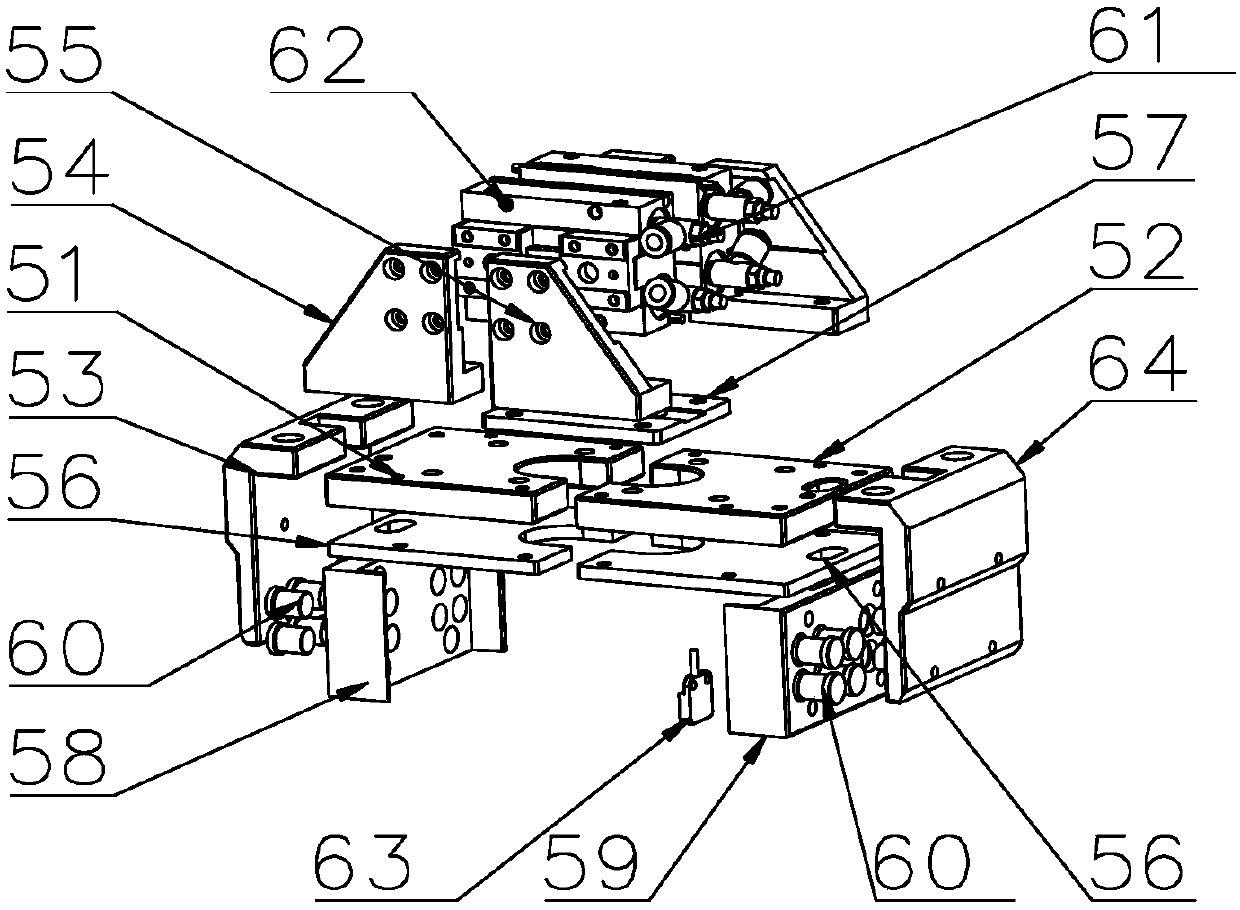

Mechanical arm of double gripper structure and control method of mechanical arm

PendingCN107738248AFulfil requirementsCompact structureProgramme-controlled manipulatorGripping headsManipulatorPneumatic gripper

The invention discloses a mechanical arm of a double gripper structure and a control method of the mechanical arm. The mechanical arm of the double gripper structure comprises a fixing mechanism, a rotating mechanism and a double pneumatic gripper structure. The fixing mechanism is used for fixing a mechanical arm body to a machine; the rotating mechanism is connected with the fixing mechanism andthe double pneumatic gripper structure; and the double pneumatic gripper structure is provided with two pneumatically-controlled pneumatic grippers. The mechanical arm of the double gripper structureand the control method of the mechanical arm are easy to implement, and efficiency of battery gripping can be remarkably improved.

Owner:深圳市精实机电科技有限公司

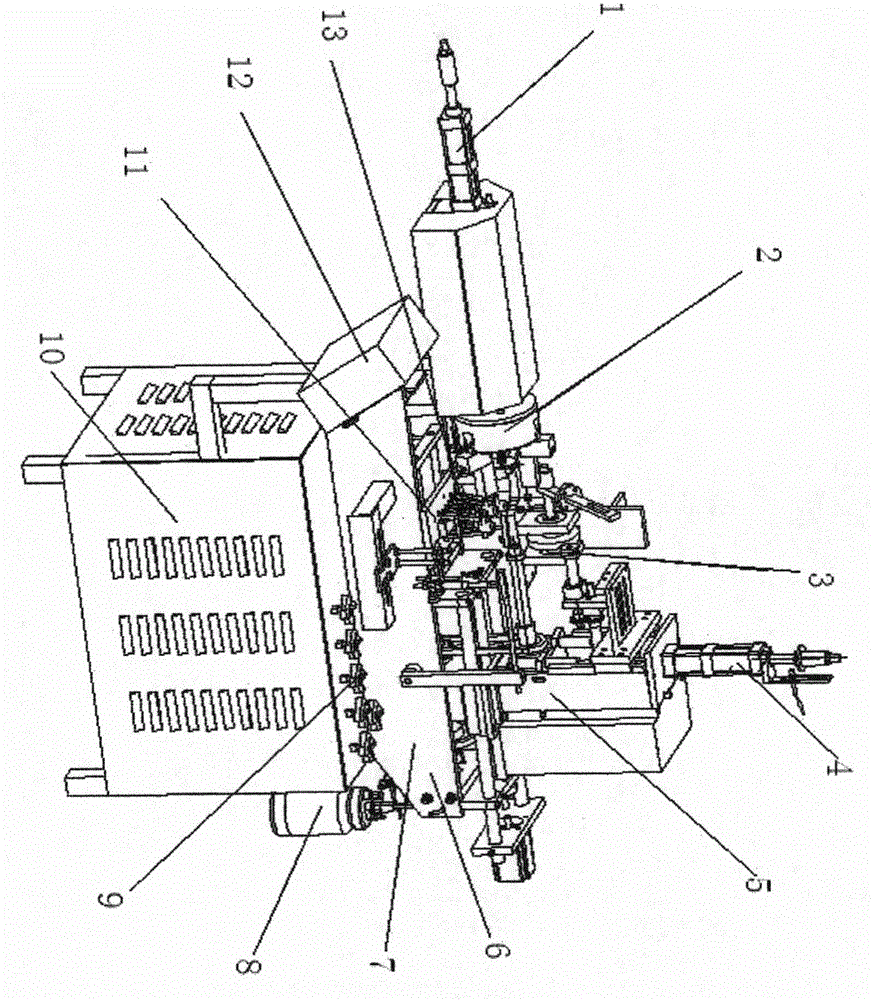

Multifunctional glass cup making machine

InactiveCN104445889AWon't pinchQuality assuranceGlass reforming apparatusGlass productionSteering wheelAgricultural engineering

