Patents

Literature

34results about How to "Splash won't" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

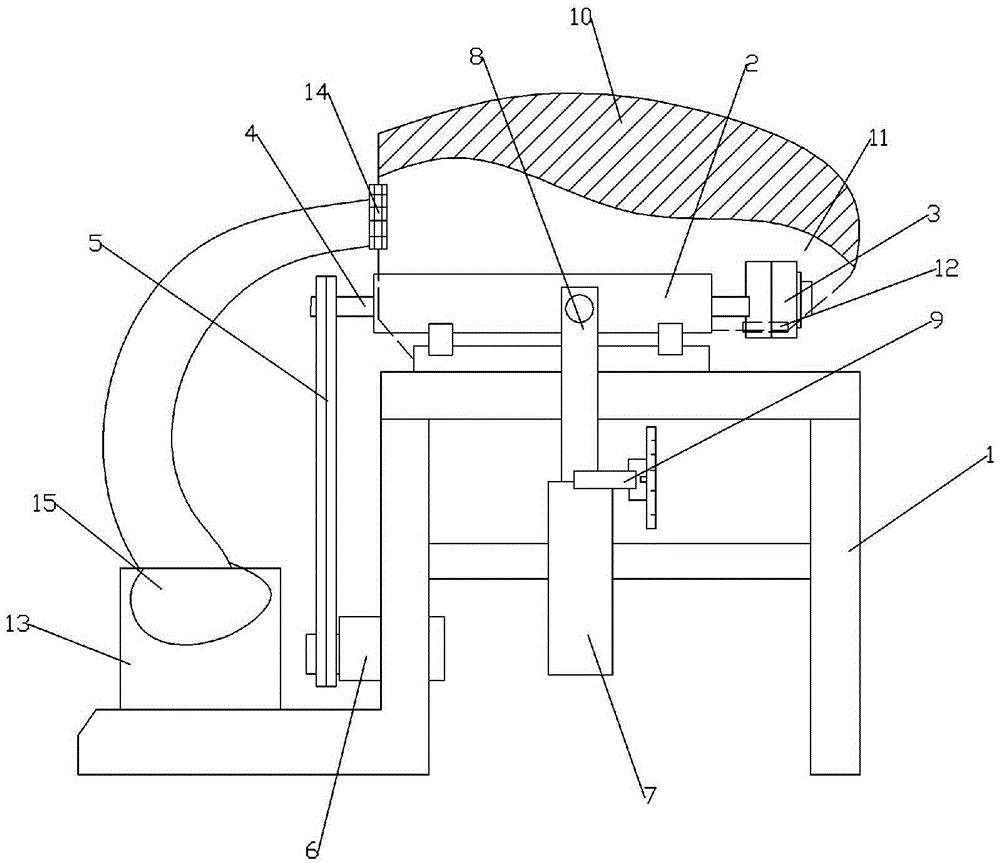

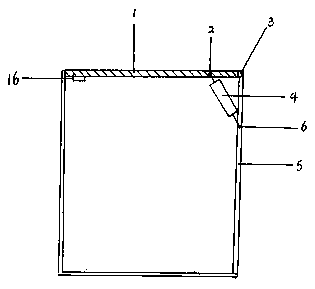

Polishing device for casting parts

InactiveCN105415129AEffective protectionEffective personal safetyEdge grinding machinesGrinding/polishing safety devicesDrive motorEngineering

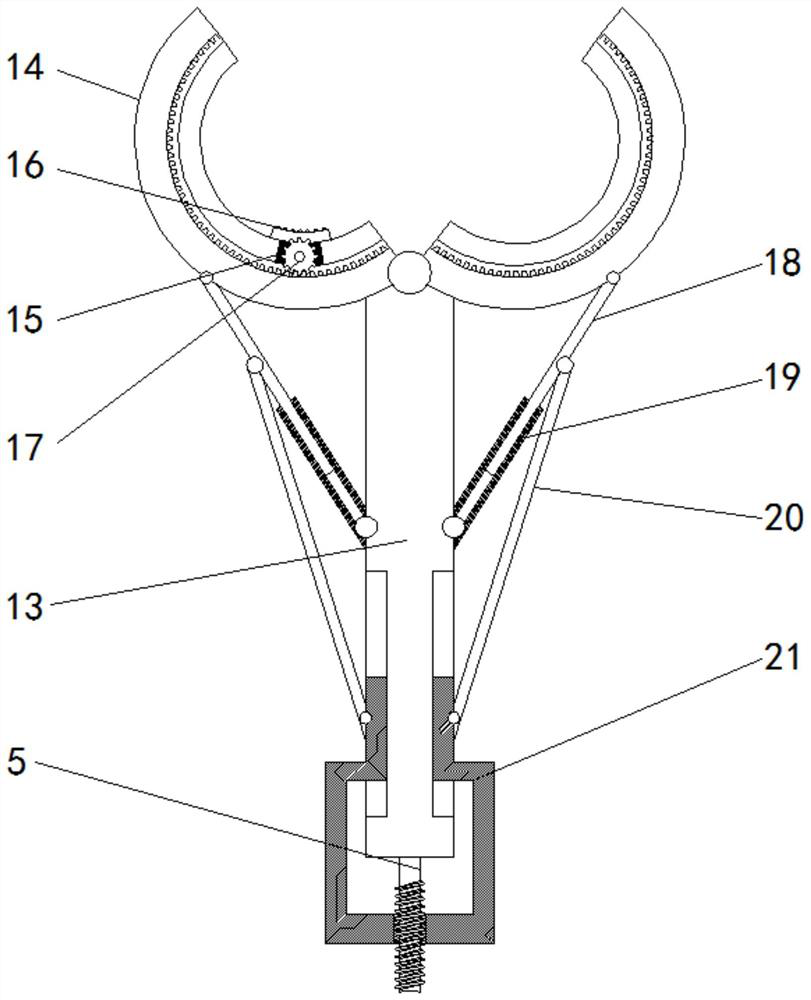

The invention discloses a polishing device for casting parts. The polishing device for casting parts comprises a rack and a grinding wheel frame arranged on the rack. A grinding wheel for polishing workpieces is arranged on the grinding wheel frame and is hinged to the grinding wheel frame through a rotating shaft. The rotating shaft is connected with a driving motor through a belt. The driving motor is installed on the rack. The rack is provided with supporting columns located below the two sides of the grinding wheel frame. Adjusting rods are arranged on the two sides of the grinding wheel frame and sleeved with the supporting columns. Adjusting bolts are arranged on the joints of the adjusting rods and the supporting columns. An arc-shaped hollow protective box is installed on the adjusting rods. A shielding part is arranged on one side of the protective box and is provided with a polishing hole which is inclined downwards, and the grinding wheel penetrates the polishing hole. By means of the polishing device for casting parts, personal safety of operators can be effectively protected, operating difficulty of the polishing device is reduced, and finished product quality is improved.

Owner:CHONGQING YU DA LIU XING POWER PLANT

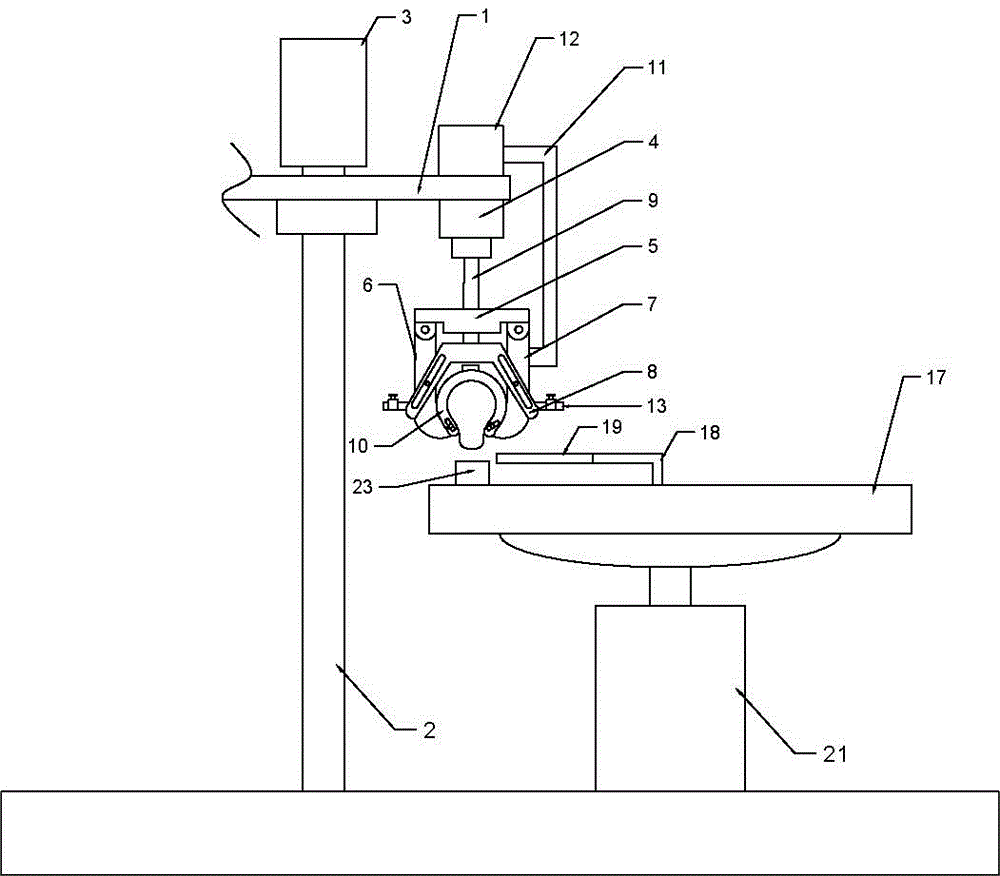

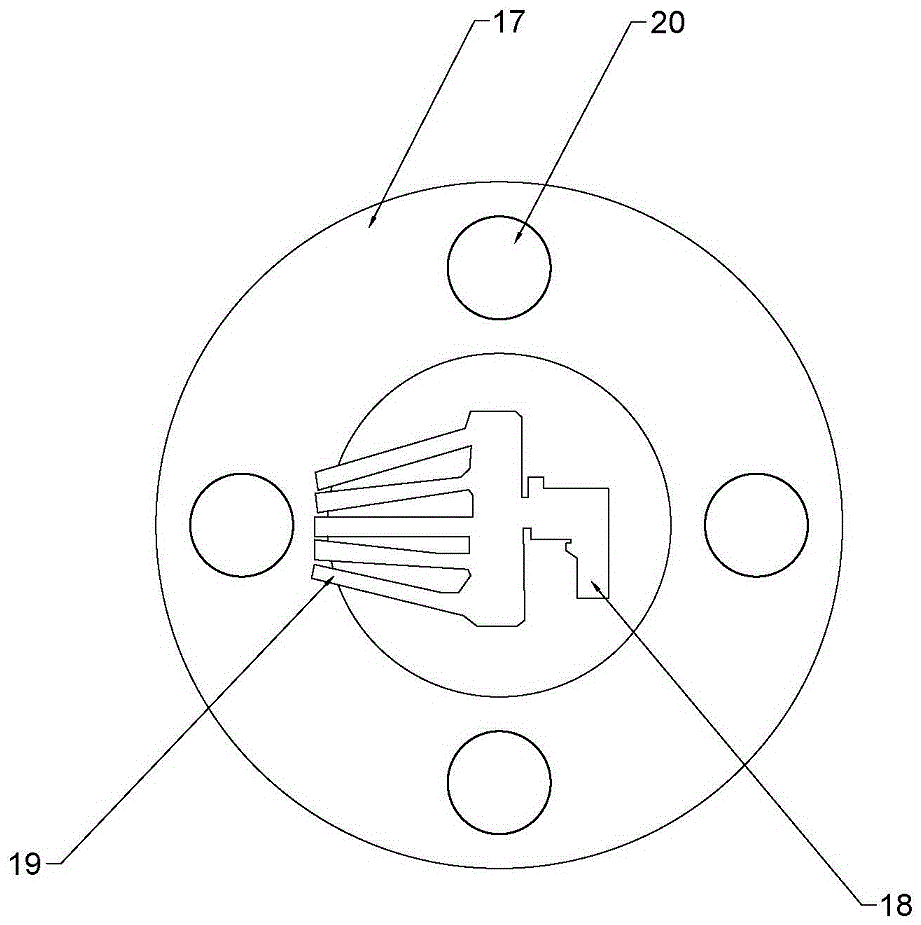

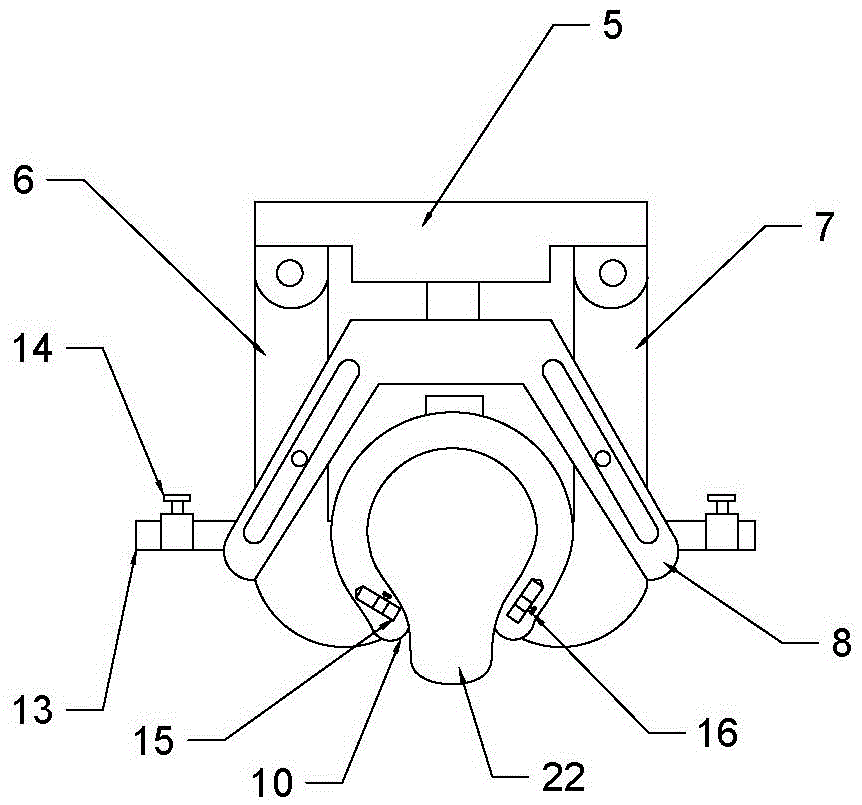

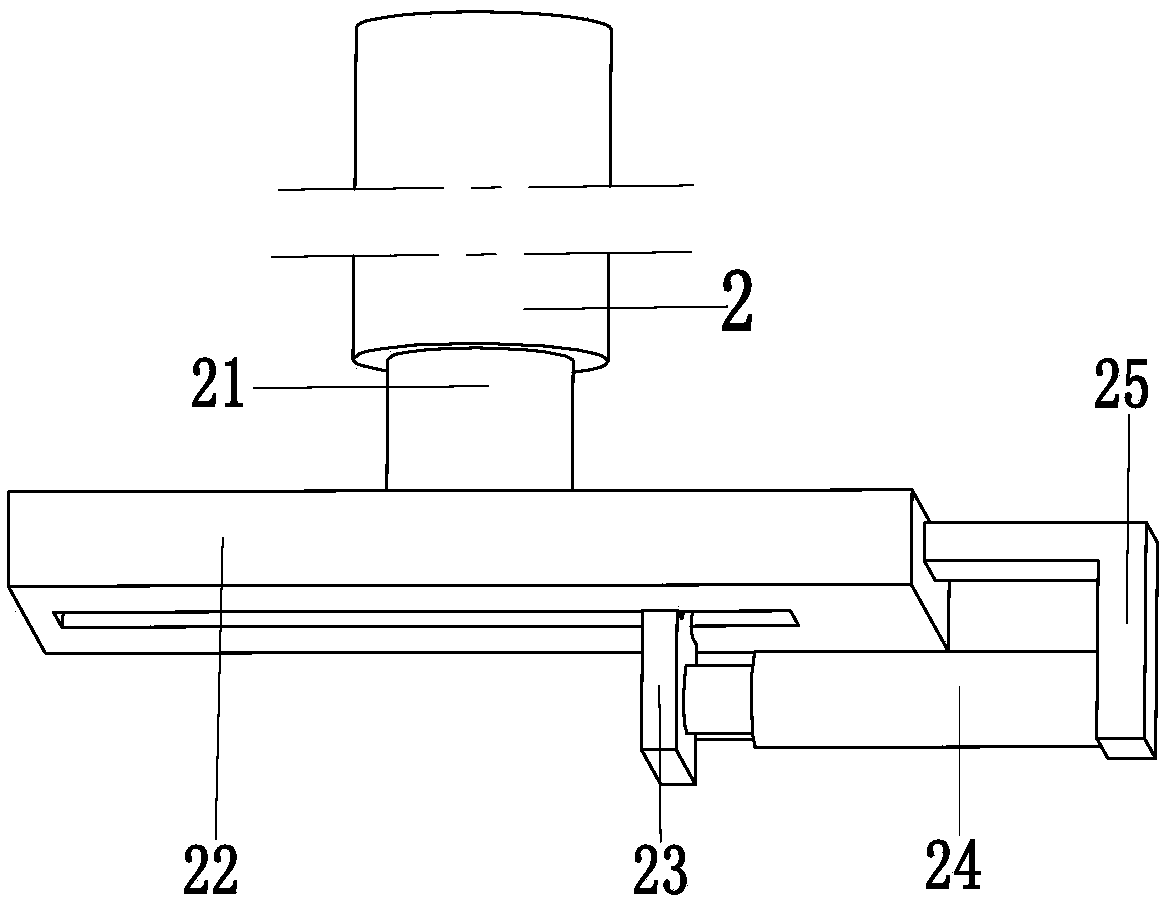

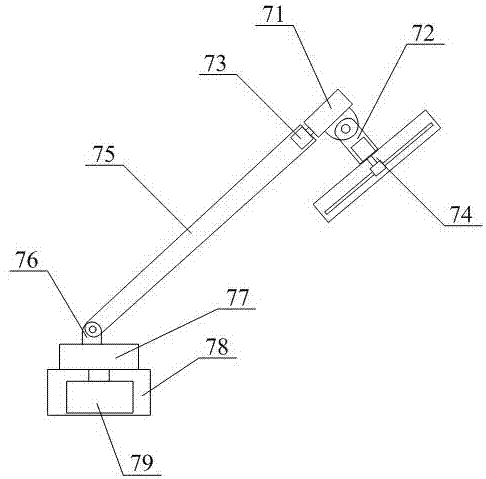

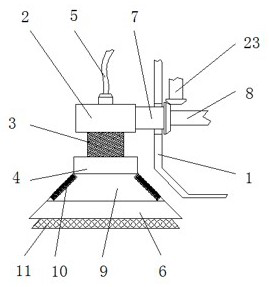

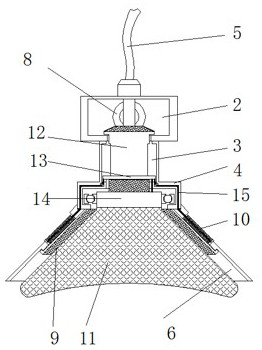

LED lamp production device

The present invention relates to the field of illuminating lamp production and discloses an LED lamp production device. The device comprises a frame, a gas pipe, and a sintering mouth. The frame is provided with a rotating disk which is provided with a plurality of wick seats. The device also comprises a cylinder which is connected to a manipulator which comprises a clamping arm frame, a first clamp finger, a second clamp finger, and a splayed sliding block. The clamping arm frame is provided with a through hole. A piston rod goes through the through hole in a sliding way. One end of the piston rod is connected to a cylinder, and the other end of the piston rod is connected to the splayed sliding block. The first clamp finger and the second clamp finger are hinged to two ends of the clamping arm frame. A water belt is connected between the first clamp finger and the second clamp finger. The water belt is connected to the inner sides of the first clamp finger and the second clamp finger. The top end of the water belt is provided with a water inlet pipe which is connected to a constant pressure water supply device. Two sides of the water belt are connected to a water-spraying pipe which goes through the clamp fingers to be connected to a first valve. Compared with the prior art, the splash of high temperature residue to a lamp cover to cause lamp cover burst can be prevented.

