Multifunctional glass cup making machine

A glass, multi-functional technology, applied in the field of mechanical equipment, to achieve the effect of fast speed, cost reduction and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

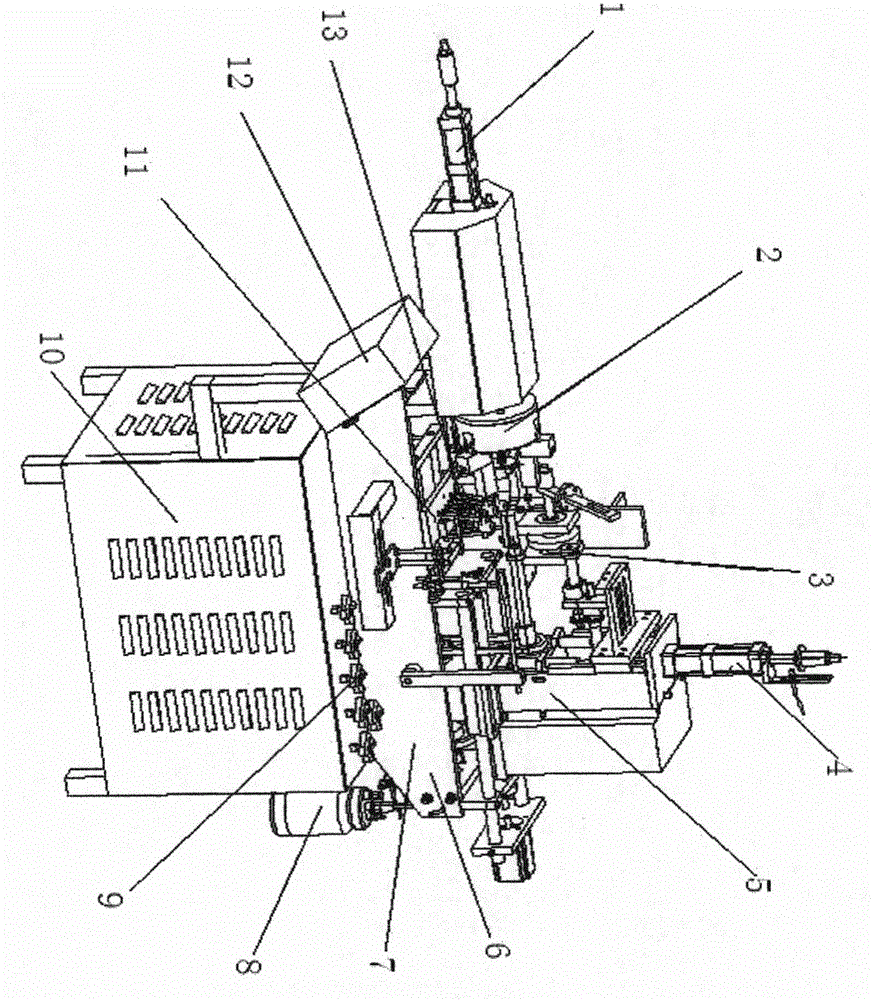

[0014] exist figure 1Among them, the power box 10 is made of angle iron and iron sheet, and heat dissipation holes are arranged on the iron sheet, and the frame 7 is made of iron plate and square iron, and the right side of the frame 7 is provided with a machine head 5, which is pressed with a Front vertical cylinder 4 and embossing die 3, in the middle part of frame 7, there are iron plate 6, fuel injection frame, burner 13 and horizontal dragging device 11, and there are automatic chuck 2 and horizontal adjustable on the left side of frame. Cylinder 1, presses the switch 9 that has liquefied petroleum gas in the upper middle part of power box 10, is placed with oil storage tank 8 on the right side, is pressed with microcomputer 12 on the left side. The top of frame 7 is welded with square iron, long fixed plate and support plate, is welded with two small guide rods between square iron and support plate, is pressed with small linear slider on the small guide rod, between two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com