Safe magnetic glass wiping device

A glassware and magnetic technology, applied in the field of daily cleaning products, can solve the problems of pinching fingers, uneconomical, unable to scrub single-layer glass, etc., and achieve the effect of quick and convenient conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

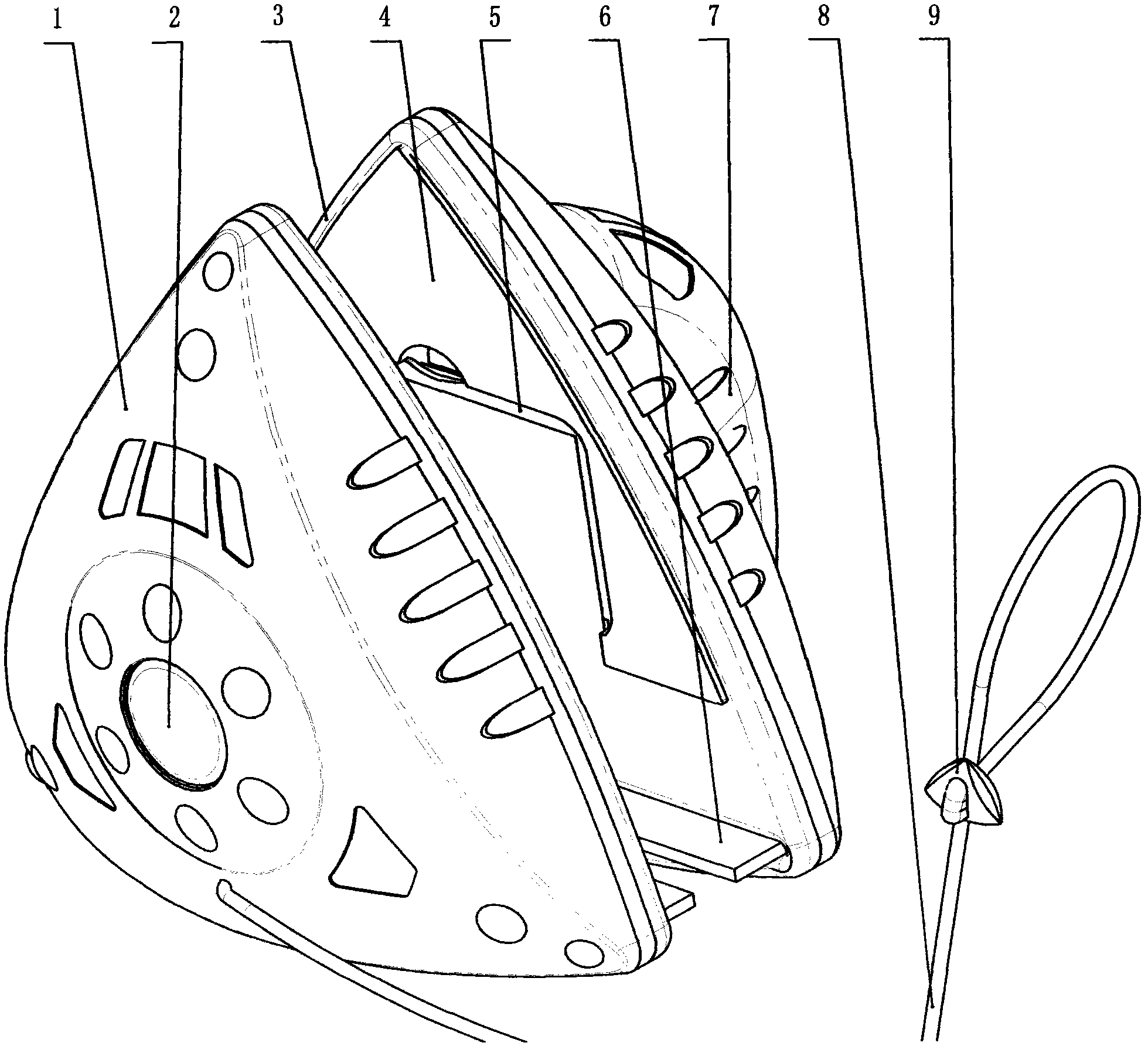

[0042] like figure 1 As shown, the safety magnetic glass wiper of the present invention is composed of a main magnetic glass wiper and a secondary magnetic glass wiper, which are respectively adsorbed on the inner and outer surfaces of the glass. Push the handle 7 of the main magnetic glass cleaner by hand, and the main magnetic glass cleaner drives the auxiliary magnetic glass cleaner to move together, one side is wiped, and both sides are clean. The safety magnetic glass cleaner mainly includes a casing composed of an upper cover 1 and a lower casing 3 , a rubber scraper 6 , a felt 4 , a string 8 , and a buckle 9 .