The invention discloses a multifunctional glass cup making machine. A power box is made of angle iron and sheet iron, a frame is made of sheet iron and square iron, a nose is arranged on the right side of the frame, and a front vertical cylinder and an embossing mold are arranged on the nose; an iron plate, an oil spray rack, a fire head and a transverse dragging device are arranged at the middle of the frame; an automatic chuck and a transverse adjustable cylinder are arranged on the left side of the frame; a liquefied gas switch is arranged at the middle upper part of the power box, an oil storage tank is arranged on the right side of the power box, and a microcomputer is arranged on the left side of the power box; a main shaft is arranged at the lower part of the frame, an upper chuck sprocket and a lower chuck sprocket are arranged at two ends of the main shaft, and a transmission sprocket is arranged at the middle part of the main shaft; a transverse carriage is arranged on two small linear slide blocks, a steering wheel and an elongated slot are arranged on a rocker arm, a pull rod is arranged in the center of the automatic chuck, a spring is arranged on the pull rod, a pressure-relief panel is provided with three circular holes, a thrust bearing is arranged on the pressure-relief panel, a connecting column is arranged on the pull rod of the transverse adjustable cylinder, two small cylinders are arranged on a middle fixed plate, an upper fixed plate is provided with three slot holes, an upper shaft and a middle shaft are arranged on a shaft fixing plate, and a tensioning sprocket is arranged on a long plate.

