Gearshift mechanism of harvesting machine, gearshift control system and harvesting machine with gearshift mechanism

A technology of harvesting machinery and gear shifting mechanism, which is applied in the direction of mechanical equipment, transmission device control, and components with teeth, etc. It can solve the problems of cumbersome gear shifting and inconvenient operation, and achieve the effect of reducing driving fatigue and convenient gear shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

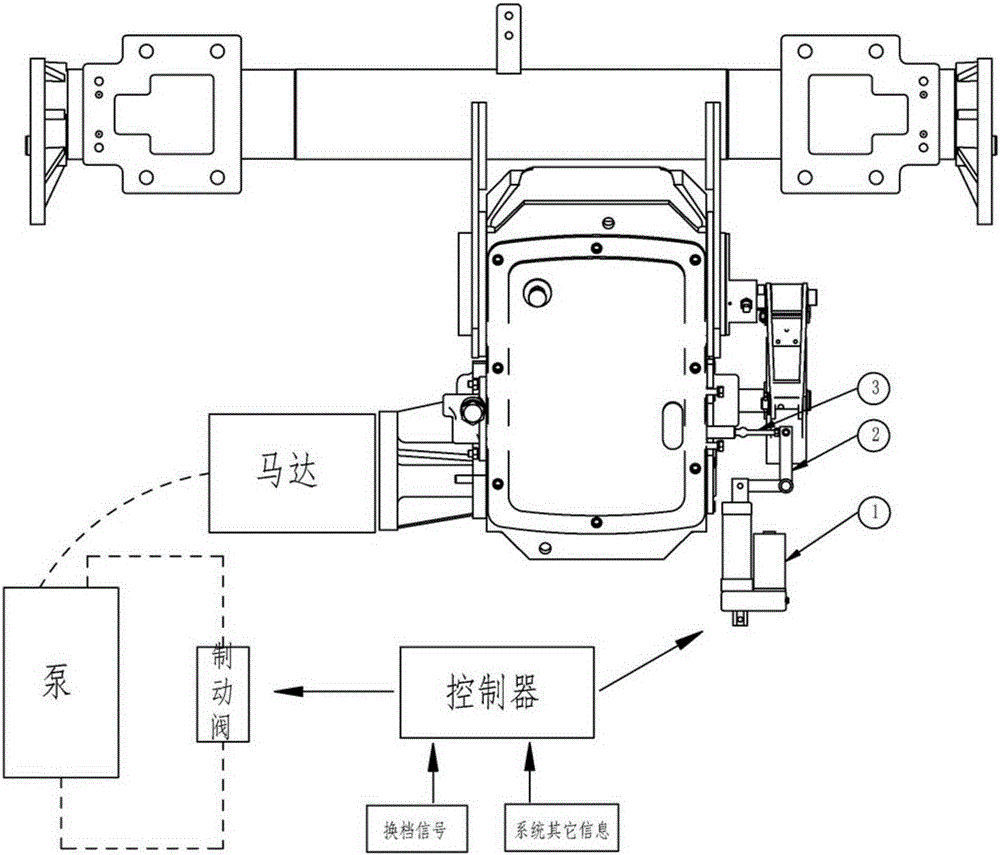

[0038] see figure 1 , a gear shifting mechanism for a harvesting machine, having:

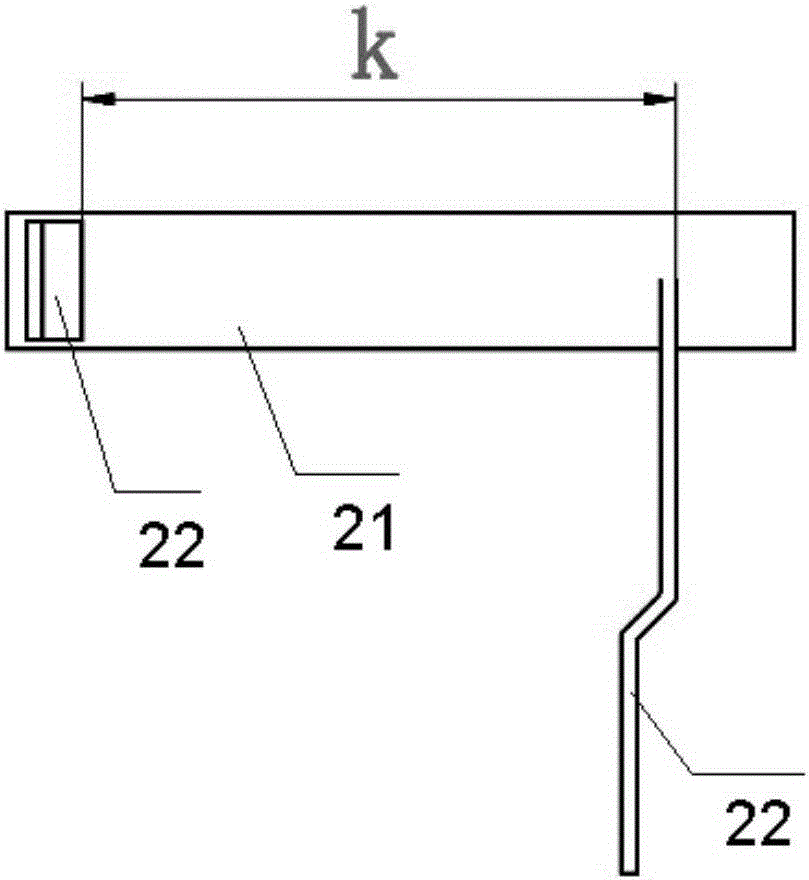

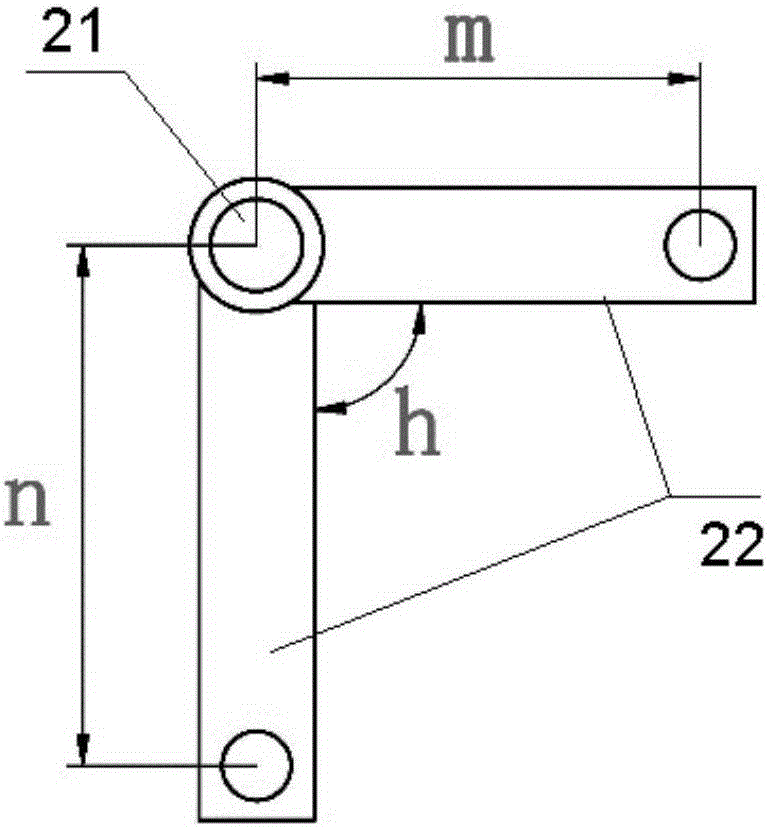

[0039] The driving rod 2, the driving part and the connecting rod 3 are rotatably set on the shaft on the body near the middle part of the driving rod 2; the end of the driving part is hinged to the first end of the driving rod 2; the first end of the connecting rod 3 is connected to the The second end of the rod 2 is hinged, and the second end of the connecting rod 3 is connected with the shift point of the gearbox of the body. The driving part is controlled by the controller, and one end of the driving rod 2 is pushed by the driving part to make the driving rod 2 rotate around the axis, and the other end of the driving rod 2 drives the connecting rod 3 to move, and the connecting rod 3 is connected to the shift point of the gearbox, thereby changing the transmission The position of the shift point to achieve the purpose of shifting. The shifting is realized by controlling the movement of th...

Embodiment 2

[0049] This embodiment is a further improvement made on the basis of the first embodiment. For the same parts as the first embodiment, reference may be made to the first embodiment, which will not be repeated here.

[0050] power input

[0051] like figure 1 As shown, the gearbox used in this system is a commonly used two-speed gearbox, the drive mode is hydraulic drive, and the left side is a pump-motor drive mode. A brake pump, the brake pump is a solenoid valve, the switch is controlled by the controller. This valve is in the normal state (closed state) and the pump outputs normally, driving the motor to work. When this valve works, the output of the pump is blocked and the motor loses power.

[0052] executive body

[0053] like Figure 4 As shown, the electric push rod 1 can be stretched out or retracted, and can send a telescopic length signal. The driving force and telescopic length of the electric push rod 1 need to be calculated and selected according to needs. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com