Processing box

A process box and end plate technology, applied in the field of process boxes, can solve problems such as inconvenient installation, and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

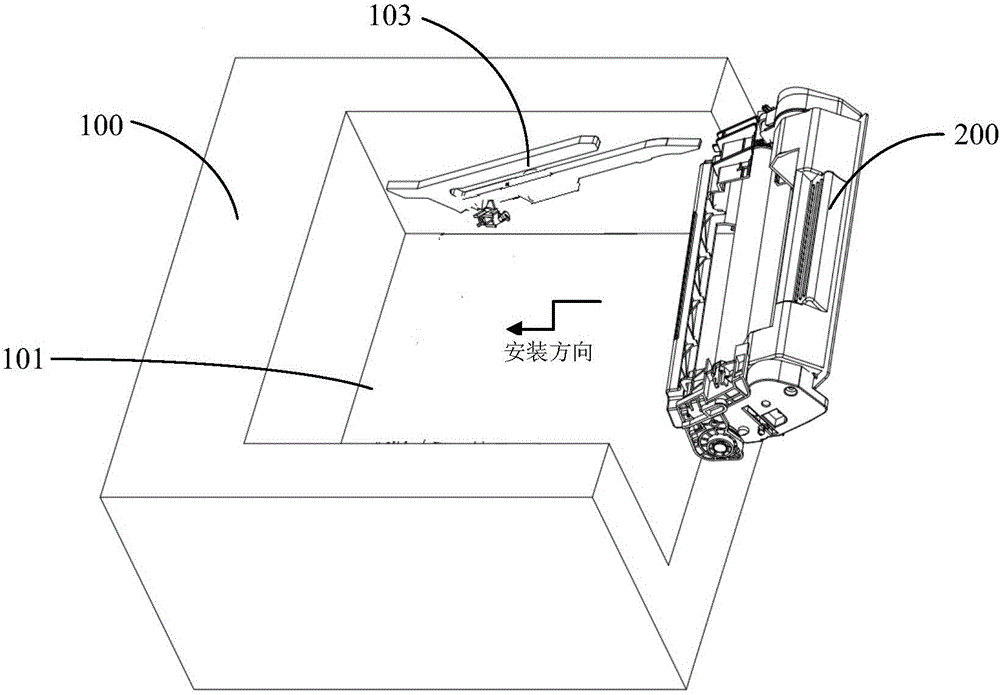

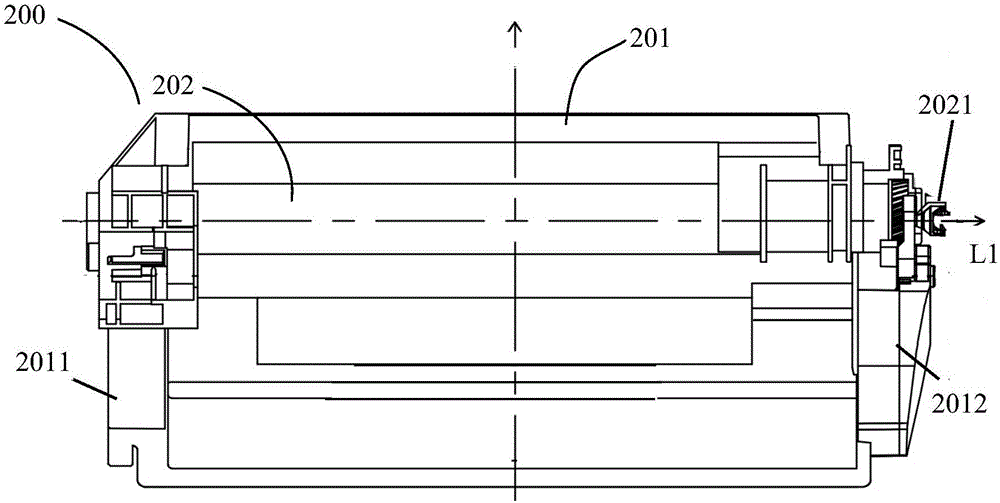

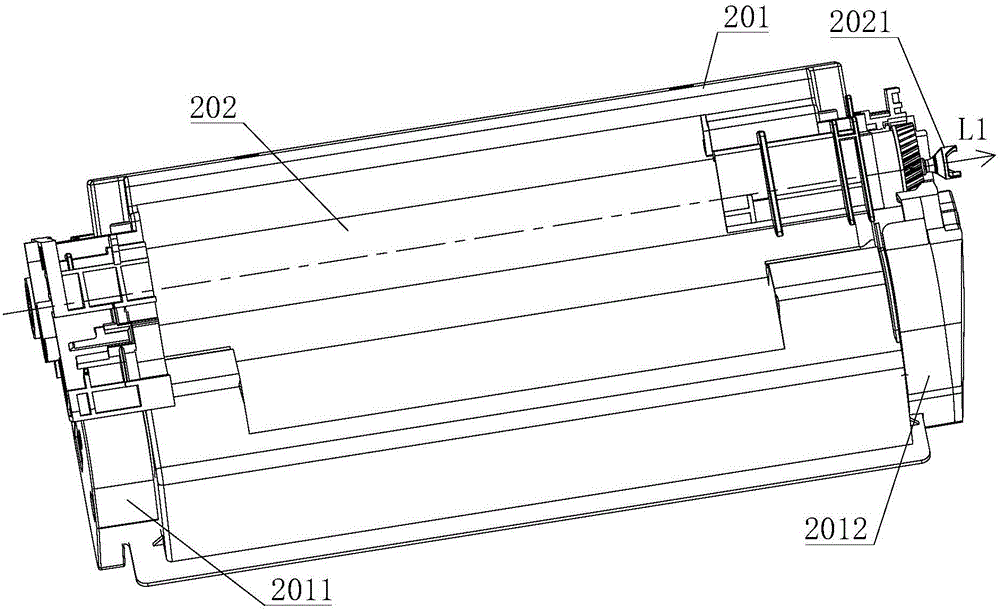

[0062] Such as figure 1 As shown, the main body 100 of the image forming apparatus has a cavity 101 for accommodating the process cartridge. On the two side walls of the cavity 101 are provided guide rails 103 for guiding the installation of the process cartridge, and on one side wall of the cavity 101 are provided A drive head 102 that drives the photosensitive drum of the process cartridge to rotate. The process box 200 is loaded into the main body of the image forming device along the guide rail 103 according to the installation direction set by the main frame of the image forming device (i.e. the predetermined mounting direction of the process box, the following installation directions all represent this meaning), and the process box is installed After being in place, the drive head 102 cooperates with the drive coupler on the process cartridge to drive the photosensitive drum of the process cartridge to rotate.

[0063] For ease of description, the state position where t...

Embodiment 2

[0076] Such as figure 1 As shown, the main body 100 of the image forming apparatus has a cavity 101 for accommodating the process cartridge. On the two side walls of the cavity 101 are provided guide rails 103 for guiding the installation of the process cartridge, and on one side wall of the cavity 101 are provided A drive head 102 that drives