Owner:施鹏宇

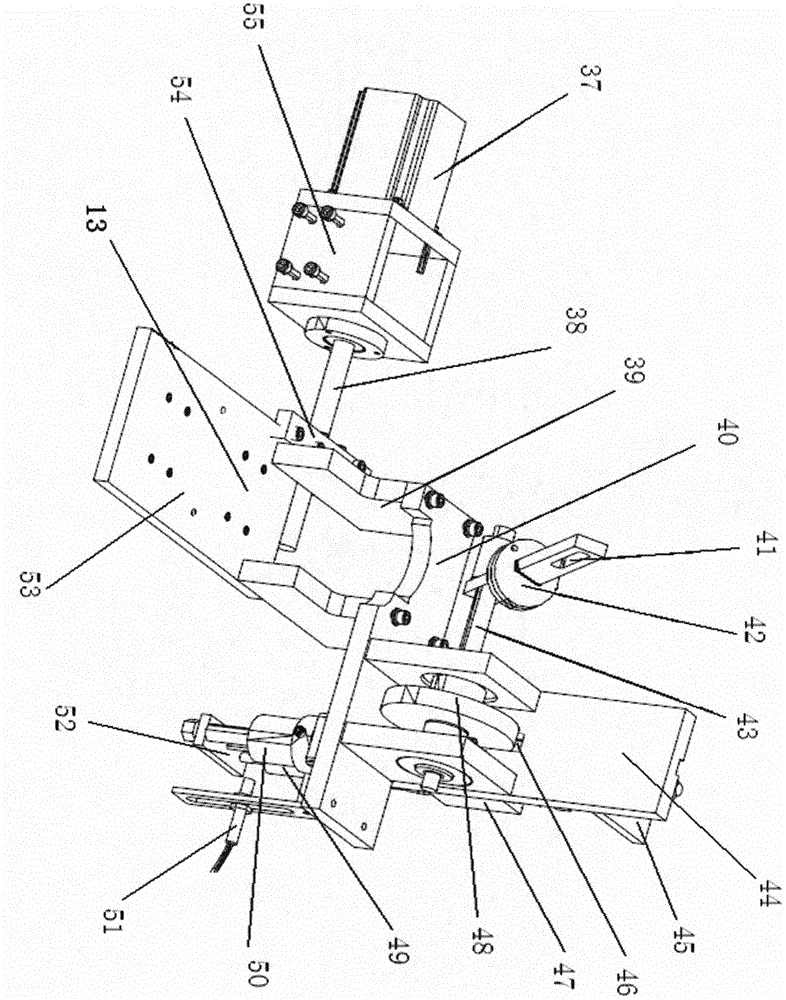

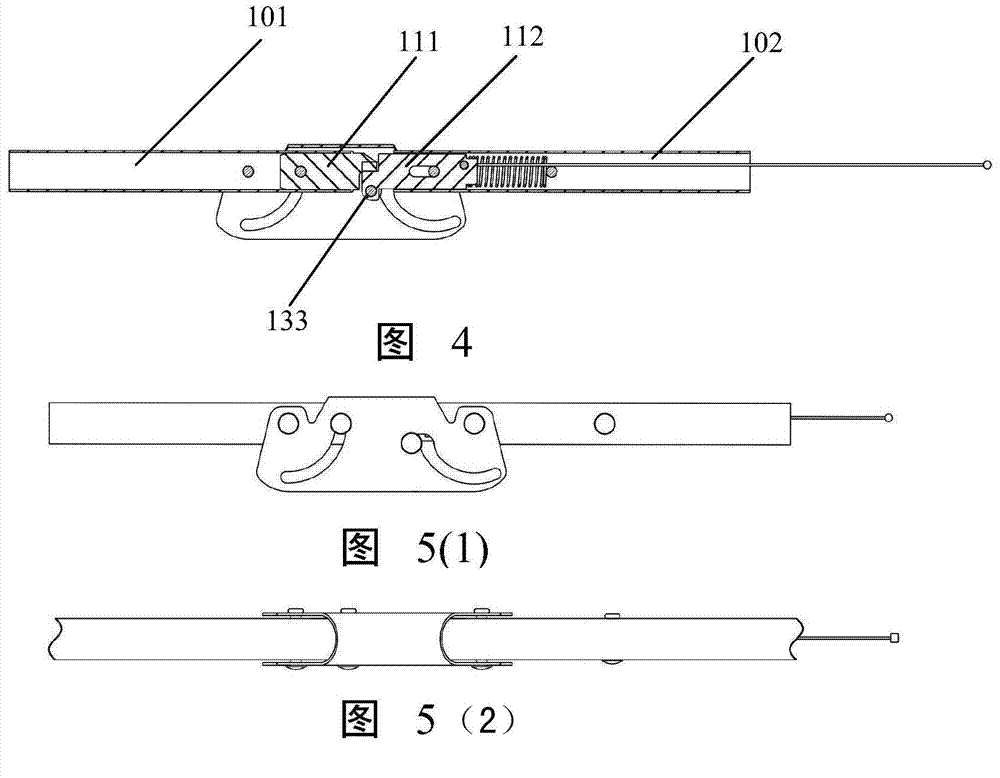

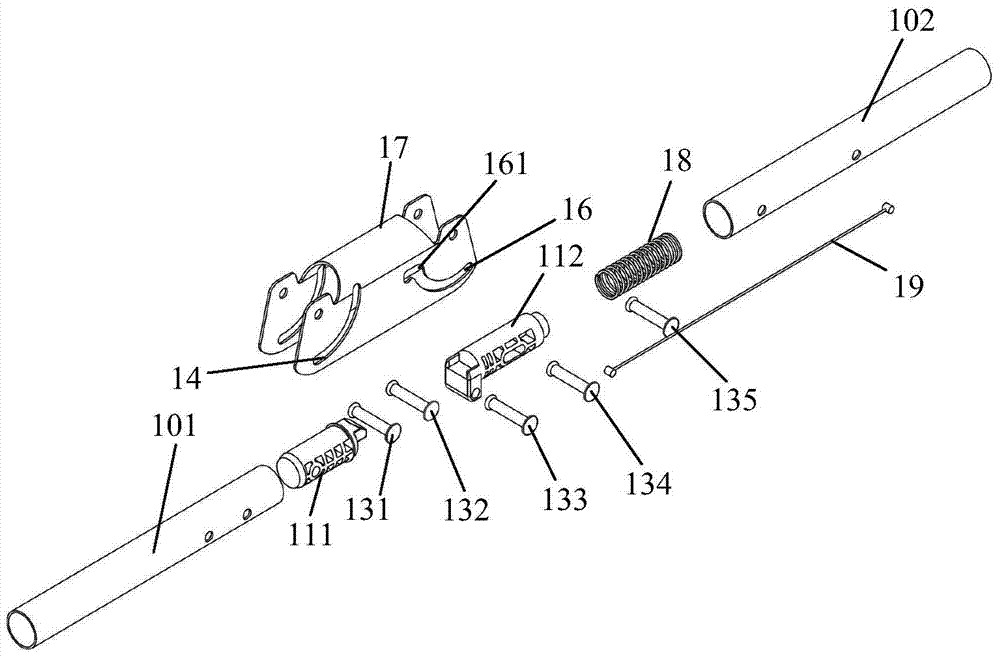

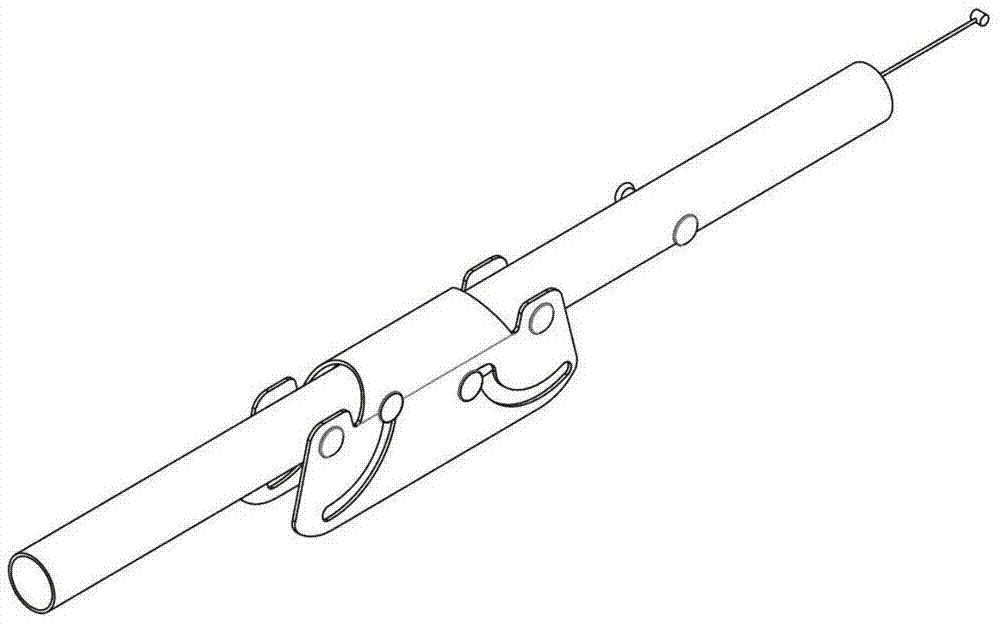

Fast positioning and disassembling device for testing mechanical performance of optical cable

The invention relates to a fast positioning and disassembling device for testing the mechanical performance of an optical cable. The fast positioning and disassembling device comprises an upper clamping plate, a lower clamping plate, a clamping plate connecting shaft pin, a sleeve for clamping the optical cable, an automatic electromagnetic opening and closing device and a self-locking device, wherein the automatic electromagnetic opening and closing device comprises an electromagnet, a permanent magnet, an electromagnet sleeve and a cover plate; the self-locking device comprises a clamping hook, springs and a locking tongue; the sleeve is divided into an upper semicircular sleeve and a lower semicircular sleeve; the upper clamping plate is rotatably connected with the lower clamping plate by the clamping plate connecting shaft pin; the upper semicircular sleeve is connected with the upper clamping plate in a detachable manner; the lower semicircular sleeve is connected with the lower clamping plate in a detachable manner; the cover plate is positioned in the upper clamping plate; the electromagnet is fixed in the electromagnet sleeve which is fixed in the upper clamping plate by the cover plate; the permanent magnet is fixed in the lower clamping plate; the clamping hook is fixed in the upper clamping plate; the locking tongue is positioned in the lower clamping plate; and the springs are positioned at the two sides of the locking tongue. The fast positioning and disassembling device provided by the invention has the advantages that the optical cable is effectively protected, the working efficiency is high and the safety is high.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