Owner:遵义市义阳光电有限公司

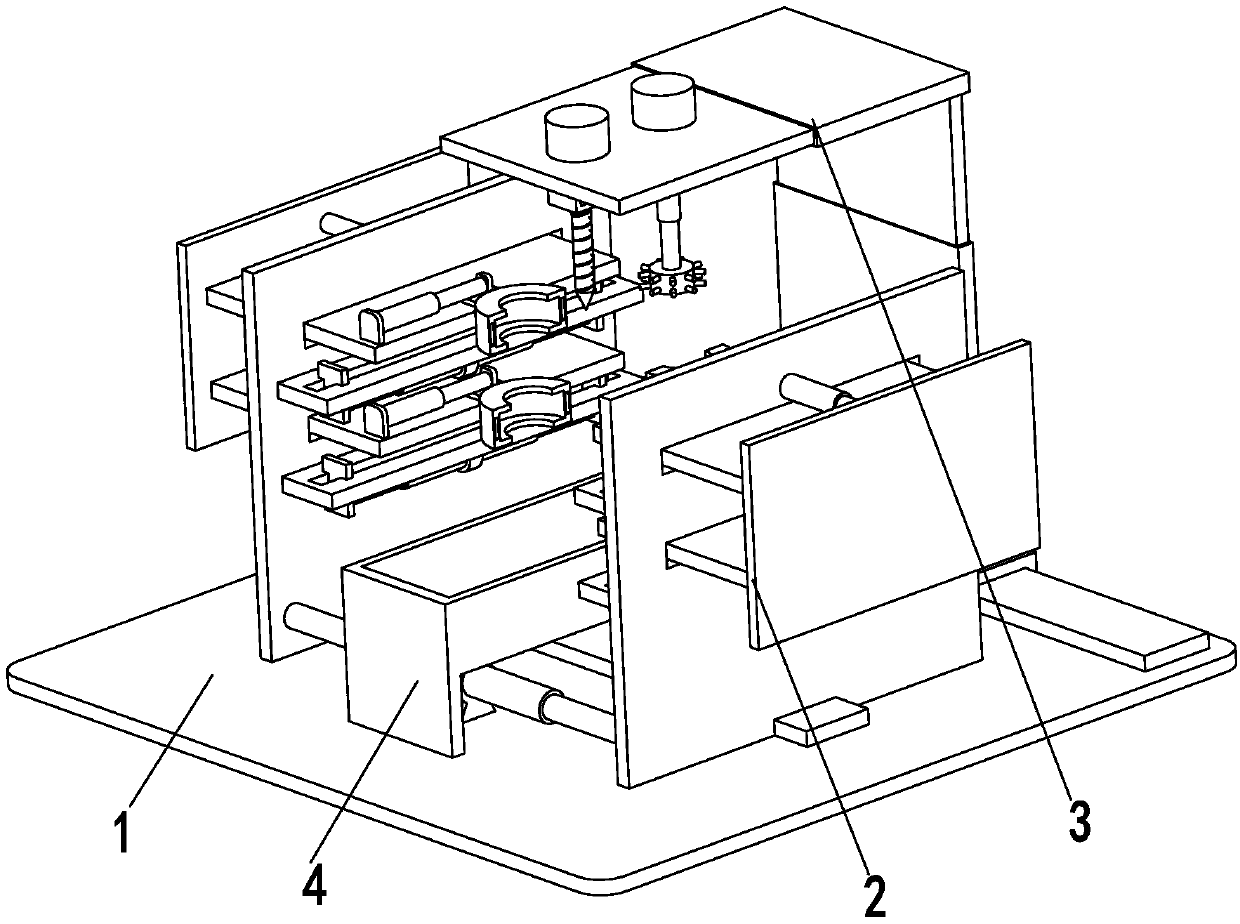

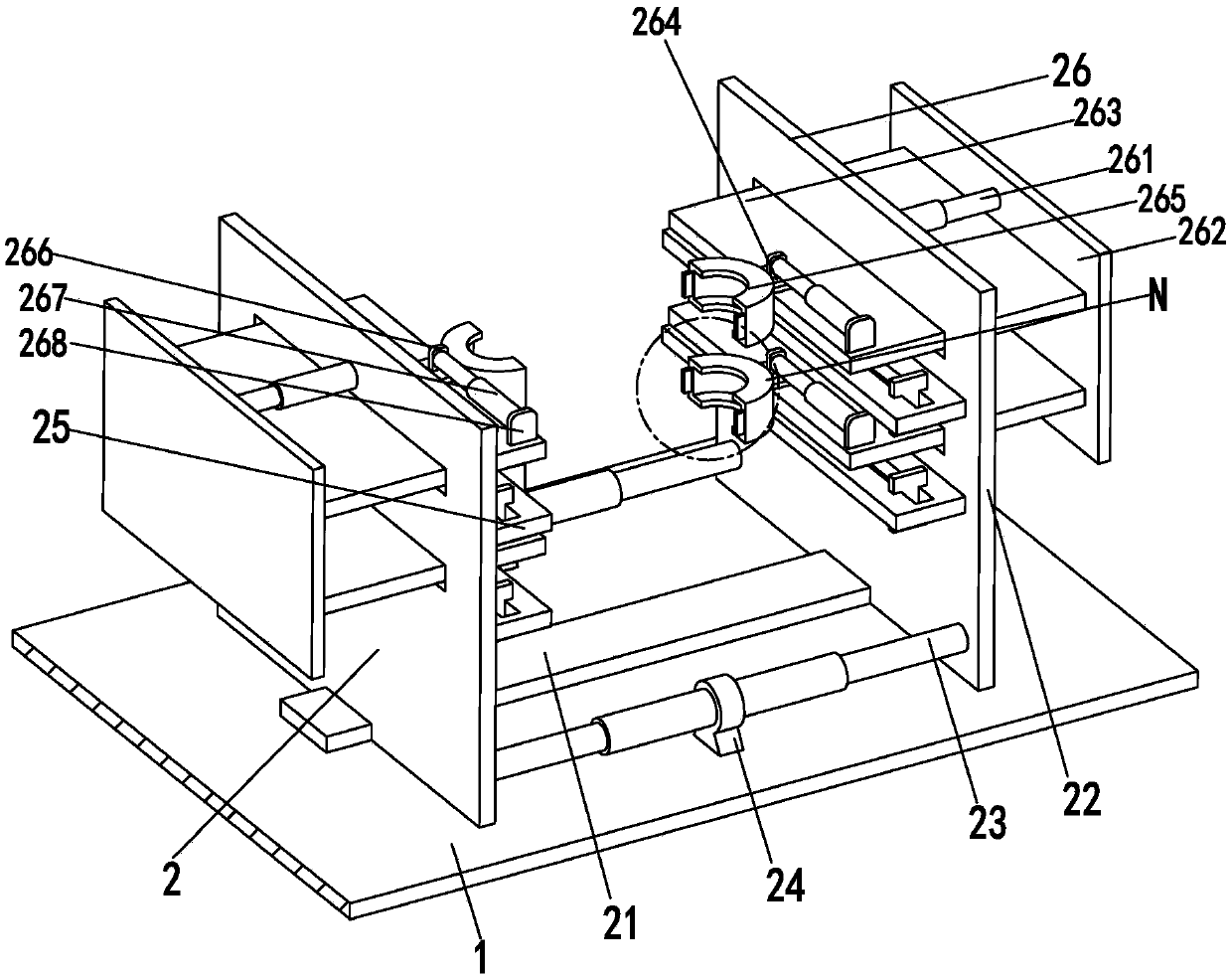

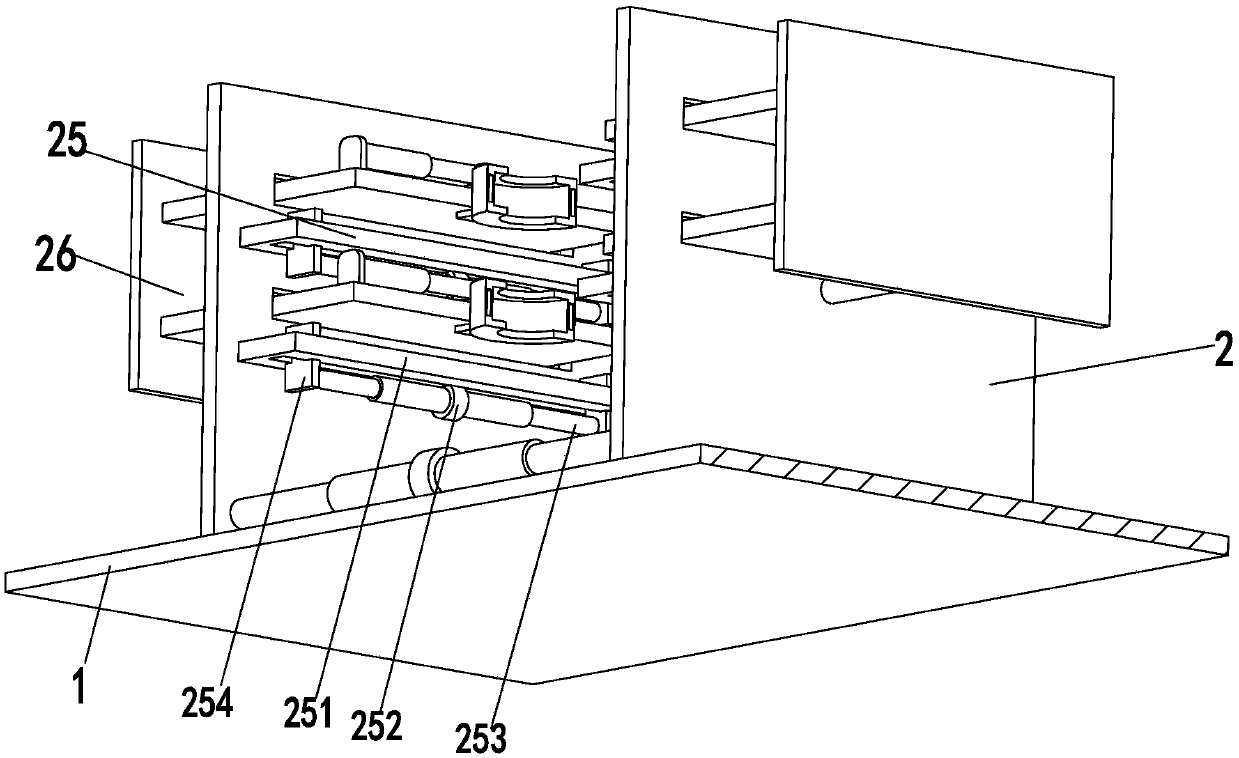

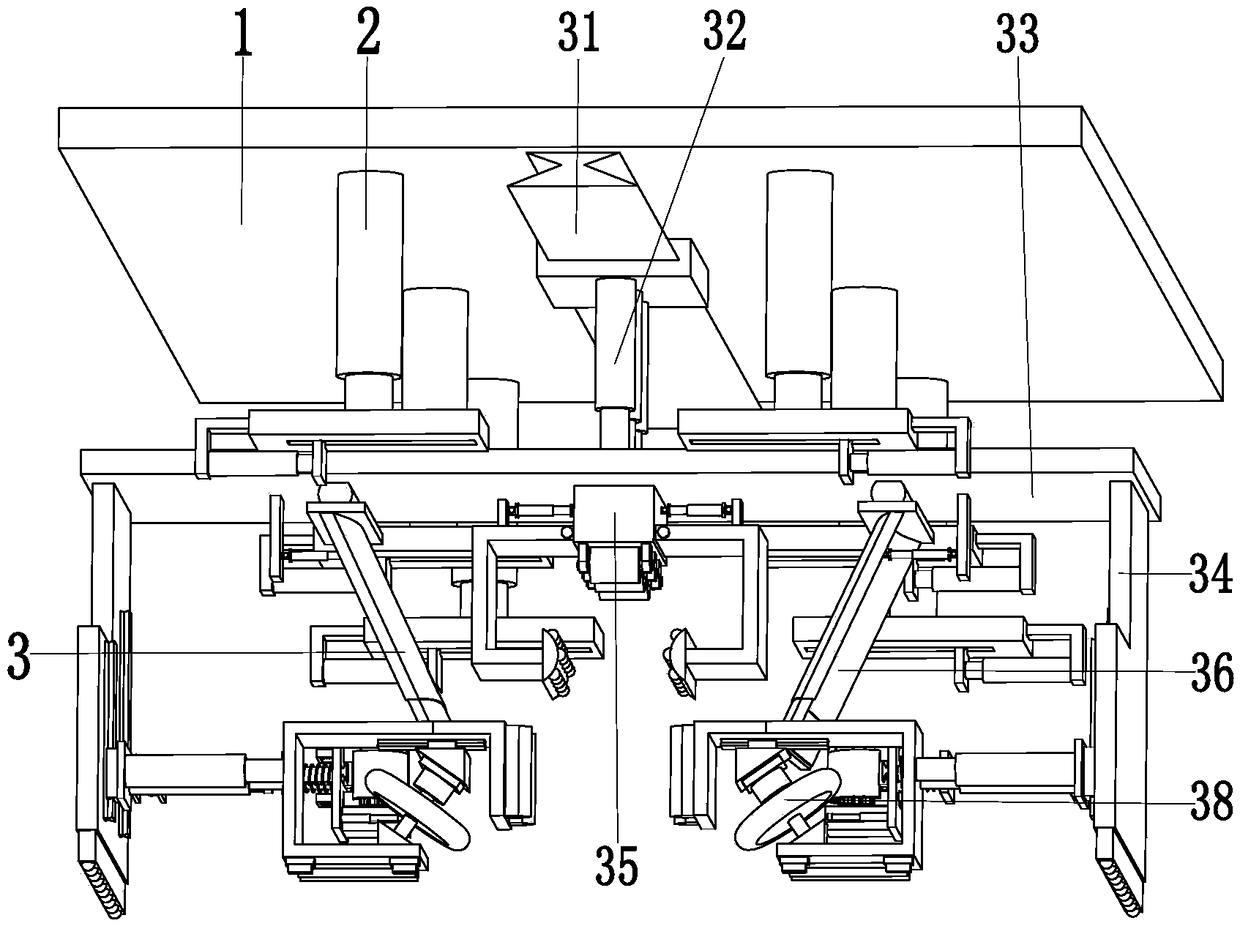

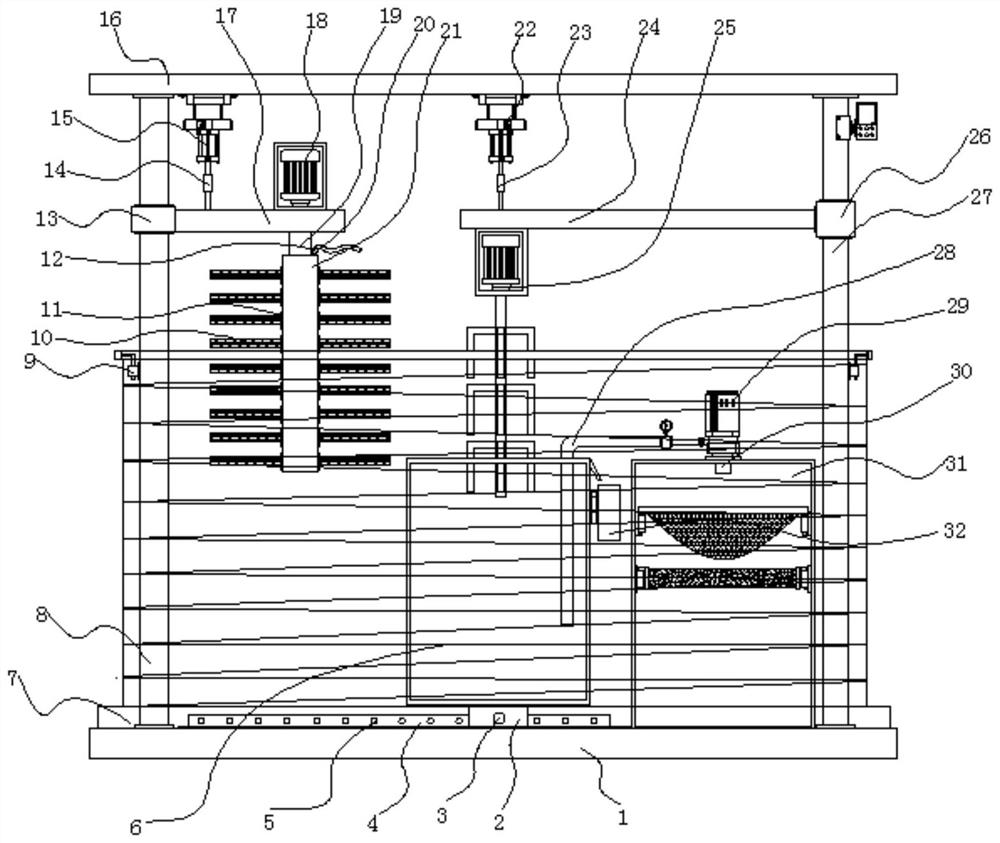

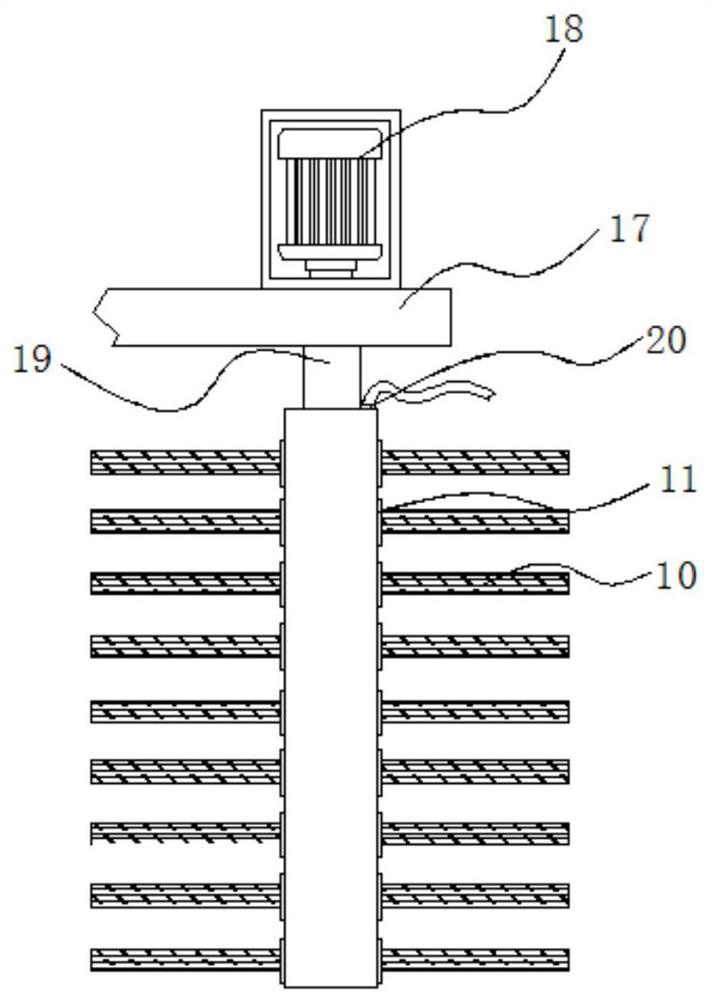

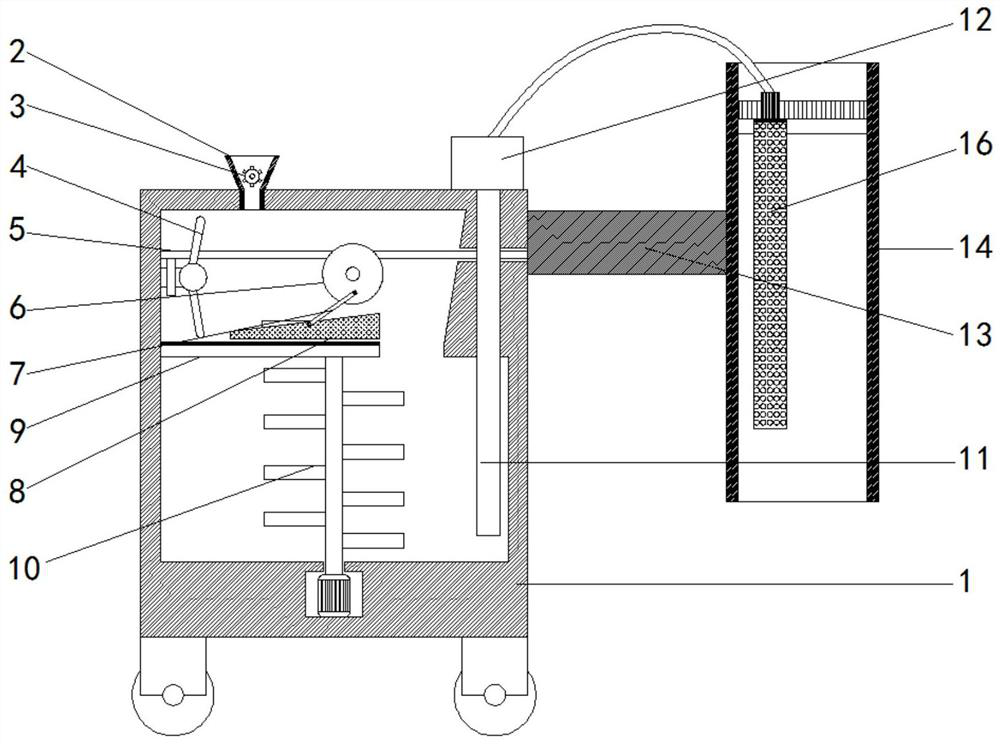

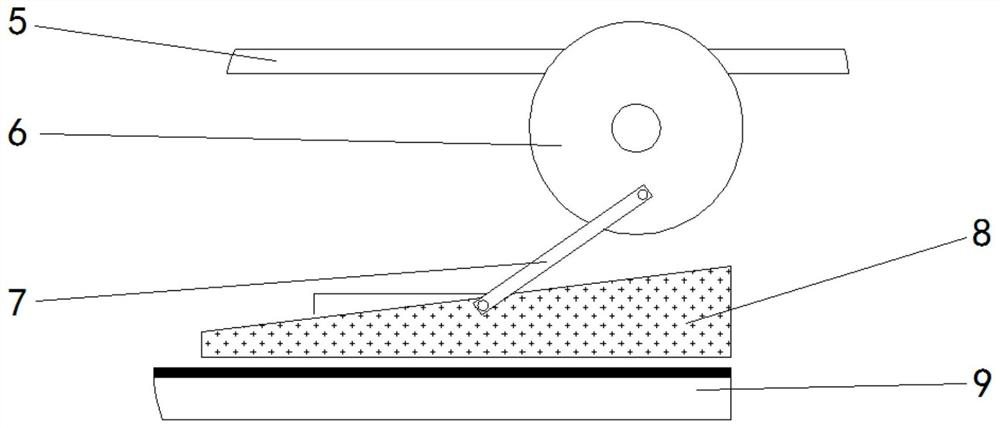

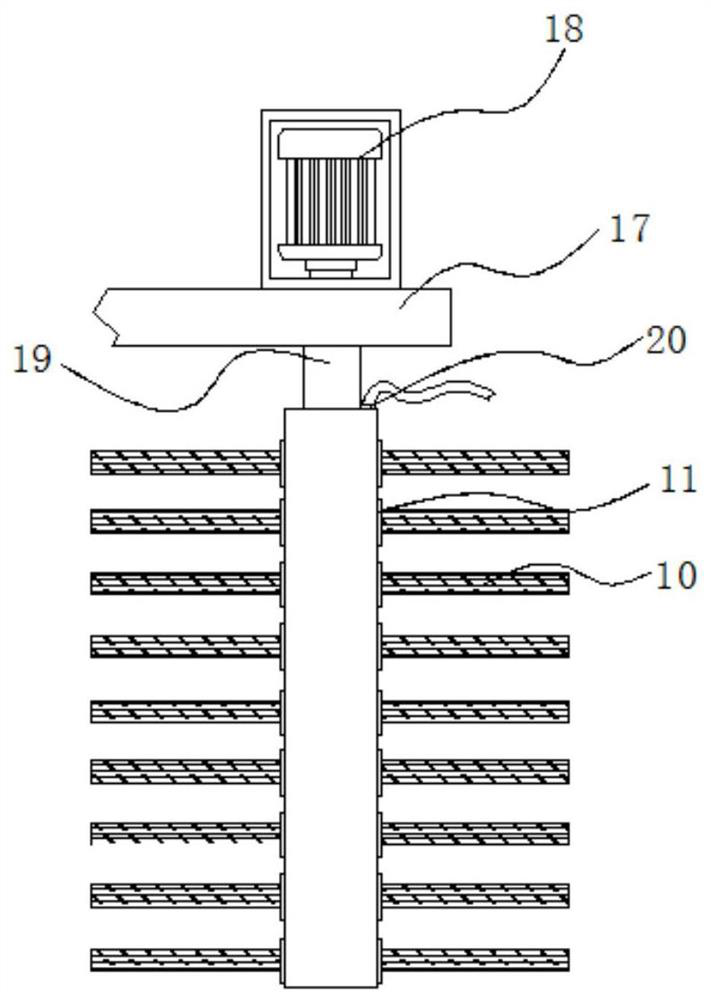

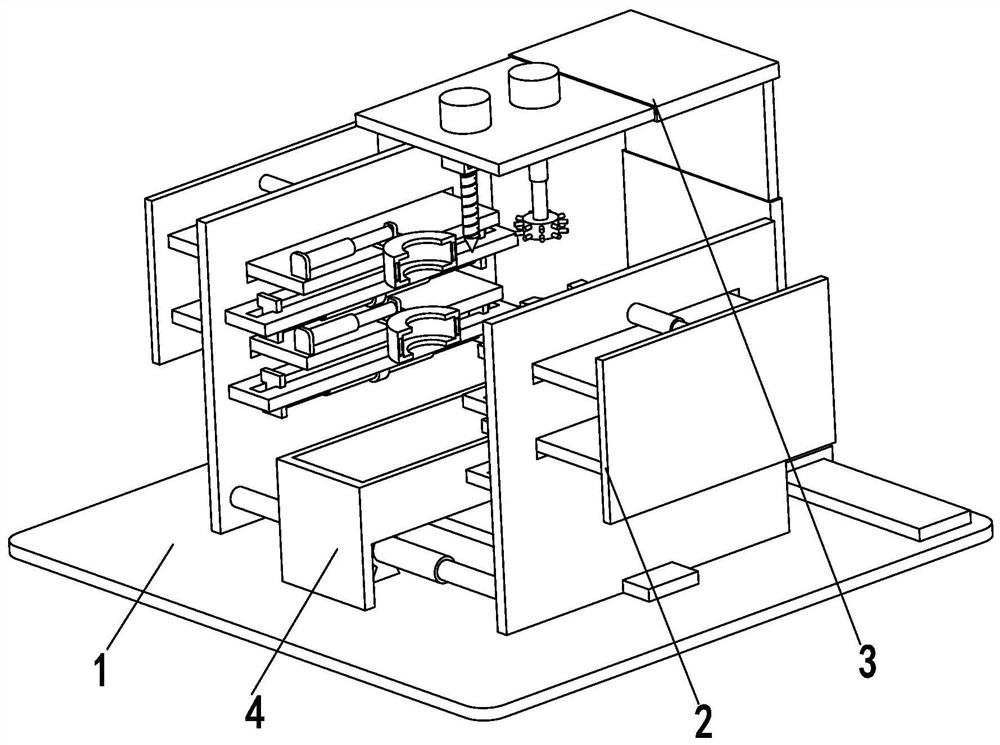

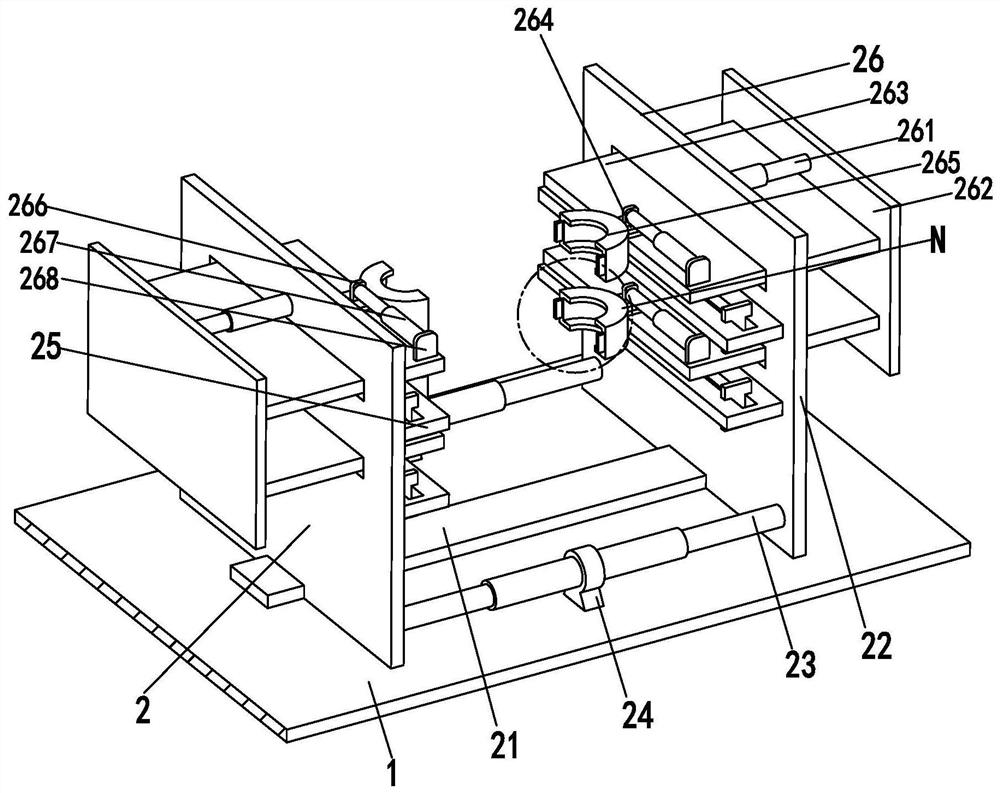

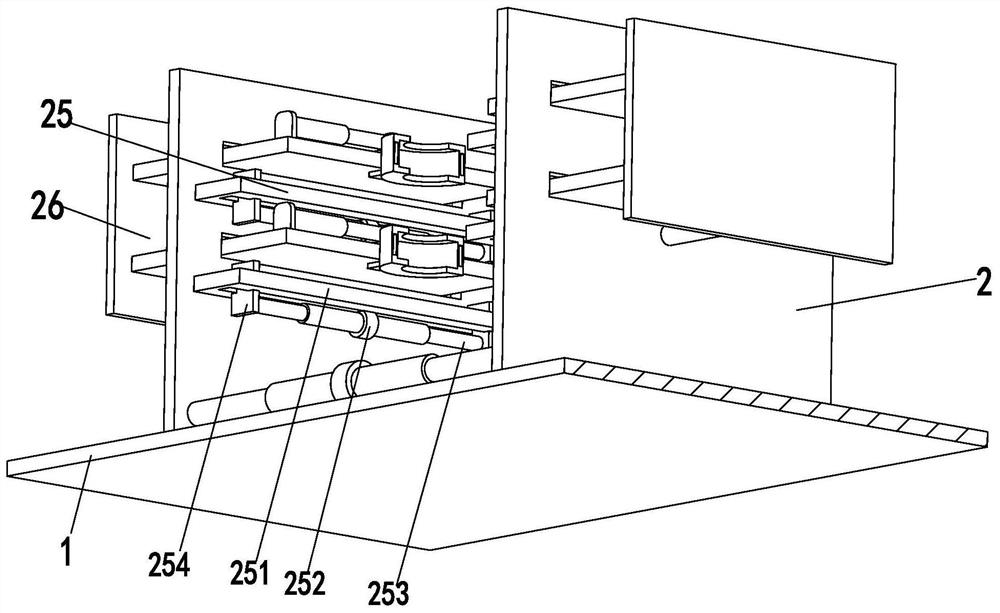

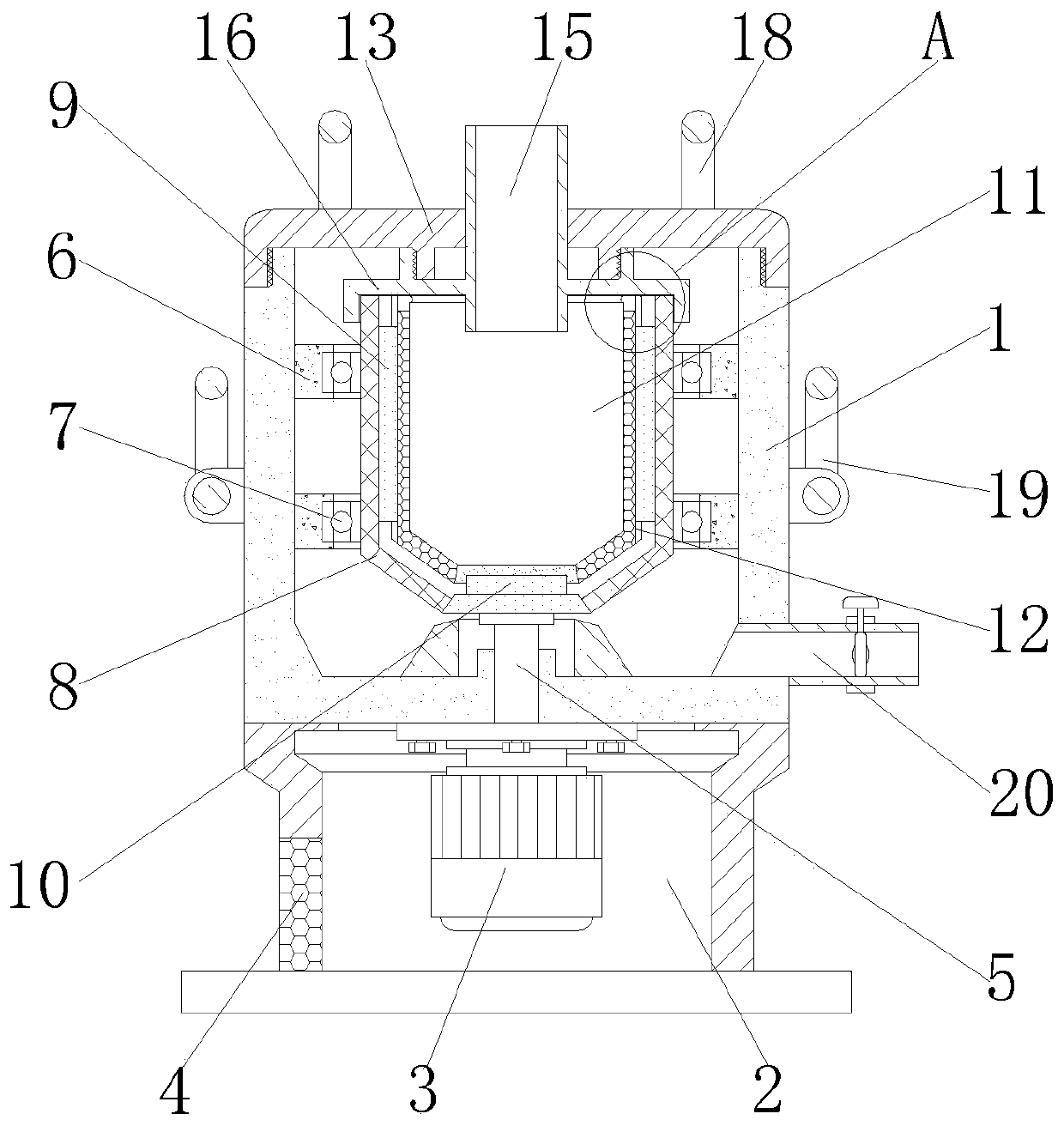

Automatic wood board machining robot

ActiveCN108673648AExpand the scope of useReduce lossesDrilling machinesBark-zones/chip/dust/waste removalWaste materialPulp and paper industry

The invention discloses an automatic wood board machining robot. The automatic wood board machining robot comprises a bottom plate, a supporting device, a perforating device and a waste material box,the perforating device is arranged on the bottom plate, the supporting device is arranged at the lower end of the perforating device, the waste material box is arranged at the lower end of the supporting device, moreover, both the supporting device and the waste material box are installed on the bottom plate, the supporting device comprises a linear guide rail, a supporting frame, a position adjusting air cylinder, a mounting seat, a fixing mechanism and a guide mechanism, and the perforating device comprises a linear slide rail, an electric sliding block, a telescopic mounting frame, a drilling mechanism and a cleaning mechanism. According to the automatic wood board machining robot, the problems that in an existing wood board drilling process, the labor cost is high, potential safety hazards exist, the working stability is poor, saw dust splashes around, and the drilling position is prone to deviation can be solved, an automatic drilling function on a wood board can be achieved, andthe advantages of being low in labor cost, good in safety, good in stability, free of splashing of the saw dust, accurate in drilling position and the like are achieved.

