Power generation strap link buckle

A buckle and strap technology, applied in the mechanical and electrical fields, can solve the problems of low energy conversion efficiency, large electromechanical coupling coefficient, slow cutting speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be described in further detail below in conjunction with the accompanying drawings.

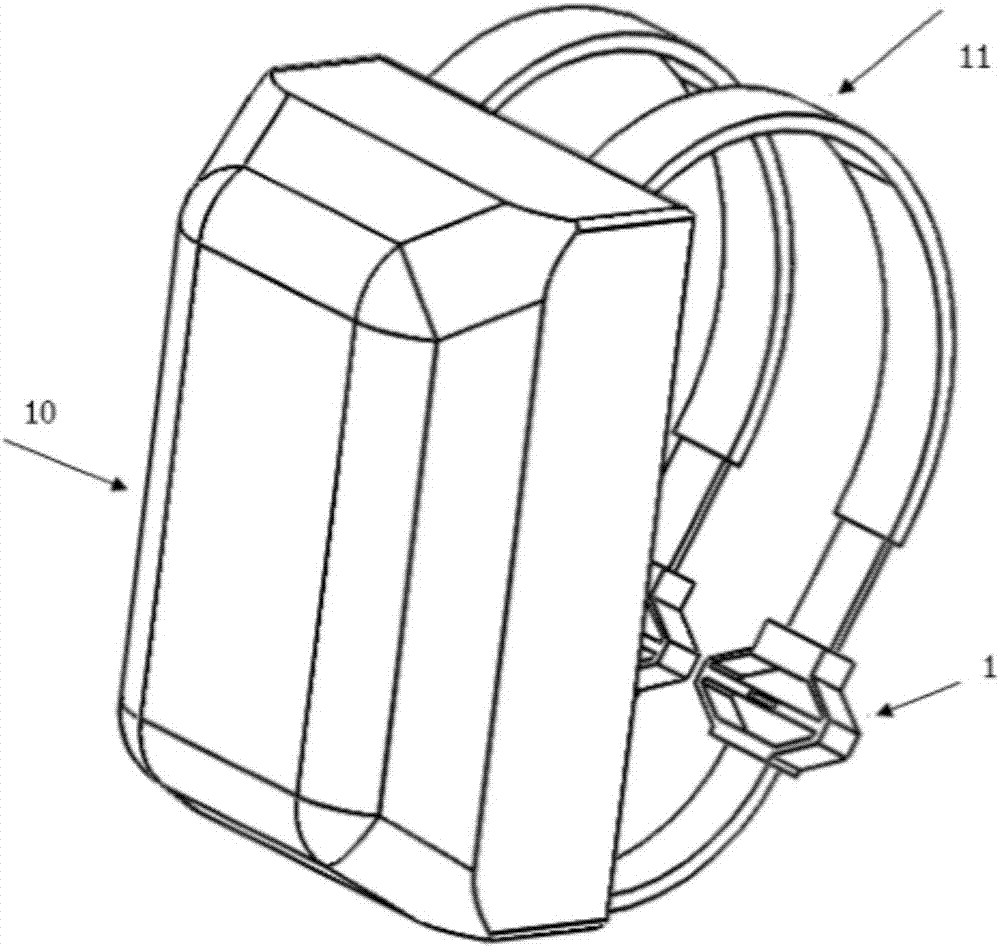

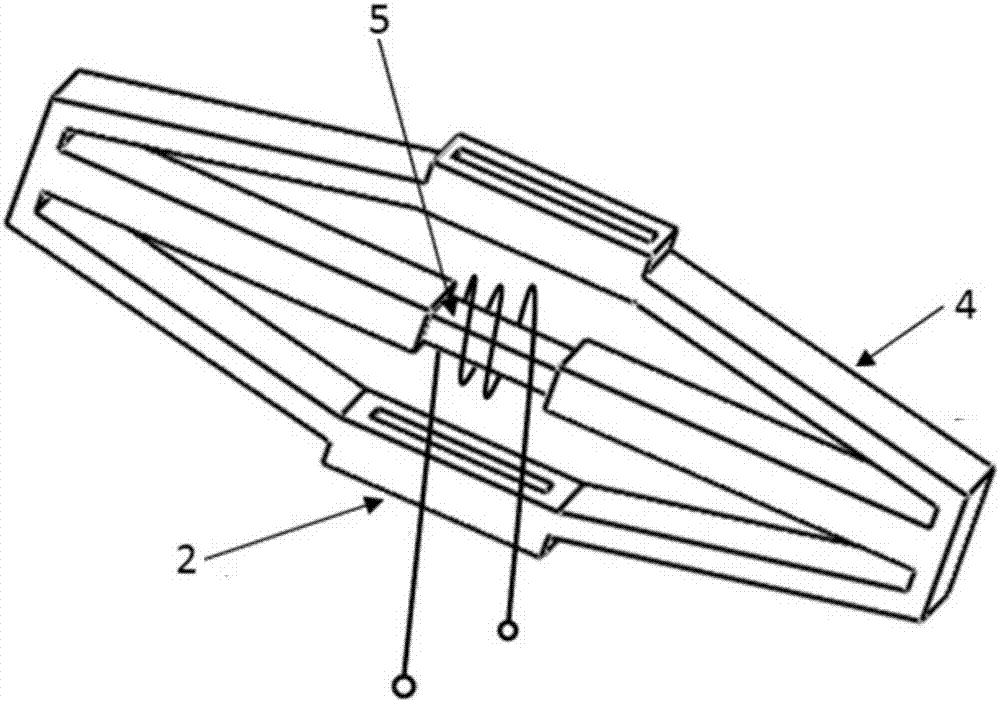

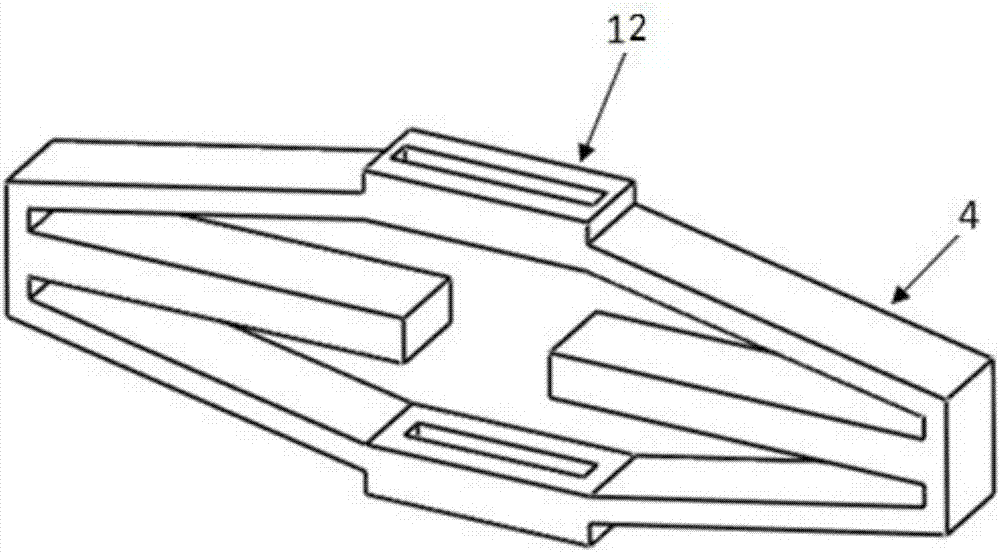

[0028] The giant magnetostrictive material power generation structure of the connecting buckle of the power generation strap of the present invention is made of giant magnetostrictive material, and an induction coil is wrapped around the giant magnetostrictive material power generation structure. This power generation strap link buckle is suitable for various types of backpacks. It can directly replace the original ordinary backpack link buckle, making the original backpack into a power generation backpack. The power generation backpack is as follows: figure 1 As shown, it includes a power generating strap connecting buckle 1 , a backpack 10 , and a strap 11 . Therefore, when the human body carries the backpack equipped with the connecting buckle of the power generation strap, it can efficiently convert part of the mechanical energy generated by the human body moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com