the photosensitive drum of the process cartridge to rotate. The process box 200 is loaded into the main body of the image forming device along the guide rail 103 according to the installation direction set by the main frame of the image forming device (i.e. the predetermined mounting direction of the process box, the following installation directions all represent this meaning), and the process box is installed After being in place, the drive head 102 cooperates with the drive coupler on the process cartridge to drive the photosensitive drum of the process cartridge to rotate.

[0077]For ease of description, the state position where th...

Embodiment 3

[0090] Such as Figure 15 , 16 As shown in and 17, the difference between this embodiment and the preceding embodiments is that a rotatable positioning assembly ( Figure 15 , Figure 16 , Figure 17 ), the positioning assembly includes a positioning guide rail 207, a rotating shaft 208 and a deflection elastic member 209, the positioning guide rail 207 is arranged on the housing 201 through the rotating shaft 208, the axis of the rotating shaft 208 is perpendicular to the plane where the positioning guide rail 207 is located, and the positioning guide rail 207 can rotate around the rotating shaft 208 . The deflection elastic member 209 is arranged between the positioning guide rail 207 and the side wall of the housing 201 or the second end plate wall. Under the elastic force of the deflection elastic member 209, the positioning guide rail 207 is not parallel to the plane perpendicular to the rotation axis of the drive head ( Figure 15 ); when the process box is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com