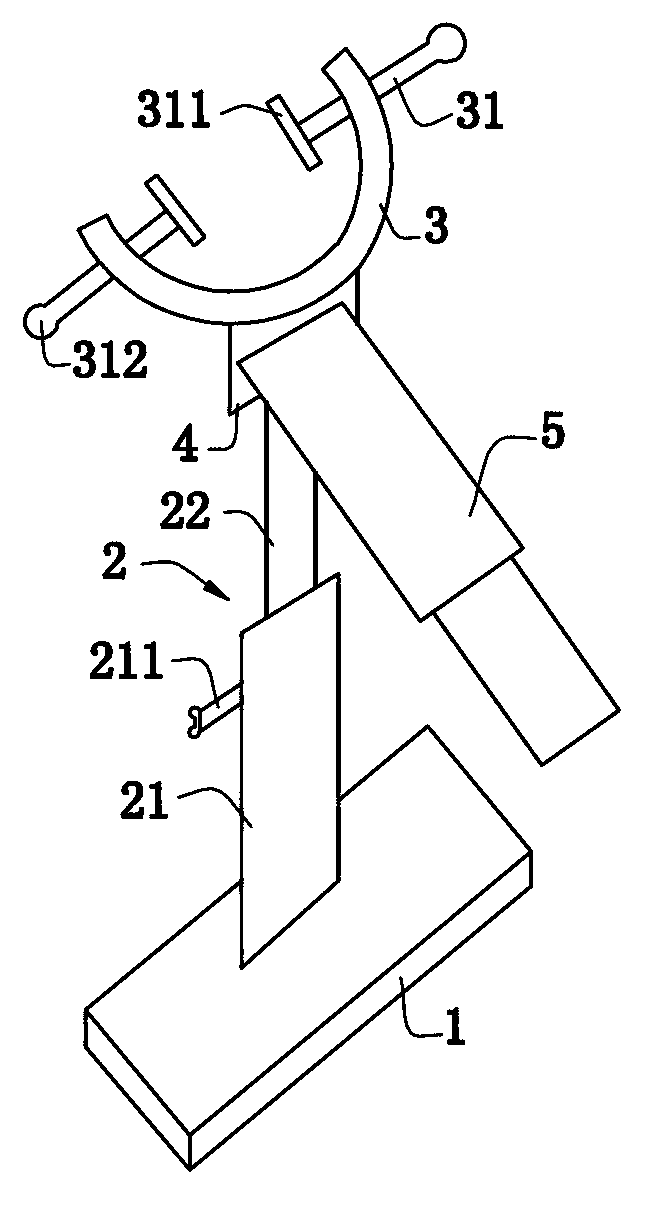

Head fixing device for neurosurgery

The invention belongs to the technical field of medical devices and particularly relates to a head fixing device for neurosurgery. The head fixing device comprises a base, a lifting device and an arc head rest. The lifting device is arranged on the base, a non-slip mat is arranged at the bottom of the base, a connecting shaft is arranged at the center of the bottom of the arc head rest, the connecting shaft is fixedly connected with the top end of the lifting device, a downward inclined telescopic plate is arranged on the connecting shaft, a threaded hole is formed in two sides of the arc head rest respectively, a threaded rod is arranged in each threaded hole, the end of the each threaded rod on the inner side of the arc head rest is provided with a clamping plate, and the end of each threaded rod on the outer side of arc head rest is provided with a handle. The head fixing device for the neurosurgery is simple in structure, convenient to operate, capable of fixing the head of a patient and supporting the neck of the patient, the patient can feel comfortable during the surgery, and the phenomenon that surgery conduction is affected due to the fact that blood circulation is not smooth is avoided.

Owner:王森林

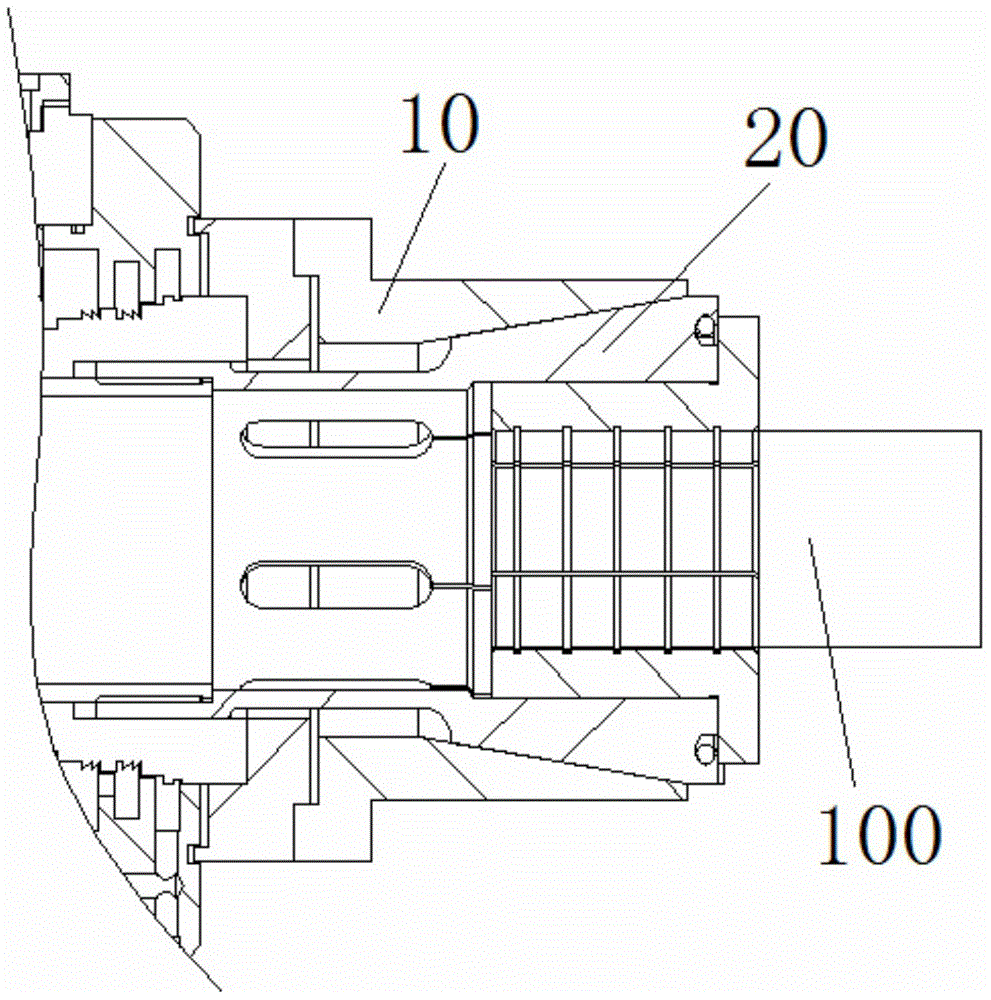

Piston rod brake device

InactiveCN104315047AExtended service lifeEasy interchangeFluid-pressure actuatorsBrake actuating mechanismsEngineeringMechanical engineering

The invention relates to a brake device which maintains extension and retraction positions of a piston rod, in particular to a piston rod brake device which is needed by sudden stop of a cylinder during the moving process of the cylinder, and uses a pneumatic element as a power source, can lock moving positions of an air cylinder, the piston rod of a hydraulic rod and other cylindrical guide pillars, and belongs to the pneumatic hydraulic technology field. The piston rod brake device comprises a cylinder barrel, wherein a plurality of locking blocks are arranged in the cylinder barrel, and a plurality of brake pads are arranged on the inner side of each locking block, an air sac is arranged on the inner wall of the cylinder barrel and each locking block, and inflation inlets communicated with the air sacs are formed in the side wall of the cylinder barrel. When the air sacs are inflated through the inflation inlets, the air sacs swell and compress the locking blocks towards the inner side of the cylinder barrel, and therefore the brake pads at the front ends of the locking blocks are driven to tightly hold the piston rod installed at the central position of the piston rod brake device. The piston rod brake device swells the air sacs by supplying air to the air sacs so as to push the locking blocks, provides stable clamping force, rapidly and reliably brakes the piston rod, and is large in brake force and reliable in reset ability.