Owner:WENZHOU QIFANG NEW ENERGY CO LTD

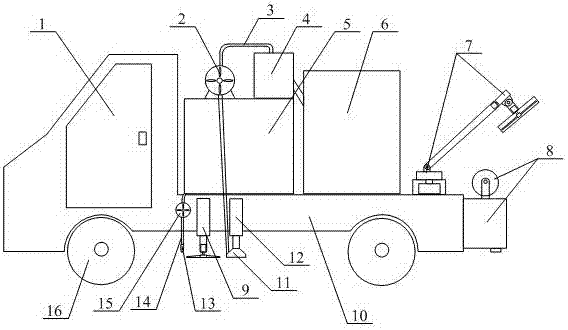

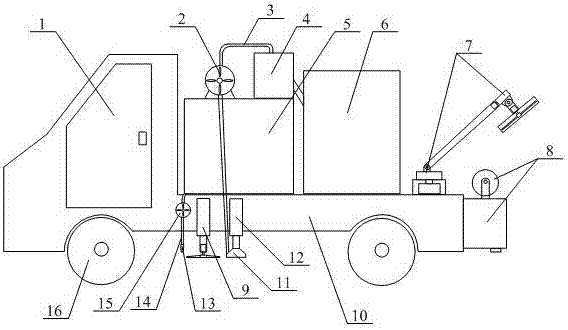

Portable multifunctional environmental sanitation sweeping device

The invention provides a portable multifunctional environmental sanitation sweeping device which comprises a control chamber, a dust suction pump, a dust suction pipe, a filter device, a water tank, a dustbin, a green belt trimming device, a pipeline dredging device, a cleaning device, a trolley, a dust suction hood, a dust suction lifting cylinder, a water spraying opening, a water pipe, a water pump and wheels. The wheels are installed on the left and right sides of the lower portion of the trolley respectively. The control chamber is arranged at the upper left portion of the trolley. The pipeline dredging device is installed on the right side of the trolley through a bolt; the green belt trimming device is installed at the right portion of the upper side of the trolley through a bolt. By arranging a purification layer and a screen net, secondary use of cleaning sewage is achieved, the water resource utilization rate is increased, and water pollution is reduced; by arranging a trimmer, the trimming effect is good, and the green belt trimming efficiency is improved; by arranging the belt, the transmission effect is good, overload protection can be achieved, a power motor is not likely to be damaged, use is more convenient, and the device is convenient to use and popularize.

Owner:轩昂环保科技股份有限公司

Electric spark machine tool machining system

ActiveCN108817721AWon't shakeSupport fixed and stableWelding/cutting auxillary devicesAuxillary welding devicesSlagEngineering

The invention relates to an electric spark machine tool machining system which comprises a supporting top plate, positioning mechanisms and a welding device. The positioning mechanisms are symmetrically mounted at the bottom of the supporting top plate; the welding device is mounted on the lower end face of the middle of the supporting top plate; the positioning mechanisms comprise positioning multi-stage push rods, positioning pressing plates, positioning plates, pushing push rods and push rod connecting frames; and the welding device comprises a welding electric sliding block, a welding position push rod, a welding supporting plate, welding side plates, a sliding mechanism, baffle mechanisms, welding mechanisms and clearing and polishing mechanisms. According to the electric spark machine tool machining system, the difficult problems that when a guiding rail of an existing electric spark machine tool is welded, the position of the guiding rail cannot be automatically corrected, the guiding rail shakes during welding, welding slag splashes everywhere during welding of the guiding rail, when the guiding rail is welded, the welding angle is changed, consequently the welding effect is poor, when discarded, welding rod ends are likely to be pasted to the machine tool, and post-welding treatment cannot be automatically conducted on the guiding rail can be solved.

Owner:SHANDONG LIAOCHENG DERUN EMT DEVING

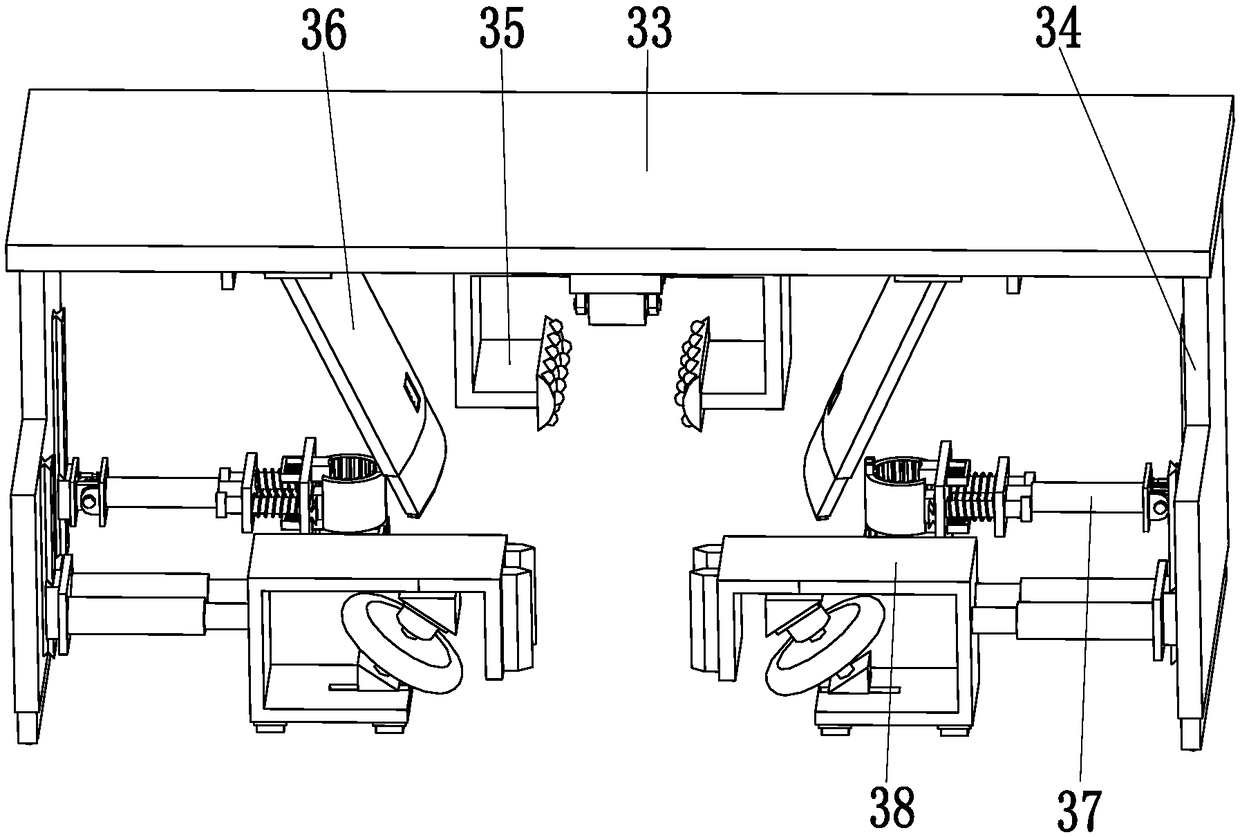

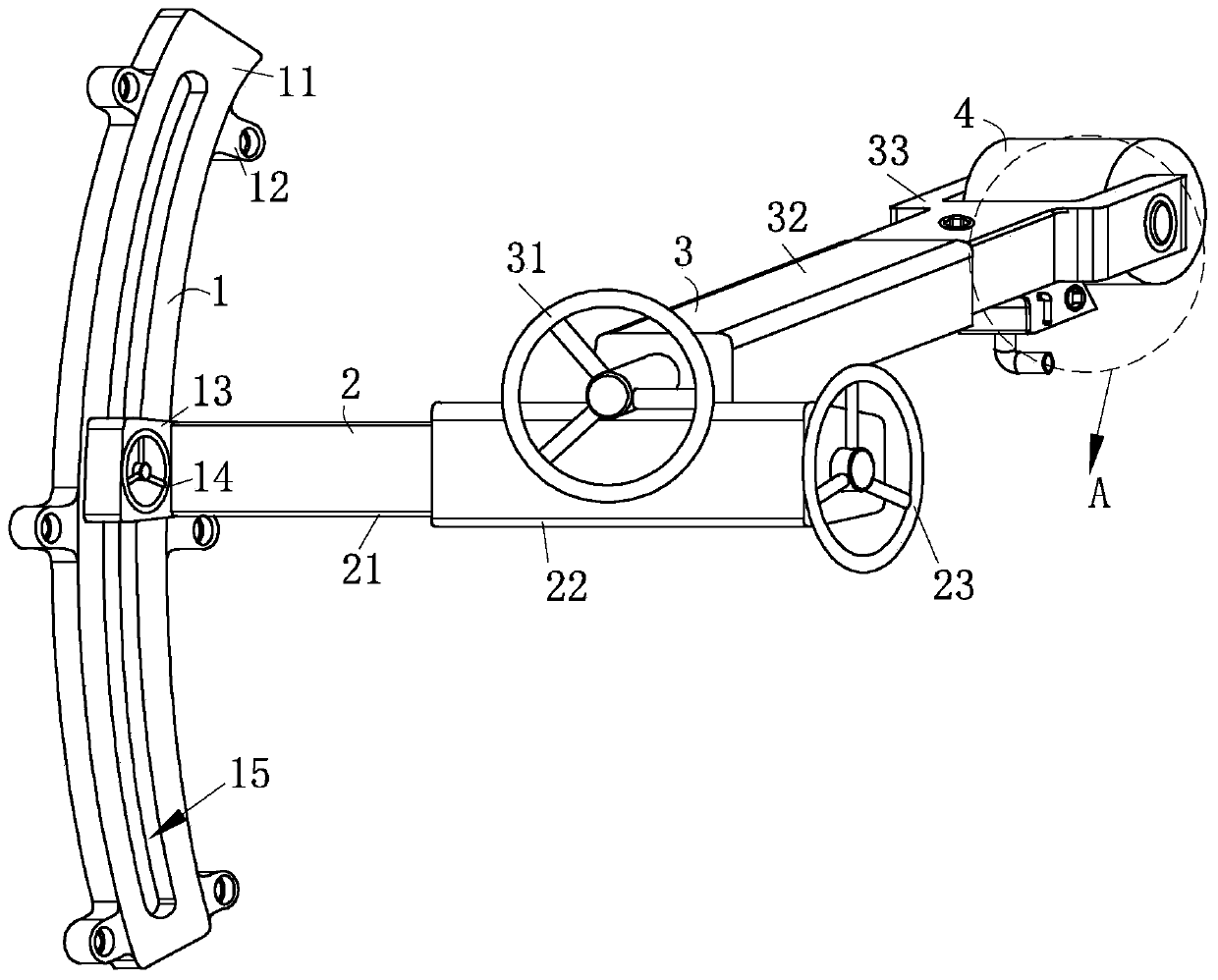

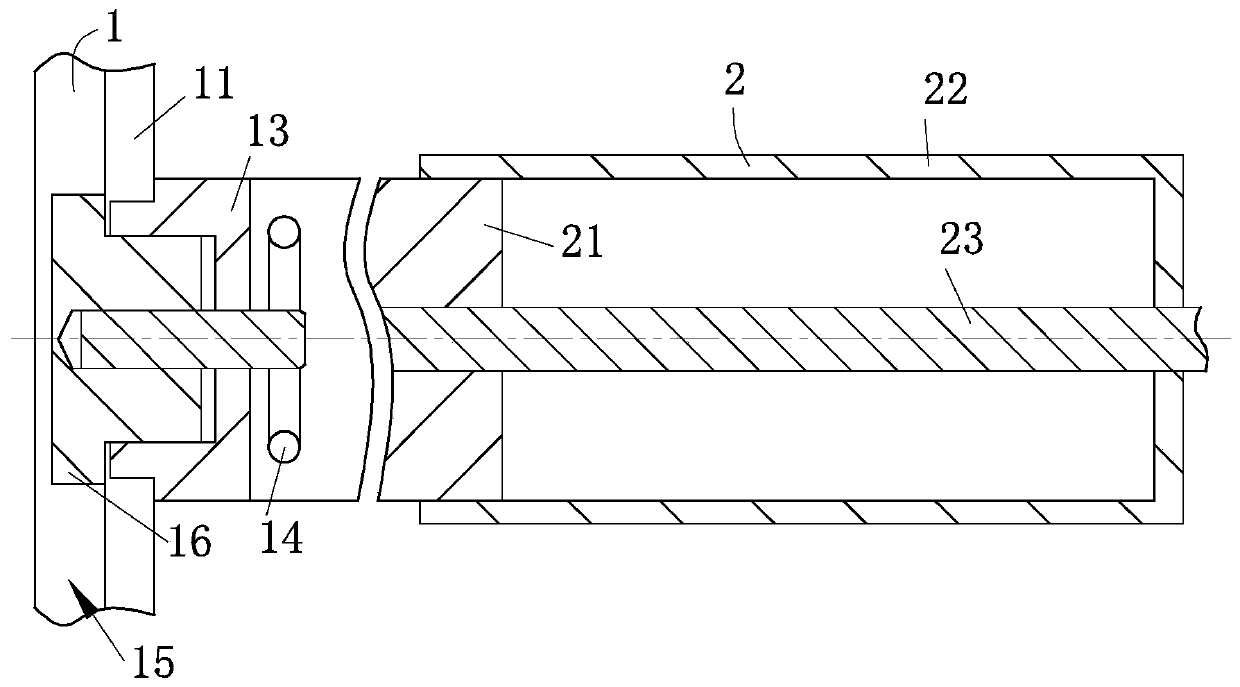

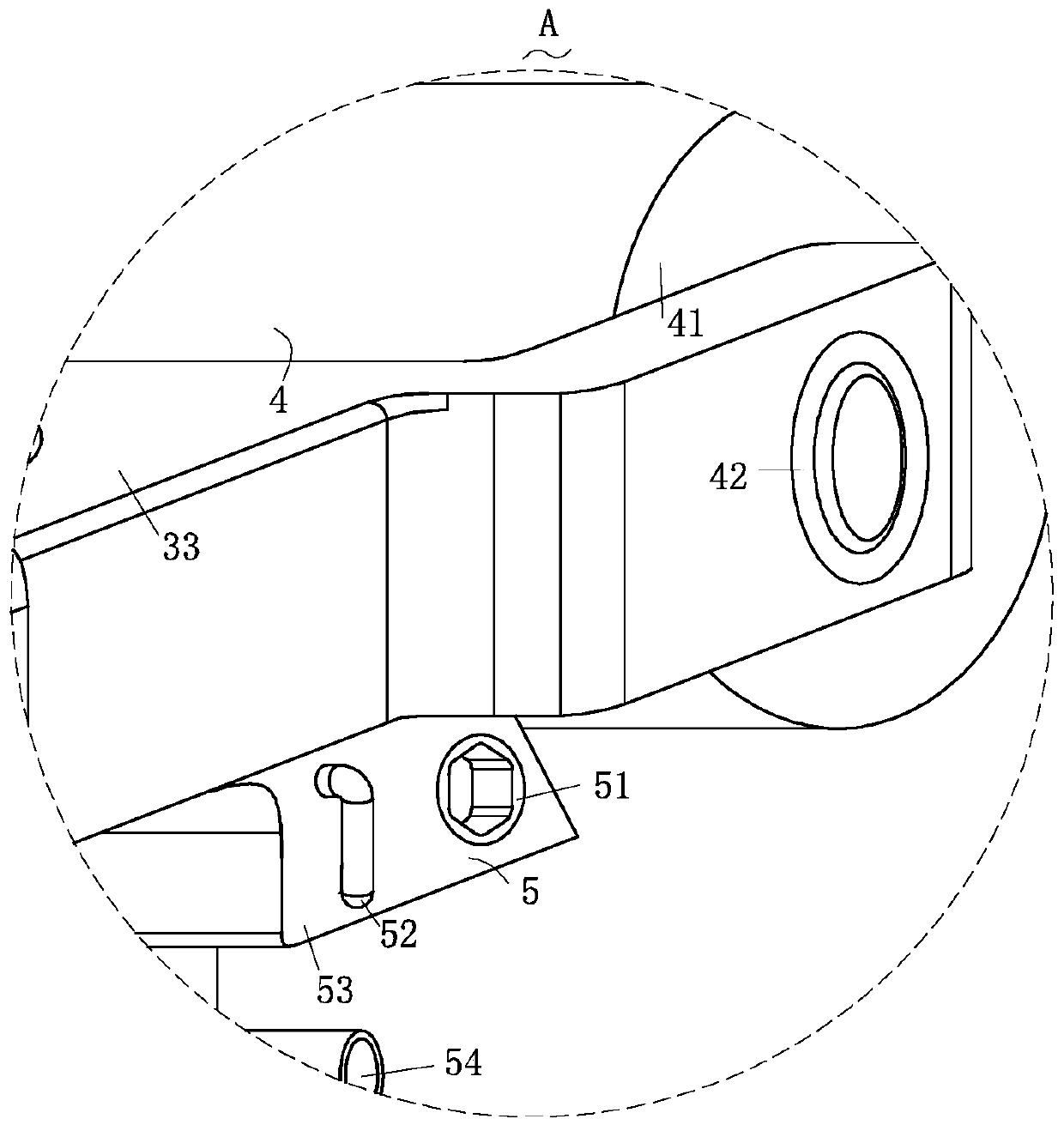

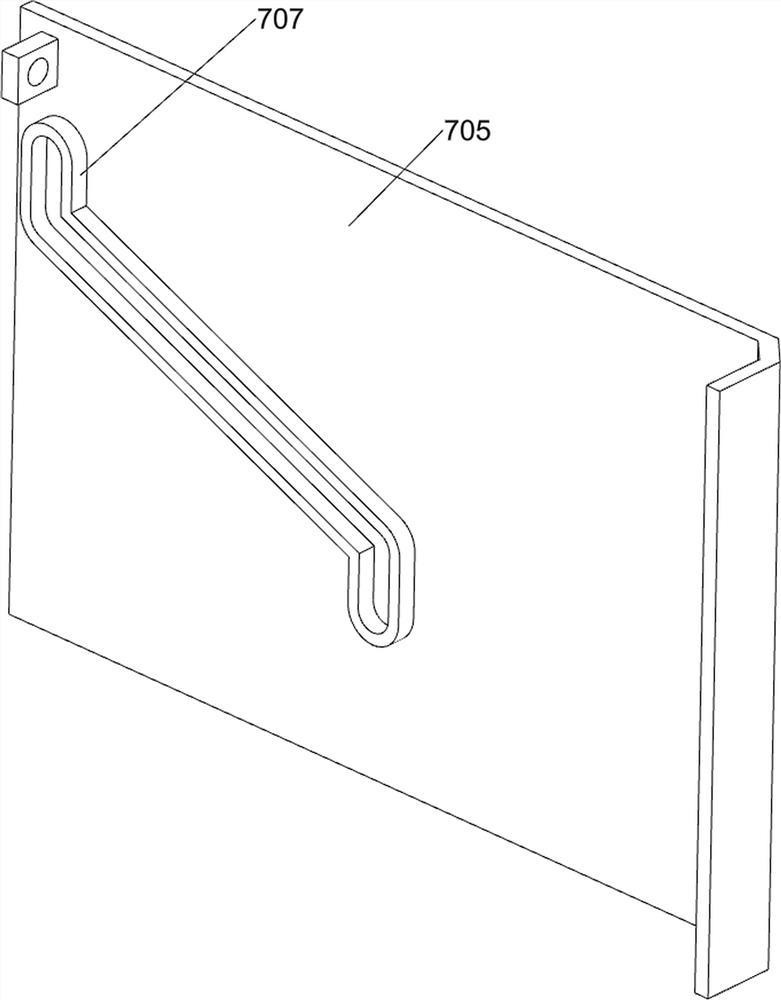

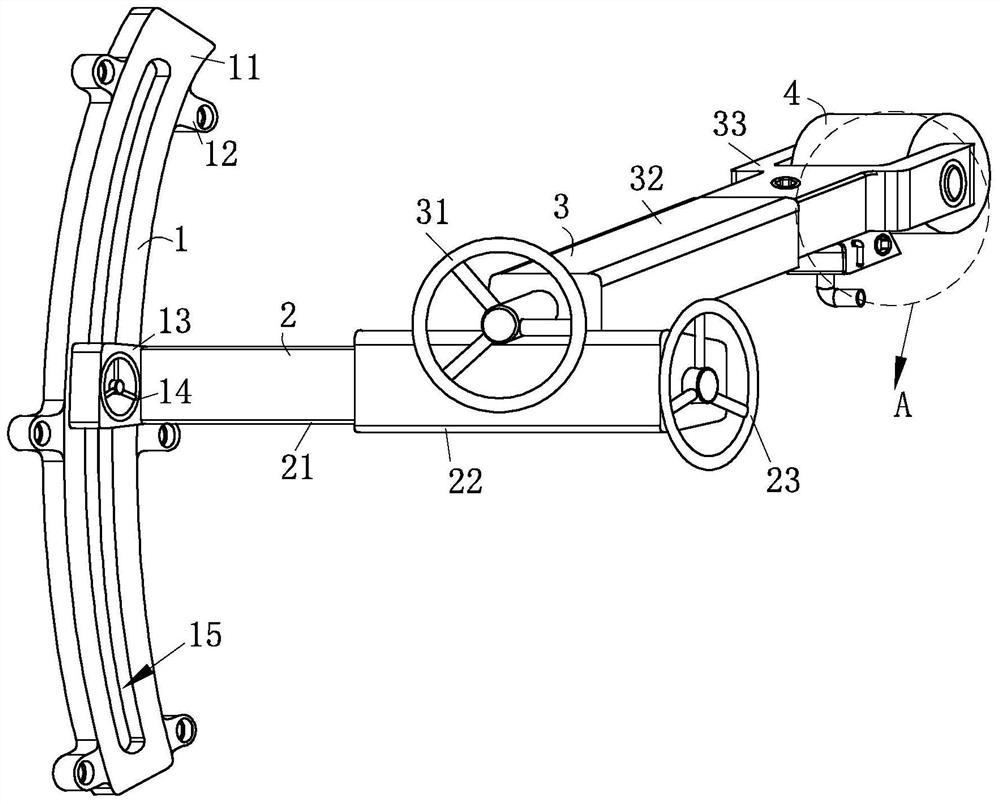

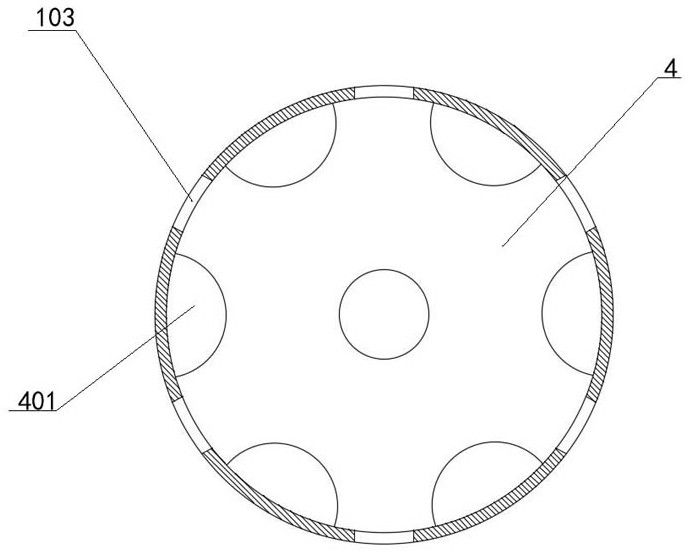

PP winding pipe production equipment with braking component

ActiveCN110815799AAdjustable positionEasy to adjustTubular articlesProcess engineeringMechanical engineering

The invention relates to the field of winding pipe production equipment, in particular to PP winding pipe production equipment with a braking component. The PP winding pipe production equipment comprises a diameter adjusting structure, a first stretching and contracting structure, a second stretching and contracting structure, a guiding structure, a braking structure and a lubricating structure, wherein use of the diameter adjusting structure facilitates to adjust the position of the first stretching and contracting structure rapidly, meanwhile, a bolt of the adjusting position is avoided frombeing subjected to force directly, and the position adjusting efficiency and quality of the first stretching and contracting structure are greatly improved; by means of the arrangement of the brakingstructure, the pressure on cooling water is reduced, the cooling water is made to be poured on the guiding structure better, the water pouring amount is increased, splashing of the cooling water on arubber strip is effectively avoided at the same time, and the rubber strip is avoided from being pasted to the guiding structure; and the lubricating structure is arranged at the end portion of the second stretching and contracting structure and is connected to the braking structure, the use of the lubricating structure facilitates resetting of the braking structure, and by means of the use of the braking structure, the fact that the lubricating structure is driven to lubricate the guiding structure while the cooling water is sprayed is facilitated.

