Bucket with crushing lid and its crushing method

A technology of crushing chamber and crushed materials, which is applied in the direction of mechanically driven excavators/dredgers, grain processing, etc., and can solve the problem of not being equal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

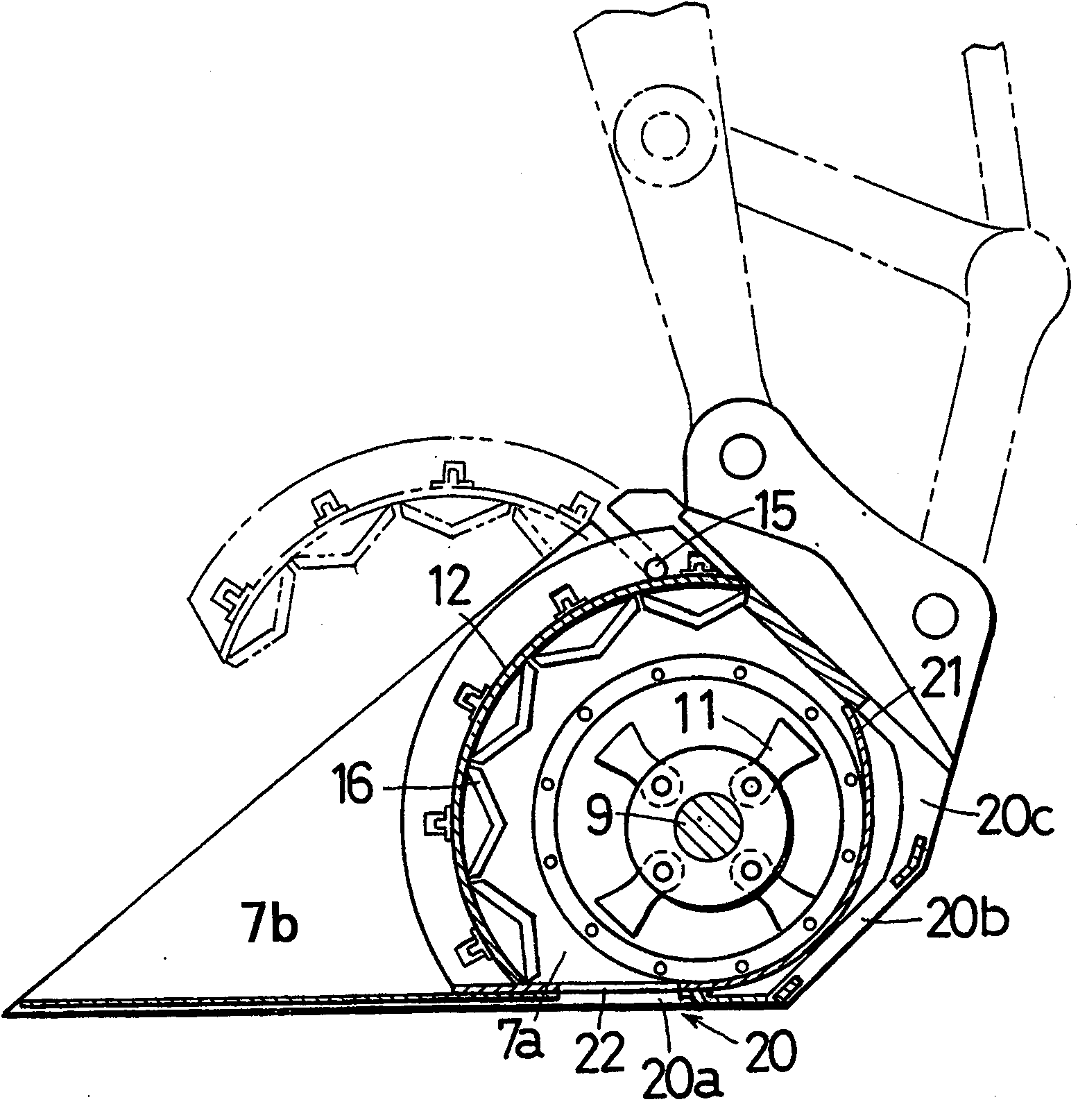

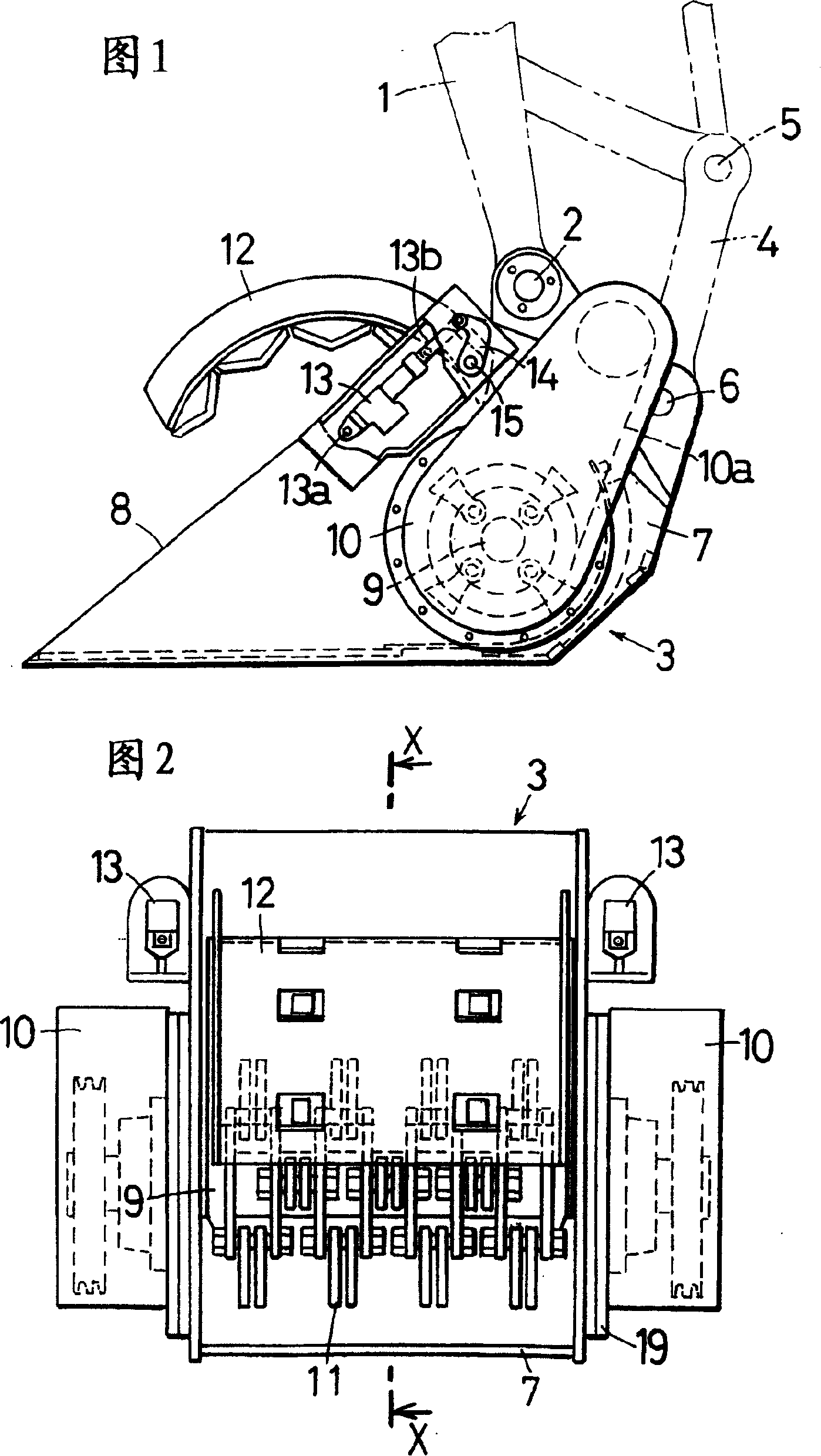

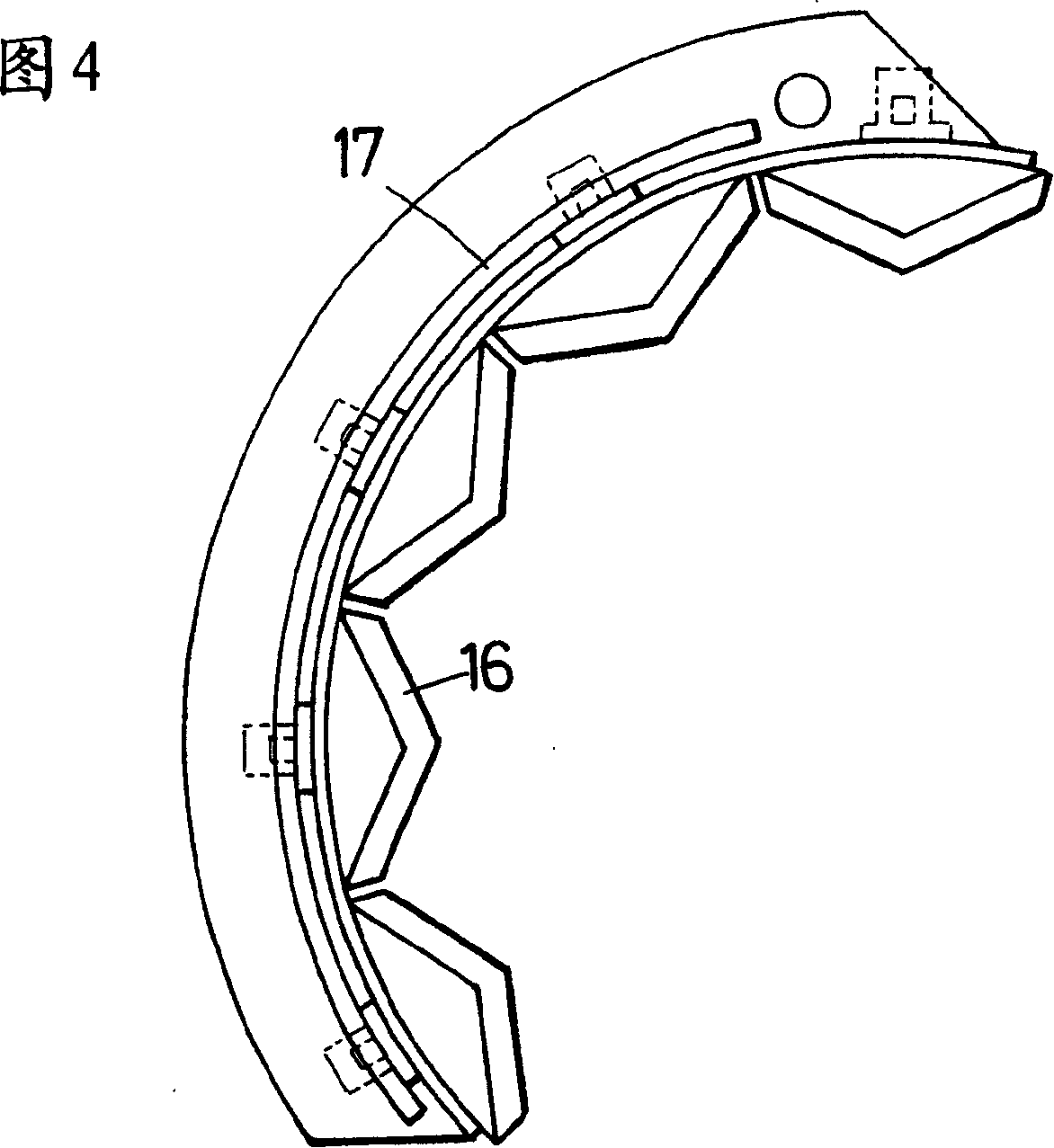

[0035] Embodiments of the present invention will be described in detail below with reference to the drawings. figure 1 It is a side view of the bucket with crushing cover of the present invention, figure 2 is the front view of the bucket with crushing lid, image 3 yes figure 2 The X-X line cross-section diagram, which represents the equivalent offigure 1 A cross-sectional view of the side, Figure 4 It is a side view of the crushing cover, showing the state where the backlash plate bushing is installed on the inner wall and the first splash prevention member is installed on the side wall, Figure 5 It is a side view of the crushing cover, showing the state where the backlash plate bushing is installed on the inner wall and the second splash prevention member is installed on the top end, Figure 6 It is an explanatory diagram showing the state of closing the crushing cover equipped with the first splash prevention member and facing the crushing bucket, Figure 7 With F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com