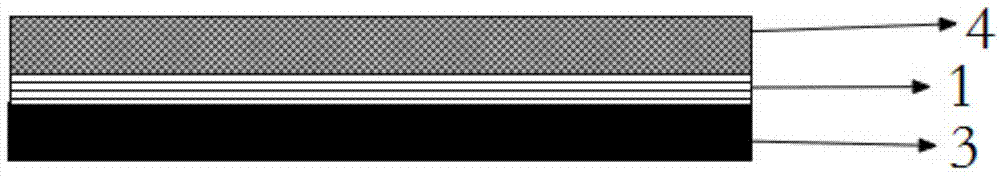

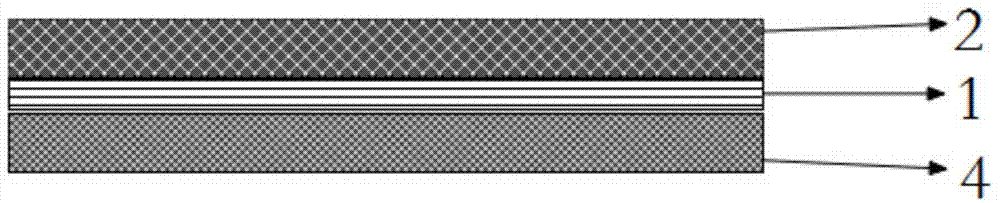

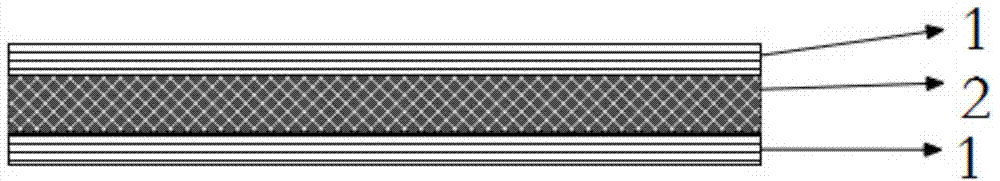

Flexible transparent conducting thin film based on graphene sandwich structure and preparation method thereof

A transparent conductive film, graphene film technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of reduced electrical conductivity, small grain size of graphene film, influence of electron transmission, etc., to increase electrical conductivity, Improve efficiency and flexibility, avoid brittle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) First, the copper foil was ultrasonically cleaned by isopropanol, acetone, ferric chloride, and deionized aqueous solution for 10 minutes, then placed on a quartz plate and placed in the center of the tube furnace together, under argon (500 sccm) and hydrogen (100 sccm) ) under the protection of a mixed atmosphere, the temperature was raised to 1000°C, and then annealed for 60mins. After that, the temperature was kept constant, and methane (30sccm) was introduced into the reaction chamber, and the metal was used to catalyze the methane, so that carbon atoms were deposited on the copper foil, and the reaction The time is 30mins, and then the temperature is rapidly lowered to obtain a graphene film layer grown on copper foil, and then a mixed solution of polymethyl methacrylate (PMMA) and acetone is spin-coated on one side of the graphene film layer, and after drying , into the ferric chloride solution to etch the copper foil substrate, and finally get the graphene f...

Embodiment 2

[0035] In Example 2, except for the following step (2), other steps (1) and (3) are the same as in Example 1, and the specific method of step (2) is as follows:

[0036] (2) Pour 20mL of sodium hydroxide (300mol / L), 1mL of copper nitrate (10mol / L), 100μL of ethylenediamine (EDA) and 70μL of hydrazine hydrate into the flask in turn, shake well, and then place the flask at 80 Heating in a water bath at ℃ temperature, and magnetic stirring continued for 0.5h at the same time, until the color of the bottom solution was colorless and clear, then continued gentle magnetic stirring for 6mins, and began to grow copper nanowires floating on the surface of the solution until the bottom solution turned red, and the reaction was over. Then pour the solution into a centrifuge tube, and inject polyvinylpyrrolidone (PVP), centrifuge to make the nanowires and polyvinylpyrrolidone layered, put the centrifuge tube in an ice bath, and finally take out the copper nanowires, and repeatedly wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com