Owner:WUXI YAZHONG PNEUMATIC HYDRAULIC

Key type bag expanding support

PendingCN109892789ALittle elasticityReduce loadLuggageOther accessoriesKey pressingArchitectural engineering

The invention discloses a key type bag expanding support. The key type bag expanding support comprises a fixing seat and a telescopic piece, wherein the middle part of the front surface of the fixingseat is provided with a telescopic channel, and the lower side of the telescopic piece is provided with a telescopic plate; the front surface of the fixed seat is provided with a lock catch assembly,the lock catch assembly comprises a key, a transmission piece, a fastener and a spring, the front surface of the fixed seat is provided with an inner stud II, the middle of the transmission piece is connected to the inner stud II in a sleeving manner, one end of the key penetrates through a side surface of the fixed seat to be hinged to the lower end of the transmission piece, and the upper end ofthe transmission piece is hinged to the fastener; two opposite end faces of the transmission piece are respectively provided with an anti-falling cone and a clamping cone, the anti-falling cone is inserted into the spring, the upper side of the telescopic channel is provided with a through hole communicated with the inside of the telescopic channel, a plurality of bayonets are uniformly distributed on the left side and / or the right side of the telescopic plate, and the clamping cone is connected with the through hole in a sleeving manner and can be clamped into or taken out of the bayonets ofthe telescopic plate. The clamping cone is transversely clamped in or taken out of the bayonets, elastic force required by the spring is quite small, the key can be pressed down by a user with only one finger, and a person with partial defective fingers can easily use the key type bag expanding support.

Owner:ADIMANER LERTHER ARTICLE & DRESS DECORATION

Safe magnetic glass wiping device

The invention provides a safe magnetic glass wiping device, which mainly comprises a shell, a permanent magnet, a magnetic conduction plate, a rubber scraper, a felt, a thread rope and a snap ring, wherein the shell consists of an upper cover and a lower shell. The device is characterized in that: the lower shell and the permanent magnet or the magnetic conduction plate are supported directly or indirectly by using a jump spring; a trigger and a button are arranged in the shell; and the button is used for controlling the trigger to support or release the permanent magnet and controlling the magnetic conduction plate to get far away from or close to the lower shell. The safe magnetic glass wiping device can be used for wiping various types of glass of different thicknesses, is convenient to use, is very safe, and does not hurt hands.

Owner:刘忠臣

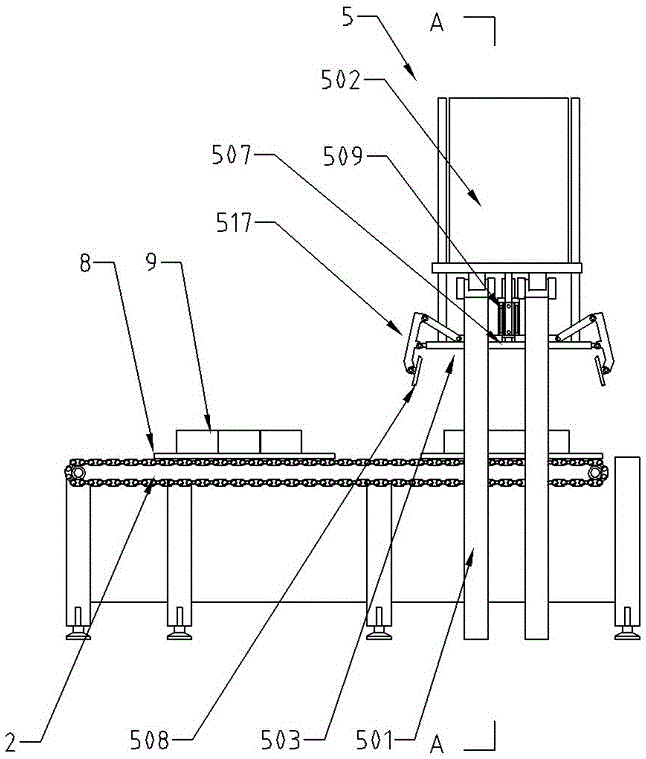

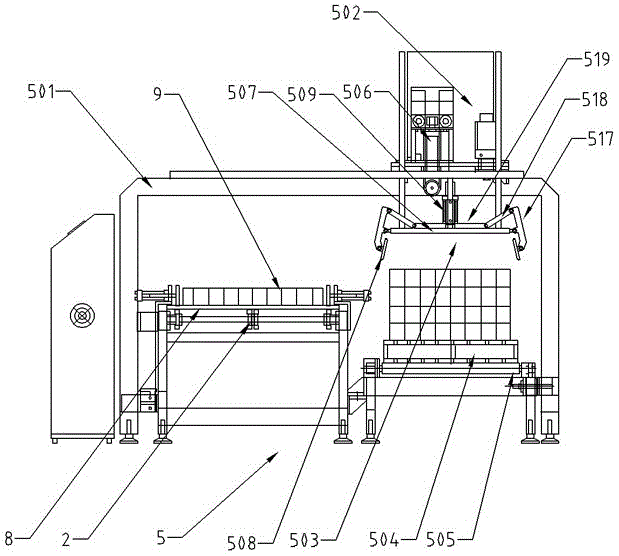

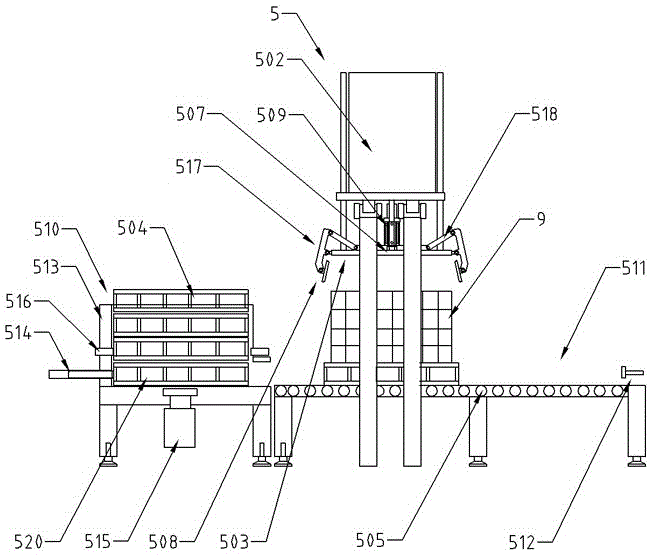

Automatic stacking device of brick machine

InactiveCN106516777ANot easy to collapseEasy to produceStacking articlesDe-stacking articlesBrickEngineering

The invention relates to an automatic stacking device of a brick machine. The automatic stacking device consists of a portal frame, a transverse trolley, a mechanical hand and a stacking transferring device, wherein a rack feeder, a stacking transferring plate and a roller conveying line are arranged in the stacking transferring device; the portal frame stretches across the two sides of the roller conveying line and the two sides of a primary conveying line; the transverse trolley can be driven by a rack in a servo mode to operate on a bridge frame rail of the portal frame back and forth; and an up-down lifting mechanism is arranged on the transverse trolley. The automatic stacking device is high in degree of automatic production; and stacked bricks are orderly, and are not liable to collapse.

