CuO-MnO2 core-shell structured nanometer material and preparation method for same

A nanomaterial, core-shell structure technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of single morphology, poor cycle stability, capacitance loss, etc., and achieve electrochemical cycle. Stable performance and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The embodiment of the present invention discloses a CuO-MnO 2 A preparation method for a core-shell structure nanomaterial, comprising the following steps:

[0041] CuO-MnO was obtained by dispersing copper nanowires in potassium permanganate solution for hydrothermal reaction 2 Core-shell nanomaterials.

[0042] The present invention uses copper nanowires and potassium permanganate solution as raw materials to obtain CuO-MnO through redox 2 Core-shell nanomaterials.

[0043] Wherein, the diameter of the copper nanowire is preferably 100-200 nm. In the present invention, there is no special limitation on the source of the copper nanowires, which can be purchased from the market or prepared according to methods well known to those skilled in the art. The preparation method of described copper nanowire is preferably:

[0044]Shake copper nitrate, sodium hydroxide, ethylenediamine and hydrazine hydrate according to the volume ratio of 4:80:0.6:0.14 until the solution ...

Embodiment 1

[0053] Add 4 mL of 0.1 mol / L copper nitrate aqueous solution, 80 mL of 15 mol / L sodium hydroxide aqueous solution, 600 μL of 30% ethylenediamine solution by mass fraction and 140 μL of 30% hydrazine hydrate aqueous solution by mass fraction in the container, and shake for 5 minutes until the solution turns milky white. Then the container containing the above mixed solution was placed in a water bath at 65° C., and reacted for 1 h. The reacted mixed solution was placed in a centrifuge for solid-liquid separation, and the precipitate was collected, then deionized water was added to mix evenly, and then centrifuged again, and this was repeated 3 times. Finally, the collected precipitate was placed in a vacuum drying oven and dried at 60° C. for 24 hours to obtain copper nanowires with a diameter of 100-200 nm.

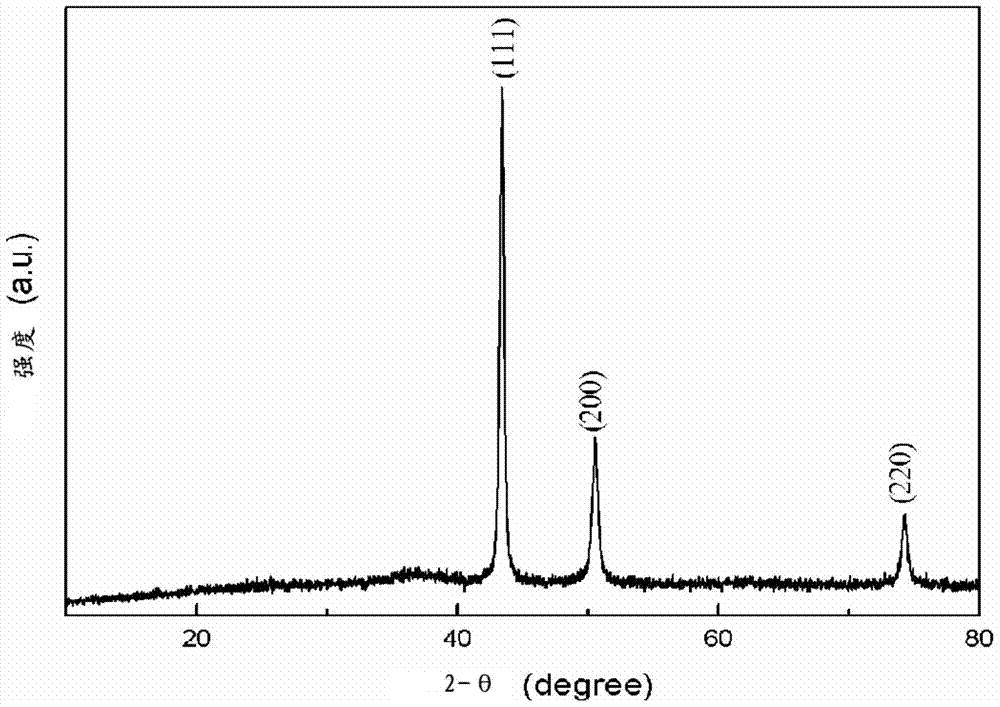

[0054] figure 1 It is the XRD spectrum of the copper nanowire prepared in Example 1.

