Long-gauge-distance strain sensor high-precision calibration frame

A strain sensor, high-precision technology, applied in the field of sensing, can solve the problems of no dial gauge fixing frame, difficulty in changing the distance of the fixture, and short calibration length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

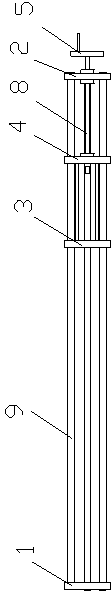

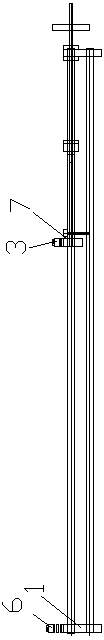

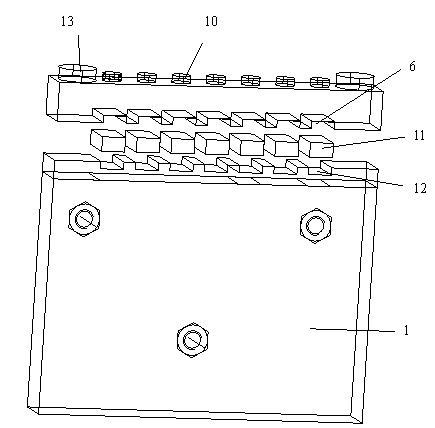

[0020] Such as figure 1 , figure 2 as well as image 3 As shown, the long gauge strain sensor calibration frame of the present invention is composed of a fixed frame, a moving mechanism, a clamping and measuring device and the like. Strain is directly applied to the long-gauge sensor to be calibrated by the precise movement of the shifting mechanism, and there will be no relative slip and strain loss that occurs in indirect methods (such as carrier methods, etc.), and the strain can be accurately measured directly through the dial gauge. , so the calibration accuracy is high.

[0021] The fixed frame is the main part of the calibration frame, and the moving mechanism, clamping and measuring devices are installed on the fixed frame. The fixed frame is composed of a front end plate 1, a rear end plate 2, three fixing rods 9 and fixing nuts; among them, the three fixing rods 9 are distributed in an isosceles triangle in space and are parallel to each other, and are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com