Owner:HUNAN HENGSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Rotating joint and game surrounding bed with rotating joint

The invention discloses a rotating joint. The rotating joint comprises a first surrounding pipe and a second surrounding pipe, a joint shell rotationally connected with the first surrounding pipe through a first rotating shaft and rotationally connected with the second surrounding pipe through a fourth rotating shaft, and a locking mechanism for interlocking the first surrounding pipe, the second surrounding pipe and the joint shell, wherein limiting grooves and lock pin limit positioning grooves are formed in the left and right parts of the side surface of the joint shell; limiting pins are embedded in the limiting grooves; lock pins of the second surrounding pipe are embedded in the lock pin limit positioning grooves. The rotating joint is characterized in that the locking mechanism comprises a first locking dog in sliding arrangement with the first surrounding pipe in the length direction of the first surrounding pipe, and a second locking dog arranged on the second surrounding pipe; the lock pins of the second surrounding pipe are arranged in the lock pin limit positioning grooves of the joint shell; transverse extension grooves extend from the upper ends of the lock pin limit positioning grooves. The rotating joint enables the first surrounding pipe and the joint shell not to form the seaming state, so that a cloth cover covered on the outer layer is protected from being damaged through clamping.

Owner:SHANGHAI DAAFU BABY CARRIER

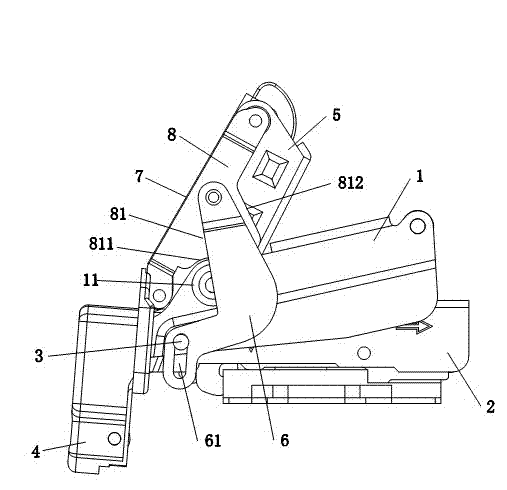

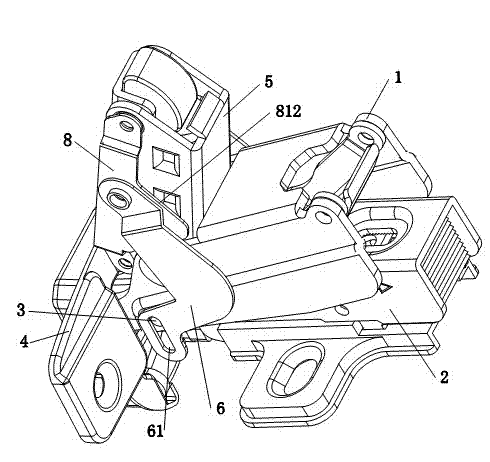

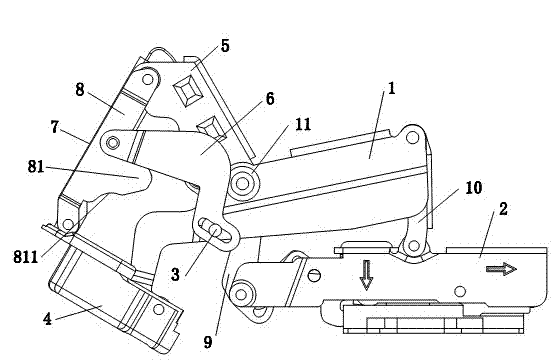

165-degree door hinge

The invention relates to a 165-degree door hinge, which comprises an inner rocker arms, a hinge cup, a crank, a connecting arm, a body, a rotating arm and an outer rocker arm, wherein the hinge cup is fixedly arranged on a door panel; the body is arranged on a framework; one end of the inner rocker arm is rotatablely connected with the hinge cup; the other end of the inner rocker arm is rotatablely connected with one end of the crank; the other end of the crank is rotatablely connected with the middle end of the connecting arm; one end of the connecting arm is rotatablely connected with the hinge cup; the other end of the connecting arm is rotatablely connected with one end of the outer rocker arm; the other end of the outer rocker arm is rotatablely connected with the middle part of the body; one end of the rotating arm is rotatablely connected with the middle part of the connecting arm; and the other end of the rotating arm is rotatablely connected with one end of the body. The 165-degree door hinge is characterized by also comprising two anti-pinch rotating arms capable of blocking an included angle between the inner rocker arm and the crank; the two anti-pinch rotating arms are bent; one ends of the two anti-pinch rotating arms are respectively matched and rotatablely connected with the outer side of the middle part of the inner rocker arms; and the other ends of the two anti-pinch rotating arms are matched and rotatablely connected with the outer side of the middle part of the connecting arm. The 165-degree door hinge has the advantages that as the two anti-pinch rotating arms and two anti-pinch blocks are arranged, the space of the included angle between the inner rocker arm and the crank is reduced; fingers cannot be pinched and the functional condition of the product is not influenced; and the use is safer and more reliable.

Owner:GUANGDONG ZHONGQIAO HARDWARE & ELECTRICAL

Safe multi-gear magnetic force glass-wiping device

The invention provides a safe multi-gear magnetic force glass-wiping device, which mainly comprises a casing consisting of an upper cover and a lower casing, a permanent magnet, a magnetic conducting plate, a rubber scrapping plate, hair felt, a rope and buckles. The safe multi-gear magnetic force glass-wiping device is characterized in that a jumping-off spring is arranged between the casing and the permanent magnet and the magnetic conducting plate, the permanent magnet and the magnetic conducting plate slide along a guide slide way in the casing, a trigger and a button are arranged in the casing, and the button controls the trigger to support or release the permanent magnet and the magnetic conducting plate to be far away or close to the wiping surface of the lower casing. The safe multi-gear magnetic force glass-wiping device can wipe various glass with different thickness in a double-faced mode, is rapid in gear shifting, convenient to use and very safe, and does not clamp and hurt fingers.

