Intelligent fragile product clamping tool

A technology for clamping tooling and fragile products, applied in the field of tooling fixtures, can solve the problems of large damage to human glasses, slow jaw opening and closing speed, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

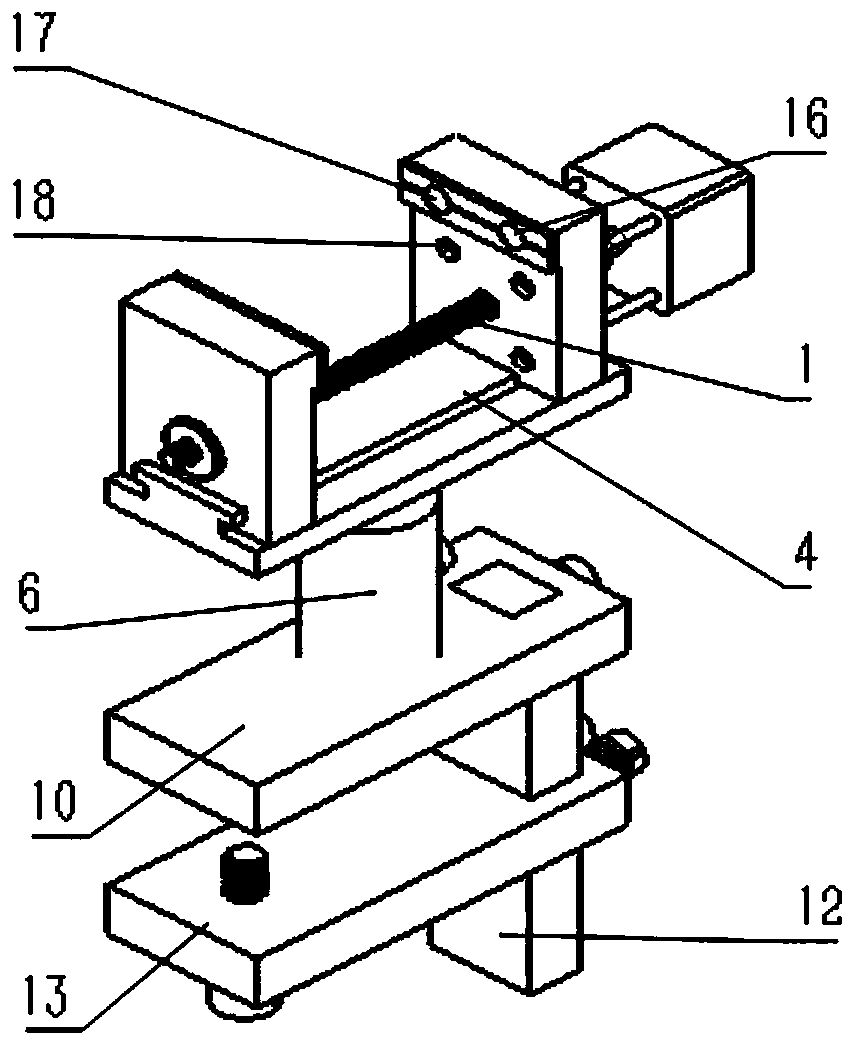

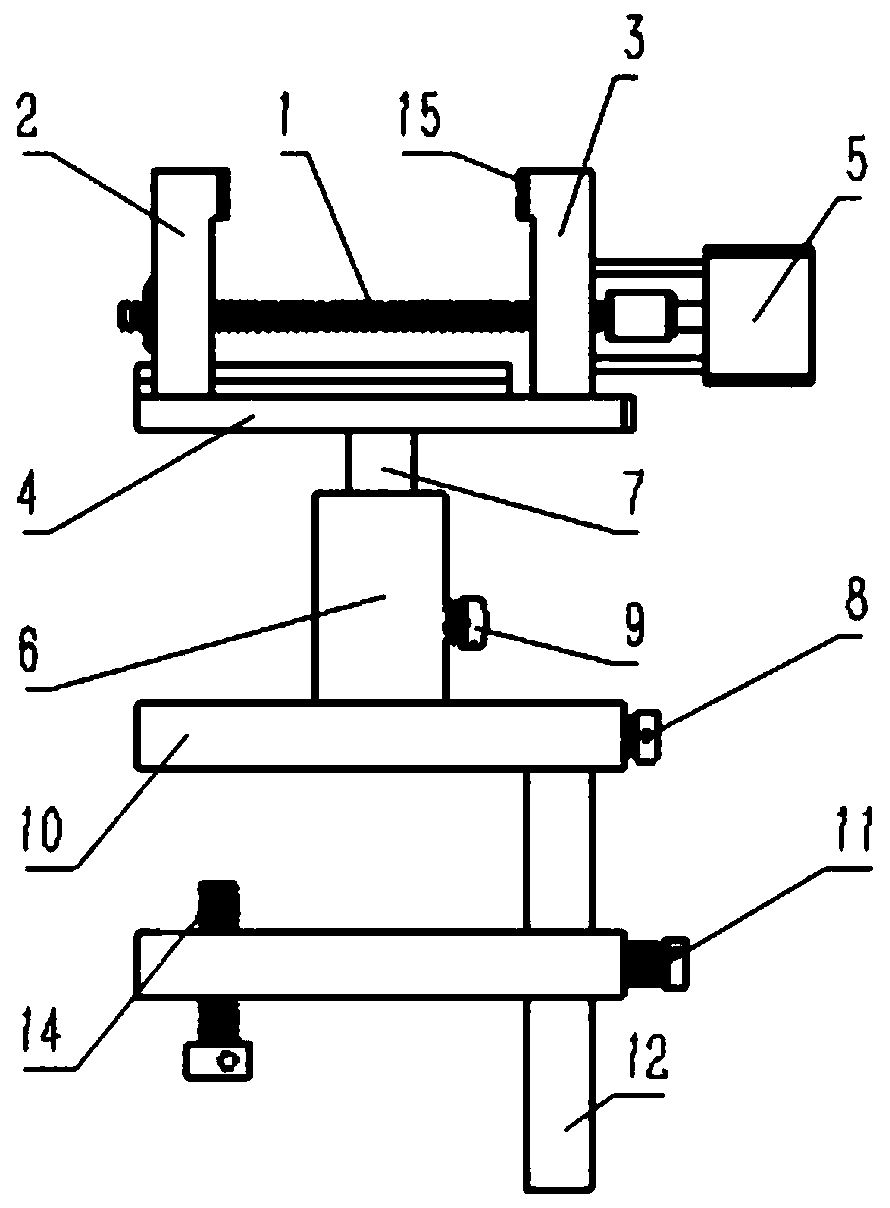

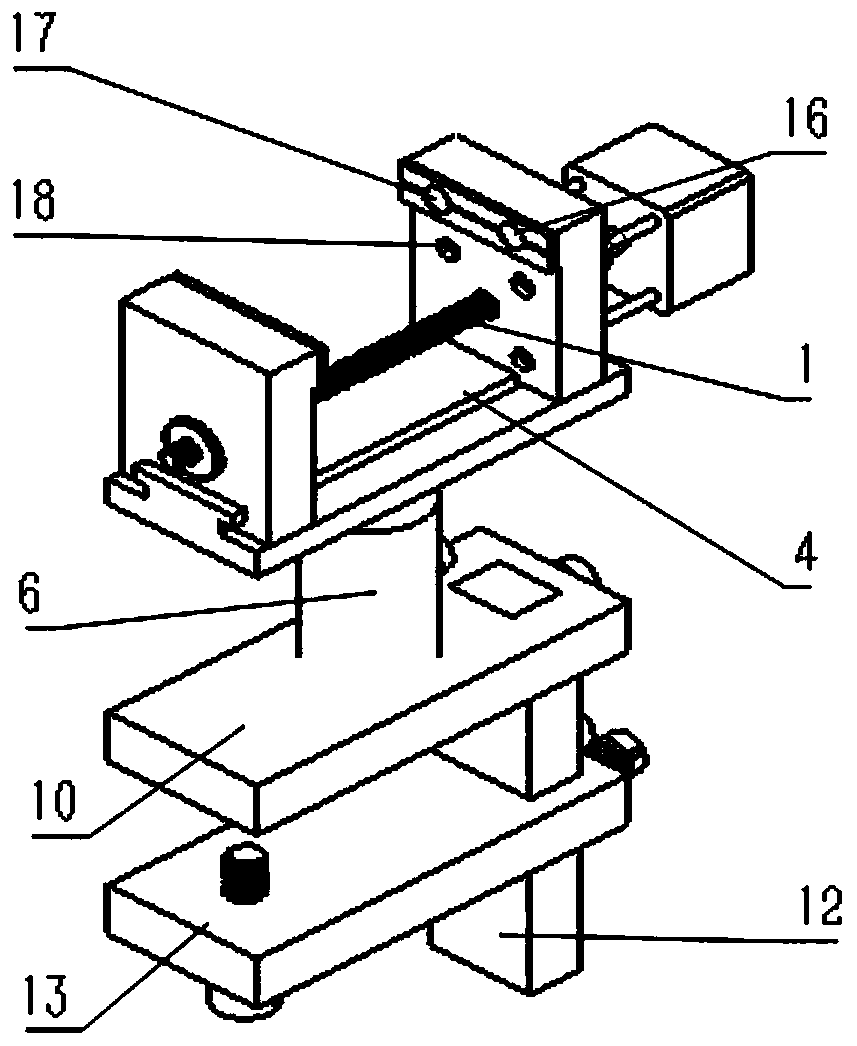

[0019] The present invention will be further described in conjunction with the above accompanying drawings.

[0020] An intelligent clamping tool for fragile products, the clamping tool includes fixed jaws (3), movable jaws (2), rubber pads (15), pressure sensors (16), ultrasonic sensors (17), vise guide rails (4), stepping motor (5), screw slide (1), rotating shaft (7), rotating shaft outer casing (6), fixing bracket (12), adjustable fixing screw (8), adjustable screw ( 14), limiting plate (10) and movable limiting device (13).

[0021] The positions of the fixed jaws (3) and the movable jaws (2) are corresponding, and the fixed jaws (3) and the vise guide rail (4) are tightly connected; the bottom of the vise guide rail (4) is connected to the rotating shaft ( 7) Connection; the movable jaw (2) is installed on one side of the guide rail (4) of the guide rail vise, the movable jaw (2) and the guide rail of the guide rail vise (4) are slidingly fitted, and the fixed jaw (3) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com