Owner:江苏八达重工科技有限公司

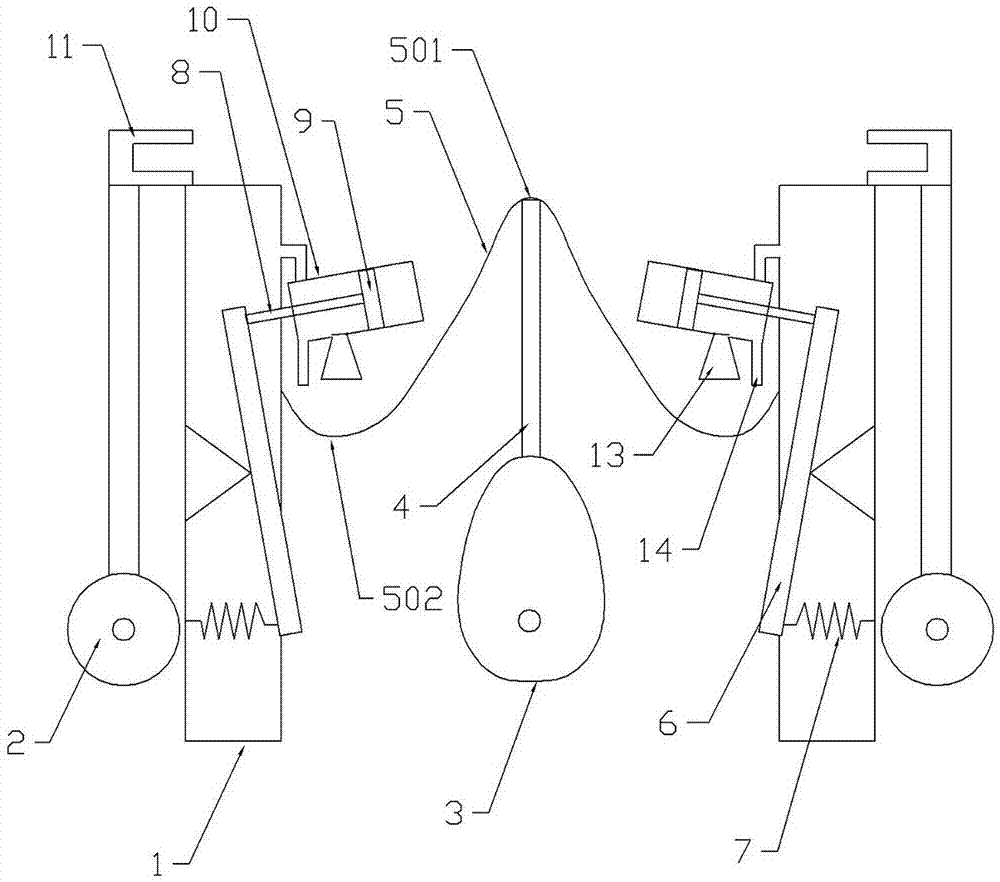

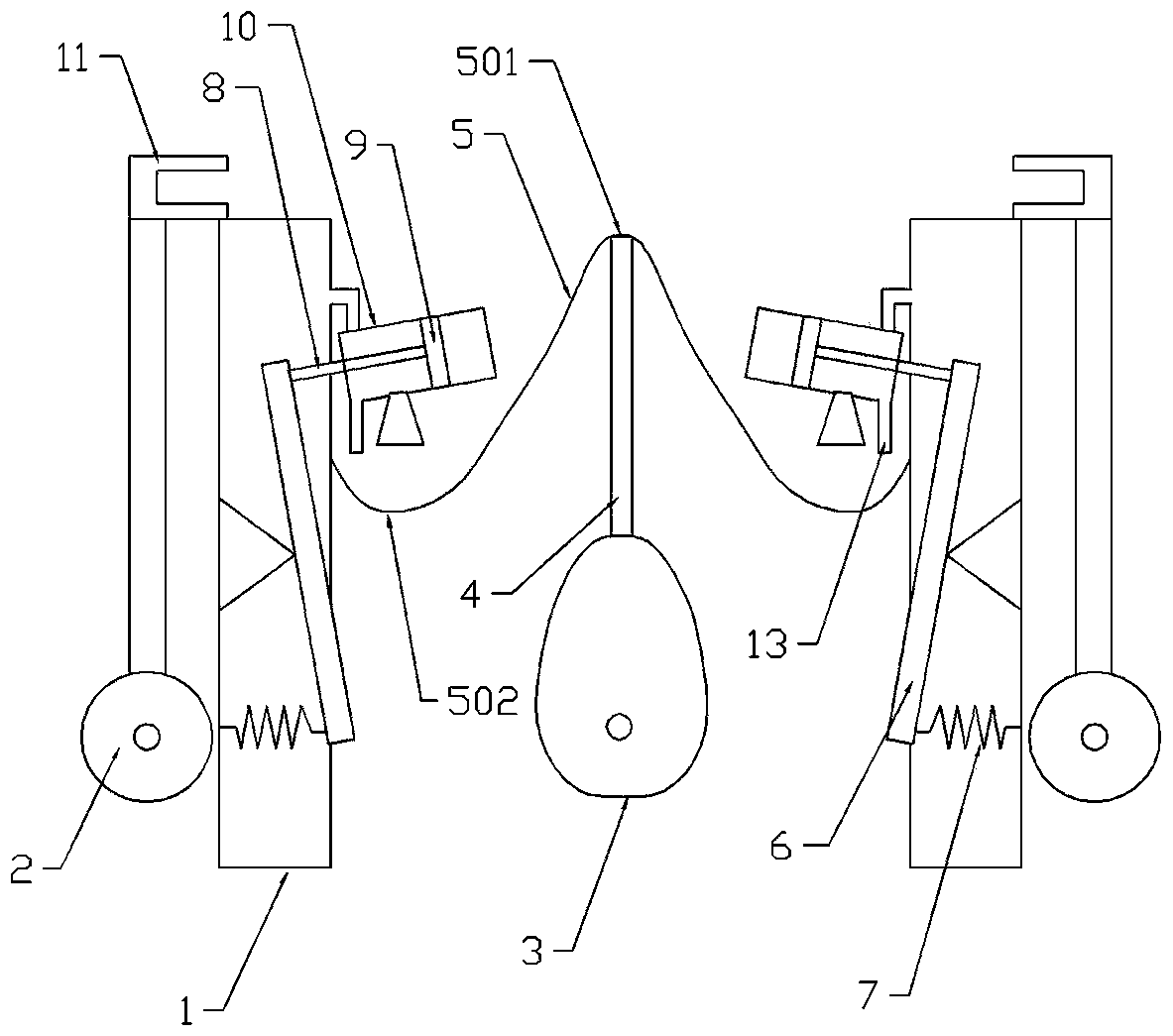

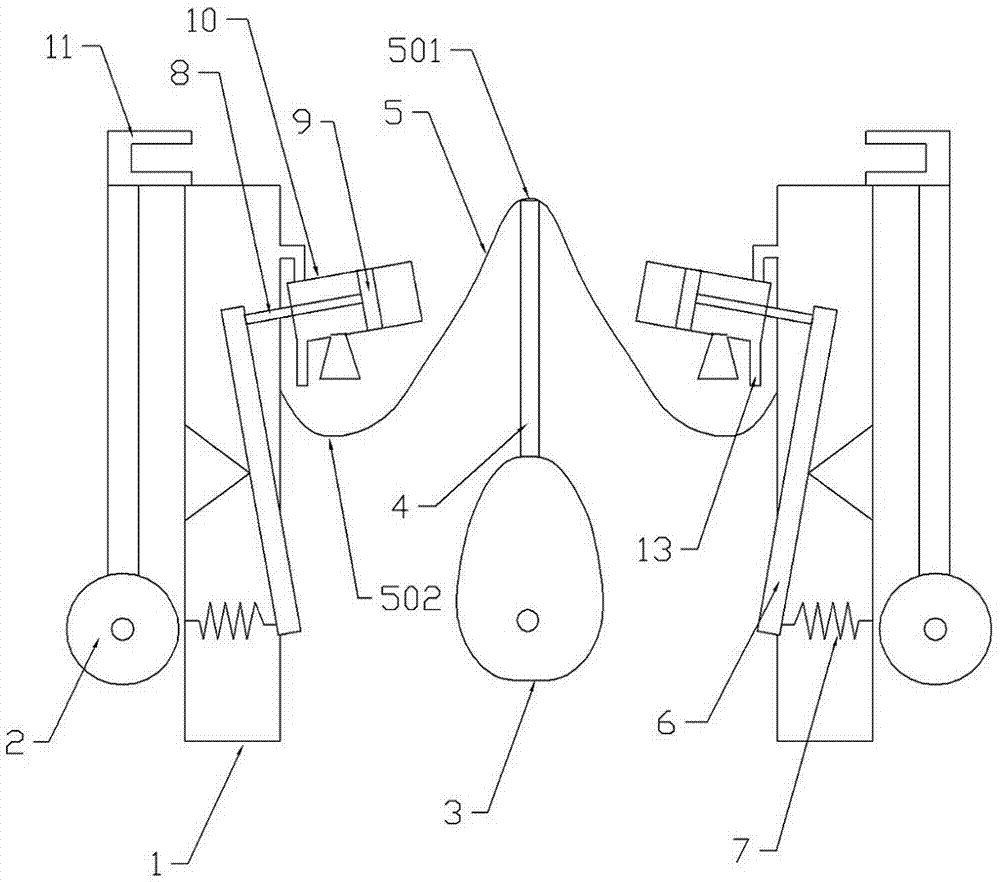

Glass cutting equipment

The invention belongs to the technical field of glass cutting or dividing and relates to glass cutting equipment. The glass cutting equipment comprises supporting frames and rotating cylinders, and the supporting frames are in opposite arrangement. A cam, an ejection rod and cloth are sequentially arranged on inner sides of the supporting frames from bottom to top, two ends of the cloth are detachably connected to the supporting frames respectively, the cloth comprises two concave surfaces and a convex surface, and the convex surface is in detachable connection with the ejection rod. A lever is mounted in each supporting frame, the lower end of each lever is positioned on the outer side of the corresponding supporting frame, a spring is connected between the lower end of each lever and the inner wall of the corresponding supporting frame, and the upper end of each lever is arranged on the inner side of the corresponding supporting frame and connected with a piston rod. Cylinder bodies are arranged above the concave surfaces of the cloth and in slide fit with pistons internally, each piston is connected with a piston rod, each cylinder body is provided with an opening, and a cover plate is hinged to each opening. The rotating cylinders are symmetrically arranged on the outer sides of the supporting frames along the center axis of the ejection rod, and the end of each rotating cylinder is connected with a clamping seat. The glass cutting equipment has advantages of splattering prevention in glass cutting, high automation degree, simplicity in operation and high practicality and can be popularized in the field of glass cutting.

Owner:CHONGQING SHUNHUA SAFETY GLASS CO LTD

A portable multifunctional sanitation cleaning device

The invention provides a portable multifunctional environmental sanitation sweeping device which comprises a control chamber, a dust suction pump, a dust suction pipe, a filter device, a water tank, a dustbin, a green belt trimming device, a pipeline dredging device, a cleaning device, a trolley, a dust suction hood, a dust suction lifting cylinder, a water spraying opening, a water pipe, a water pump and wheels. The wheels are installed on the left and right sides of the lower portion of the trolley respectively. The control chamber is arranged at the upper left portion of the trolley. The pipeline dredging device is installed on the right side of the trolley through a bolt; the green belt trimming device is installed at the right portion of the upper side of the trolley through a bolt. By arranging a purification layer and a screen net, secondary use of cleaning sewage is achieved, the water resource utilization rate is increased, and water pollution is reduced; by arranging a trimmer, the trimming effect is good, and the green belt trimming efficiency is improved; by arranging the belt, the transmission effect is good, overload protection can be achieved, a power motor is not likely to be damaged, use is more convenient, and the device is convenient to use and popularize.

Owner:轩昂环保科技股份有限公司

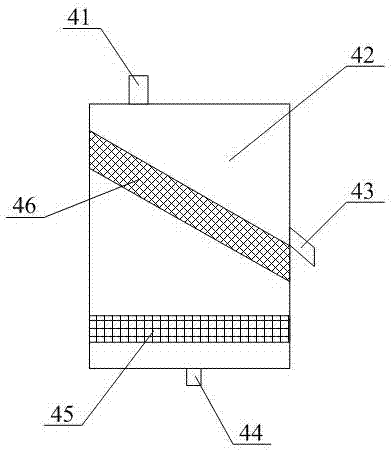

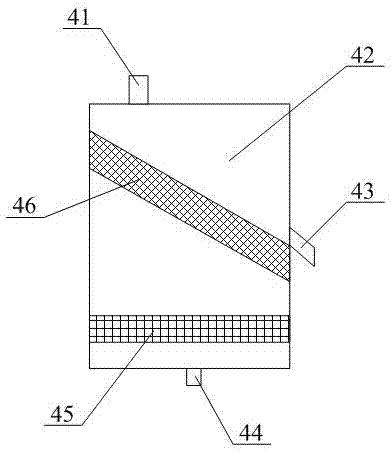

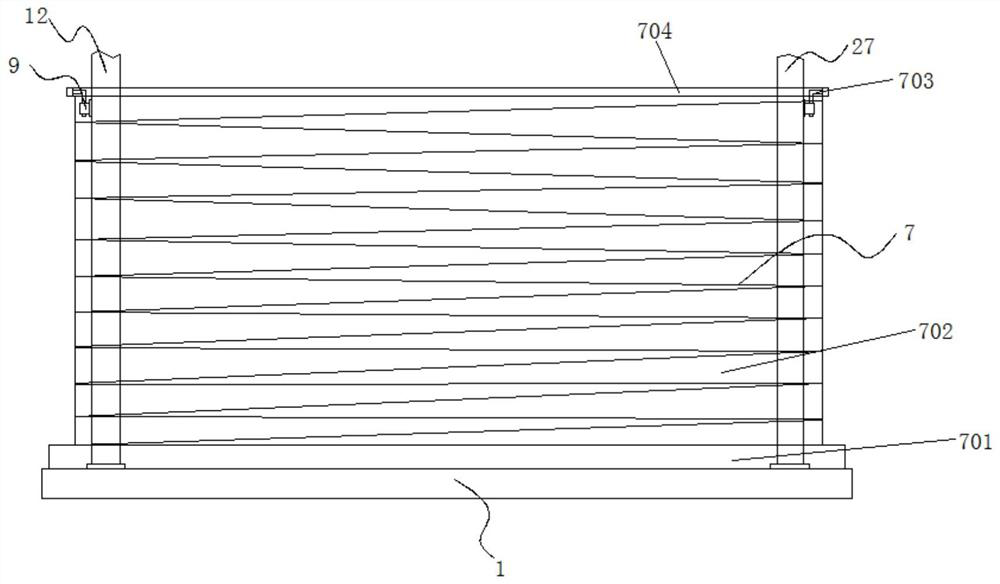

Spraying wastewater treatment equipment

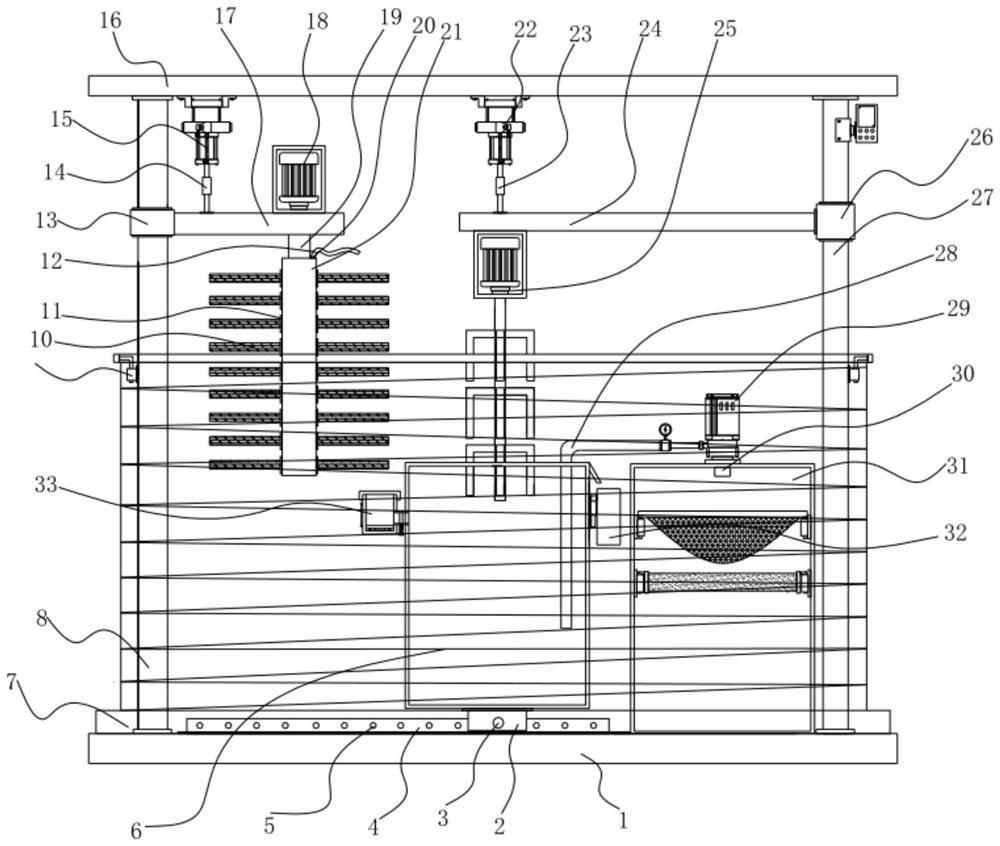

InactiveCN111807565APrevent splashAchieving ease of cleaning issuesSpecific water treatment objectivesPaint waste treatmentMechanical engineeringWastewater disposal

The invention discloses spraying wastewater treatment equipment and particularly relates to the technical field of spraying wastewater treatment. The spraying wastewater treatment equipment comprisesa base and a top plate, the top end of the base is fixedly connected with an anti-splashing structure, a first supporting column is fixedly connected to one side of the top end of the base in the anti-splashing structure, a second supporting column is fixedly connected to the other side of the top end of the base in the anti-splashing structure, a top plate is fixedly connected to the top ends ofthe first supporting column and the second supporting column, a first hydraulic air cylinder is fixedly connected to the bottom end of the top plate, and a first telescopic rod is fixedly connected tothe bottom end of the first hydraulic air cylinder. The scum collecting structure is composed of a drainage groove, a collecting box, a fixing block and a mounting groove. Due to the fact that the drainage groove is obliquely formed in one side of the top end of the box body, dross is pushed into the collecting box at the bottom of the drainage groove through a tool, then the fixing block is taken out of the mounting groove, the dross in the collecting box is cleaned away, and the interior of the pipe body cannot be blocked.

Owner:合肥乡情园林景观设计有限公司

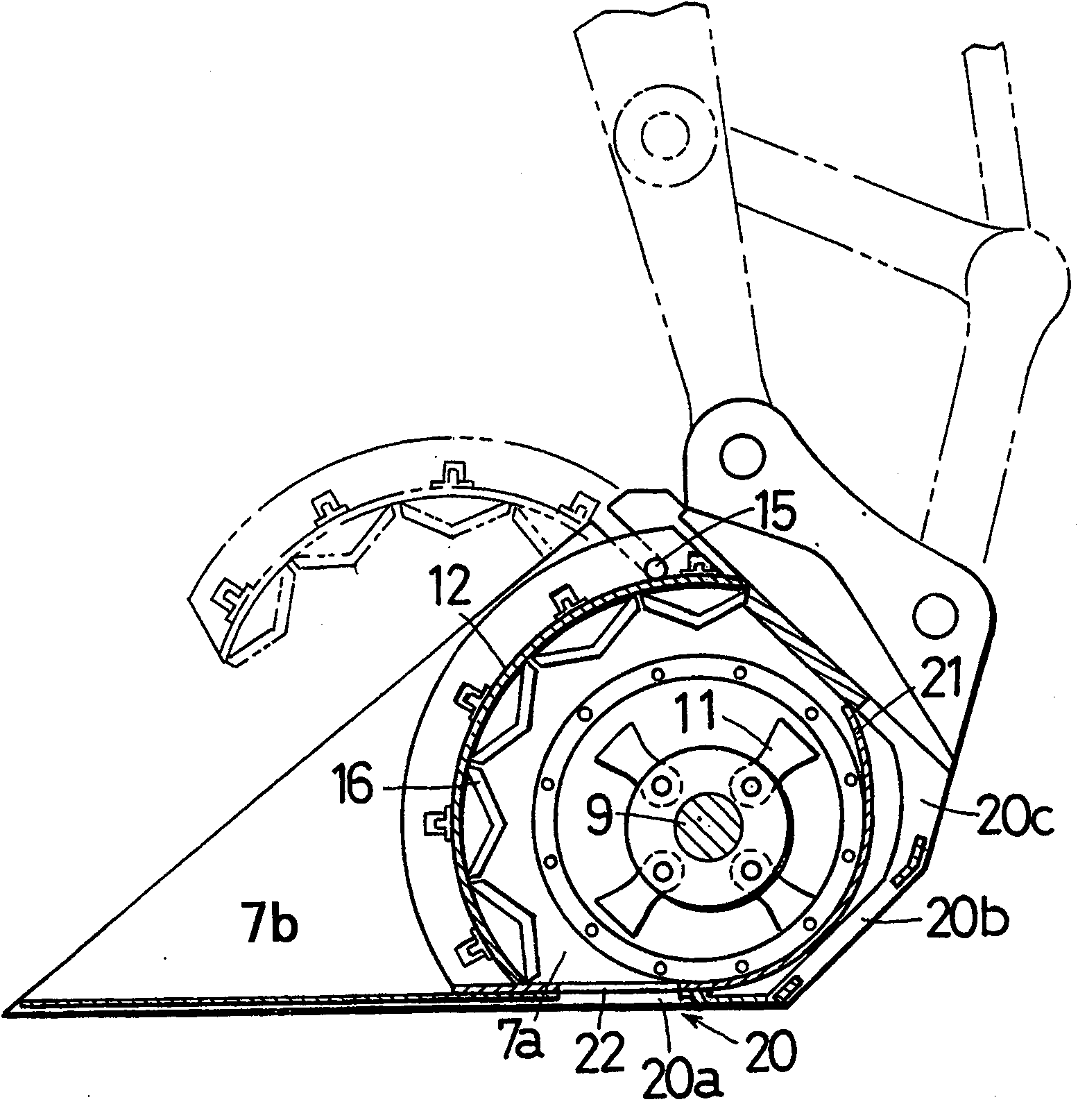

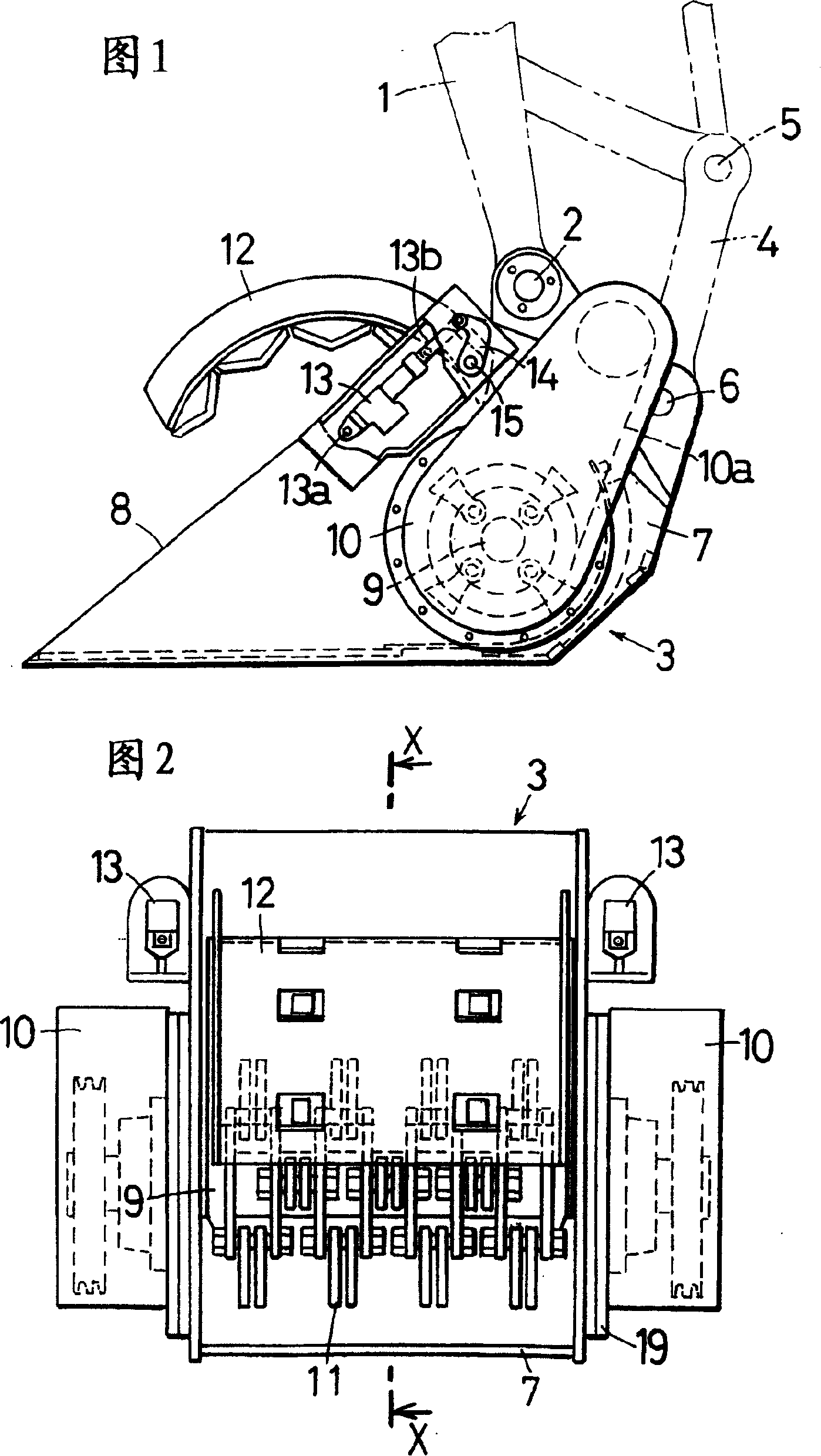

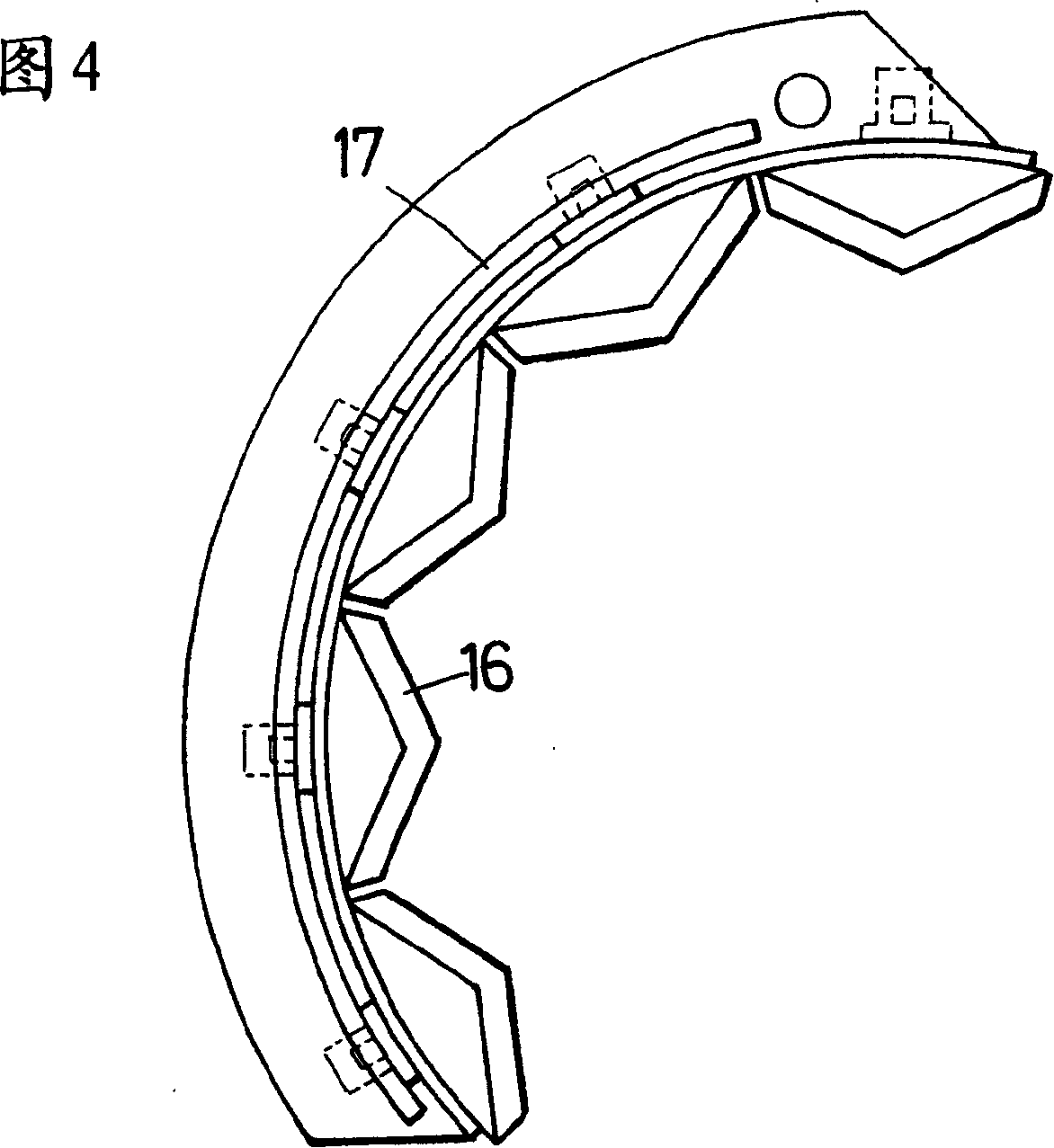

Bucket with crushing lid and its crushing method

InactiveCN1800518AArbitrary adjustment of shape and particle sizeEfficient crushingMechanical machines/dredgersGrain treatmentsEngineeringMechanical engineering

