Forward-and-backward rotation variable-speed hub motor

A technology of in-wheel motors and motor shafts, which is applied in electromechanical devices, electrical components, mechanical equipment, etc., can solve problems such as reduced power and torque, and easy burnout of motors and control systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

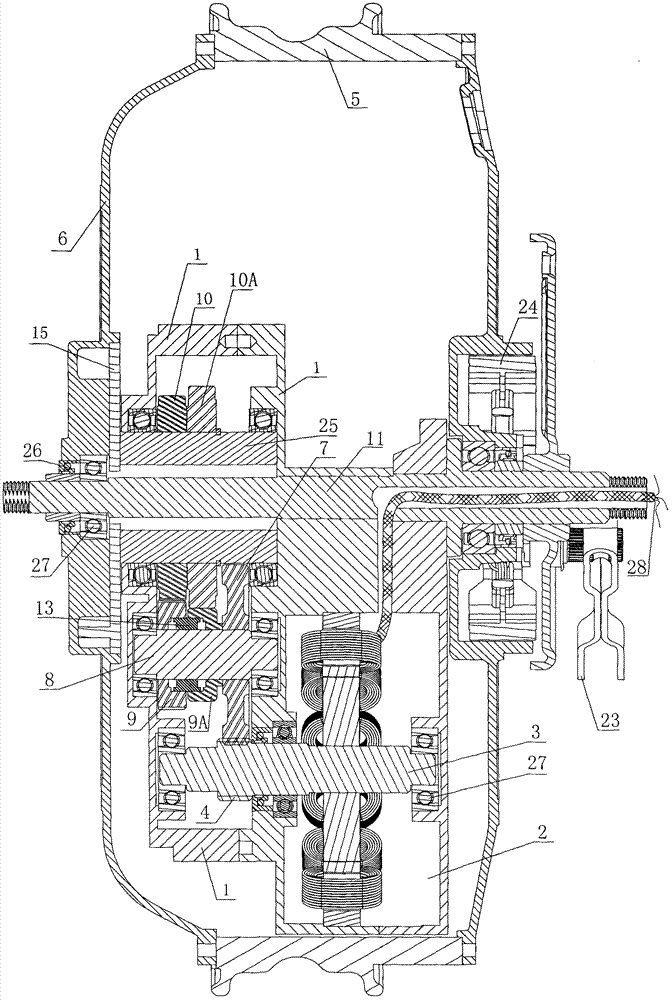

[0018] Such as Figure 1 to Figure 6 Shown is the first embodiment of the hub motor with forward and reverse speed change of the present invention. The electric vehicle transmission includes a hub ring 5, a box body 1 and related transmission mechanisms, and the box body 1 is fixedly connected to the motor 2 and the support shaft 11. Above, the fulcrum 11 is used to connect and fix the whole machine on the vehicle frame.

