Tractor transmission mechanism

A transmission mechanism and tractor technology, which is applied in the field of tractors, can solve the problems of few power output speed gears, cannot meet the speed requirements, and small speed change range, etc., and achieve more gear speed matching, reasonable speed distribution, and high transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

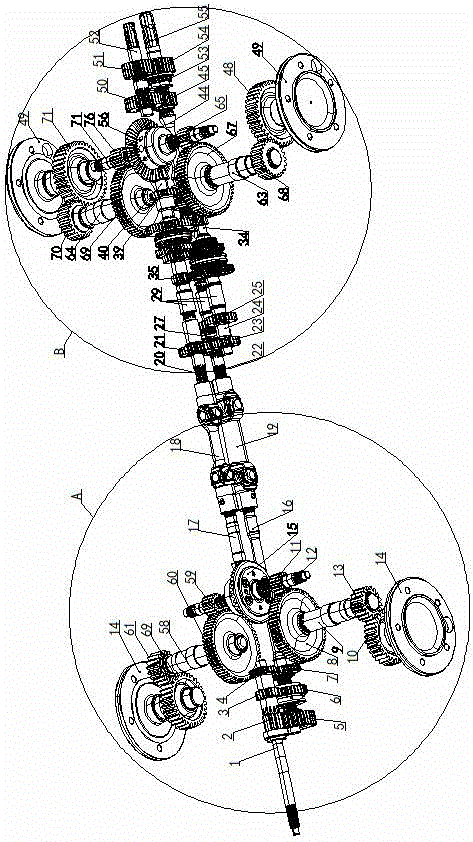

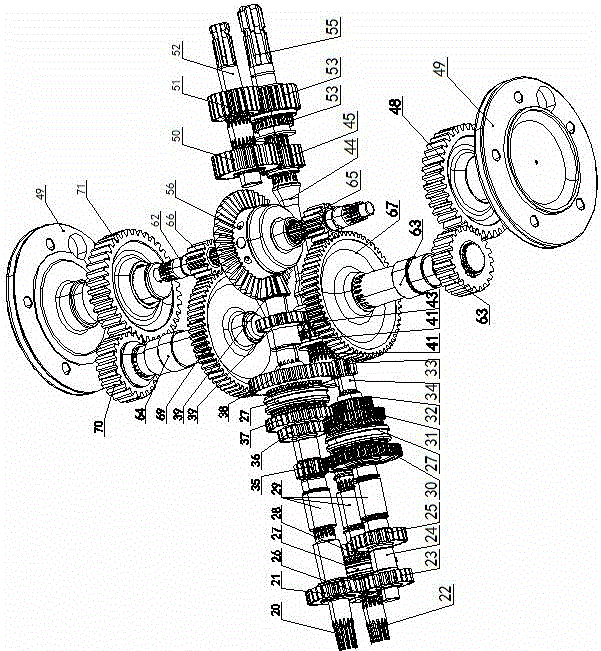

[0024] Embodiment 1: as figure 1 As shown, a tractor transmission mechanism, the transmission mechanism includes an auxiliary transmission, a universal joint combination, a shuttle shift mechanism, a main transmission and a power output device connected in sequence, between the auxiliary transmission and the universal joint combination A front speed reducer with a differential A15 combined with a universal joint is provided, and a rear speed reducer with a differential B56 meshing with the main transmission is provided between the main transmission and the power output device. The two sides of the front reducer and the rear reducer are respectively provided with traveling wheel mounting flanges 14 .

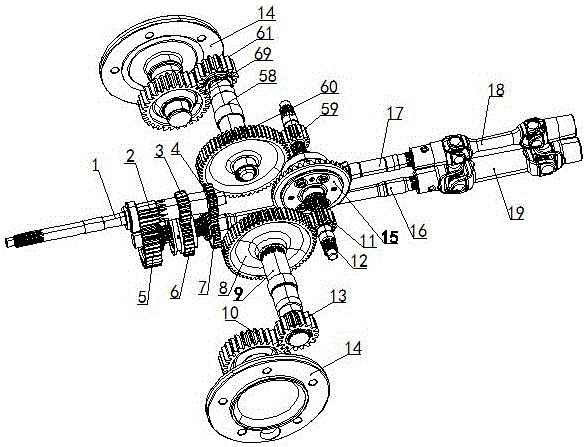

[0025] Among them, such as figure 2 As shown, the auxiliary transmission includes a first power input shaft 1 and a second power input shaft 16 arranged in parallel; A low-grade driving gear 2, a middle-range driving gear 3 and a high-grade driving gear 4 are arranged in seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com