Owner:株式会社中山铁工所

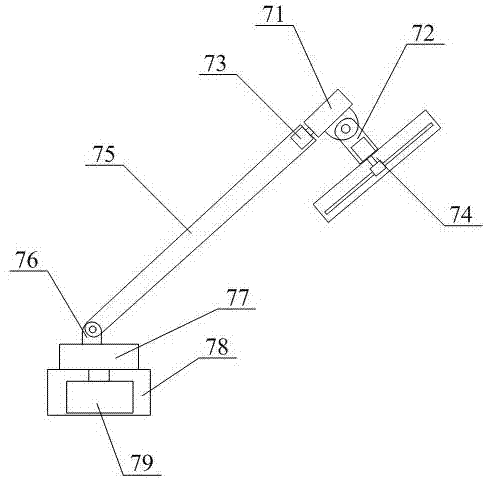

Table leg paint spraying equipment capable of uniformly spraying paint and preventing splashing

InactiveCN112439604APrevent splashPaint stabilizerSpraying apparatusGrain treatmentsStructural engineeringSpray painting

The invention relates to the technical field of table leg paint spraying equipment, and discloses table leg paint spraying equipment capable of uniformly spraying paint and preventing splashing. The table leg paint spraying equipment comprises a paint spraying tank, a feeding pipe is inserted into the top of the paint spraying tank, a buffer wheel is fixedly connected to the interior of the feeding pipe, a supporting rod is fixedly connected to the right side of the paint spraying tank, a clamping jaw is movably connected to the right side of the supporting rod, a strut is movably connected tothe outer side of the supporting rod, an ejector rod is movably connected to the left side of a sliding rod, and a connecting frame is movably connected to the left side of the ejector rod. Accordingto the table leg paint spraying equipment capable of uniformly spraying paint and preventing splashing, a transmission shaft rotates to drive the connecting frame to slide rightwards, the connectingframe moves to drive the ejector rod to move rightwards, the ejector rod drives the sliding rod to slide rightwards, the sliding rod drives the clamping jaw to be closed, a driving wheel rotates at the moment, the driving wheel rotates to drive a sliding block to move, and through the coordinated use of the sliding block and a spray plate, the effects of stable paint spraying and no splashing to other places are achieved.

Owner:宿州市尖端木业有限公司

Toilet control device and design method

InactiveCN107938786AEasy to controlAvoid obstaclesWater closetsFlushing devicesLiquid mediumEngineering

The invention discloses a toilet control device. The device includes: a squatting door, a squatting wall, a first cylinder, a medium pipeline, a second cylinder, a valve pull rod, the first cylinder includes a cylinder wall, a first pull rod, a first piston, the first pull rod and the first The piston is connected through the cylinder, the top of the first pull rod has a first connection point, and the bottom of the first cylinder has a second connection point, and the two connection points are respectively connected to the squatting door and the squatting wall, and the squatting door and the squatting wall are connected to the The two connection points of the first cylinder are connected by the rotating shaft. The bottom of the first cylinder and the top of the second cylinder are connected through a medium pipeline, and the bottom of the first cylinder and the top of the second cylinder are connected with the medium pipeline. For liquid medium, the valve pull rod penetrates into the second cylinder and connects with the second piston.

Owner:ZHEJIANG KEZHUDA MACHINERY TECH CO LTD

Spraying wastewater treatment equipment convenient for adding medicament

InactiveCN112093939APrevent splashAchieving ease of cleaning issuesPaint waste treatmentSpecific water treatment objectivesMechanical engineeringWater treatment

The invention discloses spraying wastewater treatment equipment convenient for adding chemicals, and particularly relates to the technical field of spraying wastewater treatment. The spraying wastewater treatment equipment comprises a base and a top plate, an anti-splashing structure is fixedly connected to the top end of the base, and a first supporting column is fixedly connected to one side ofthe top end of the base in the anti-splashing structure; a second supporting column is fixedly connected to the other side of the top end of the base in the anti-splashing structure, a top plate is fixedly connected to the top ends of the first supporting column and the second supporting column, a first hydraulic air cylinder is fixedly connected to the bottom end of the top plate, and a first telescopic rod is fixedly connected to the bottom end of the first hydraulic air cylinder. In the equipment, the residue collecting structure is composed of the flow guiding groove, the collecting box, the fixing block and the mounting groove, the flow guiding groove is obliquely formed in one side of the top end of the box body, residue is pushed into the collecting box at the bottom of the flow guiding groove through a tool, then the fixing block is taken out of the mounting groove, and the residue in the collecting box is cleaned away; thus, the interior of the pipe body is free of blockage.

Owner:合肥乡情园林景观设计有限公司

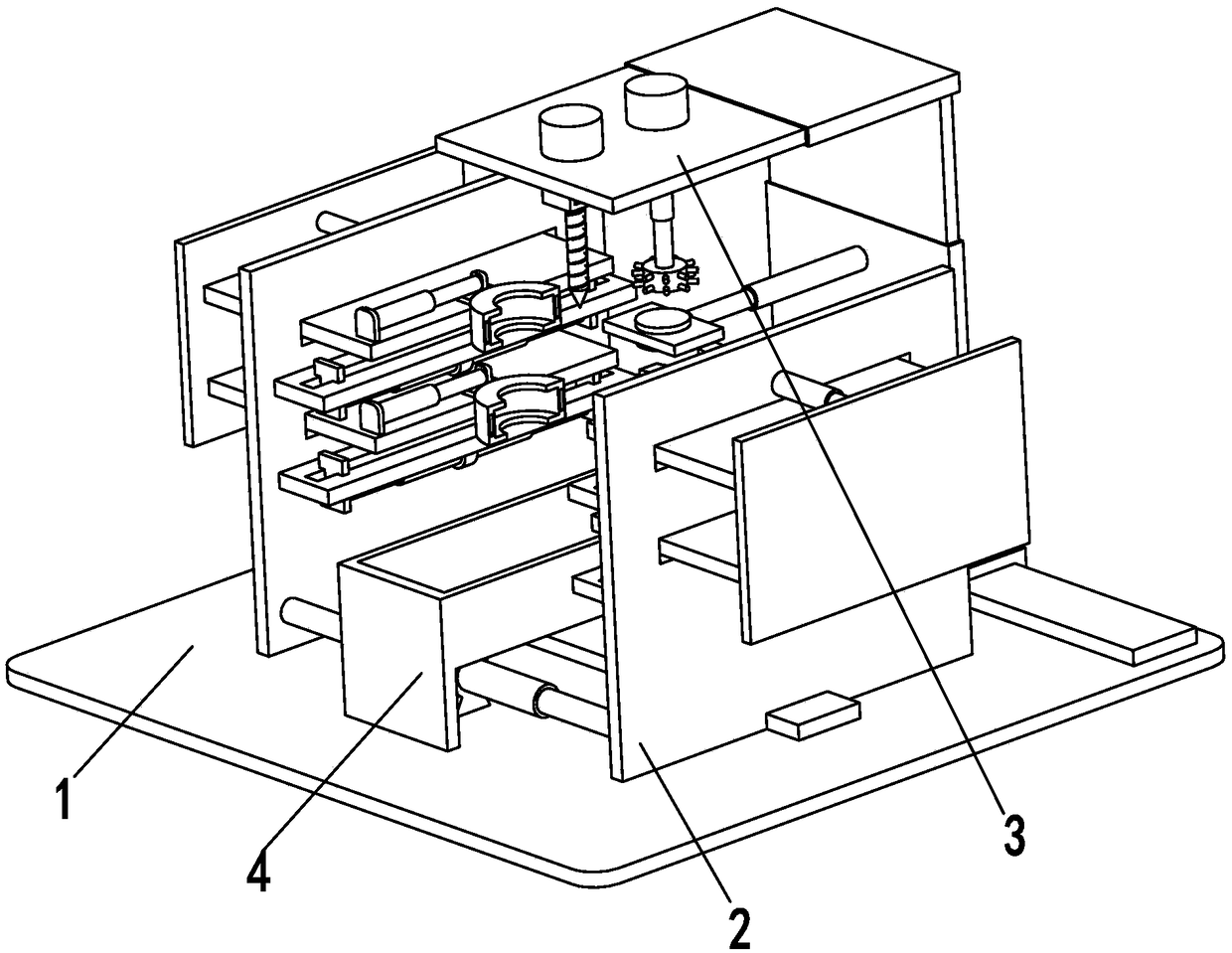

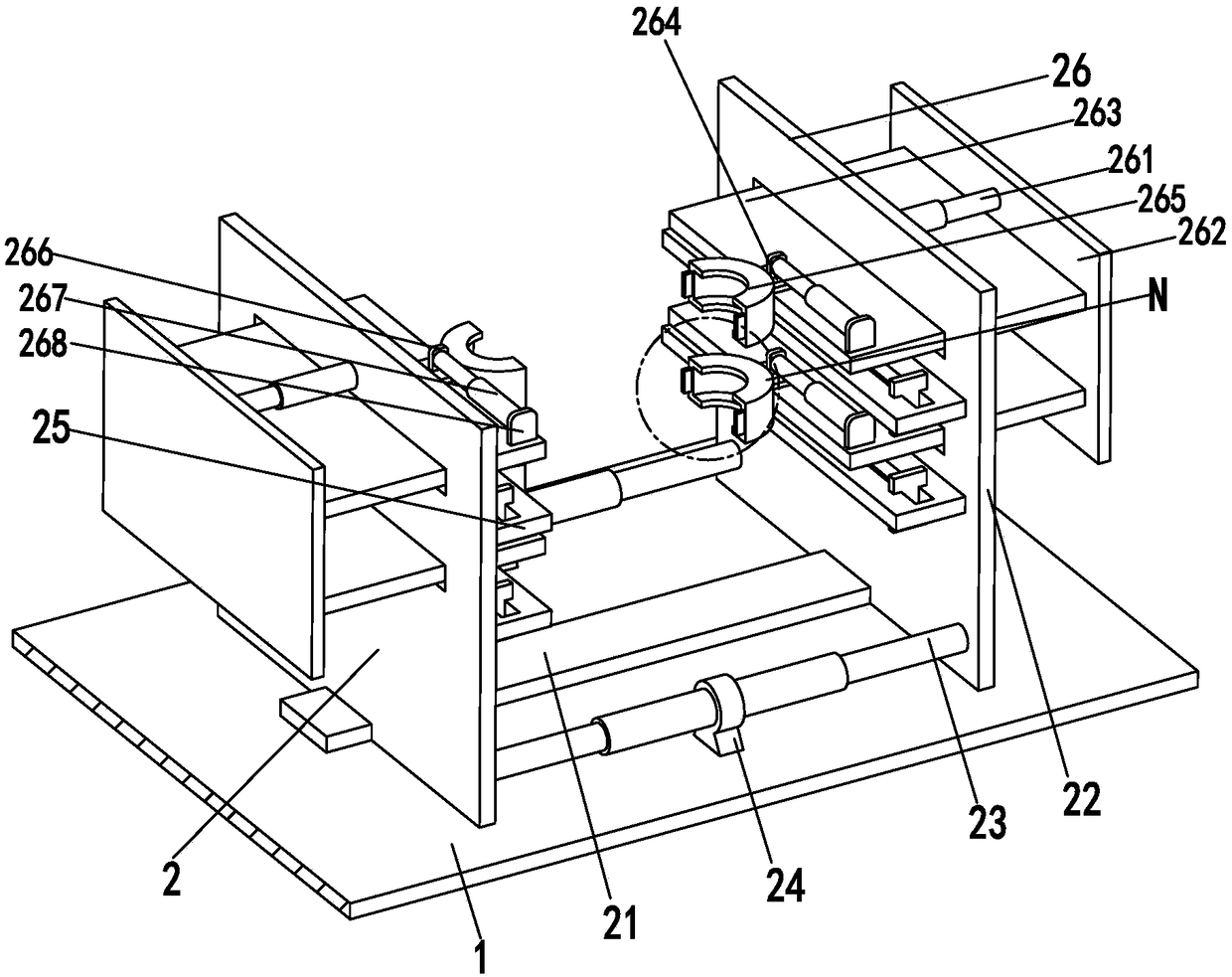

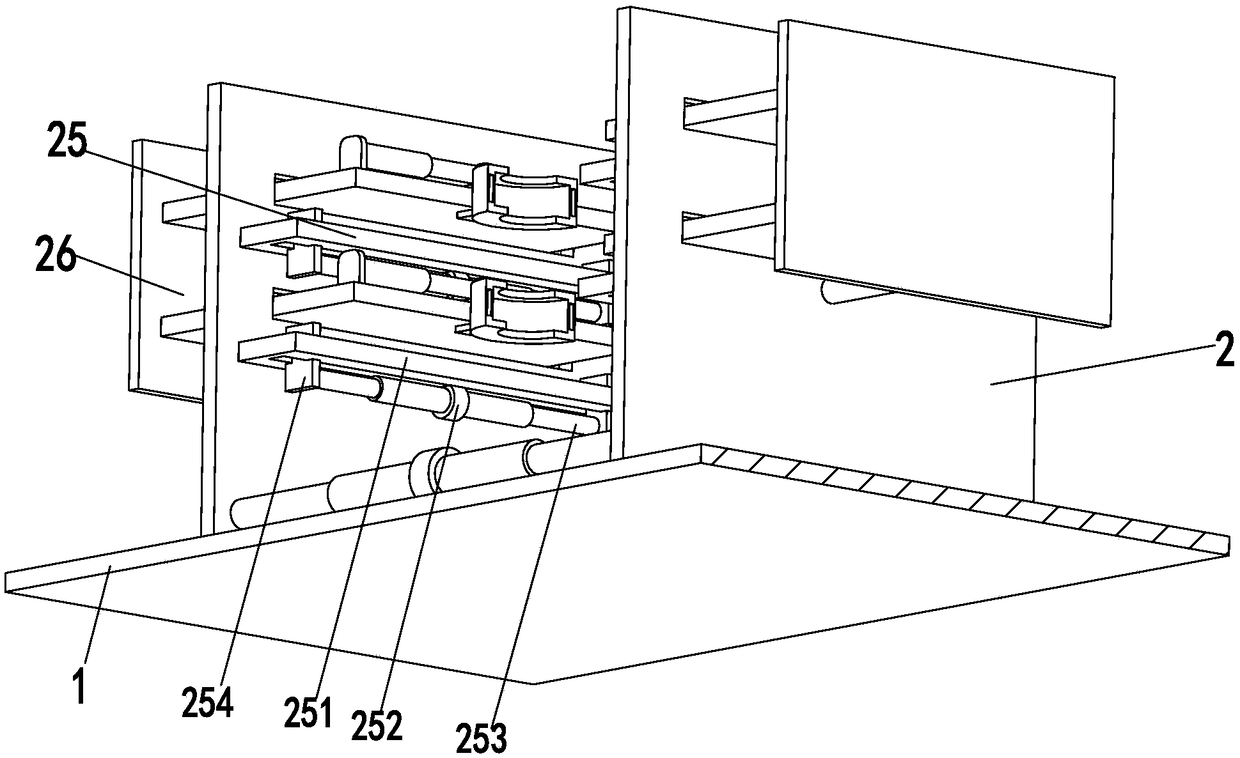

Assembly line for wood panel machining

ActiveCN108705612AExpand the scope of useReduce lossesStationary drilling machinesBark-zones/chip/dust/waste removalScrapAssembly line

The invention relates to an assembly line for wood panel machining. The assembly line comprises a bottom plate, a supporting device, a punching device and a waste box. The punching device is arrangedon the bottom plate. The supporting device is arranged at the lower end of the punching device. The waste box is arranged at the lower end of the supporting device. The supporting device and the wastebox are arranged on the bottom plate. The supporting device comprises a linear guide rail, a supporting frame, a position adjusting air cylinder, an installing base, a fixing mechanism and a guidingmechanism. The punching device comprises a linear sliding rail, an electric sliding block, a telescopic installing frame, a humidity adjusting mechanism, a drilling mechanism and a cleaning mechanism.The assembly line can solve the problems that in the existing wood panel drilling process, the labor cost is high, potential safety hazards exist, the work stability is poor, wood scraps are splashedall around, and the drilling position is likely to deflect; the automatic wood panel drilling function can be achieved; and the beneficial effects that the labor cost is low, safety is good, stability is good, the wood scraps cannot be splashed, and the drilling position is accurate are achieved.

Owner:广州法尼奥家居有限公司

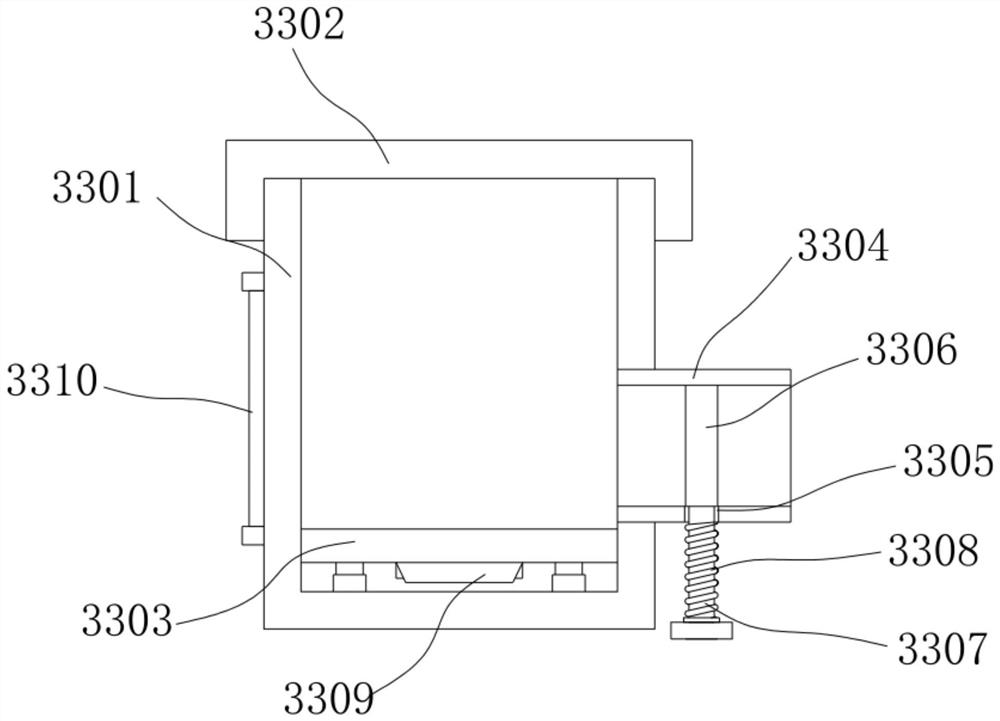

Medical biological tissue mashing device

The invention relates to a mashing device, in particular to a medical biological tissue mashing device. According to the medical biological tissue mashing device, discharging can be facilitated, splashing can be prevented, and a container can be fixed. According to the technical scheme, the medical biological tissue mashing device comprises a shell, a base, an isolation frame and a sterilizing lamp, the shell is connected to the middle of the top of the base, a square hole is formed in the front side of the shell, and the isolation frame for preventing biological tissue from splashing during mashing is arranged on the front side in the shell; sterilizing lamps capable of emitting ultraviolet rays to sterilize the biological tissues are connected to the left side and the right side of the top in the isolation frame. And an isolation frame can prevent the biological tissue from splashing outwards, and in the mashing process, a first contact rod can drive a guide plate and a movable door to be automatically closed, so that the shell is further blocked, and the biological tissue cannot be splashed out towards the front side.

Owner:LONGHUA BIOINDUSTRY & INNOVATION RES INST OF SHENZHEN UNIV

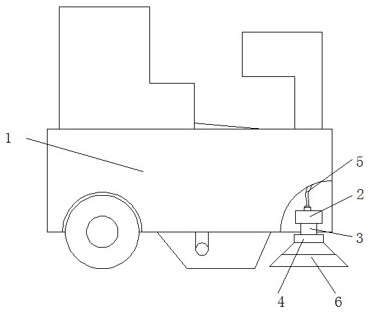

Sweeping disc device capable of automatically adjusting water sprinkling for motor sweeper

The invention discloses a sweeping disc device capable of automatically adjusting water sprinkling for a motor sweeper. The device comprises a machine body, rotating rings are arranged on the two sides of the bottom of one end of the machine body, connecting rods are fixedly connected to the bottoms of the rotating rings, fixing blocks are fixedly connected to the bottoms of the connecting rods, and water pipes are arranged on the tops of the rotating rings; a bottom rotating sleeve is arranged at the bottom of the fixing block, and a fixing cylinder is arranged on the side, close to the machine body, of the rotating ring. A second connecting line drives a connecting block to stretch, so that the connecting block moves towards one side of a pressure spring, the end, close to a water pipe, of a water outlet groove in the bottom is expanded, the water flowing end of the water outlet groove is expanded, the water outlet position is enlarged, water flow can flow to the top of a cleaning strip more widely, and the cleaning effect is improved. The device has the advantages that the spraying position of water flow can be adjusted, the water flow can be blocked, and splashing is prevented.