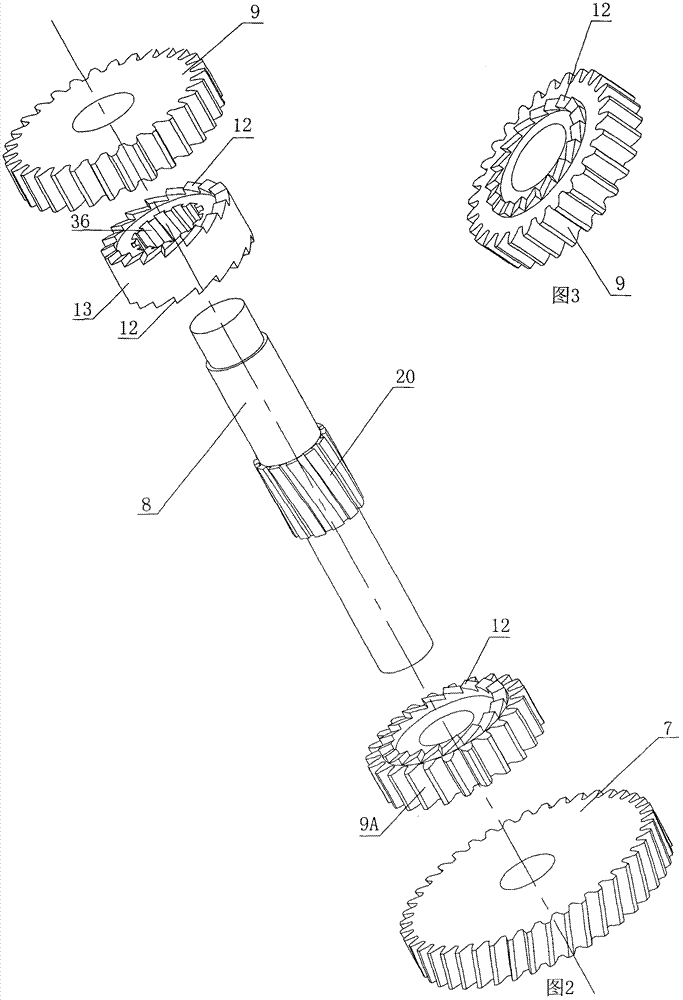

[0019] After the motor 2 is energized and rotated, the motor shaft gear 4 at the end of the motor shaft 3 meshes with the main shaft input gear 7 to rotate, and the main shaft input gear 7 rotates to drive the main shaft 8 to rotate.

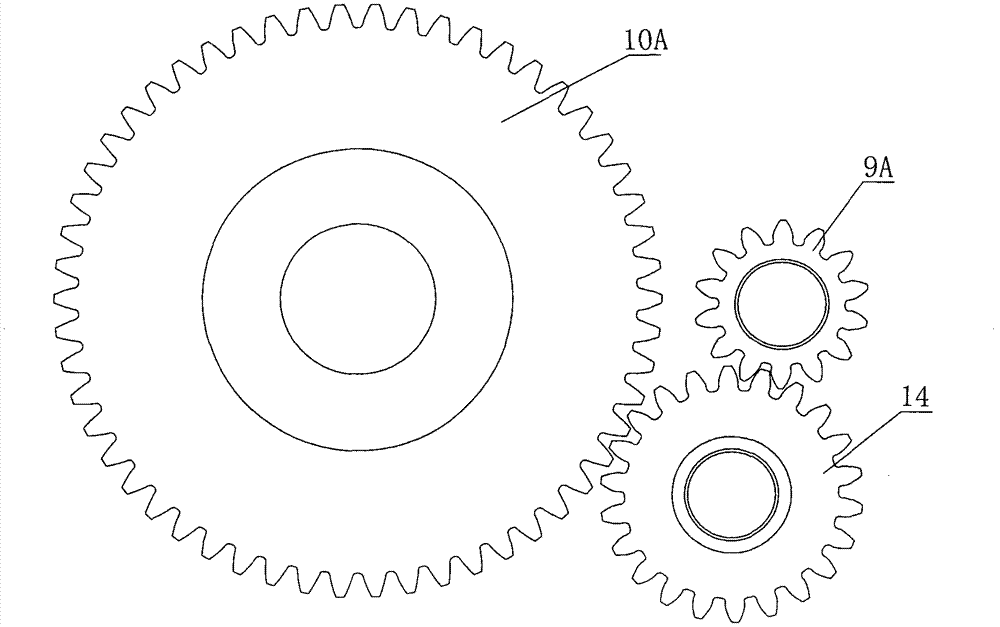

[0020] Such as figure 1 As shown in , the first gear output gear 10A and the second gear output gear 10 are fixed on the output shaft 25, and the diameters and the number of teeth of the two output gears are different. The corresponding looper on the main shaft 8 has a second gear driving gear 9 meshing with the second gear ...

Embodiment 2

[0025] Such as Figure 7 As shown in , the hub ring is provided with two motors 2 fixed on the side of the support shaft 11, and the motor shafts 3 of the two motors are parallel to the support shaft 11. The casings of the two motors 2 are connected structures. As long as the casings of the motors 2 are fixed on the support shaft 11, the corresponding motors are fixed. Therefore, the installation of the motor 2 is only related to the support shaft 11, and is related to the support shaft 11. The hub ring 5 is irrelevant, and there is no need to consider the concentricity between the motor shaft 3 and the support shaft 11, so it is convenient to select the same or different types of motors 3 according to needs, including different speeds, different sizes or different powers. Moreover, the motors are relatively fixed, and the overall rigid structure is good. The diameters of the motor shaft teeth 4 on the two motor shafts 3 are the same or different. This embodiment has two gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com