Polishing device for casting parts

A casting and grinding wheel holder technology is applied in the field of grinding devices for castings, and can solve problems such as safety accidents, large wound surfaces, and grinding wheel explosions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

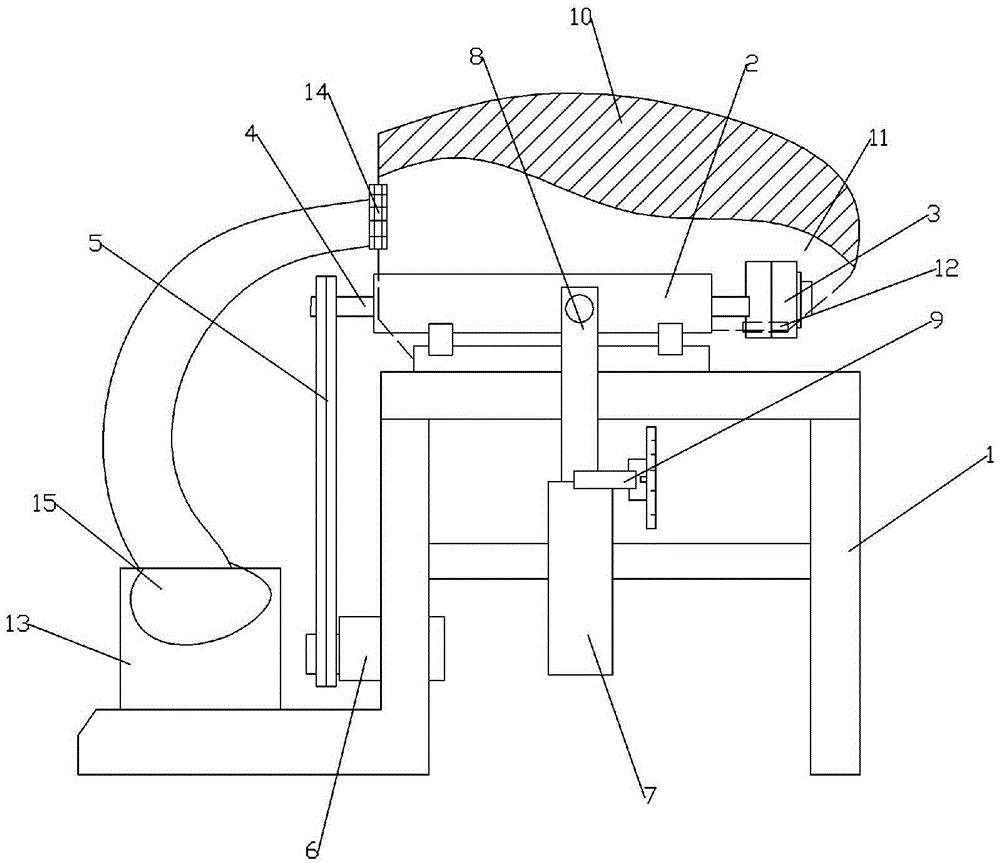

[0011] The reference signs in the drawings of the description include: frame 1, grinding wheel frame 2, grinding wheel 3, rotating shaft 4, belt 5, driving motor 6, supporting column 7, adjusting rod 8, adjusting bolt 9, protection box 10, shielding part 11 , Grinding hole 12, induced draft fan 13, grid 14, bag filter 15.

[0012] The embodiment is basically as attached figure 1 Shown: a grinding device for castings, including a frame 1 and a grinding wheel frame 2 arranged on the frame 1. A grinding wheel 3 for grinding workpieces is installed on the grinding wheel frame 2. The grinding wheel 3 is hinged on the grinding wheel frame 2 through a rotating shaft 4. The rotating shaft 4. The drive motor 6 installed on the frame 1 is connected with the belt 5. The frame 1 is provided with support columns 7 located under both sides of the grinding wheel frame 2. Both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com