A method for preparing multi-element alloys by powder spraying technology

A multi-element alloy and powder spraying technology, which is applied in the field of preparation of multi-element alloy, can solve the problems of poor air permeability in the furnace, easy flameout, furnace cover breakdown, etc., and achieve the effect of reducing the formation of slag layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The method for preparing a multi-element alloy by powder spraying technology, the preparation and implementation steps are as follows:

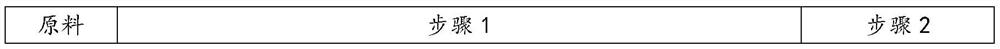

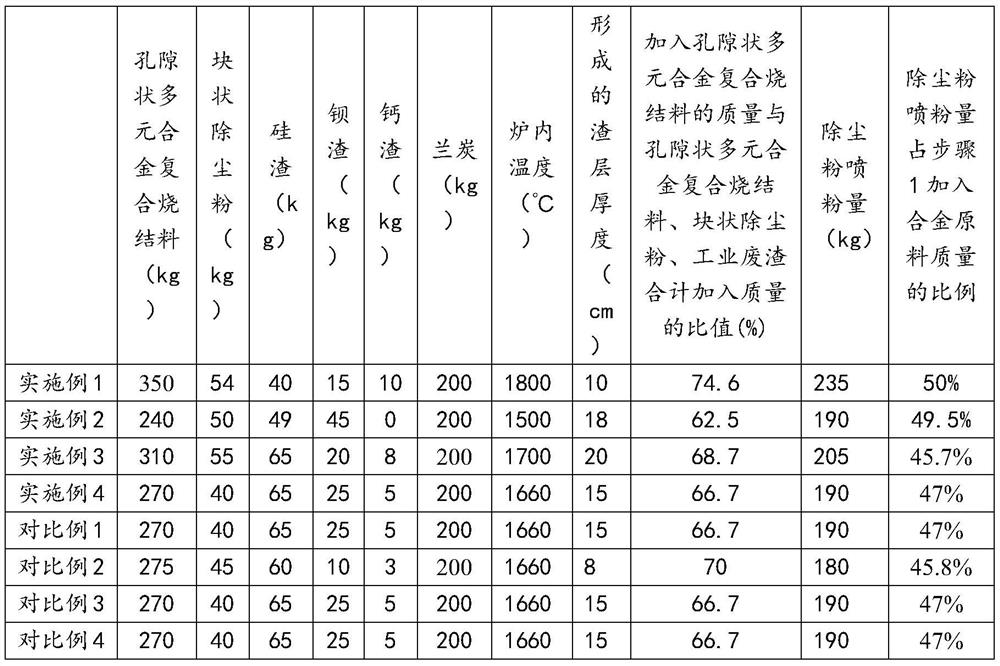

[0023] Step 1: Design the alloy composition. The alloy design composition in the specific examples is shown in Table 1. After the alloy composition is designed, add the following raw materials to the refining furnace: porous multi-element alloy composite sintering material, block dust removal powder, industrial waste slag, semi-coke , wherein the amount of porous multi-element alloy composite sintered material added is not less than 60% of the total mass of porous multi-element alloy composite sintered material, massive dust removal powder, and industrial waste slag, and the amount and ratio of each raw material added meet the requirements of the alloy after melting. A slag layer not less than 10 cm thick can be formed on the surface of the melt, and the amount of raw materials added in the specific examples is shown in Table 2;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com