Fast positioning and disassembling device for testing mechanical performance of optical cable

A technology of mechanical properties and optical cables, applied in the field of new devices, can solve the problems of optical cable damage, clamping force, difficulty in accurate control, small friction, etc., to reduce impact and noise, reduce operating time, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

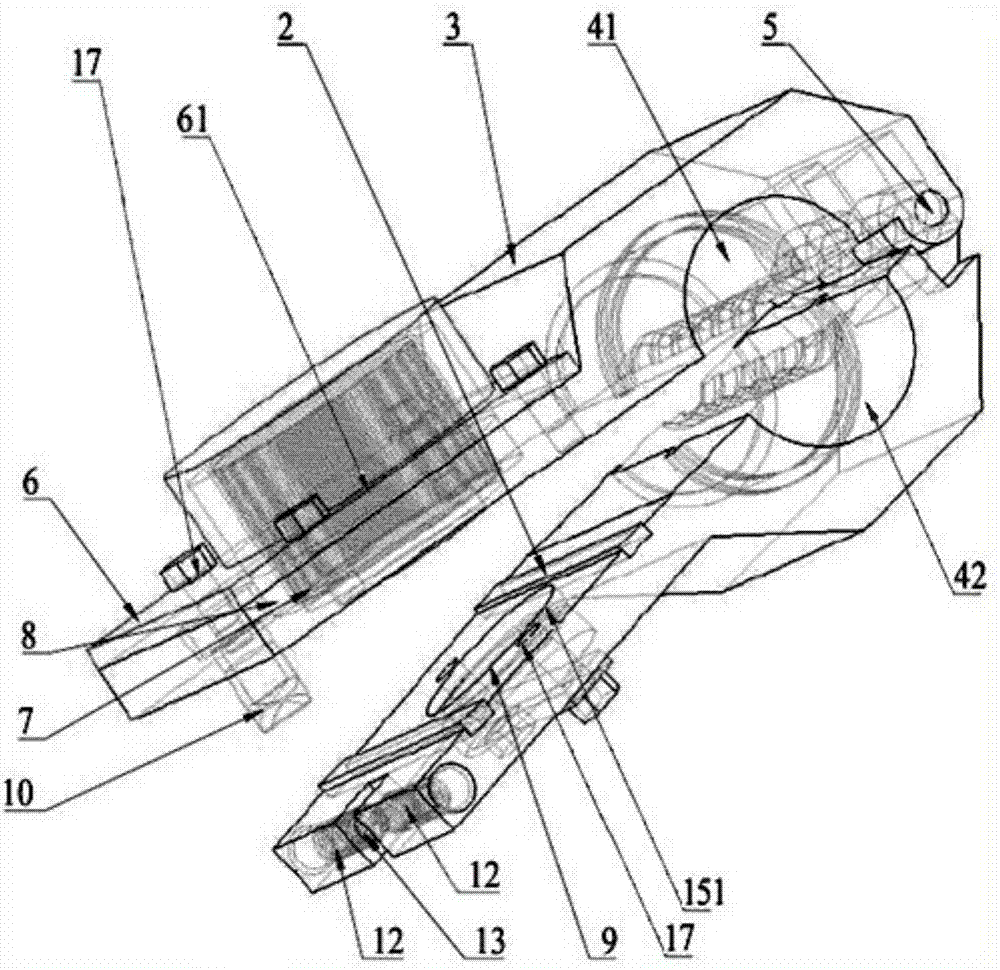

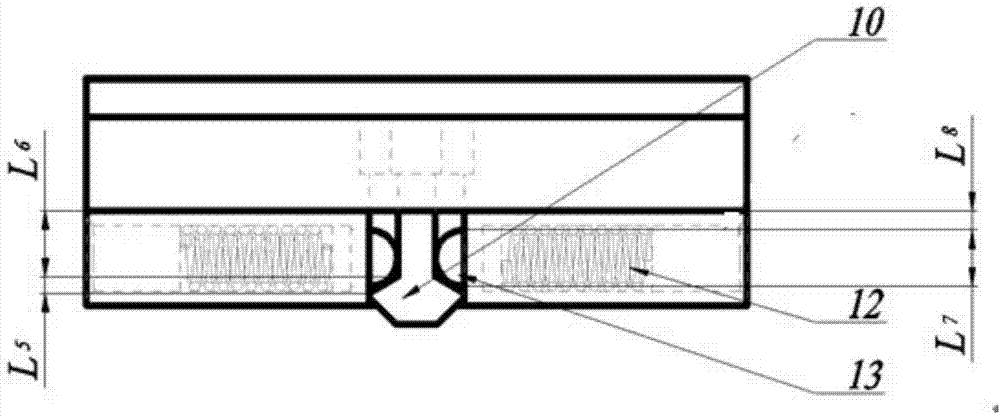

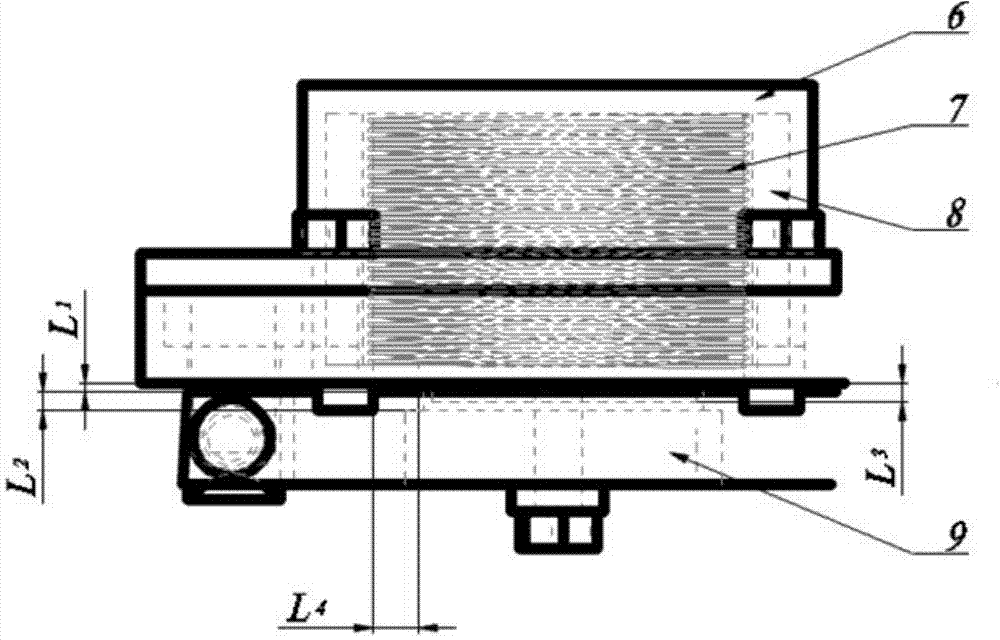

[0026] Such as figure 1 As shown, a quick positioning and unloading device for testing the mechanical properties of optical cables includes an upper splint 3, a lower splint 15, a splint connecting shaft pin 5, a sleeve for clamping optical cables, an electromagnetic automatic switch, and a self-locking device , the electromagnetic automatic switch includes an electromagnet 7, a permanent magnet 9, an electromagnet sleeve 8 and a cover plate 6, the electromagnet 7 is composed of a coil and an iron core, and the self-locking device includes a hook 10, a spring 12, and a dead bolt 13, The sleeve is divided into an upper semicircle sleeve 41 and a lower semicircle sleeve 42. The upper splint 3 is connected to the lower splint 15 through the pivot pin 5 of the splint. The upper semicircle sleeve 41 is detachably connected with the upper splint 3. The lower semicircle sleeve 42 is connected The lower splint 15 is detachably connected, the cover plate 6 is located in the upper splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com