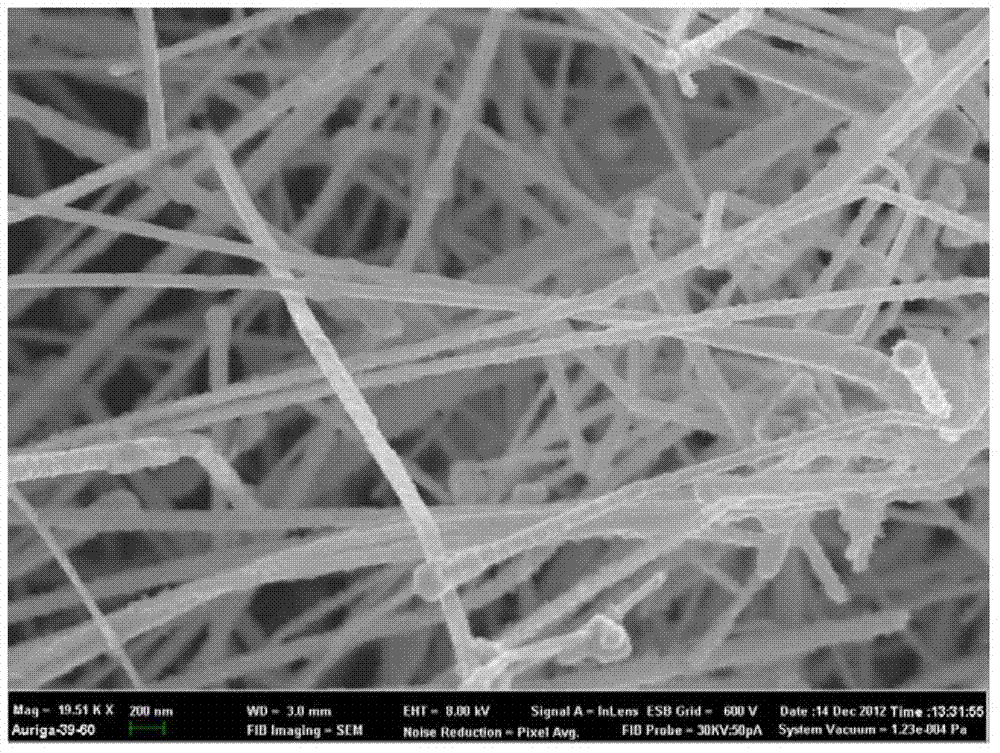

[0055] figure 2 It is the SEM image of the copper nanowires prepared in Exampl...

Embodiment 2

[0058] Taking the newly prepared Cu nanowires in Example 1 as the substrate, using 0.05mol / L potassium permanganate solution, the volume ratio of the quality of the copper nanowires to the 0.05mol / L potassium permanganate solution is 10mg: 30mL The ratio of the two is mixed in a container, and magnetically stirred for 10 minutes to obtain a mixed system.

[0059] Move the mixed system to a hydrothermal reaction kettle lined with polytetrafluoroethylene, conduct a hydrothermal reaction at a temperature of 160°C for 24 hours, and then perform solid-liquid separation of the mixed liquid after the hydrothermal reaction , collect the precipitate after the reaction, add the obtained precipitate to deionized water and stir to mix evenly, place it in a centrifuge, and perform centrifuged solid-liquid separation again, repeat this 3 to 6 times, collect the final obtained precipitate, dry and obtain CuO -MnO 2 Core-shell nanomaterials.

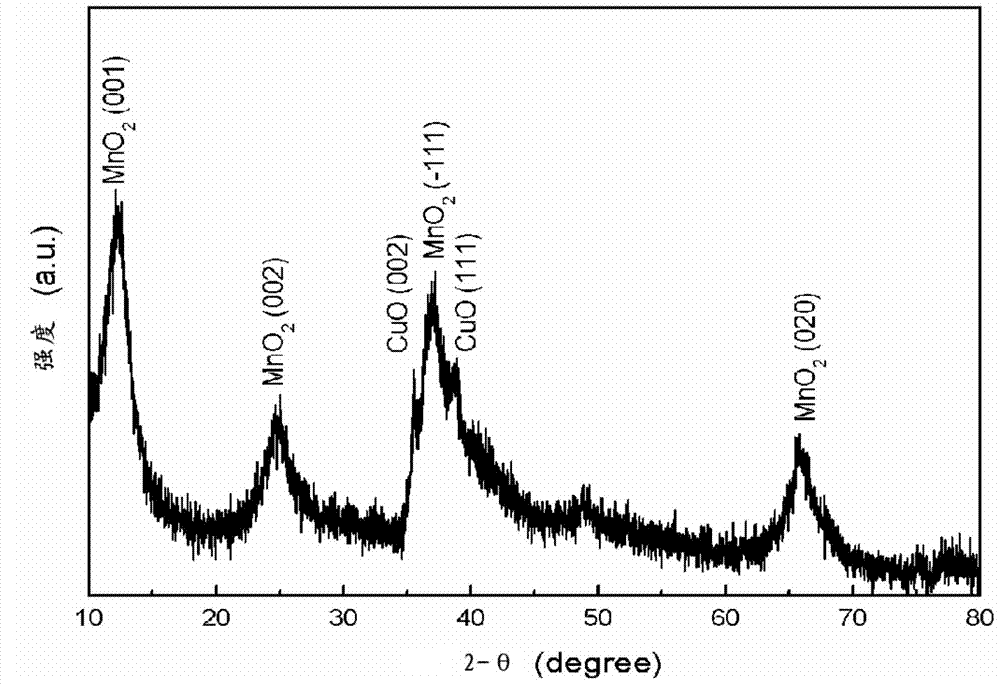

[0060] image 3 CuO-MnO prepared for Example 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com