LED lamp production device

A technology for producing devices and LED lamps, which is applied in the direction of turning off electric tubes/lamps, etc., which can solve the problems of small astigmatism and heat explosion of the lampshade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

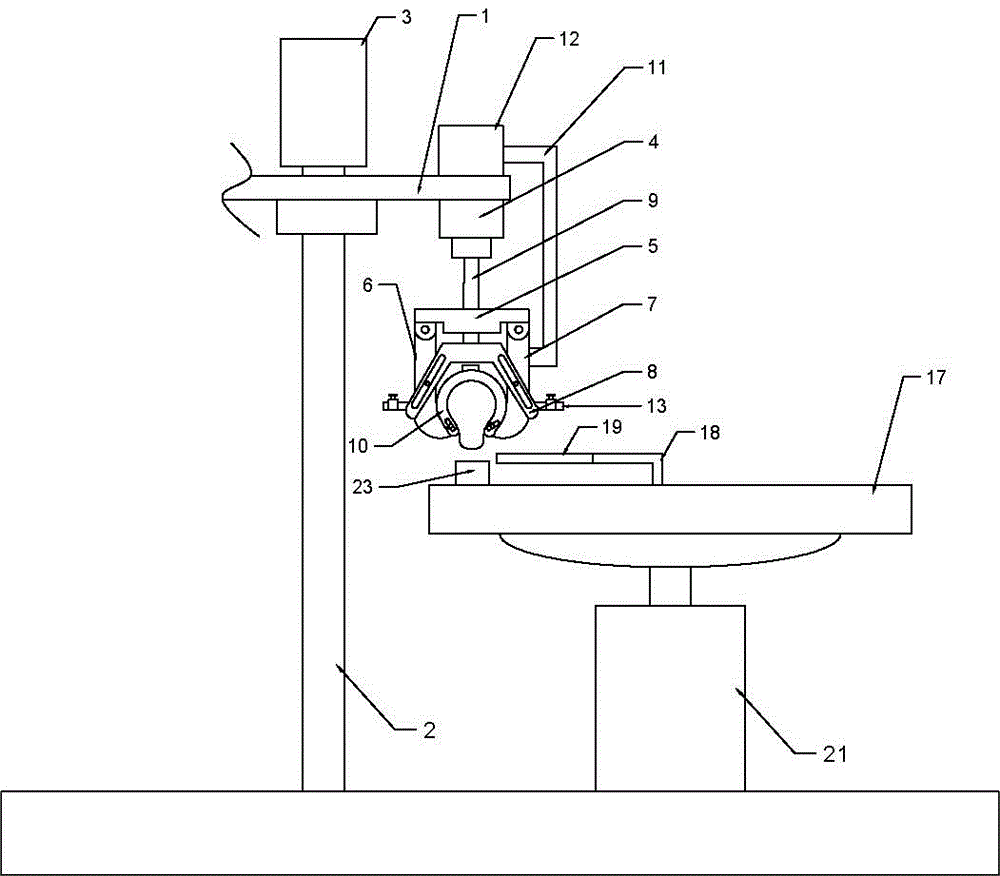

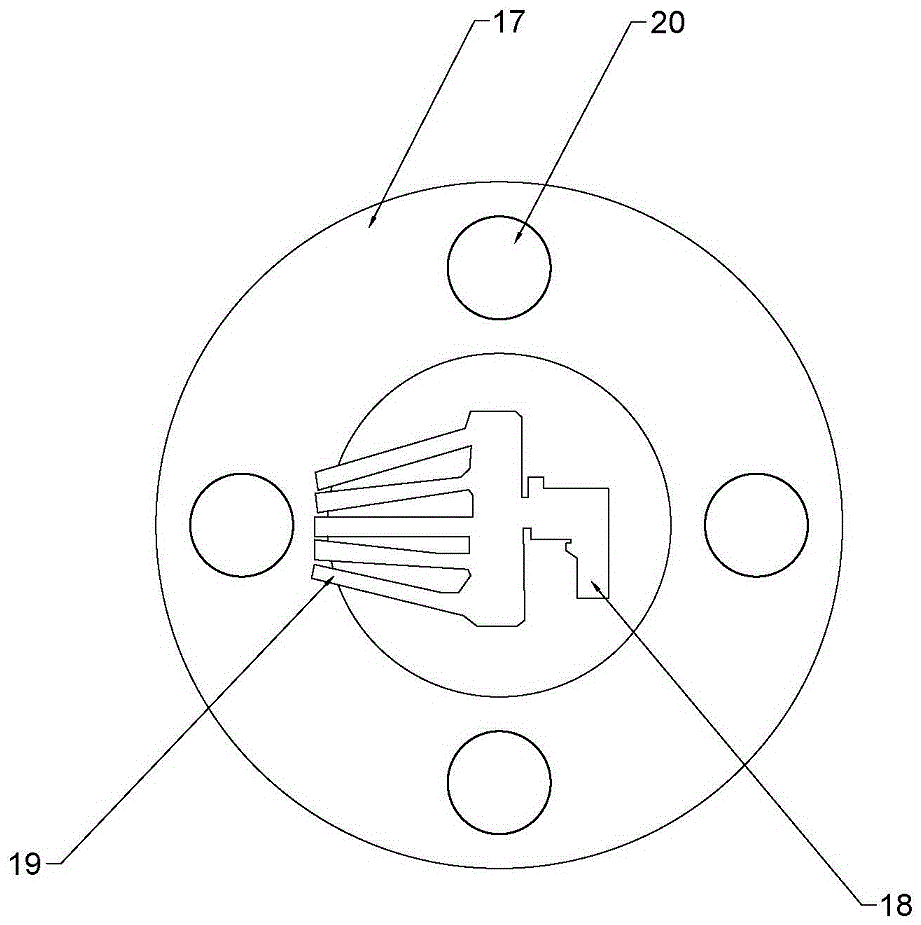

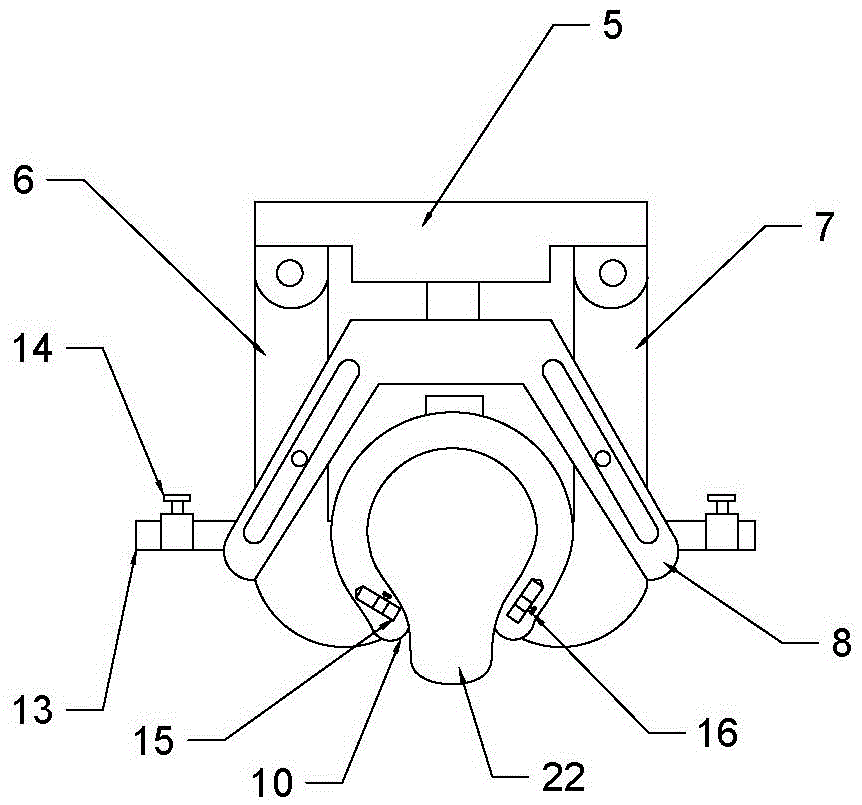

[0018] The reference signs in the drawings of the description include: cross bar 1, vertical bar 2, first stepper motor 3, cylinder 4, clamp arm frame 5, first clamp finger 6, second clamp finger 7, figure-eight slider 8 , piston rod 9, hose 10, water inlet pipe 11, constant pressure water supply device 12, water spray pipe 13, first valve 14, water nozzle 15, second valve 16, rotating disc 17, gas pipe 18, sintering nozzle 19. A wick holder 20 , a second stepping motor 21 , a lampshade 22 , and a wick 23 .

[0019] Example basic reference Figure 1-Figure 3 Shown: LED lamp sealing machine clamping device, including frame, gas pipe 18 and sintering nozzle 19, gas pipe 18 is connected with sintering nozzle 19, a rotating disk 17 is arranged on the frame, and the bottom of the rotating disk 17 is connected with a second Two stepper motors 21, four wicks 23 are provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com