Hydraulic operating mechanism, ECU, clutch system and car

A control mechanism and clutch technology, applied in ECU, hydraulic control mechanism, clutch system and automobile field, can solve the problem of aggravating the driver's labor intensity, achieve low cost, meet the needs of clutch separation, and facilitate the shifting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

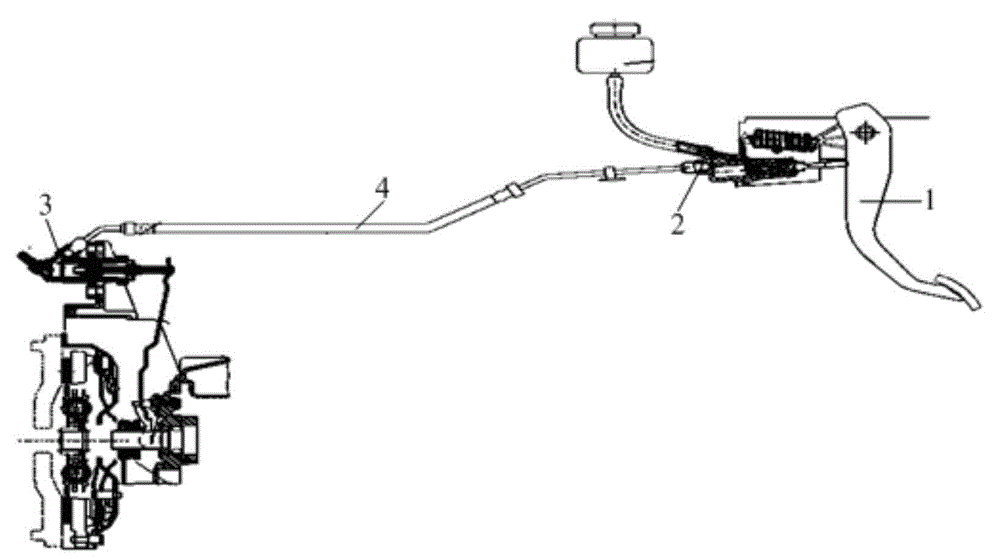

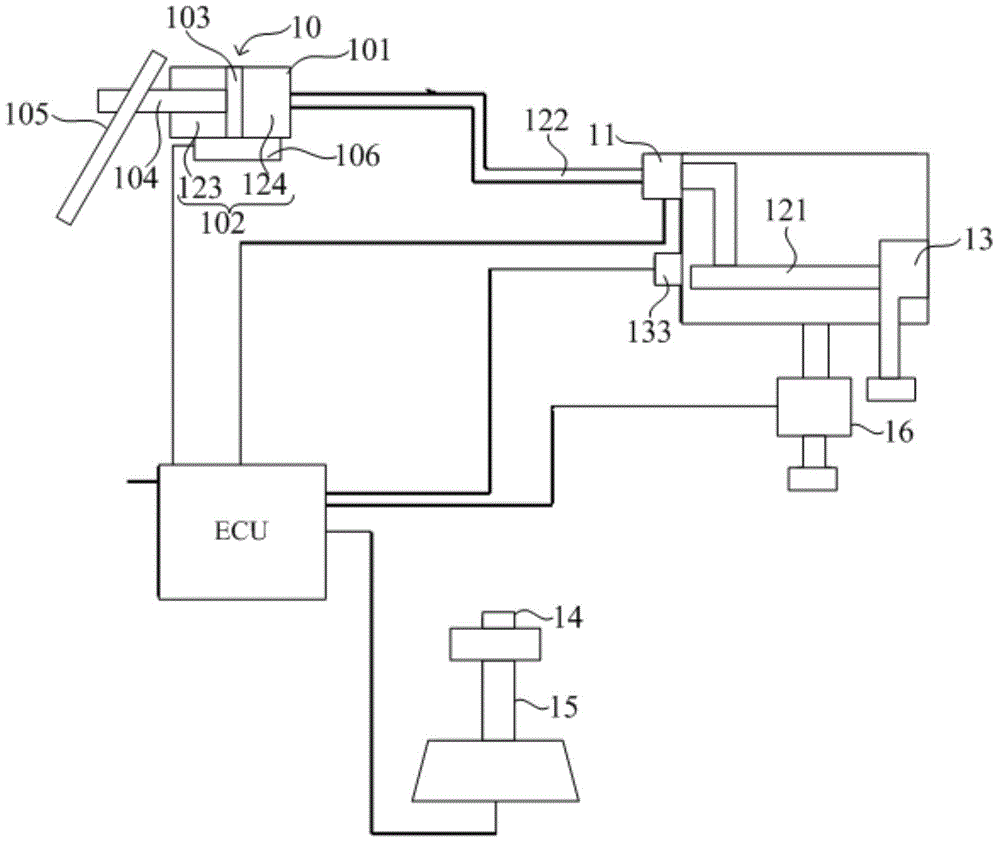

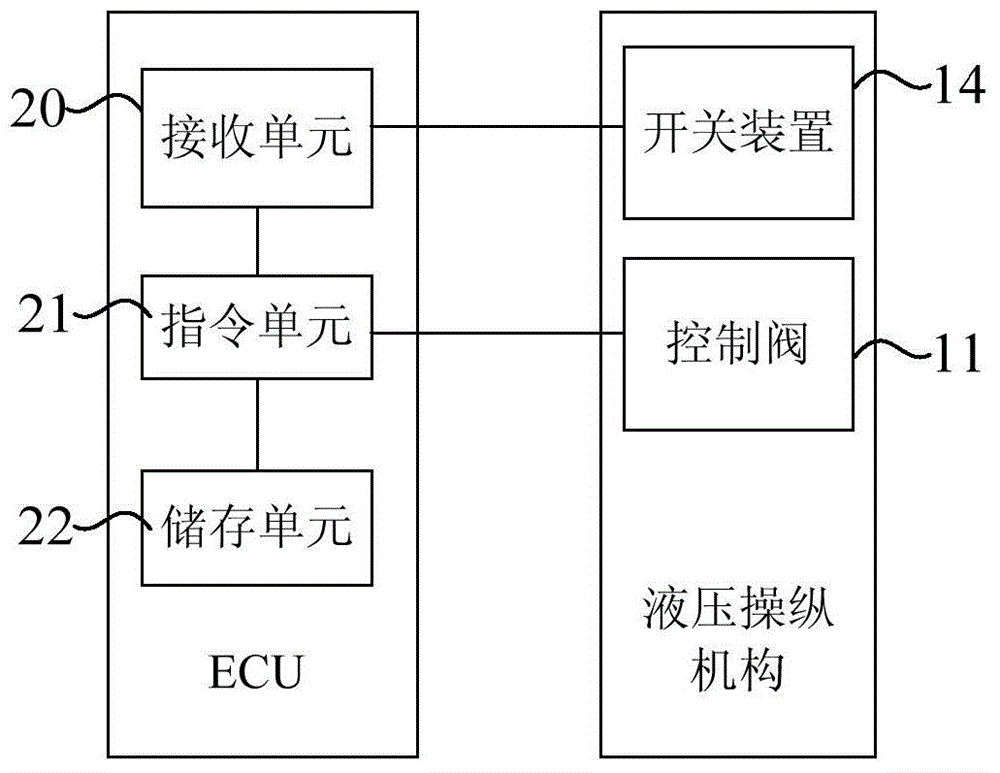

[0040] refer to figure 2 , the hydraulic control mechanism of the present embodiment includes:

[0041] clutch separation auxiliary cylinder 10;

[0042] The control valve 11 has an oil inlet, an oil outlet and an oil drain (not shown in the figure), the oil inlet is connected to the mechanical oil pump 13 through the main oil passage 121, and the oil outlet is connected to the clutch release pair through the hydraulic oil passage 122 Cylinder 10, the drain hole leads to the oil pan;

[0043] The switch device 14 is arranged on the shift lever 15, and is used to control the switching of the oil circuit of the control valve 11, so that the oil outlet hole communicates with the oil inlet hole to charge oil to the clutch release auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com