Owner:刘忠臣

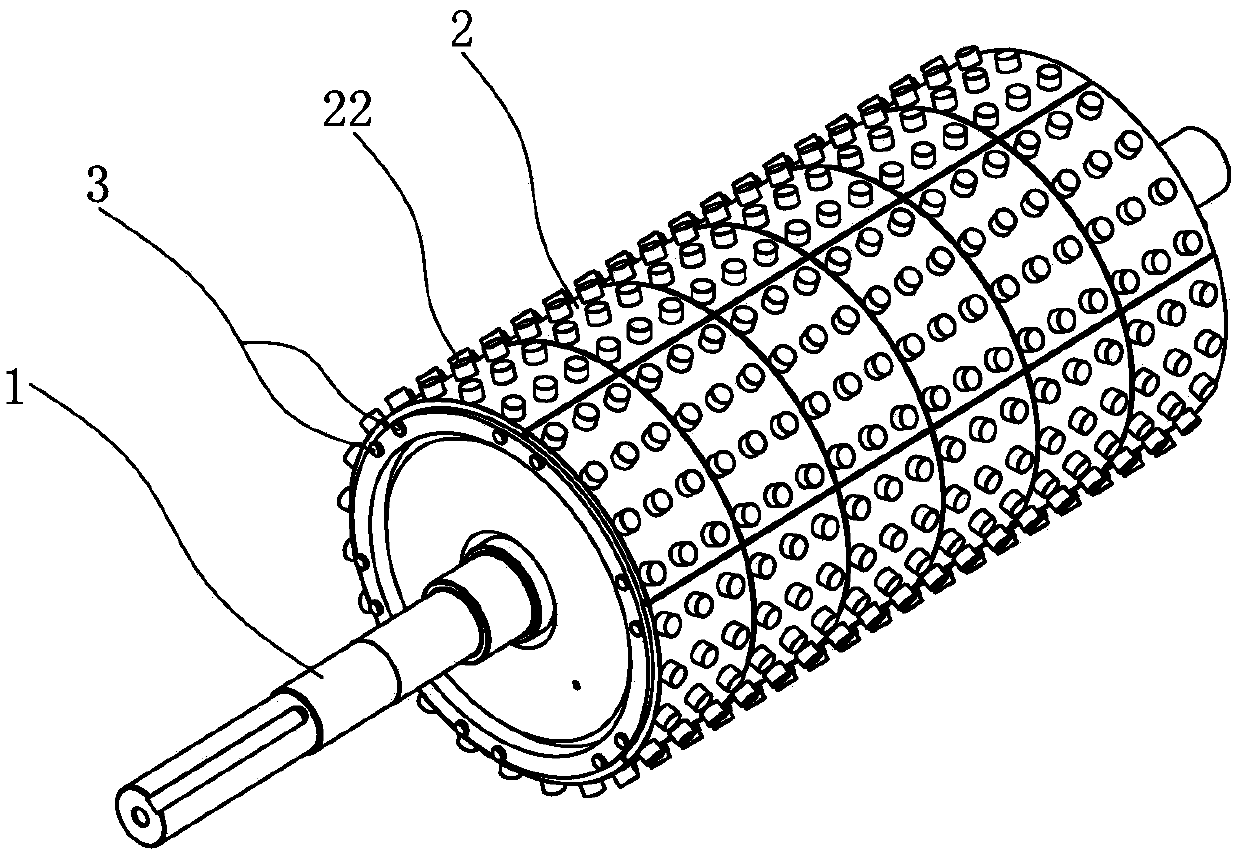

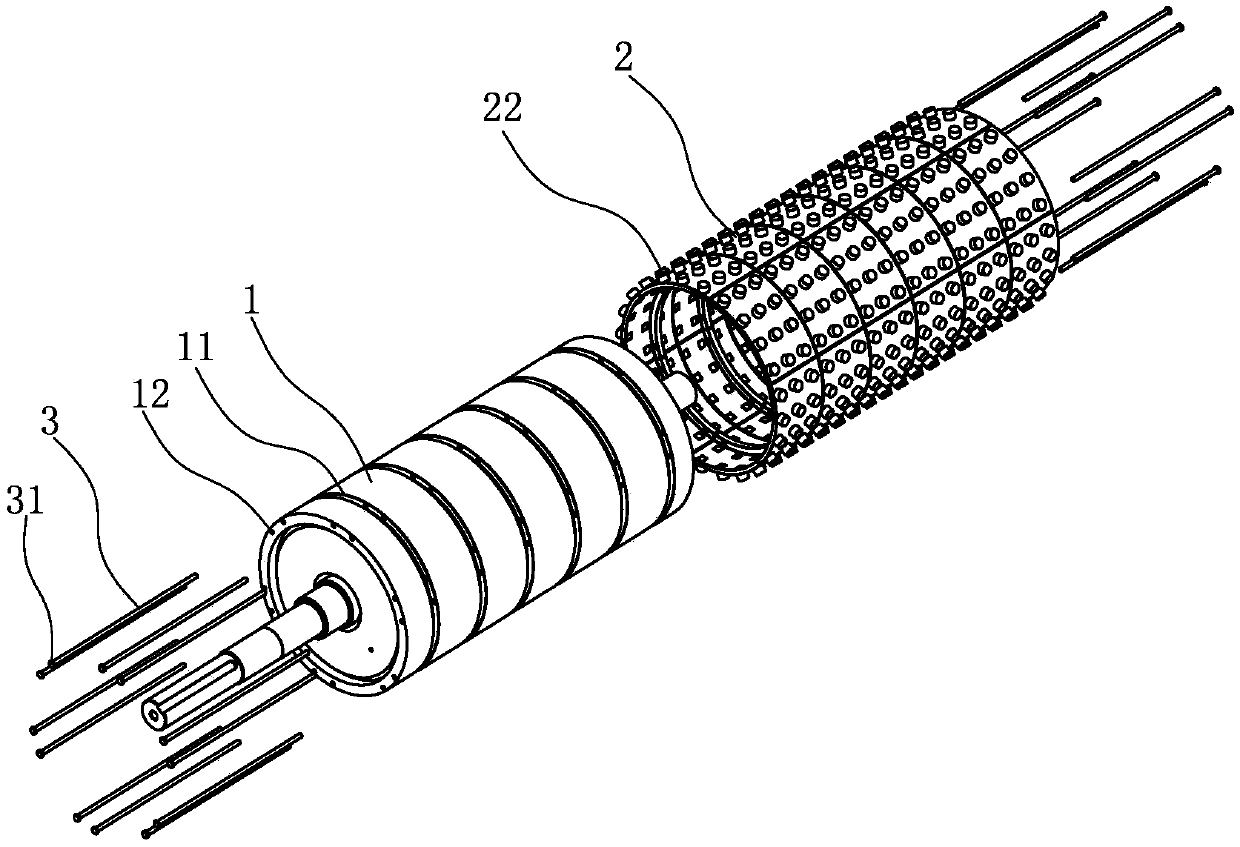

A crushing roller and an arrangement and combination method of crushing teeth of the crushing roller

PendingCN109529999AGuaranteed breakageReduce use costGrain treatmentsLocking mechanismPulp and paper industry

Disclosed are a crushing roller and an arrangement and combination method of crushing teeth of the crushing roller. The crushing roller includes a roller body and multiple tooth plates detachably arranged on the roller body. Each tooth plate includes a bottom plate and multiple crushing teeth detachably arranged on the bottom plate. Each bottom plate is provided with multiple mounting holes used for mounting the crushing teeth. Each crushing tooth includes a working part and a connecting part capable of being embedded into the corresponding mounting hole. A locking mechanism is arranged between each connecting part and the corresponding mounting hole. The crushing teeth are detachably arranged on the bottom plates through the cooperation of the mounting holes, connecting parts and lockingmechanisms. When the crushing teeth are damaged, only the damaged crushing teeth are replaced without replacing the whole tooth plate or replacing the whole crushing roller, thereby greatly reducing the use cost, reducing resource waste, and ensuring the crushing of a recycled asphalt mixuture.

