Automatic stacking device of brick machine

A technology of a stacking device and a brick press, which is applied in the stacking of objects, destacking, transportation and packaging of objects, etc., can solve the problems that the palletizing robot is prone to malfunction and affect production, so as to reduce occupational damage and improve The effect of working efficiency and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings and embodiments.

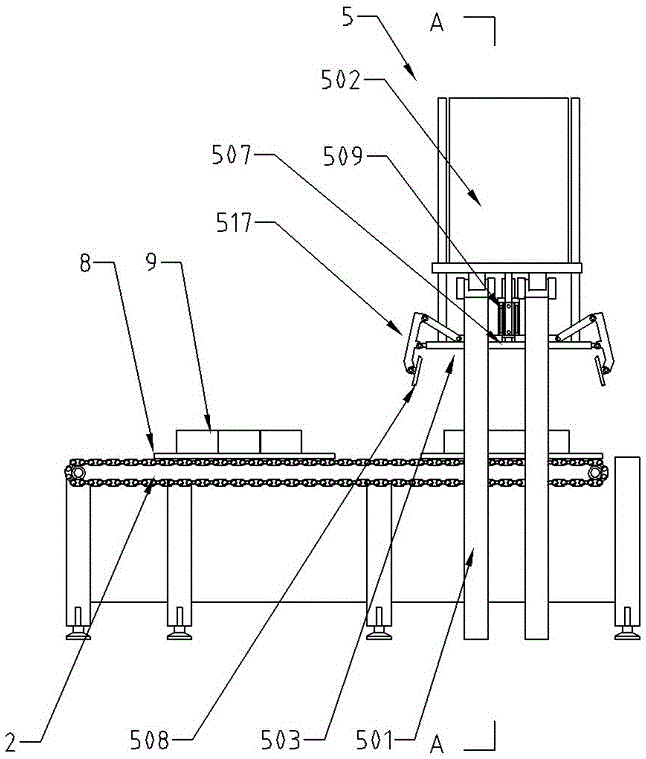

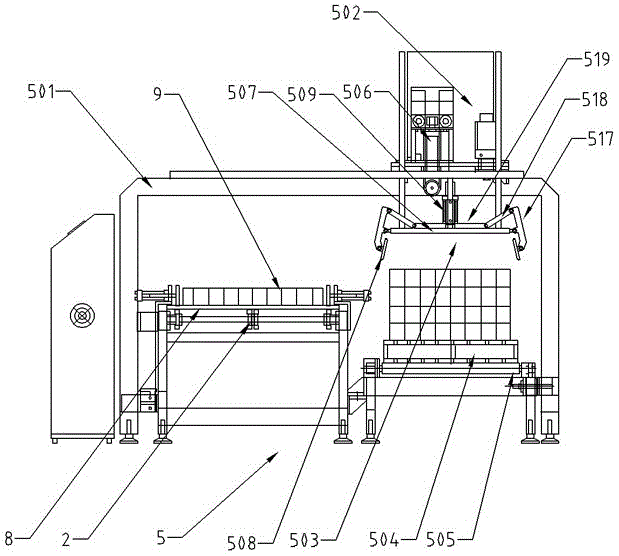

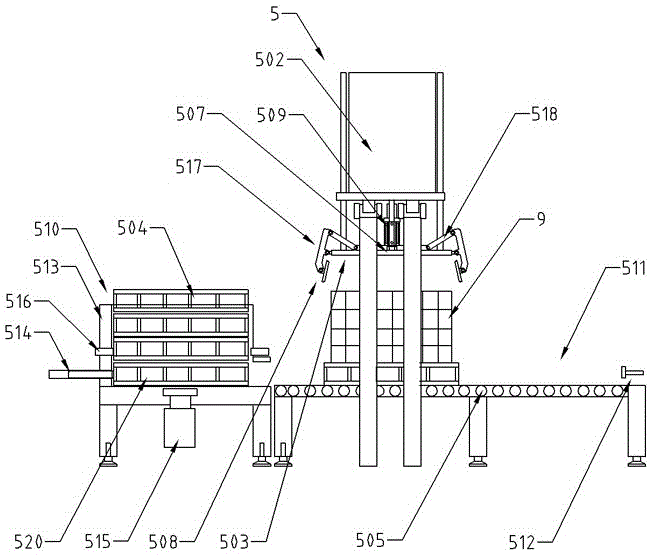

[0014] attached Figure 1-3 express

[0015] An automatic stacking device for a brick press, which is located on a main conveying line (2) behind the brick press, and consists of a gantry (501), a transverse trolley (502), a manipulator (503) and a stacking transfer device; The stack transfer device includes a rack feeder (510), a blank stack transfer plate (504) and a roller conveying line (505); the roller conveying line (505) is parallel to the main conveying line (2), and the roller conveying line (505) The overall length should be greater than the length of the three blank stack transfer plates (504) arranged; one end of the roller conveying line (505) is provided with a rack feeder (510), the other end is a transfer outlet (511), and the middle is a stacking position; Position sensors (512) are arranged on both the transfer outlet (511) and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com