Assembling and disassembling tool for disk type permanent magnet motors and method for installing motor end covers

A permanent magnet motor and motor end cover technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of increasing unsafe factors, easy to pinch fingers, easy to bump coils, etc., to avoid adjusting the end cover Clearance between the rotor and the effect of safety improvement and safe installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

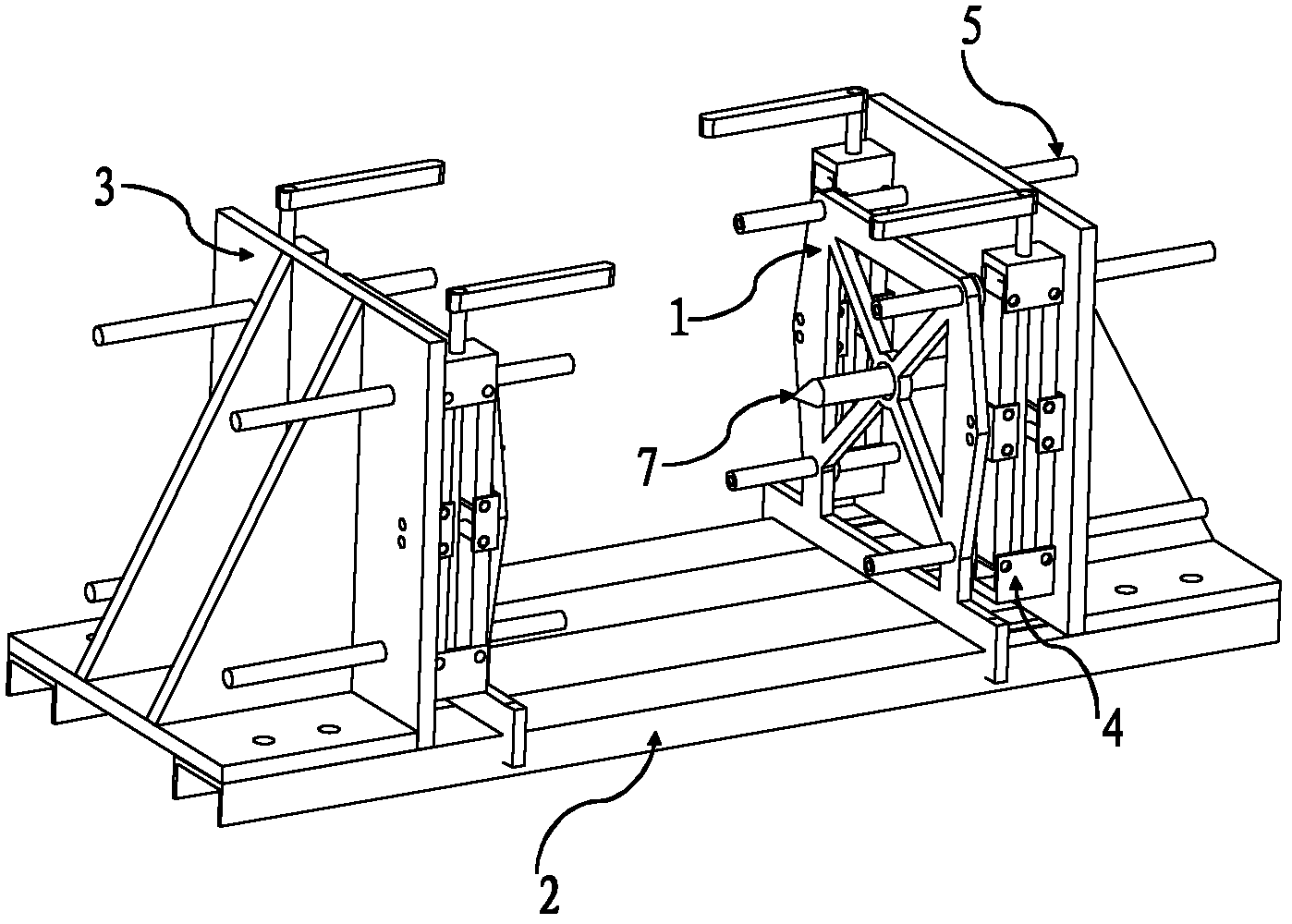

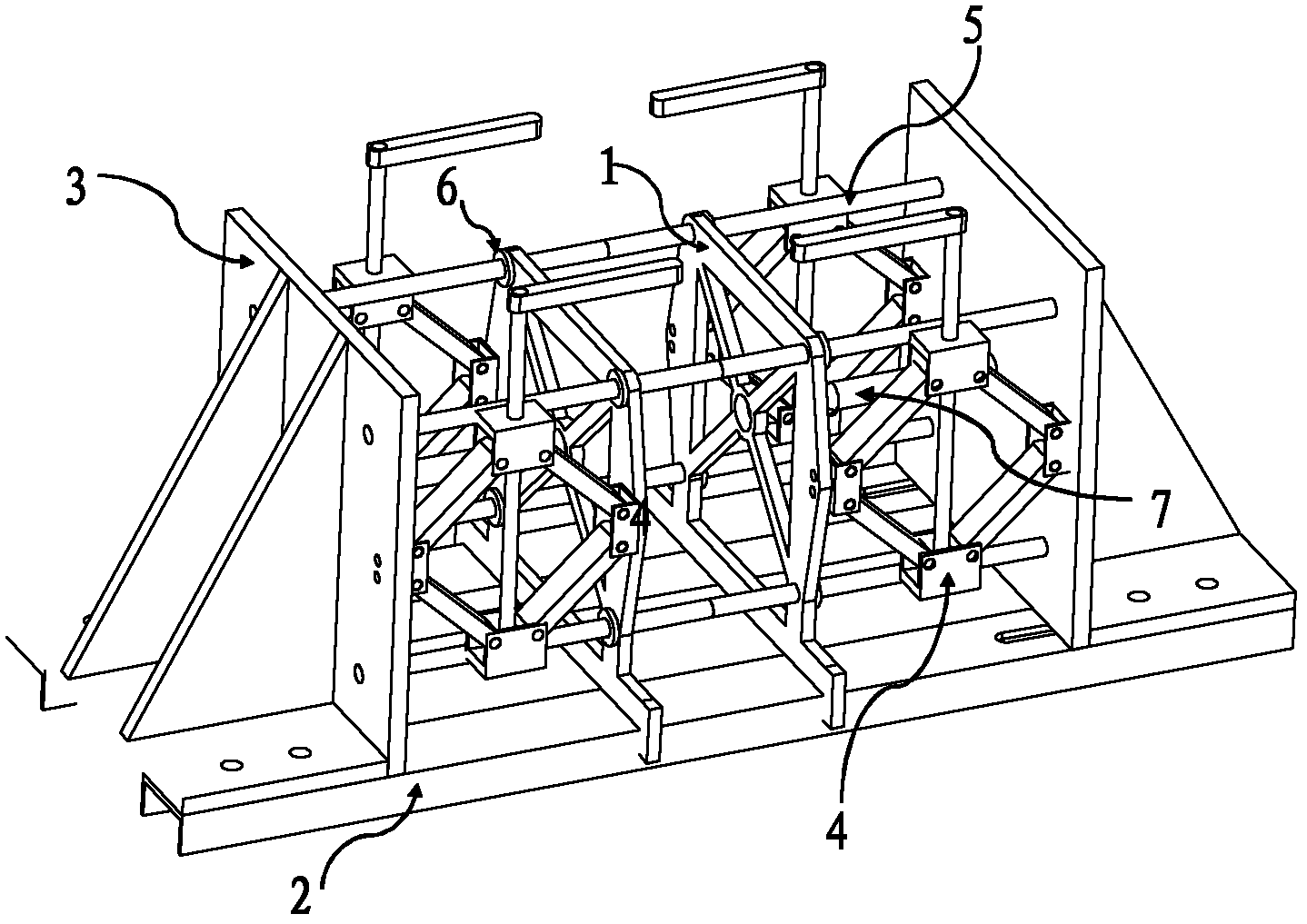