[0043] A button 2 is set at the central position of the loam cake 1, and a string 8 is worn on the side. Felt 4 is set in the bottom groove of lower shell 3. In order to prevent the felt from falling off from lower shell 3, a pressure frame 5 is provided on the edge of the bottom groove of lower shell 3, and a rubber scraper 6 is provided at the tail of lower s...

Embodiment 2

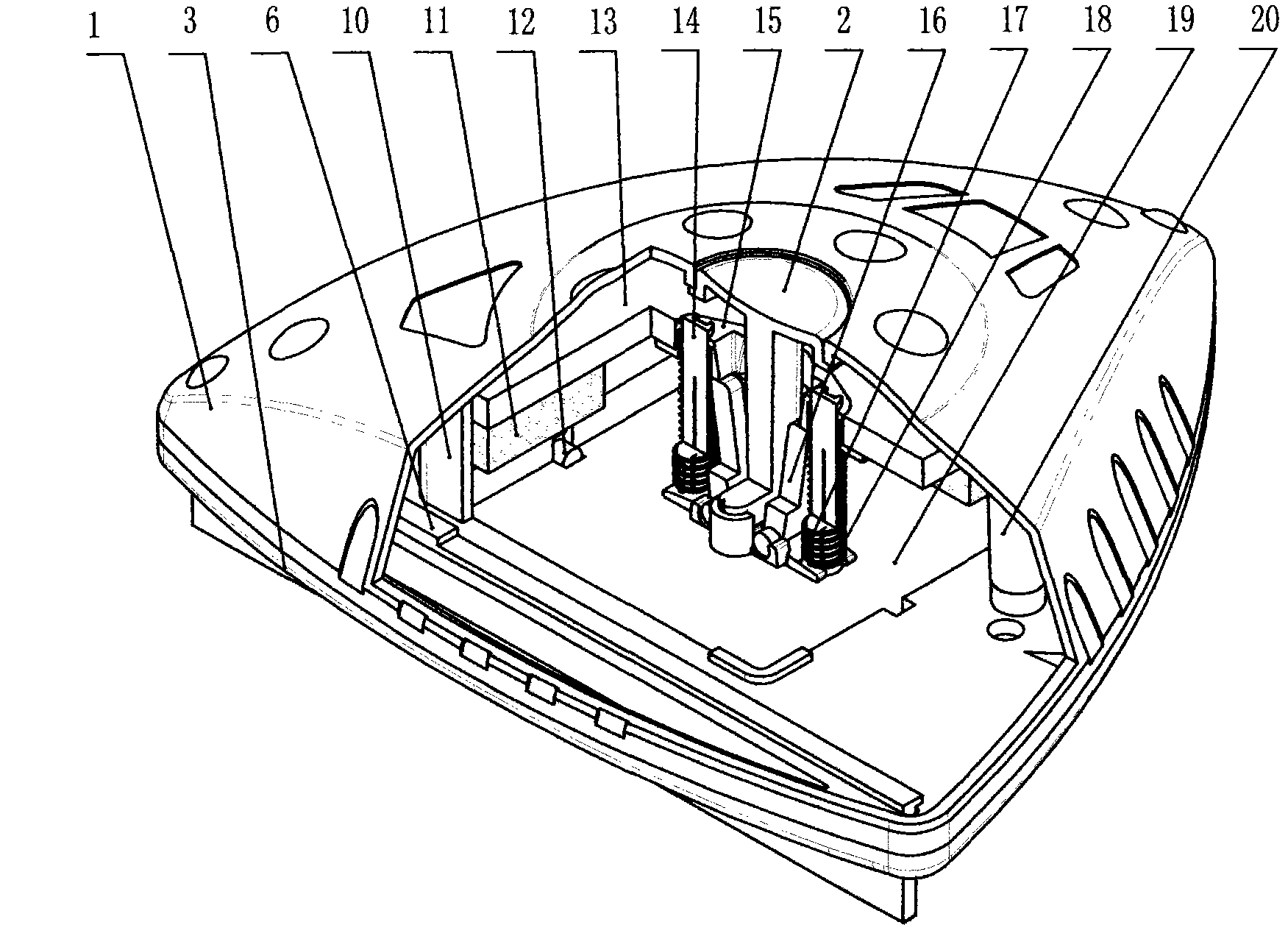

[0055] like Figure 8 As shown, the safety magnetic glass cleaner mainly includes a shell consisting of an upper cover 1 and a lower shell 3, a rubber scraper 6, a permanent magnet 11, and a magnetic plate 13, and a jumper is set between the shell and the permanent magnet 11 or the magnetic plate 13. 18 from the spring. The button 2 is set in the center of the loam cake 1 and is connected with the return spring 36. A columnar trigger lever 26 is arranged below the button 2. The bottom of the trigger lever 26 is provided with a V-shaped groove 35. The bottom of the trigger lever 26 of the button 2 is provided with a trigger 16. The rotating shaft 23 is hinged with the open axle sleeve 21 of the trigger seat 38, and the trigger seat 38 is fixed at the bottom center of the lower shell 3. Self-locking spring 37 is set between two triggers 16, and self-locking spring 37 pushes the trigger 16 at two ends to both sides, and trigger 16 is provided with shoulder 32 and inclined wedge ...

