Rapid pressing device for mechanical manufacturing equipment

A technology of mechanical manufacturing and pressing devices, which is applied in the field of quick pressing devices for mechanical manufacturing equipment, can solve the problems of complicated steps and general efficiency, and achieve the effect of easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

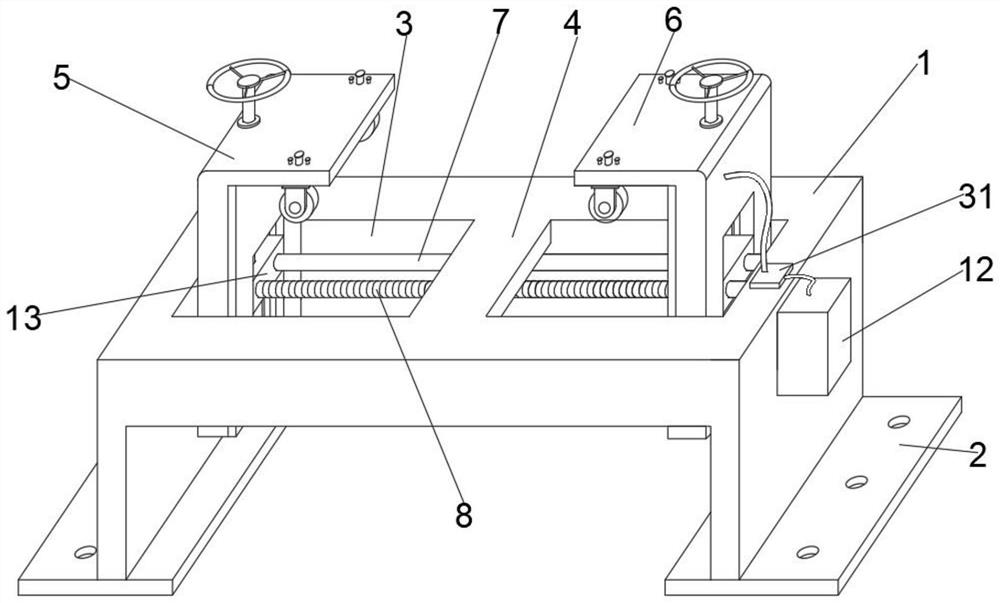

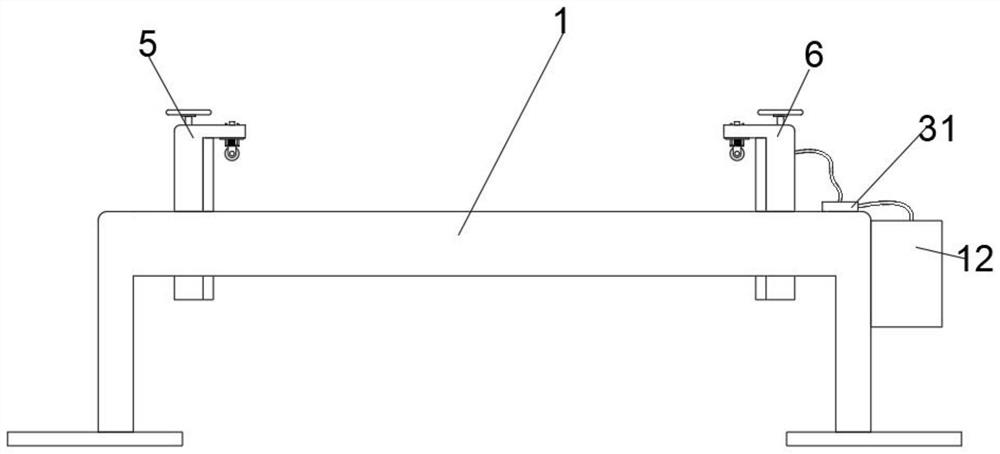

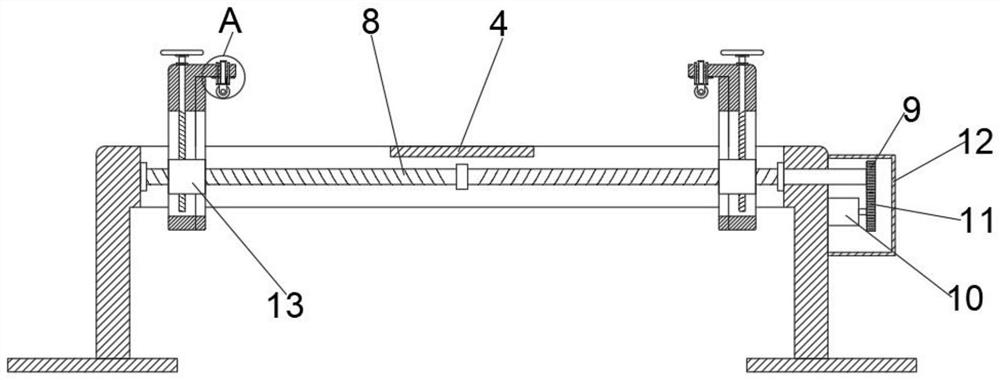

[0034] like Figure 1-7 As shown in the figure, the embodiment of the present invention provides a quick pressing device for mechanical manufacturing equipment, including a bracket 1, a bottom plate 2 is fixedly arranged on the lower ends of both sides of the bracket 1, and a number of positioning holes are opened on the plate body of the bottom plate 2 to facilitate the The device is installed and fixed on the horizontal plane, the upper end face of the bracket 1 is provided with a movable groove 3 near the center, and a support plate 4 is fixedly connected between the front and rear walls at the top of the center of the movable groove 3, and the upper end face of the support plate 4 and the bracket 1 The upper end surface is flush, this design can ensure that the workpiece to be processed can be placed on the support 1 smoothly, the inner end of the movable groove 3 is provided with a sliding rod 7 and a bidirectional screw 8, and the two ends of the sliding rod 7 are fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com