Rotating joint and game surrounding bed with rotating joint

A rotary joint and joint technology, applied in the field of rotary joints and game enclosures with the rotary joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

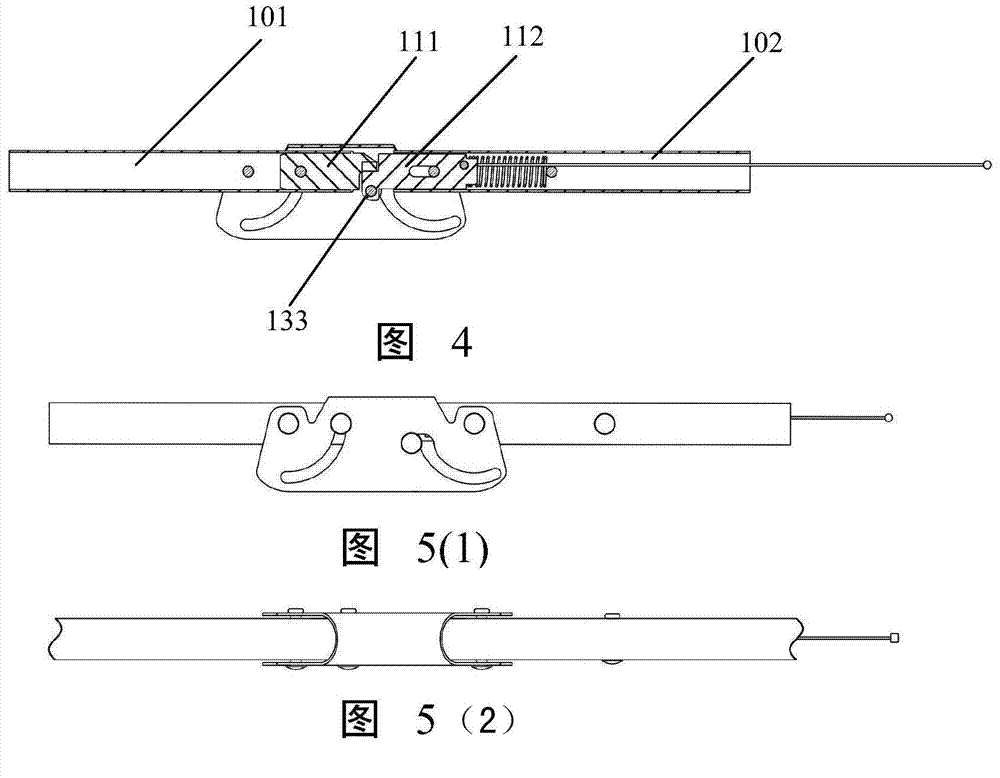

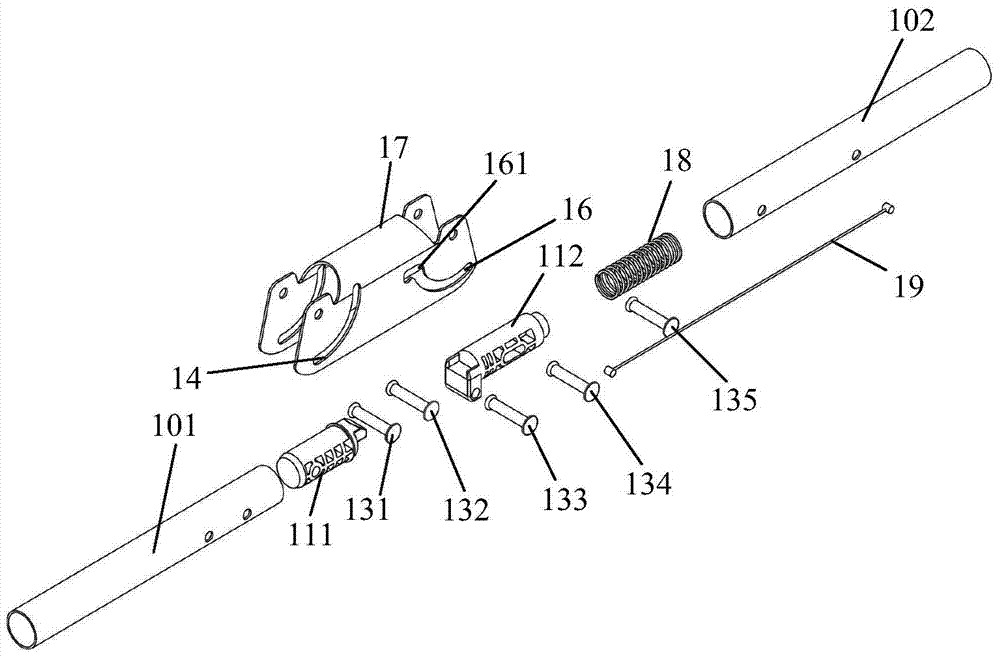

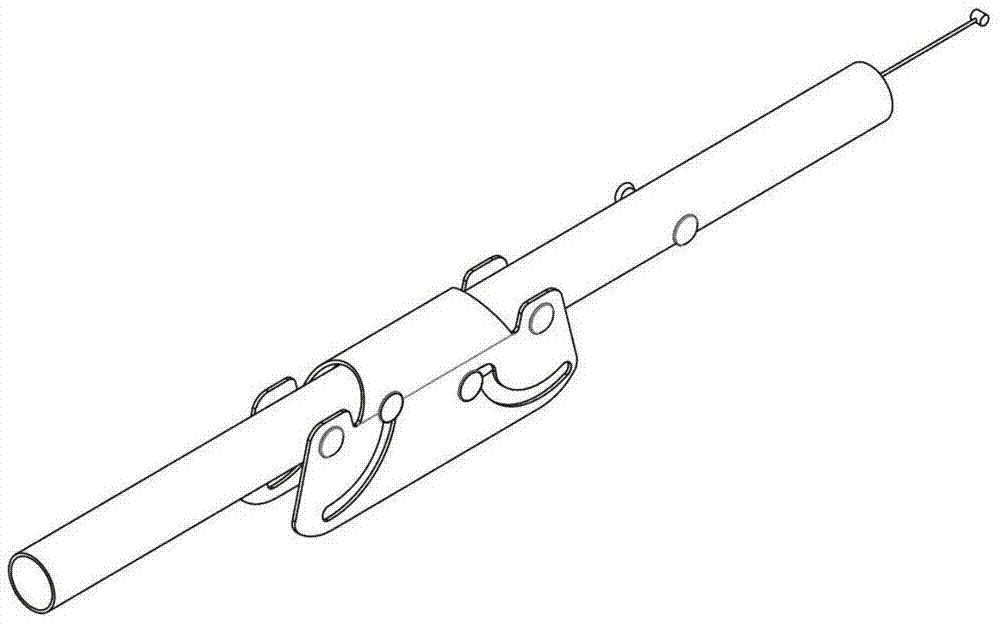

[0036] See figure 1 As shown, the rotary joint of the present invention includes a first surrounding tube 101 and a second surrounding tube 102 which are rotatably connected inside, and the two surrounding tubes are movably connected through a joint shell 17. The positioning groove 14 and a locking pin define the positioning slot 16, and cooperate with the first locking pin 131 and the fourth locking pin 134 to be connected with the pivots 121 and 122 of the two surrounding pipes through two pin holes, and the limiting pin 132 is embedded in the In the first limiting groove 14 , the lock pin 133 of the second surrounding tube 102 is embedded in the locking pin limiting groove 16 , thus the two surrounding tubes are movably connected through the joint shell 17 .

[0037] A first locking tongue 111 is embedded in the lumen at the end of the first surrounding tube 101, a second locking tongue 112 is slidably arranged in the lumen of the second surrounding tube 102, and a spring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com