Embodiment 3

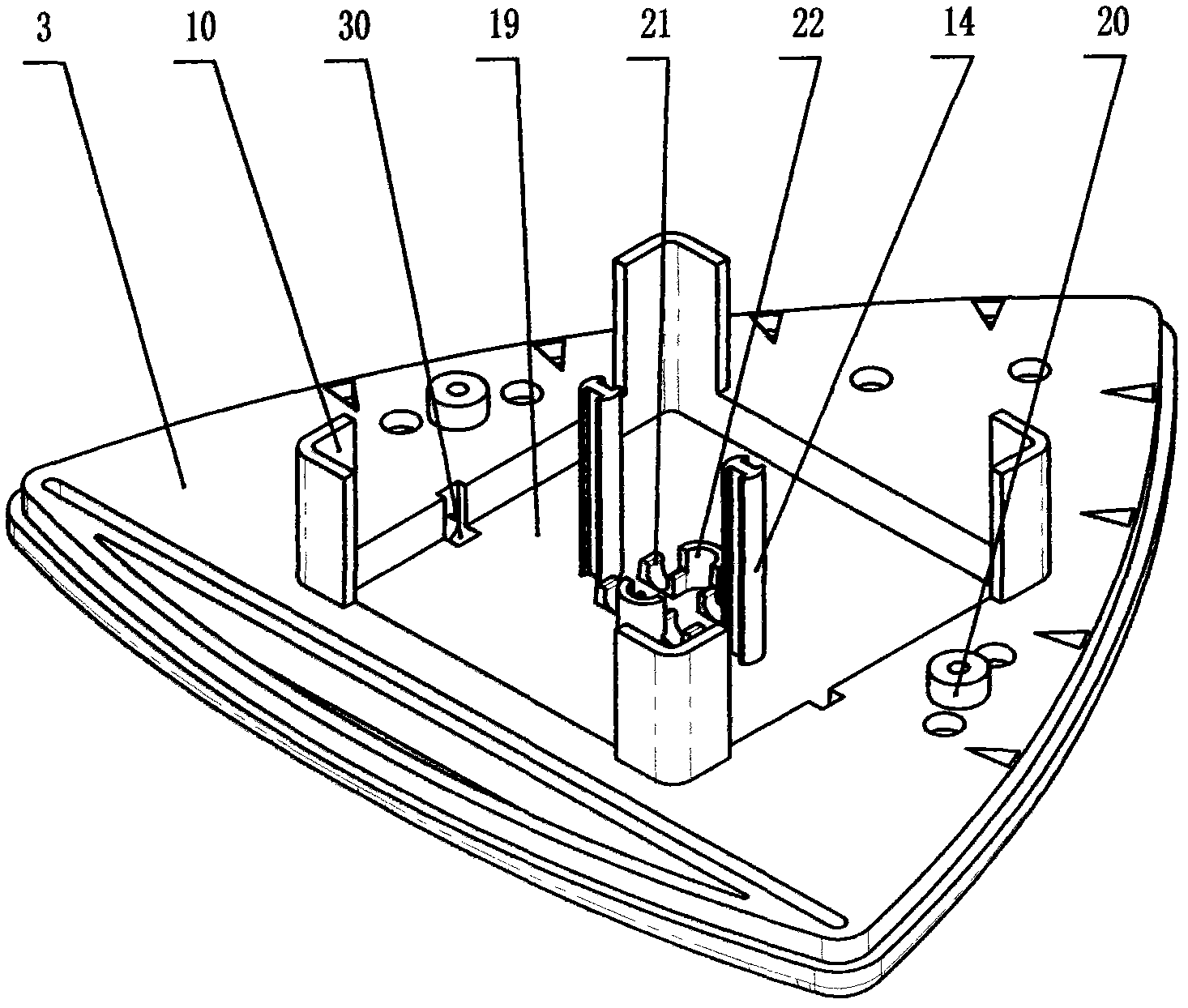

[0059] like Figure 9 The structure shown with Figure 8 The structures shown are substantially the same, the difference is that there are two or more jumping off springs 18 of the safety magnetic glass cleaner, and guide posts 14 are arranged on the surface of the lower case 3 to support the jumping off springs 18 to avoid spring instability. The position of the return spring 36 can also be arranged in the central groove near the bottom of the lower case 3 .

[0060] The hinge of the trigger 16 and the open shaft sleeve 21 of the trigger seat 38 at the bottom can be connected as a whole, and the deformable flexibility and elasticity of the plastic material are utilized to realize the automatic recovery function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com