Owner:HUNAN UNIV OF TECH

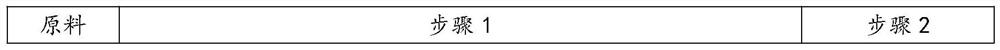

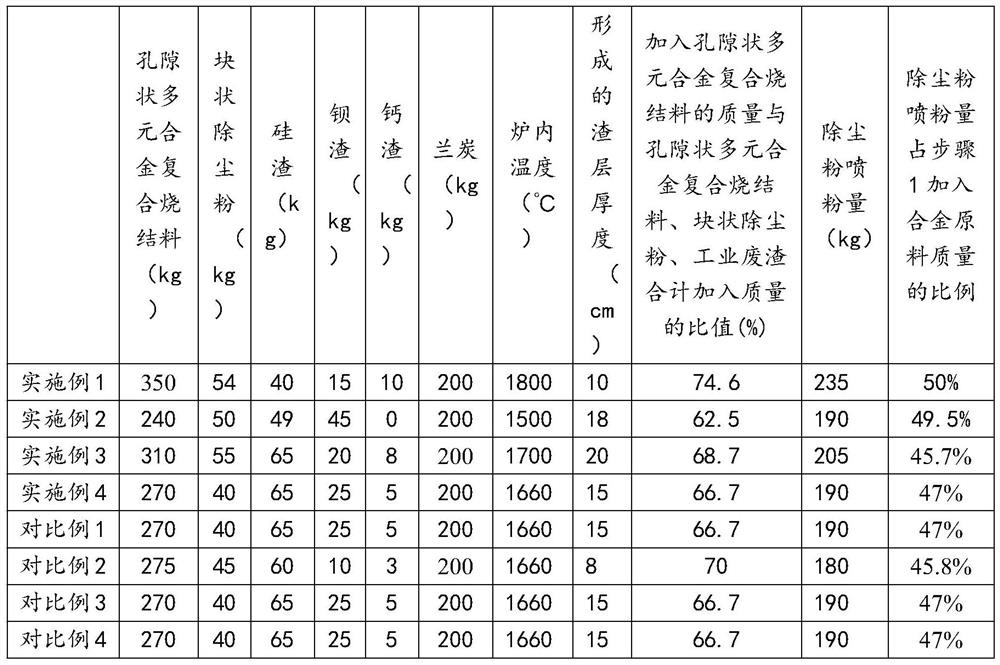

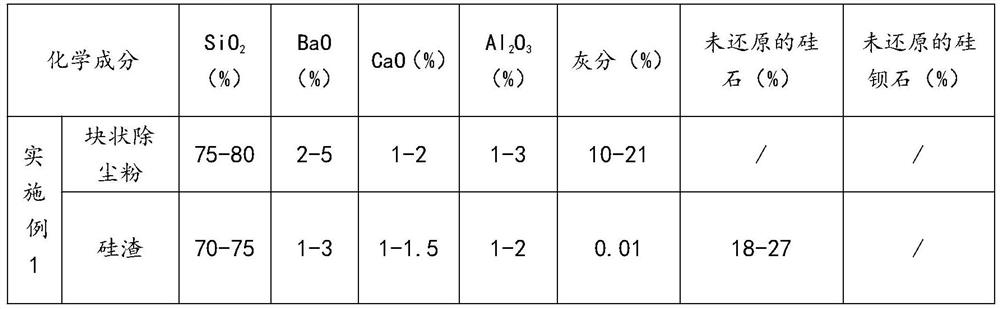

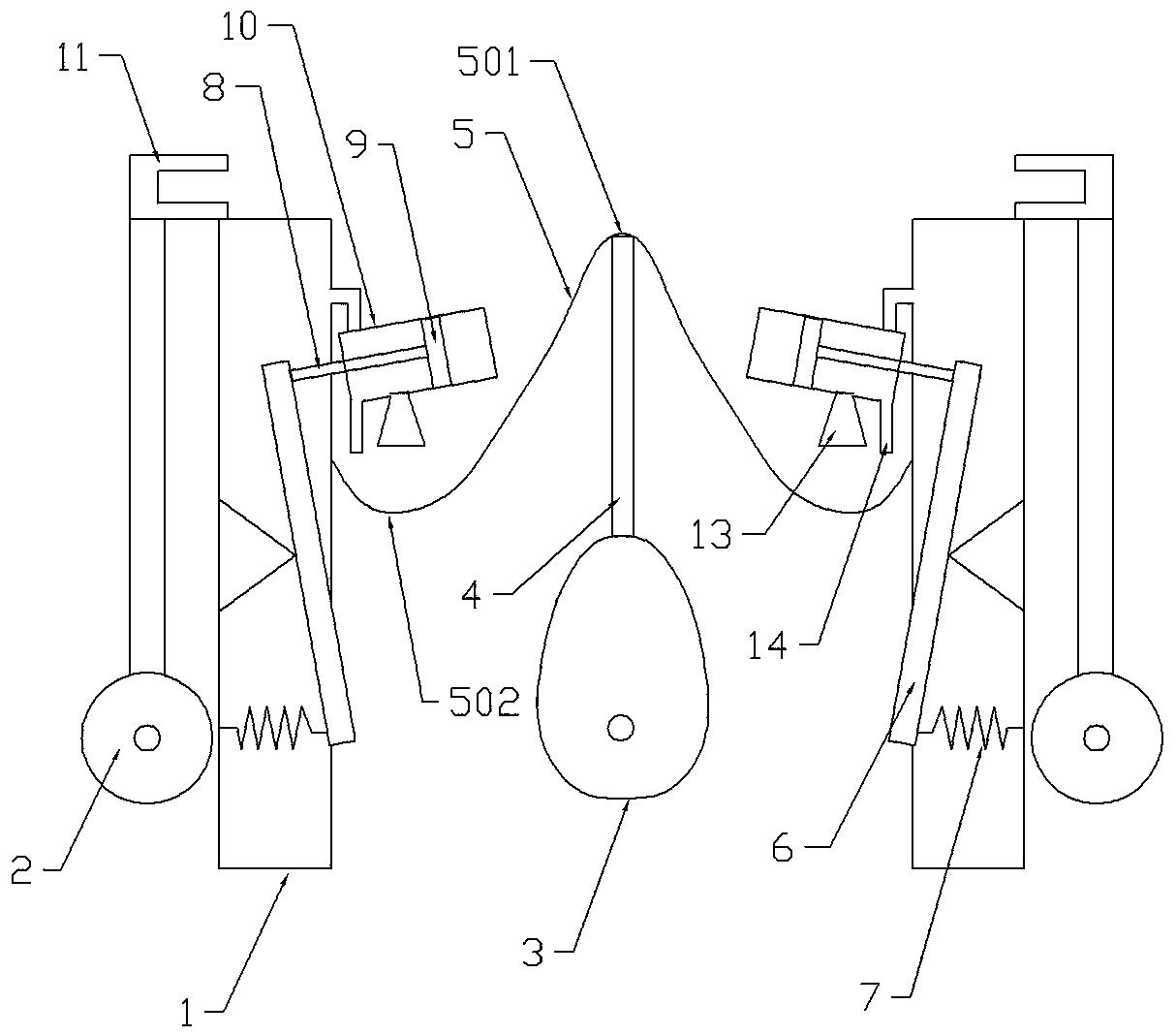

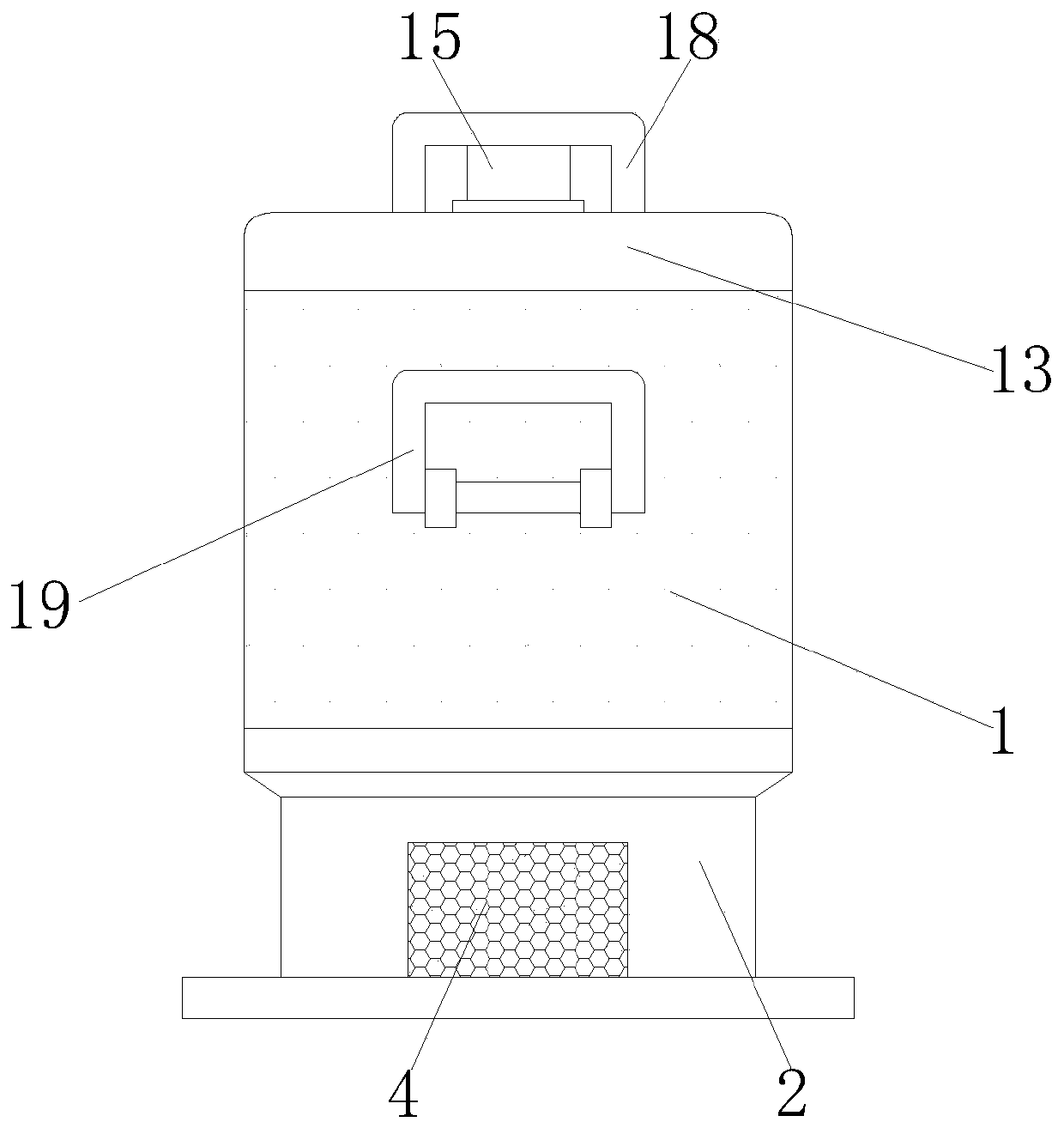

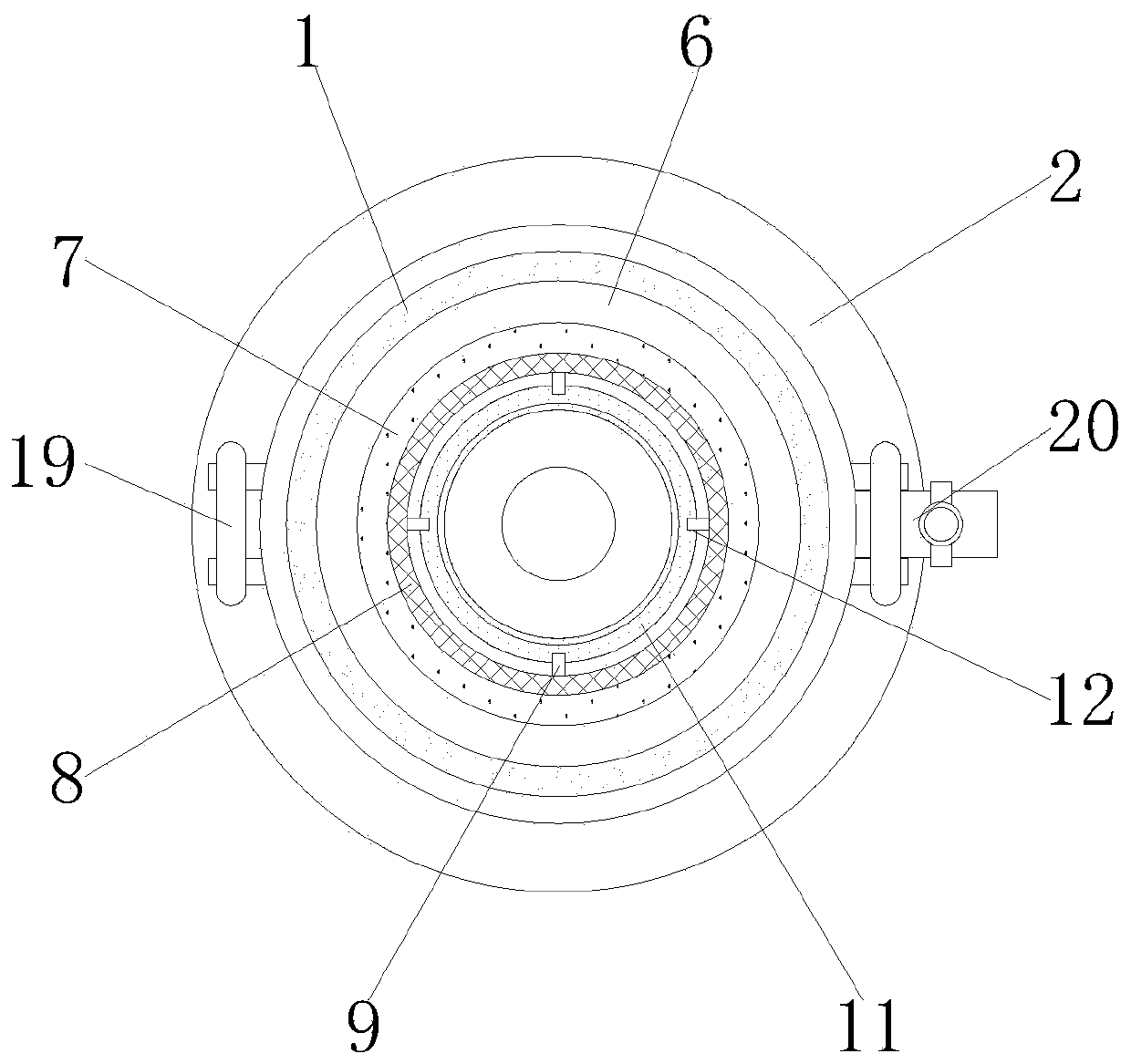

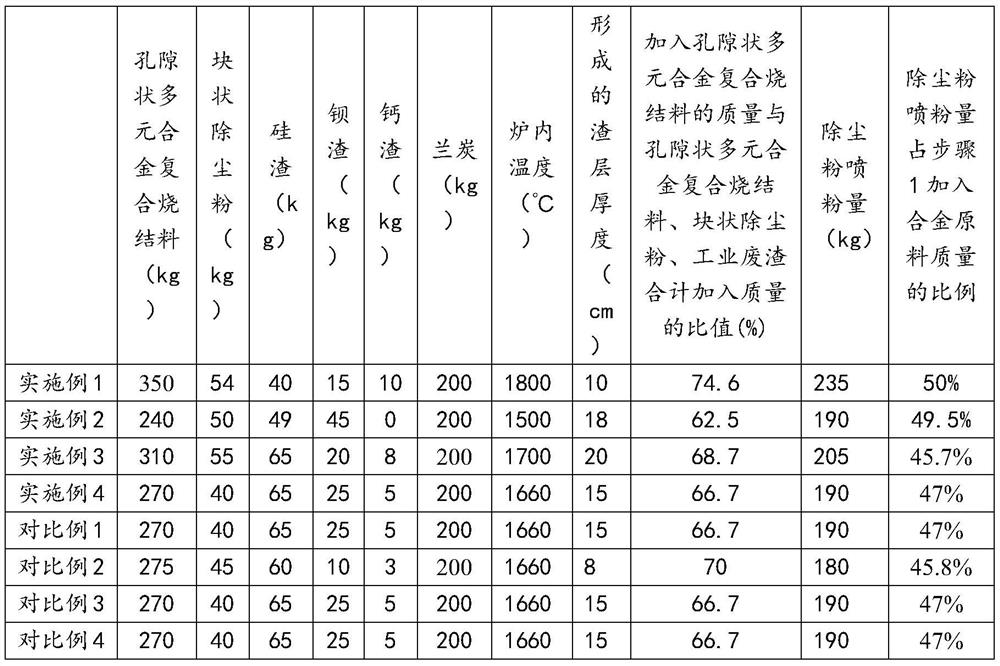

Method for preparing multi-component alloy by using powder spraying technology

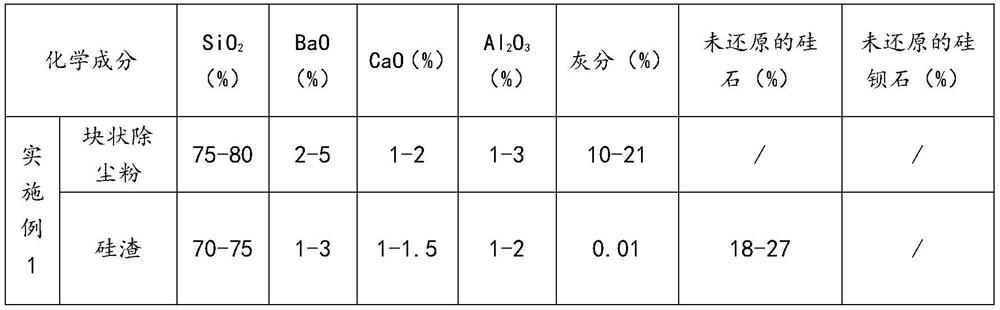

The invention relates to a method for preparing a multi-component alloy by using a powder spraying technology. The method comprises the following steps that a porous multi-component alloy composite sintering material, blocky dust removal powder, industrial waste residues and semi-coke are added into a refining furnace until all the raw materials in a furnace are molten, and then the dust removal powder is added into an alloy solution through a metal conveying pipeline inserted into the furnace in a powder spraying mode, after the dust removal powder is completely smelted into a metal solution,the alloy liquid is sampled and tested, and after the alloy liquid is compared with designed alloy components, substances such as the dust removal powder and the industrial waste residues with the corresponding mass are further added according to the element content requirement till the smelted multi-component alloy chemical components reach the designed alloy components. According to the method,the multi-component alloy is prepared in a powder spraying mode, the dust removal powder recycled in the metallurgical industry and the industrial waste residues containing metal elements are fully utilized, meanwhile, the effect of an artificial slag former is achieved, a thick slag layer is formed above the liquid level of the alloy solution, and rolling and splashing of molten metal are resisted in the powder spraying process.

Owner:SHIZUISHAN BAOMA XINGQING SPECIAL ALLOY CO LTD

glass cutting equipment

The invention belongs to the technical field of glass cutting or dividing and relates to glass cutting equipment. The glass cutting equipment comprises supporting frames and rotating cylinders, and the supporting frames are in opposite arrangement. A cam, an ejection rod and cloth are sequentially arranged on inner sides of the supporting frames from bottom to top, two ends of the cloth are detachably connected to the supporting frames respectively, the cloth comprises two concave surfaces and a convex surface, and the convex surface is in detachable connection with the ejection rod. A lever is mounted in each supporting frame, the lower end of each lever is positioned on the outer side of the corresponding supporting frame, a spring is connected between the lower end of each lever and the inner wall of the corresponding supporting frame, and the upper end of each lever is arranged on the inner side of the corresponding supporting frame and connected with a piston rod. Cylinder bodies are arranged above the concave surfaces of the cloth and in slide fit with pistons internally, each piston is connected with a piston rod, each cylinder body is provided with an opening, and a cover plate is hinged to each opening. The rotating cylinders are symmetrically arranged on the outer sides of the supporting frames along the center axis of the ejection rod, and the end of each rotating cylinder is connected with a clamping seat. The glass cutting equipment has advantages of splattering prevention in glass cutting, high automation degree, simplicity in operation and high practicality and can be popularized in the field of glass cutting.

Owner:CHONGQING SHUNHUA SAFETY GLASS CO LTD

A wood panel automatic processing robot

ActiveCN108673648BSplash won'tReduce labor costsDrilling machinesBark-zones/chip/dust/waste removalWaste materialIndustrial engineering

The invention discloses an automatic wood board machining robot. The automatic wood board machining robot comprises a bottom plate, a supporting device, a perforating device and a waste material box,the perforating device is arranged on the bottom plate, the supporting device is arranged at the lower end of the perforating device, the waste material box is arranged at the lower end of the supporting device, moreover, both the supporting device and the waste material box are installed on the bottom plate, the supporting device comprises a linear guide rail, a supporting frame, a position adjusting air cylinder, a mounting seat, a fixing mechanism and a guide mechanism, and the perforating device comprises a linear slide rail, an electric sliding block, a telescopic mounting frame, a drilling mechanism and a cleaning mechanism. According to the automatic wood board machining robot, the problems that in an existing wood board drilling process, the labor cost is high, potential safety hazards exist, the working stability is poor, saw dust splashes around, and the drilling position is prone to deviation can be solved, an automatic drilling function on a wood board can be achieved, andthe advantages of being low in labor cost, good in safety, good in stability, free of splashing of the saw dust, accurate in drilling position and the like are achieved.

Owner:WENZHOU QIFANG NEW ENERGY CO LTD

A method of cutting glass

ActiveCN107417081BProtectiveIntegrity guaranteedGlass severing apparatusCutting glassReciprocating motion

The invention relates to a method for cutting glass, and belongs to the technical field of glass cutting or division. The method comprises the following steps: I, preparing a glass cutting device; II, rotating a rotating cylinder, and fixing a piece of glass; III, cutting a trace by using a glass cutting device; IV, powering on a motor, and driving a top rod to make reciprocation movement at the cut part of the glass; and V, pushing a lever through a cam, driving a piston to slide inside the cylinder, and sucking glass dribs. By adopting the scheme, glass splashing is prevented, and the method is high in automation degree, simple to operate and good in practicability and can be popularized in the field of glass cutting.

