Normal loading device of fretting fatigue test system

A test system, fretting fatigue technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, can solve the problems of low reliability, large error in test results, alternating deformation of samples, and achieve good test repeatability , high degree of automation, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

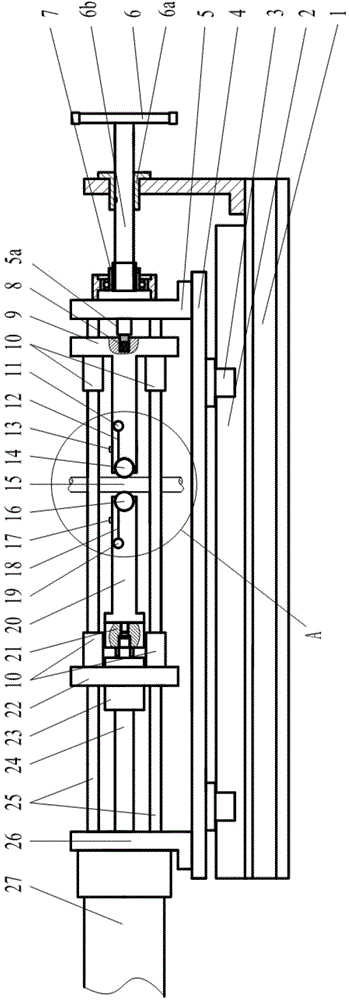

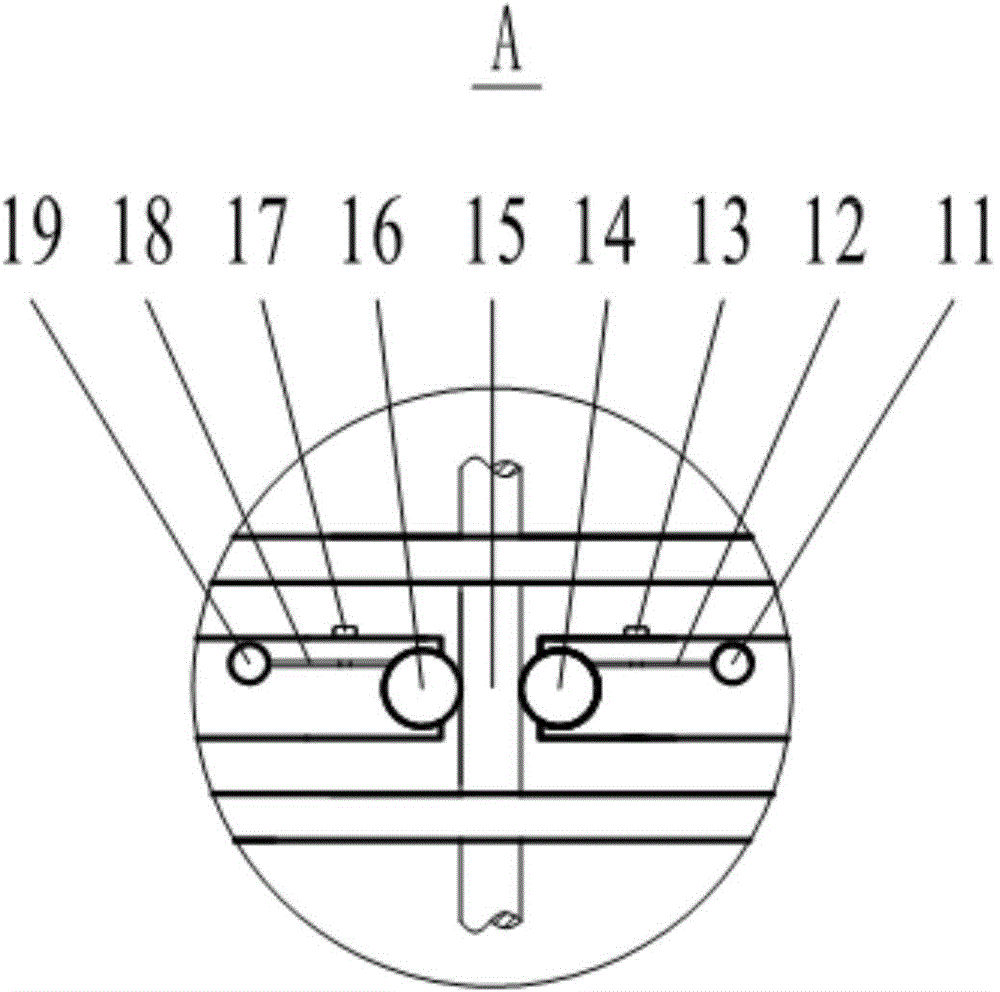

[0024] figure 1 figure 2 As shown, a normal loading device of a fretting fatigue test system, its structural characteristics are:

[0025] The base 1 is threaded and fixed on the table of the tension-torsion multi-axis fatigue testing machine. Two transverse guide rails 2 are fixed on the upper surface of the base 1. The nut 6a of the lead screw 6 is installed on the right end of the base 1, and the screw of the lead screw 6 6b is connected to the right baffle plate 5 of the clamping mechanism through a ball bearing 7;

[0026] The concrete composition of described clamping mechanism is: the slider 3 on the bottom surface of the base plate 4 cooperates with the guide rail 2 on the base 1; the left and right ends of the base plate 4 are respectively fixed with a left baffle plate 26 and a right baffle plate 5; 26 and the right baffle 5 are connected by four guide rods 25; the right chuck 9 fits on the four guide rods 25 through the linear bearing 10, and a pressure sensor 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com