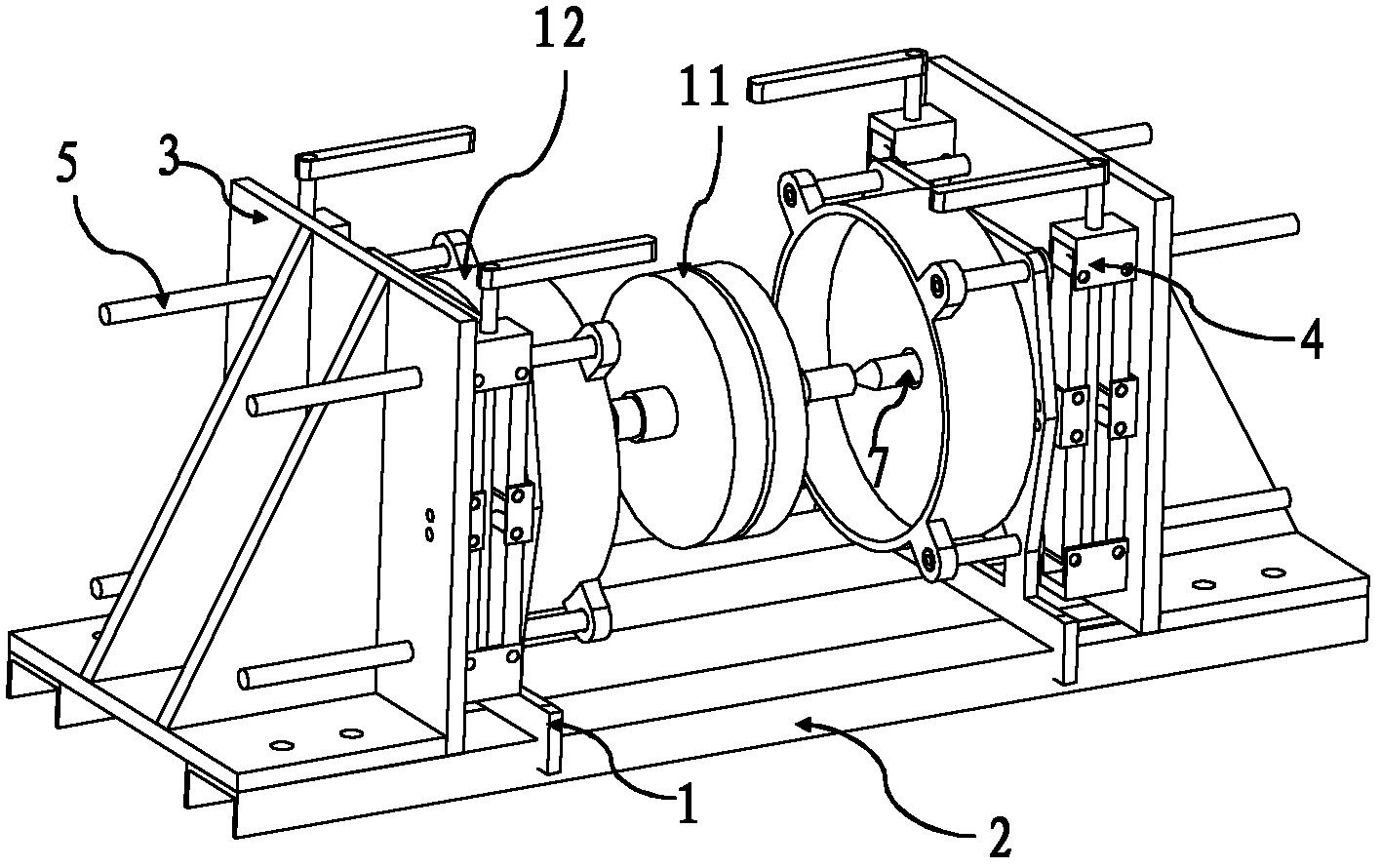

[0036] see figure 1 and figure 2 , in order to better understand the technical solutions of the present invention, specific embodiments will be described below in detail in conjunction with the accompanying drawings.

[0037] see figure 1 and figure 2 , in the present embodiment, the disc permanent magnet motor dismounting tool of the present invention comprises guide rail 2, two mounts 3 perpendicular to guide rail 2, two fixed plates 1 and motor end that are respectively located at guide rail 2 two ends A fixing device for fixing the cover on the fixing plate 1;

[0038] The bottom of the seat frame 3 is welded to the plane parallel to the guide rail, so that the seat frame 3 becomes an L-shaped part. Through the cooperation between the plane parallel to the guide rail 2 and the bolt, the seat frame 3 is fixed on the two ends of the guide rail 2, The purpose of such design is in order to facilitate the adjustment of the distance between the two mounts 3 on the guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com