Owner:CHONGQING SHUNHUA SAFETY GLASS CO LTD

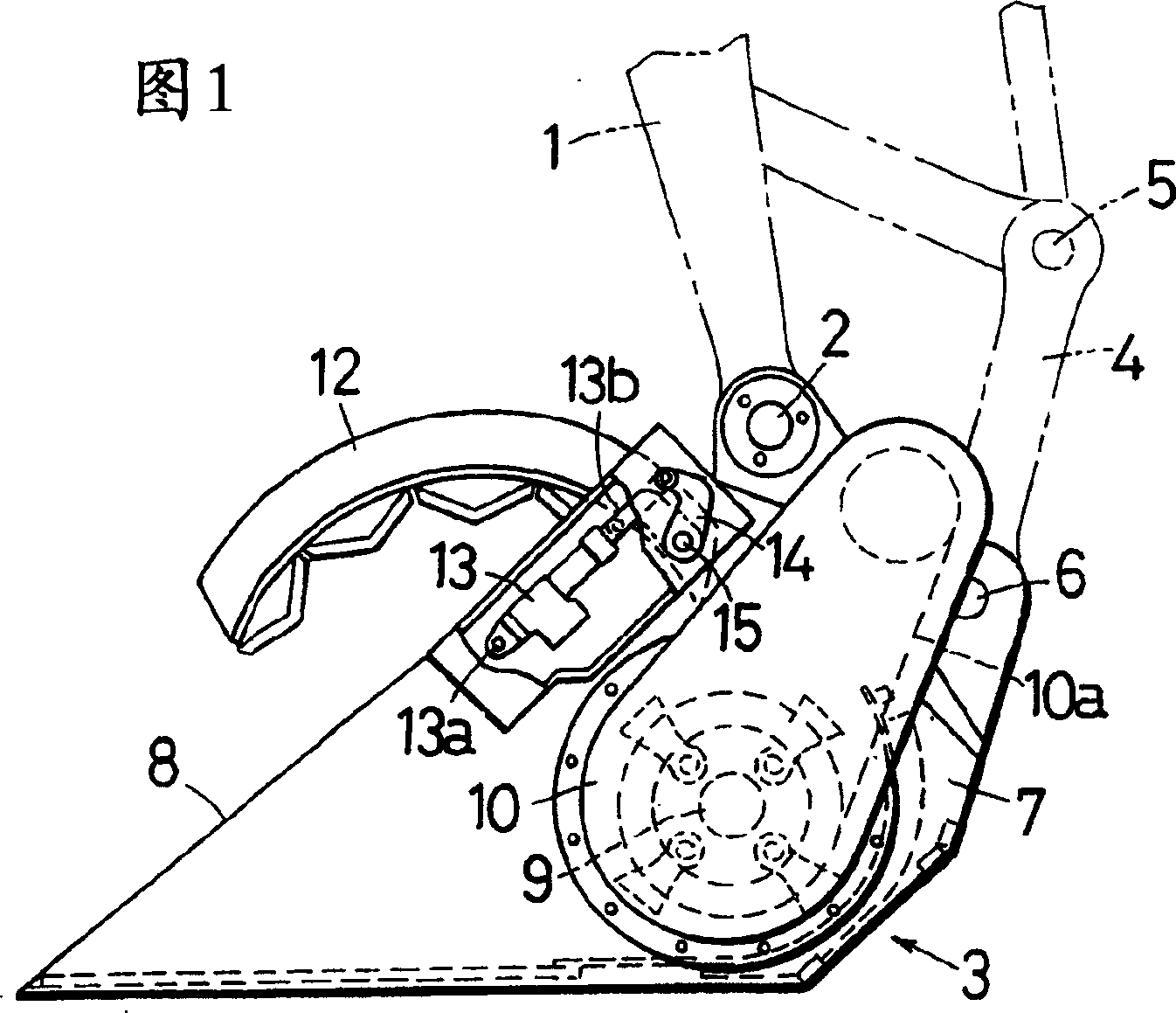

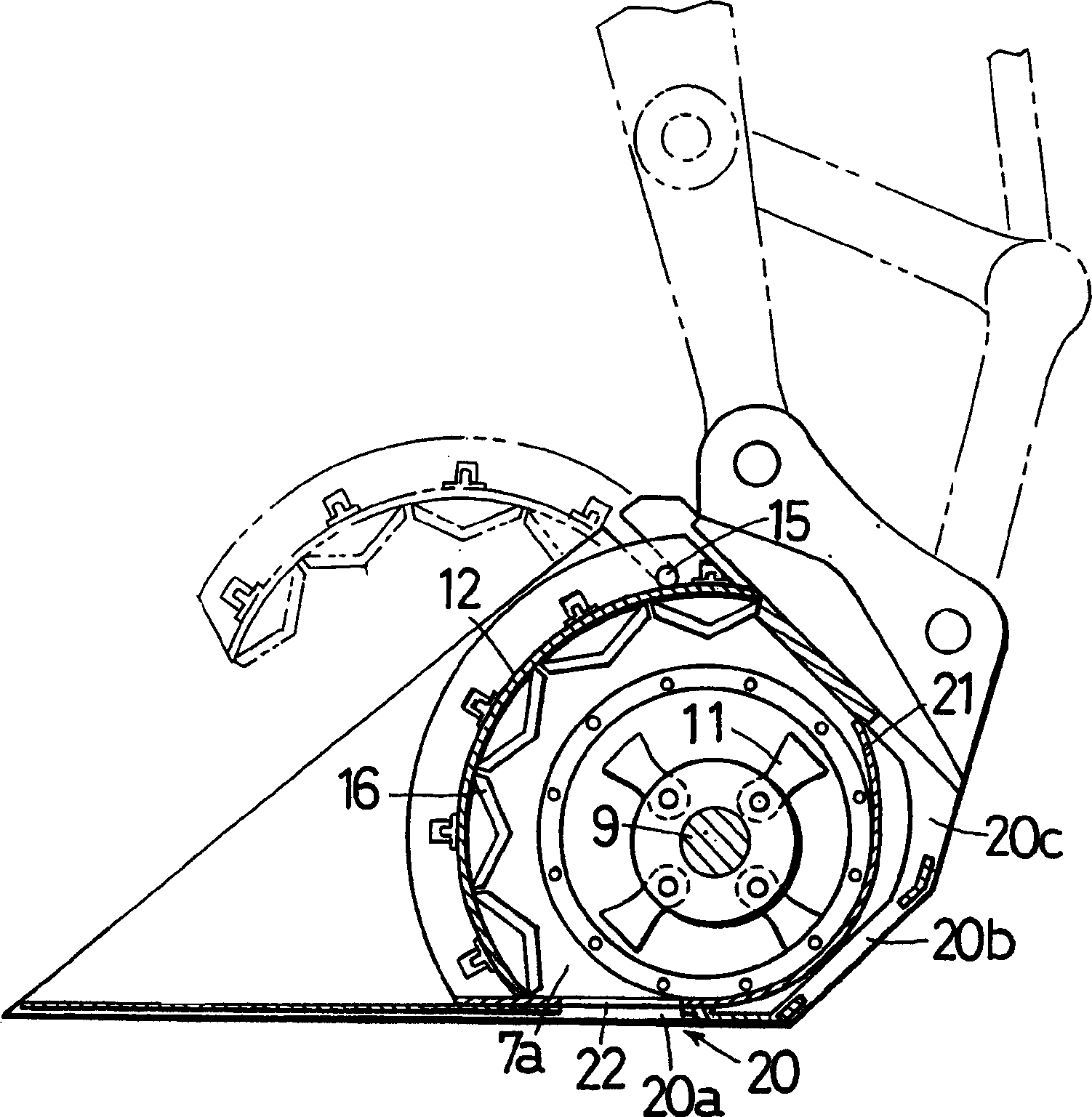

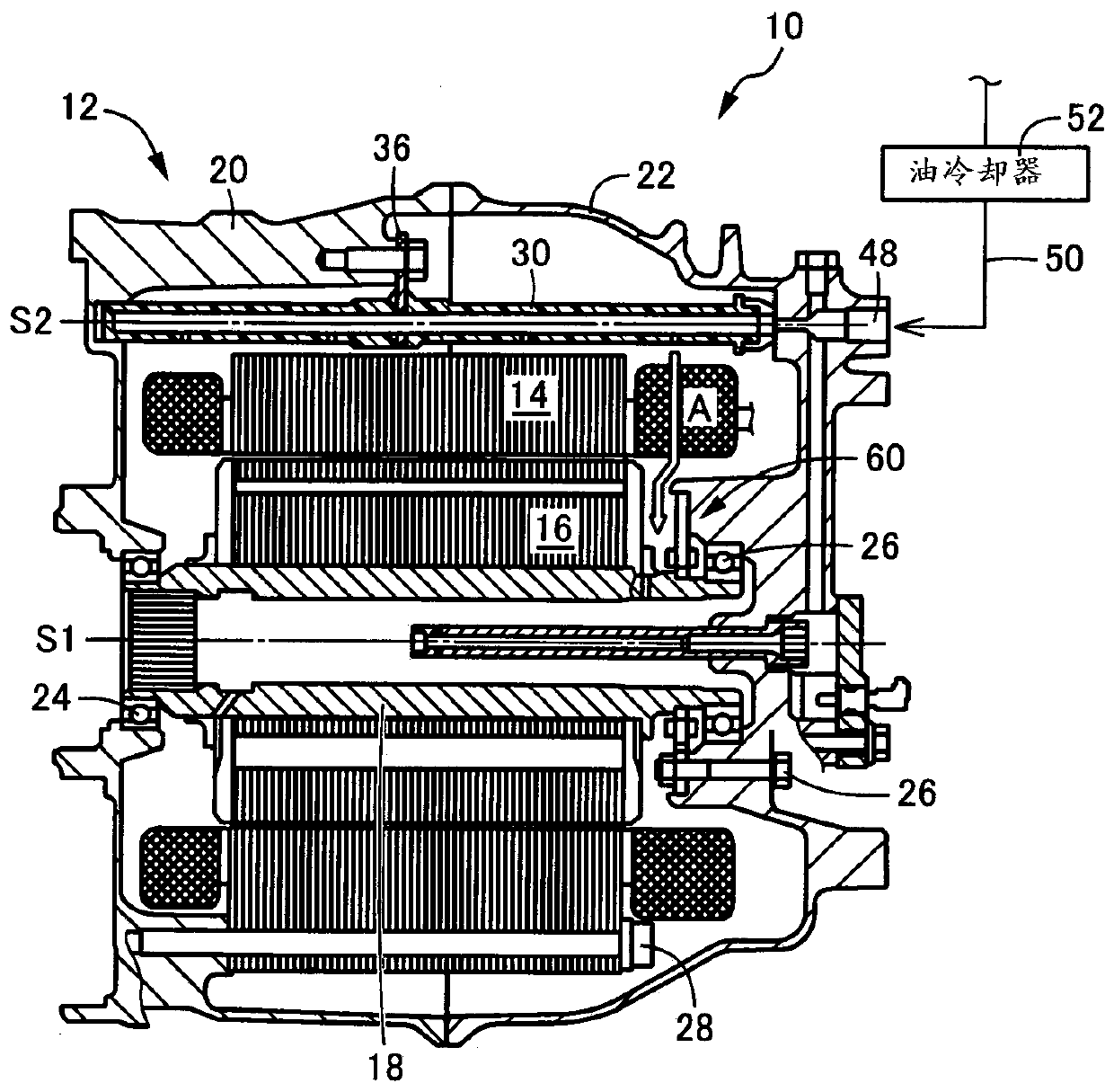

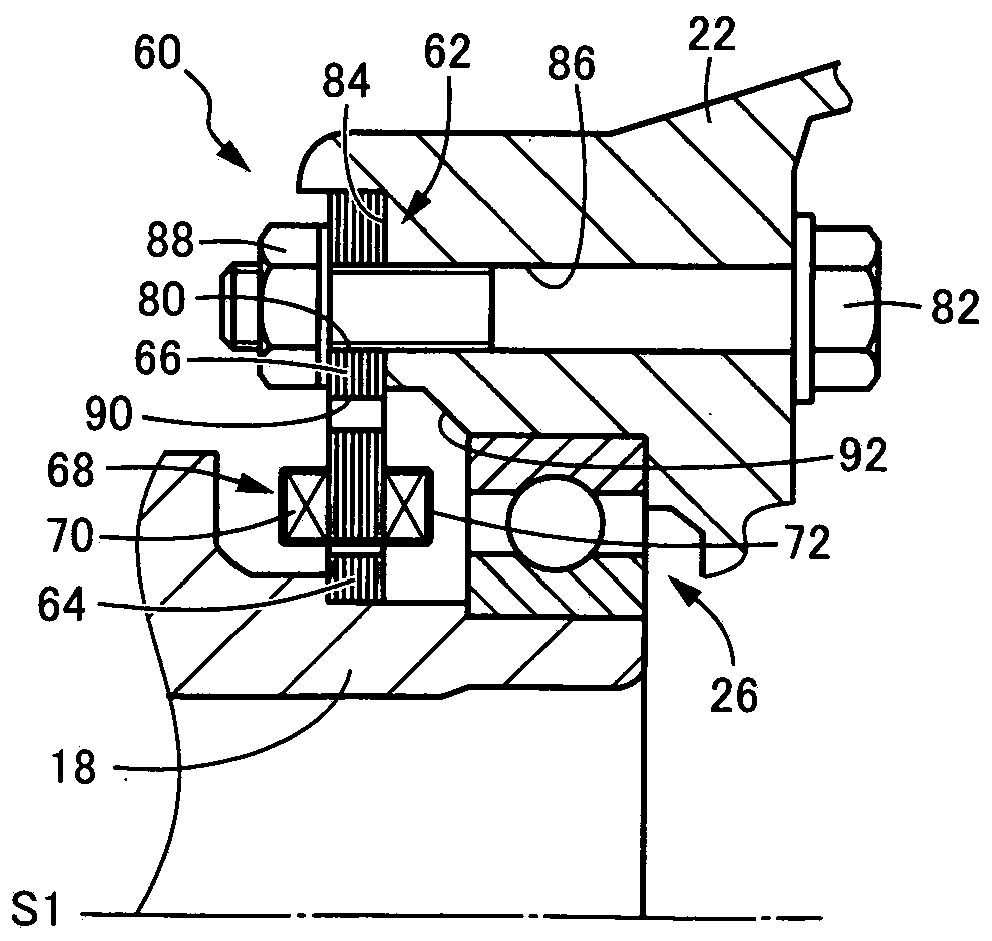

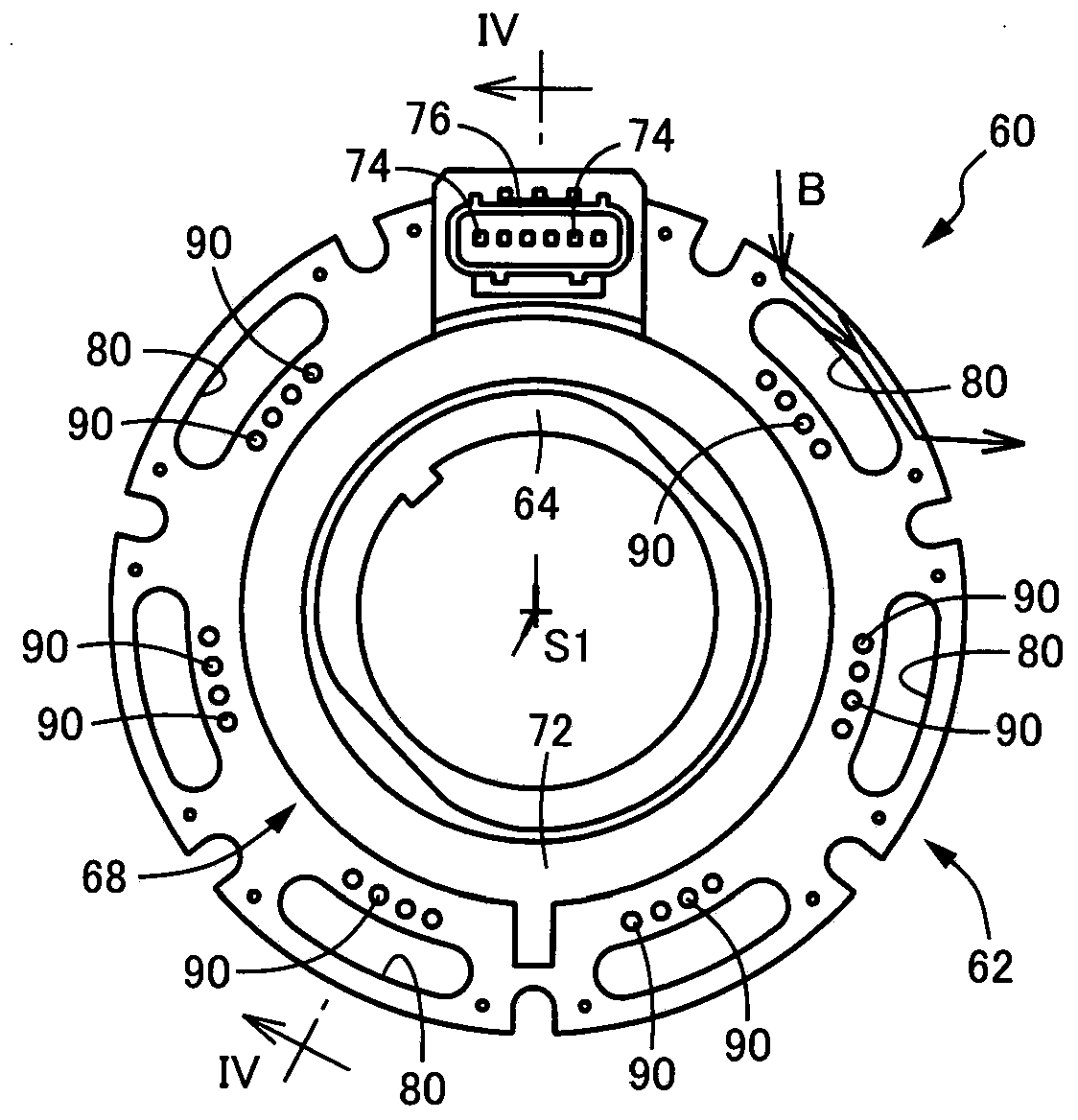

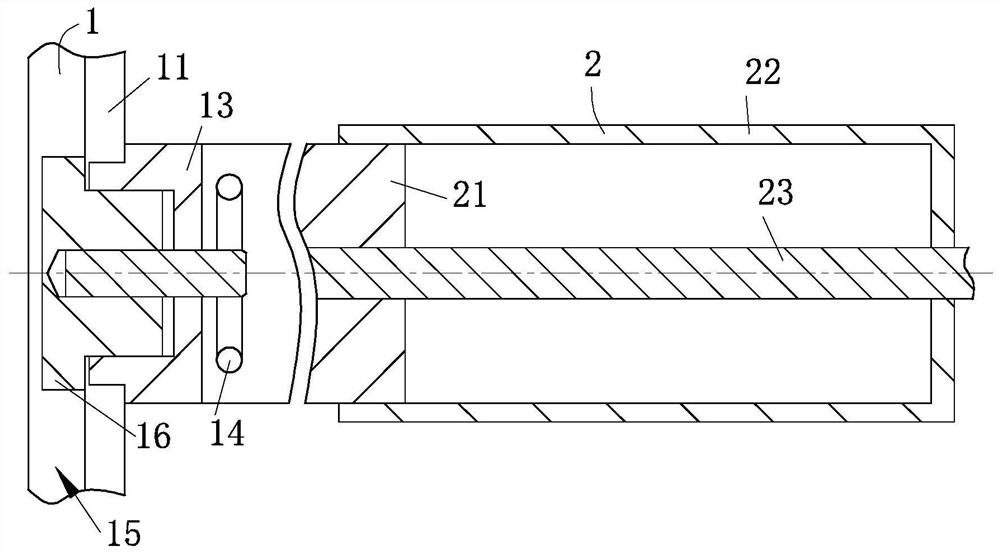

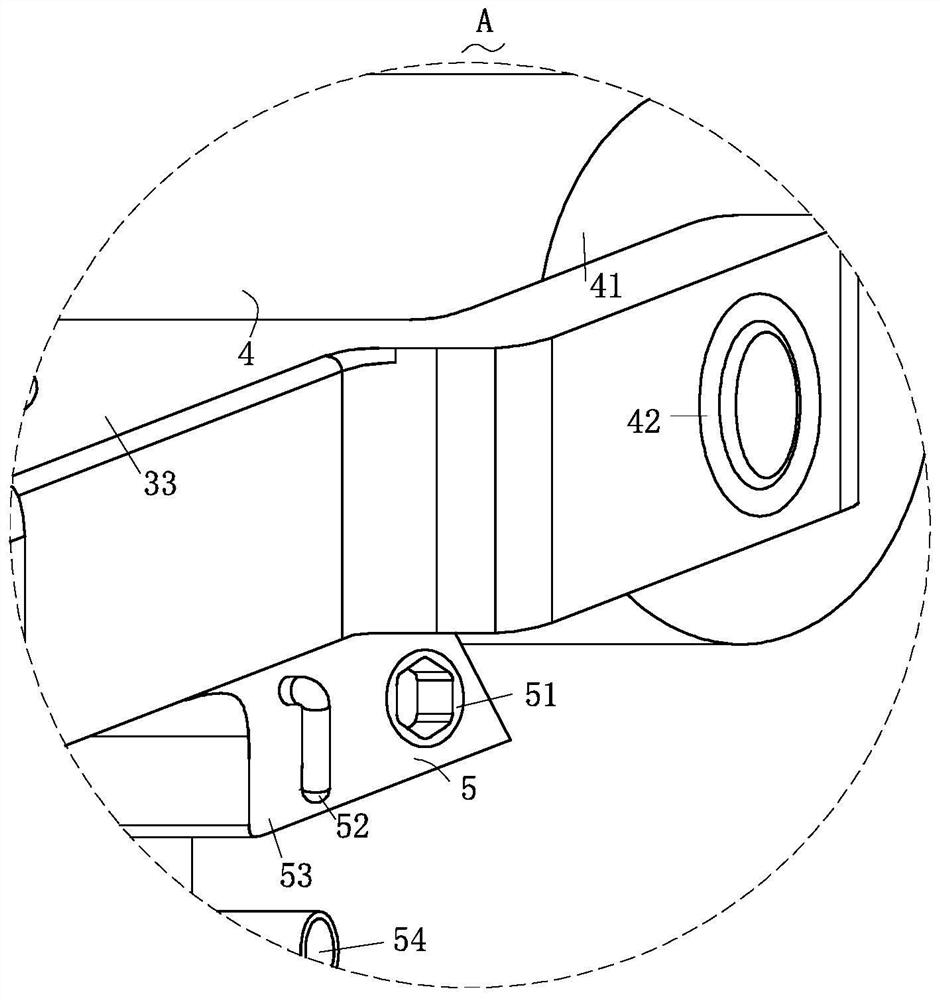

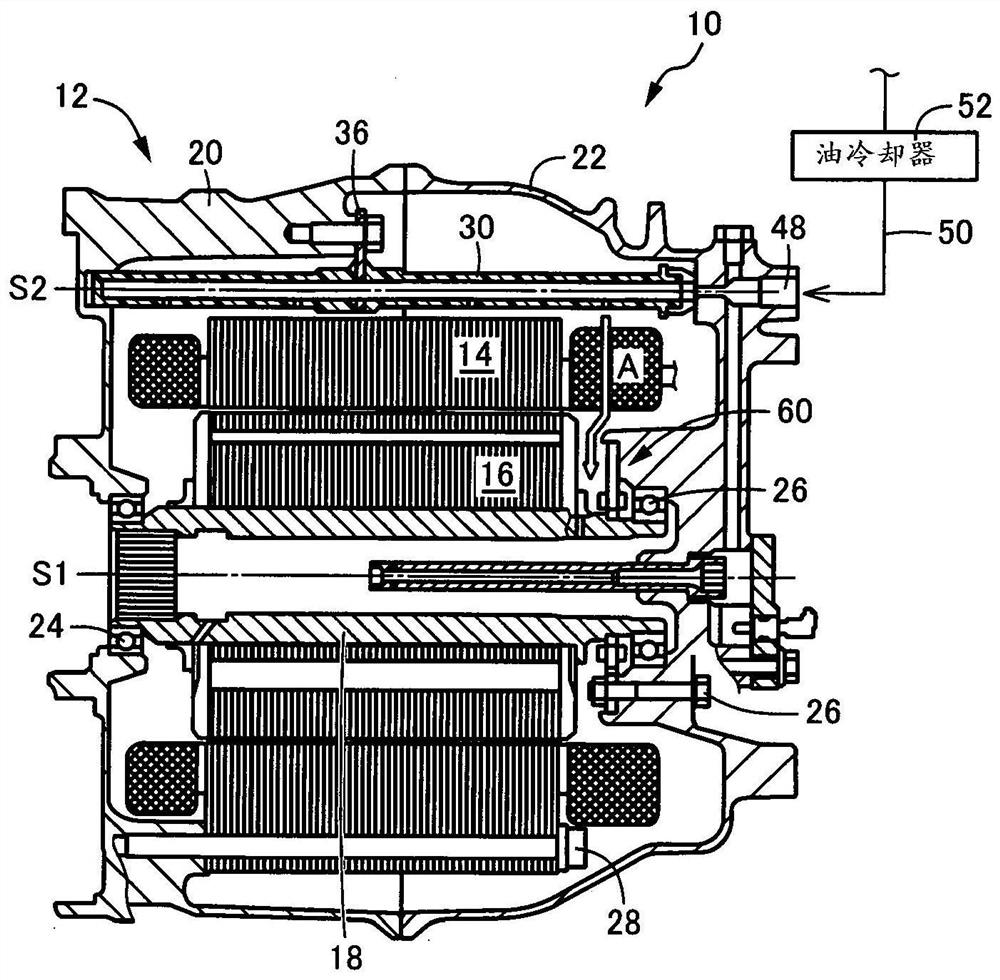

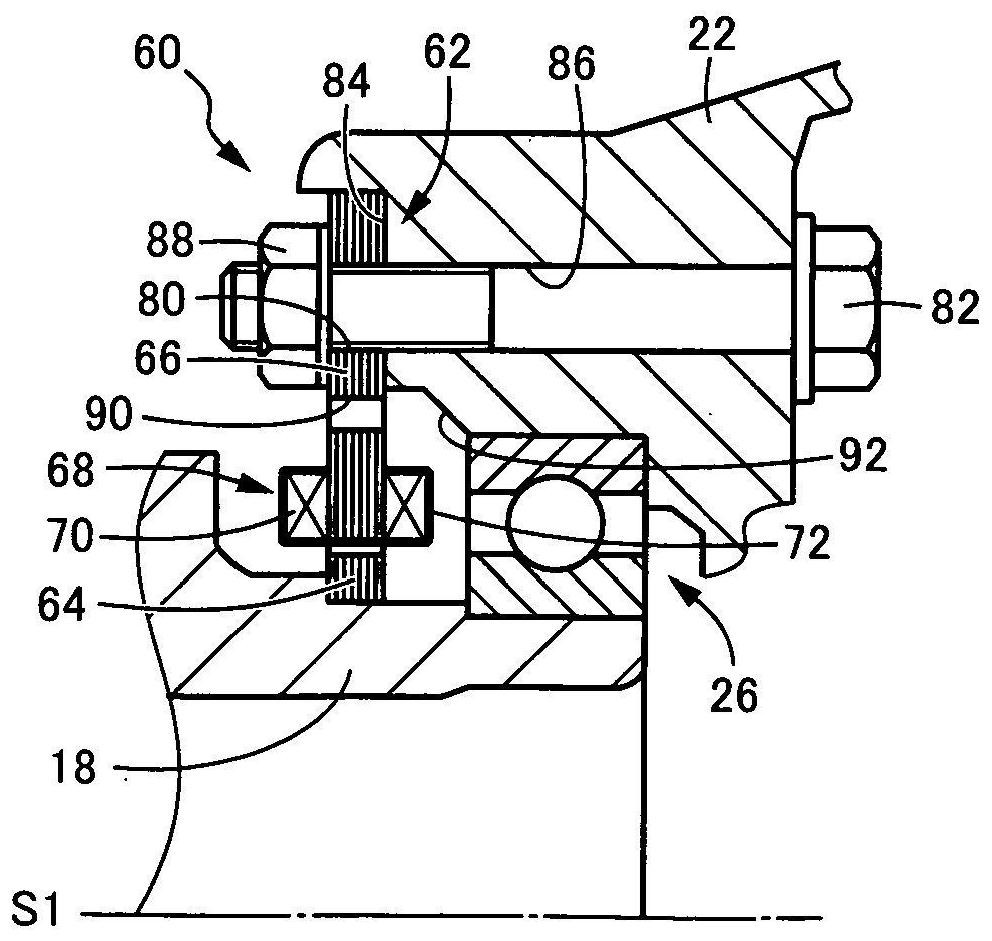

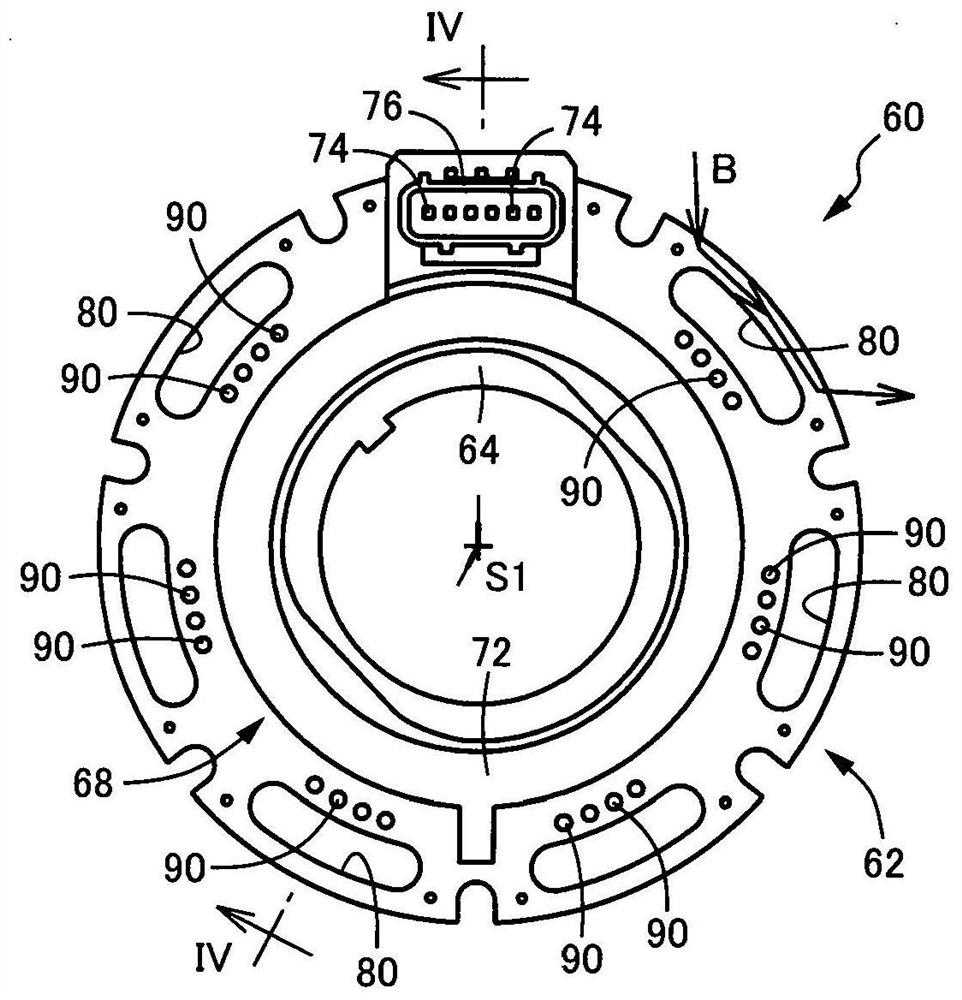

Rotating machine lubrication structure

The invention relates to a rotary machine lubricating structure. In a rotary machine in which a resolver is disposed in a housing, lubricating oil can be appropriately supplied to a bearing on the outer side of the resolver. A through oil hole (90) is provided in the inner peripheral portion of a resolver stator (62) fixed to a mount (84) on the inner surface of a second housing member (22). Therefore, a part of the lubricating oil flowing down from the stator coil part of the rotary machine directly flows into the through oil hole (90) or indirectly flows into the through oil hole (90) due tosplashing or the like caused by rotation of the shaft (18) or the rotor and is supplied to the bearing (26). Since the resolver stator (62) is fixed to the second housing member (22), lubricating oildoes not spatter due to centrifugal force, and a sufficient amount of lubricating oil can be supplied to the bearing (26) and appropriately lubricated by appropriately determining the size, the number, the position, etc. of the through oil holes (90).

Owner:TOYOTA JIDOSHA KK

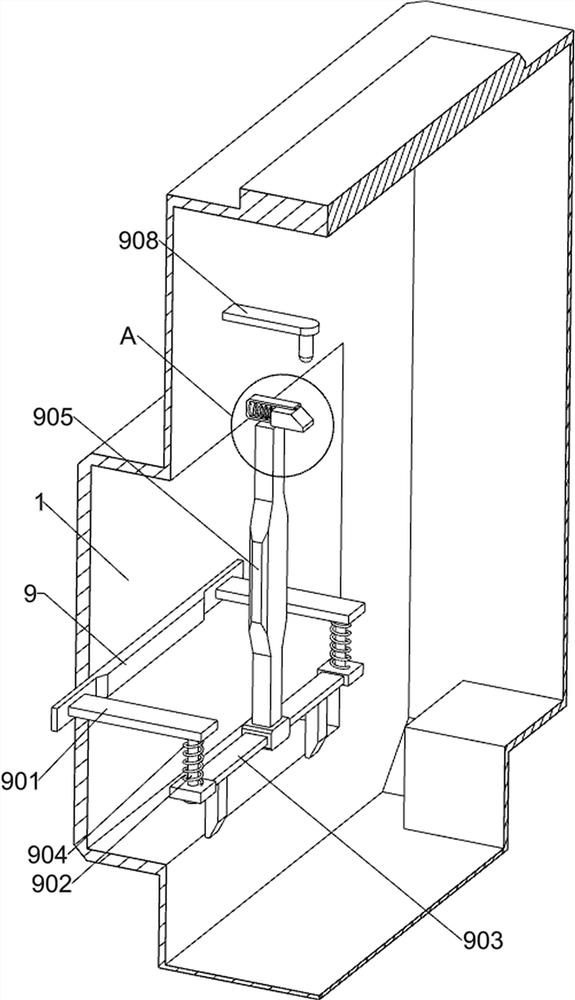

Traditional Chinese medicine filtering device

InactiveCN111135626AEasy to addSplash won'tMembrane filtersMoving filtering element filtersMedicinal herbsDrive shaft

The invention discloses a traditional Chinese medicine filtering device. The device comprises an engine base and a screen bucket; the bottom edge of the engine base and a fixed seat are fixedly installed; a motor is fixed to the center of the bottom of the engine base; the output end of the motor is connected with a transmission shaft; a fixed disc is welded to the surface of the inner side of theengine base; a thin-wall bearing is arranged on the inner side of the fixed disc; a filtering barrel is arranged on the inner side of the thin-wall bearing; the bottom of a filter barrel is fixed tothe top end of the transmission shaft; the bottom of the screen bucket is in butt joint with the top end of a boss; and a chute is formed in the surface of the outer side of the screen bucket. According to the traditional Chinese medicine filtering device, the screen bucket is positioned and butted with a limiting plate on the inner wall of the filter barrel through the chute in the outer side surface to make the screen bucket to be clamped and mounted in the filter barrel; and when water and waste residues of fine particles in the screen bucket are discharged, a sealing cover is opened, the screen bucket is pulled to longitudinally slide through the chute and a limiting plate, and therefore traditional Chinese medicine materials in the screen bucket can be conveniently taken out and collected.