Owner:FUJIAN TIETUO MACHINERY

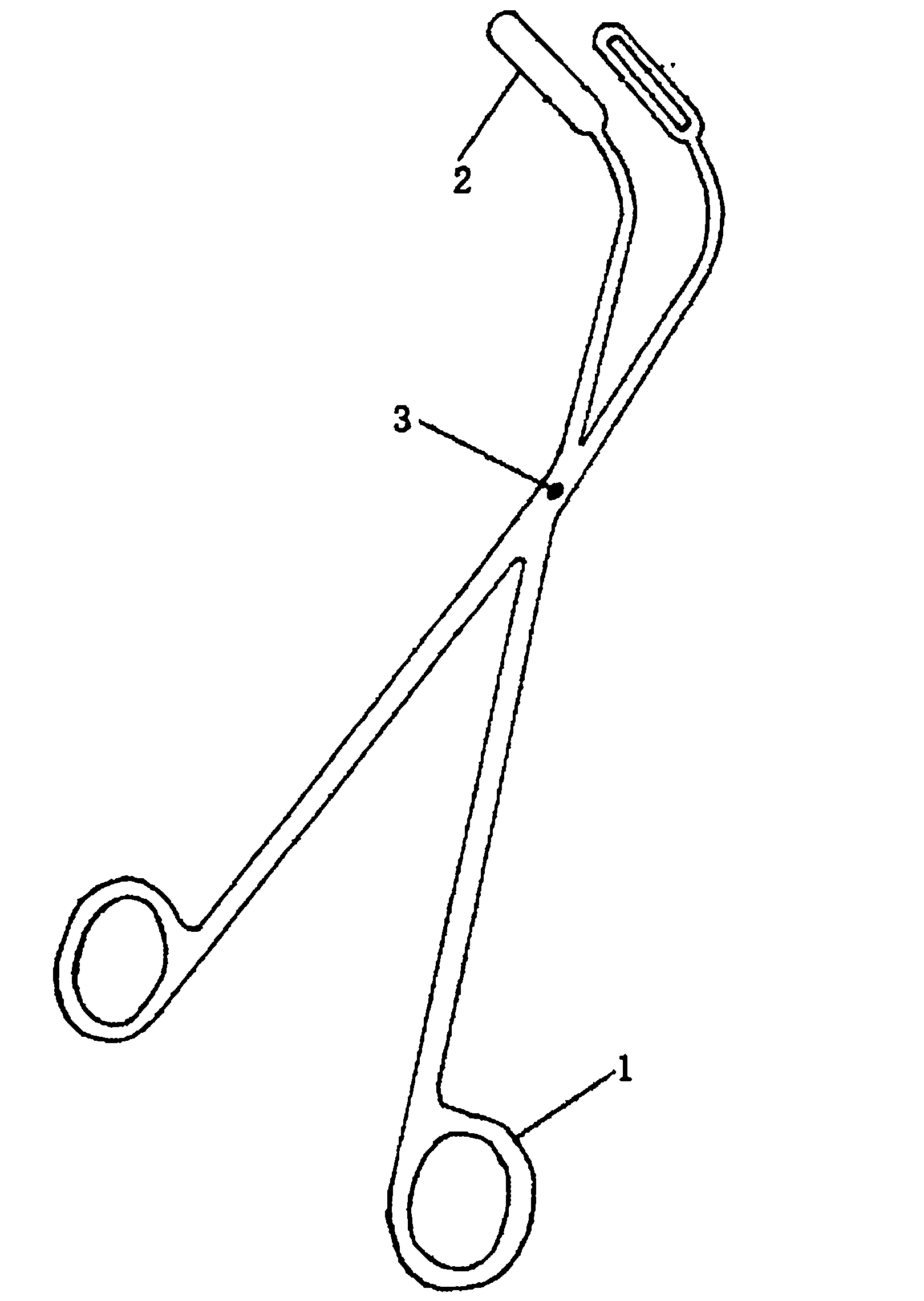

Tongs used for taking vessel cancer embolus

The invention discloses tongs used for taking vessel cancer embolus. The tongs used for taking the vessel cancer embolus comprise a handle and a tong body. The handle is connected with the tong body in a pivot-rotating mode through a connection shaft. The tong body is in a semi-oval spherical shape. Compared with the prior art, the tongs used for taking the vessel cancer embolus have the advantages of being simple in structure, convenient to use, good in vessel cancer embolus taking effect due to the fact that the vessel cancer embolus can not be damaged when clamped, capable of reducing surgical risk, easy to clean during a surgery, and capable of reducing the implantation metastasis probability of iatrogenic tumor.

Owner:XIAN JIAOTONG UNIV JINGSHENG SCI & TECH DEV

Intelligent fragile product clamping tool

The invention discloses an intelligent fragile product clamping tool. The intelligent fragile product clamping tool comprises a fixed jaw, a movable jaw, a rubber pad, a pressure sensor, an ultrasonicsensor, a jaw vice guide rail, a stepping motor, a screw sliding table, a clamping support, a rotating shaft, a rotating shaft outer sleeve, a fixed support, an adjustable fixed screw, an adjustablescrew, an elastic screw, a limiting plate and a movable limiting device. The fixed jaw, the movable jaw, the rubber pad, the pressure sensor, the ultrasonic sensor, the stepping motor, the screw sliding table, the jaw vice guide rail, the clamping support, the rotating shaft, the rotating shaft outer sleeve, the fixed support, the adjustable fixed screw, the adjustable screw, the elastic screw, the limiting plate and the movable limiting device are connected in sequence from top to bottom to form a whole. Pre-tightening force is intelligently adjusted, so that fragile products cannot be brokendue to clamping, 360-degree non-dead-corner rotation is achieved, the object fixing range is widened, and more aspects are obviously improved compared with a previous clamping device.

Owner:HUNAN ELECTRICAL COLLEGE OF TECH

Rapid pressing device for mechanical manufacturing equipment

PendingCN114770161AWon't pinchQuick clampingWork clamping meansPositioning apparatusMachine buildingGear wheel

The invention provides a rapid pressing device for mechanical manufacturing equipment, and relates to the field of machining tools. The rapid pressing device for the mechanical manufacturing equipment comprises a support, a movable groove is formed in the position, close to the center, of the upper end face of the support, a sliding rod and a two-way lead screw are arranged at the inner end of the movable groove, the two ends of the sliding rod are fixedly connected to the side wall of the movable groove correspondingly, one end of the two-way lead screw is rotationally connected to one side wall of the movable groove, and the other end of the two-way lead screw is rotationally connected to the other side wall of the movable groove. And the outer end of the two-way lead screw is fixedly sleeved with a first gear, and a motor is fixedly arranged on the portion, close to the first gear, of the outer wall of the support. According to the pressing device designed by the invention, the plate-shaped workpiece can be automatically and quickly clamped through the control of the pressure sensor, manual operation is not needed, the device is convenient and quick, and meanwhile, the device can also be used for pressing and fixing the upper ends of the plate-shaped workpieces with different thicknesses.

Owner:SHANDONG POLYTECHNIC COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com