Owner:孙琳 +2

A method for preparing multi-element alloys by powder spraying technology

The invention relates to a method for preparing multi-element alloys by using powder spraying technology. By adding porous multi-element alloy composite sintering material, massive dust removal powder, industrial waste residue, and semi-coke into a refining furnace, powder spraying is used until all raw materials in the furnace are melted. Add dust removal powder to the alloy melt through the metal feeding pipe inserted into the furnace. After the dust removal powder is completely smelted into the metal melt, the alloy liquid is sampled and tested, and compared with the designed alloy composition, further according to the element content requirements Add corresponding quality of dust removal powder, industrial waste slag and other substances until the chemical composition of the smelted multi-element alloy reaches the designed alloy composition. The present invention prepares multi-element alloys by spraying powder, fully utilizes dust removal powder recovered from the metallurgical industry and industrial waste slag containing metal elements, and at the same time plays the role of artificial slagging agent, so that a thicker layer is formed above the surface of the alloy melt The slag layer resists the tumbling and splashing of molten metal during the powder spraying process.

Owner:SHIZUISHAN BAOMA XINGQING SPECIAL ALLOY CO LTD

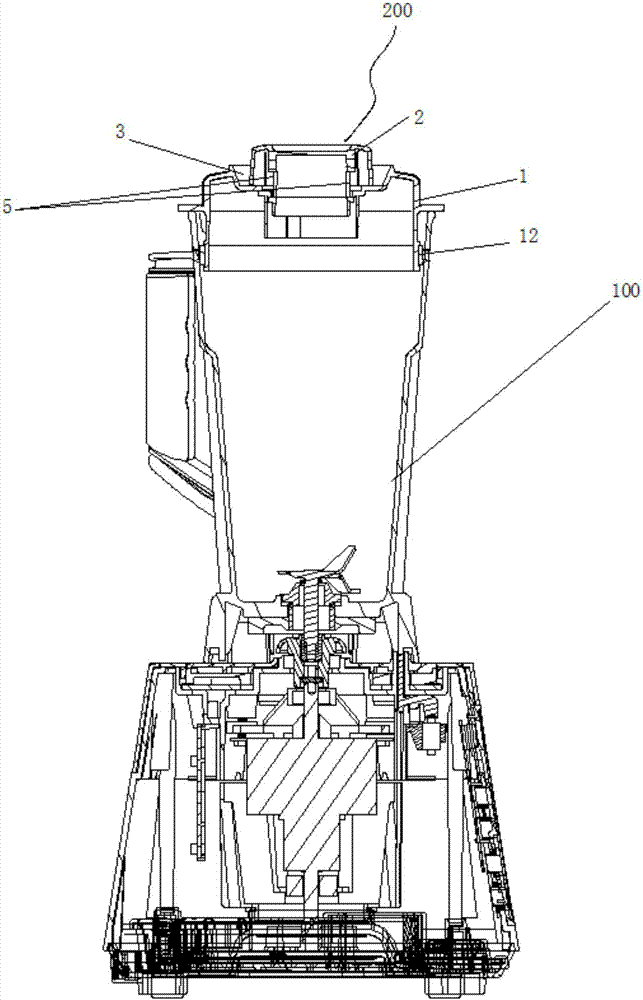

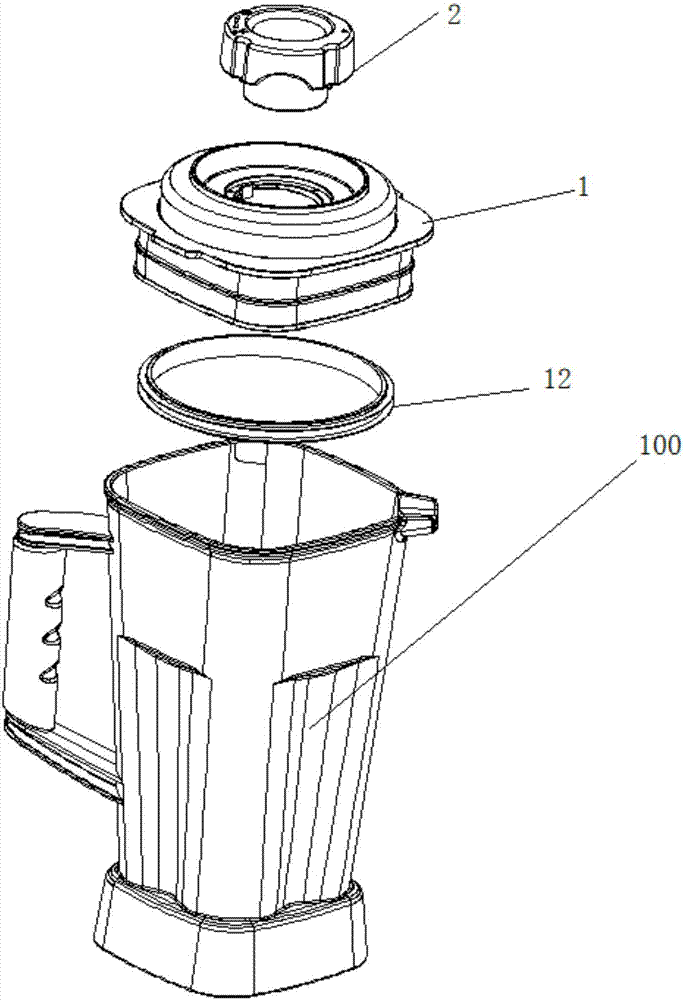

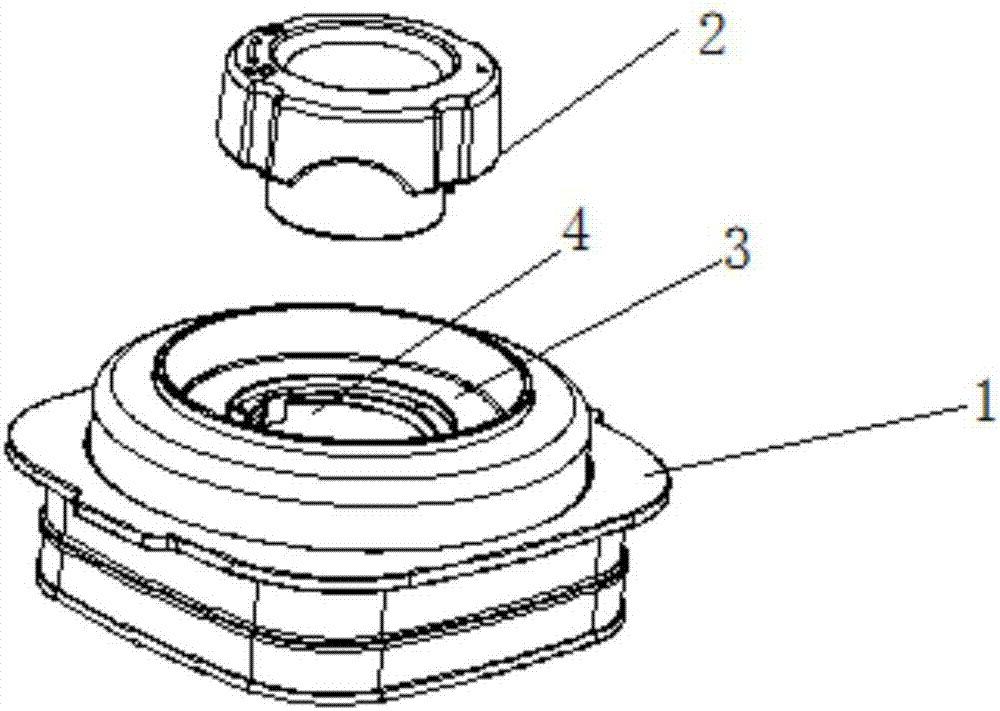

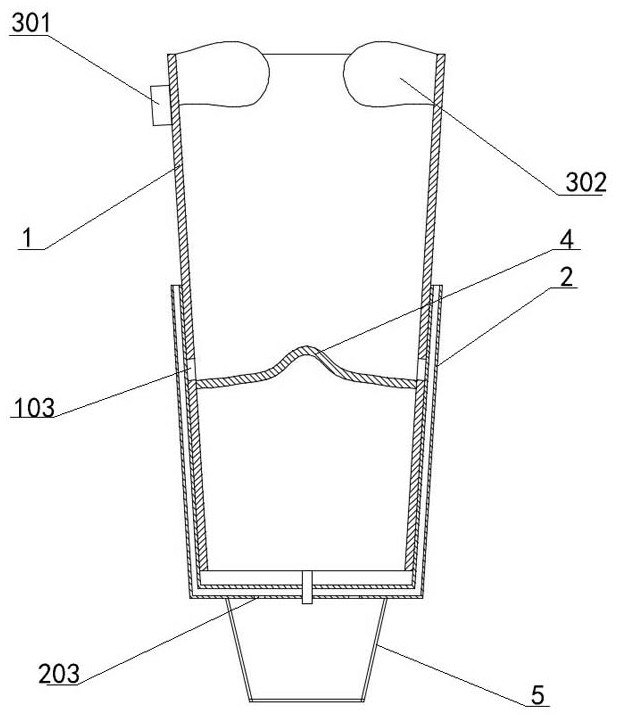

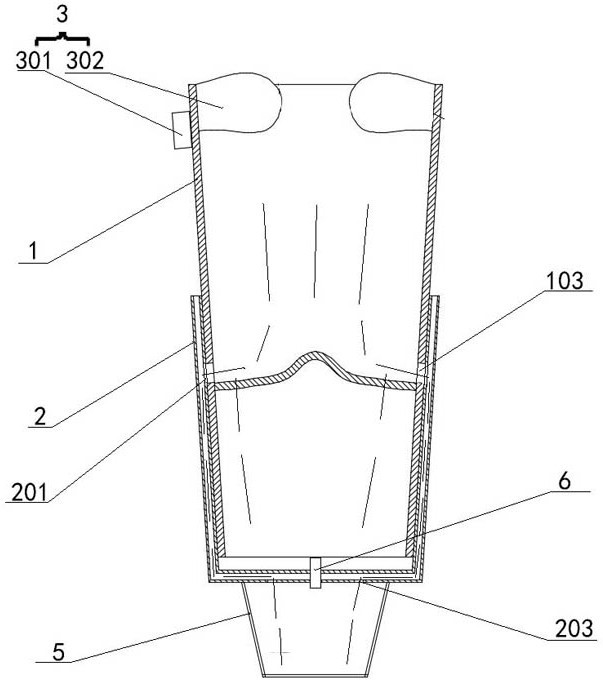

Splash-proofing and ventilating cup cover and electric food processor provided with splash-proofing and ventilating cup cover

ActiveCN107157361AAvoid spillingRealize heated exhaustBio-packagingKitchen equipmentProcess engineeringMechanical engineering

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

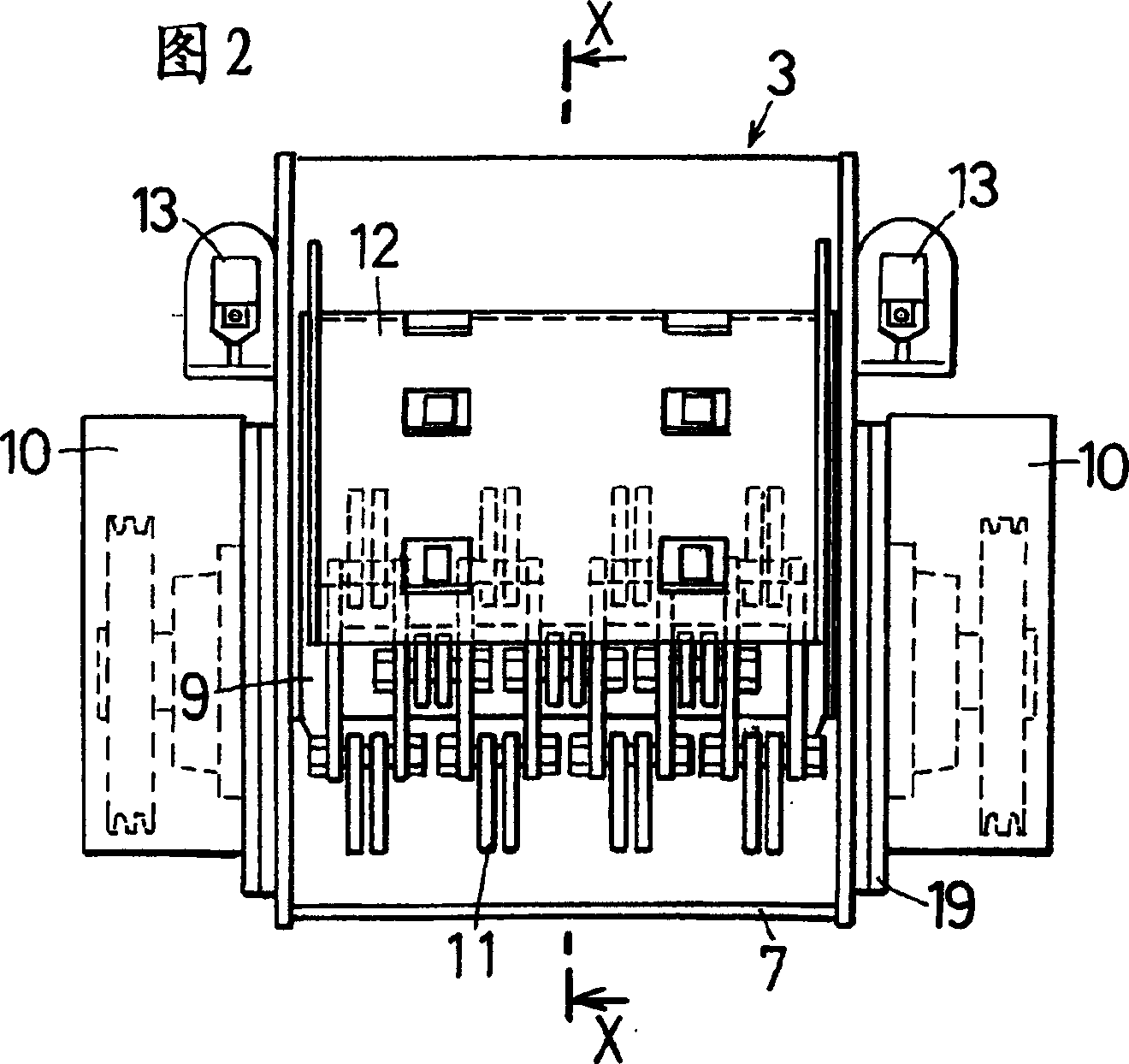

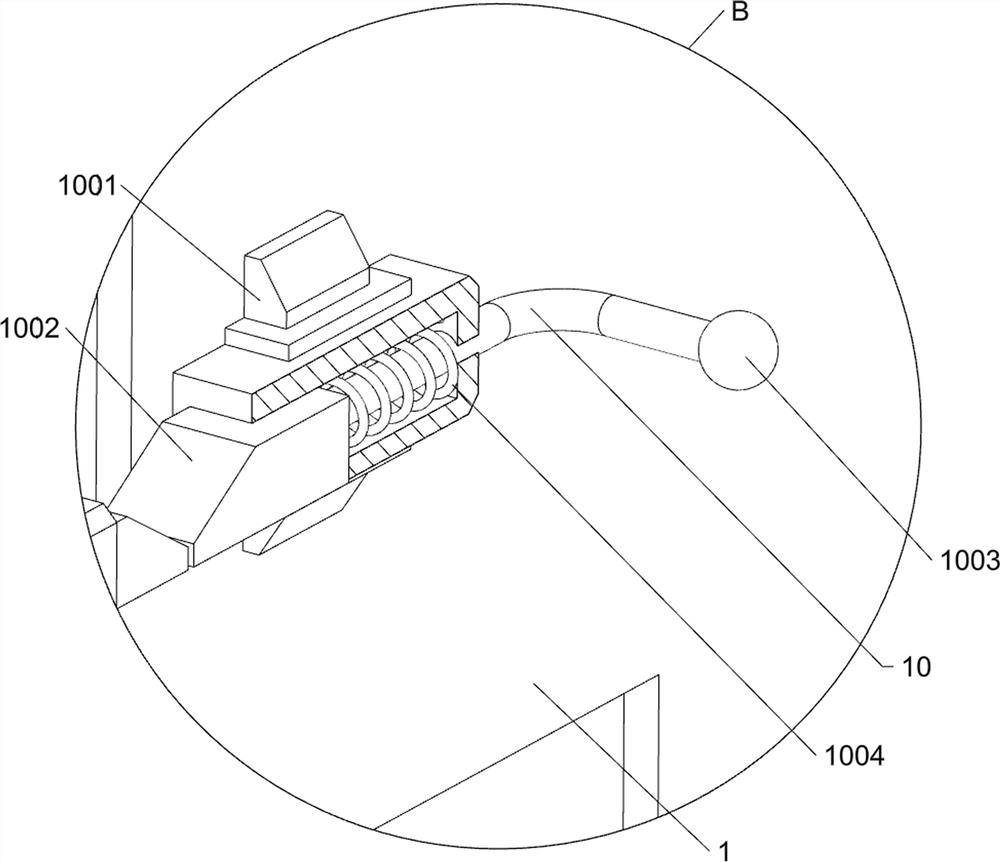

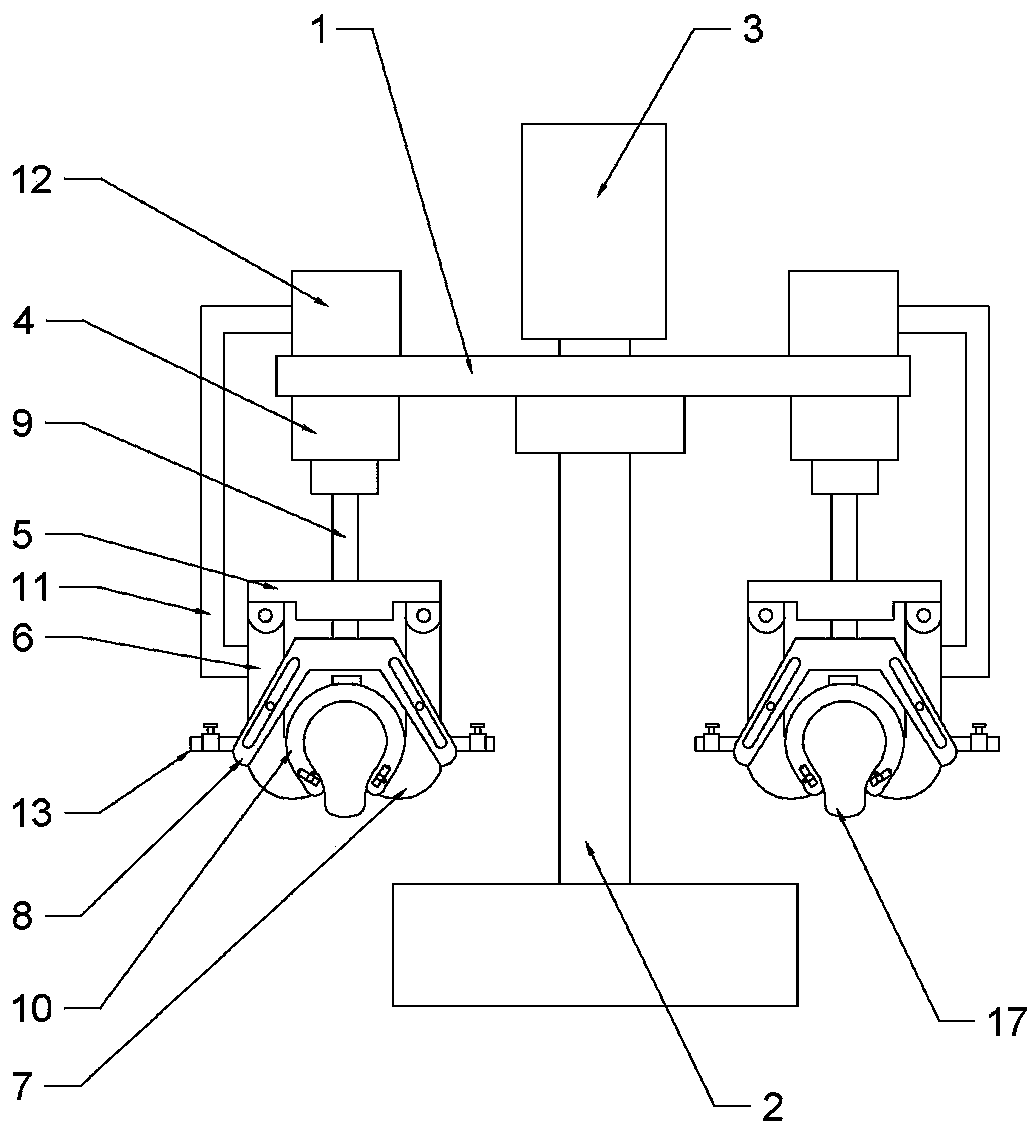

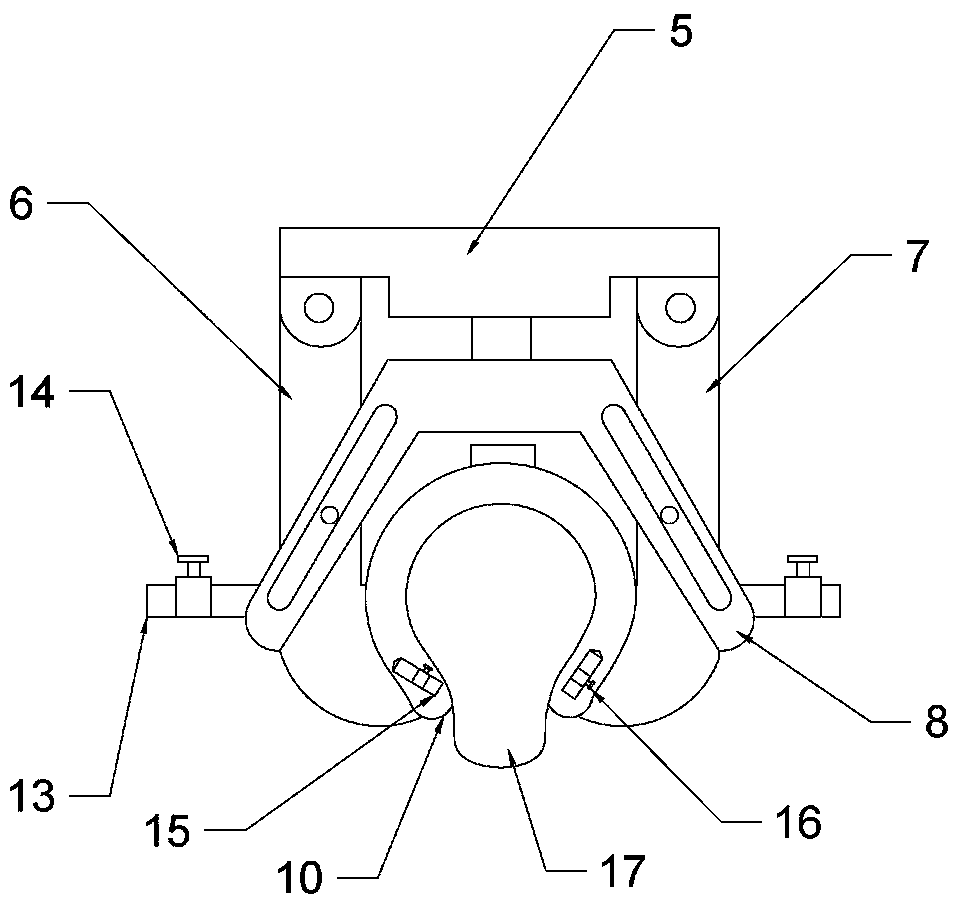

Led lamp sealing machine clamping device

ActiveCN106764556BPrevent burstSplash won'tSemiconductor devices for light sourcesEngineeringLED lamp

The invention relates to the field of illumination lamp production, and discloses a clamping device of an LED lamp sealing machine. The clamping device comprises a machine frame. Clamping mechanisms are connected to the machine frame. Each clamping mechanism comprises a cylinder. The cylinders are fixedly connected to the machine frame. Mechanical arms are connected to the cylinders. Each mechanical arm comprises a clamping arm frame, a first clamping finger, a second clamping finger and a slide block shaped like a Chinese character 'ba'. Through holes are formed in the clamping arm frames. Piston rods penetrate the through holes and are arranged in a sliding manner. One end of each piston rod is connected with the corresponding cylinder. The slide blocks shaped like the Chinese character 'ba' are connected to the first clamping fingers and the second clamping fingers in a sliding manner. A water belt is connected between each first clamping finger and the corresponding second clamping finger. One end of each water belt is connected to the inner side of the corresponding first clamping finger, and the other end of each water belt is connected to the inner side of the corresponding second clamping finger. Water inlet pipes are arranged at the top ends of the water belts and are connected with constant-pressure water supply devices. Water spray pipes are connected with the two sides of each water belt and penetrate the clamping fingers to be connected with first valves. Compared with the prior art, the situation that high-temperature residues splash to lampshades and the lampshades crack can be prevented.

Owner:南通华昱照明电器有限公司

Method for cutting glass

ActiveCN107417081AProtectiveIntegrity guaranteedGlass severing apparatusCutting glassReciprocating motion

The invention relates to a method for cutting glass, and belongs to the technical field of glass cutting or division. The method comprises the following steps: I, preparing a glass cutting device; II, rotating a rotating cylinder, and fixing a piece of glass; III, cutting a trace by using a glass cutting device; IV, powering on a motor, and driving a top rod to make reciprocation movement at the cut part of the glass; and V, pushing a lever through a cam, driving a piston to slide inside the cylinder, and sucking glass dribs. By adopting the scheme, glass splashing is prevented, and the method is high in automation degree, simple to operate and good in practicability and can be popularized in the field of glass cutting.

Owner:CHONGQING SHUNHUA SAFETY GLASS CO LTD

A pp winding pipe production equipment with a brake assembly

Owner:江苏八达重工科技有限公司

A rotary urine test sampling device

ActiveCN109692019BPrevent splashSplash won'tSurgeryVaccination/ovulation diagnosticsUrine leakageUrine collection

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

Bucket with crushing lid and its crushing method

InactiveCN1800518BAdjust the shape arbitrarilyArbitrary adjustment of shape and particle sizeMechanical machines/dredgersGrain treatmentsEngineeringMechanical engineering

Owner:株式会社中山铁工所

Lubrication structure for rotating machinery

The present invention relates to a lubricating structure for a rotating machine. In the rotating machine in which the resolver is arranged in the casing, lubricating oil can be appropriately supplied to the bearing outside the resolver. Since a through oil hole (90) is provided in the inner peripheral side portion of the resolver stator (62) fixed to the mounting seat (84) on the inner surface of the second case member (22), the oil through the oil hole (90) is provided in the inner peripheral side portion of the resolver stator (62), so that the Part of the lubricating oil that has flowed down flows into the through oil hole (90) directly or indirectly due to splashing due to the rotation of the shaft (18) or the rotor, and is supplied to the bearing (26). Since the resolver stator (62) is fixed to the second case member (22), the lubricating oil will not be splashed by centrifugal force, and by appropriately determining the size, number, and position of the through-oil holes (90), it is possible to supply the bearing to the bearing. (26) Sufficient amount of lubricating oil is supplied and lubricated appropriately.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com