Preparation method and application of Cu nanowire-reduced graphene oxide three-dimensional porous film

A three-dimensional porous and nanowire technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of low sensitivity of resistance strain sensor and narrow strain detection range, and achieve mild conditions, low cost, and excellent electrical conductivity. Effects of sexual and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing a Cu nanowire-reduced graphene oxide-PDMS composite material strain sensor, comprising the following contents:

[0021] The preparation method of graphene oxide is: slowly mix 270mL concentrated sulfuric acid / phosphoric acid mixed acid (H 2 SO 4 :H 3 PO 3 =9:1, V / V) was added dropwise to a beaker with 2g of natural graphite powder and kept stirring, then slowly added 12g of potassium permanganate, after mixing evenly, the beaker was transferred to a 50°C water bath for 12h. After the reaction was completed, 300 mL of ice water was added into the beaker, and after cooling to room temperature, 5 mL of 30% hydrogen peroxide was added dropwise to obtain a bright yellow product. Finally, the product was centrifuged and washed with hydrochloric acid and deionized water until pH = 6 at a rotation speed of 8000 rpm / min, and finally freeze-dried to obtain graphene oxide.

[0022] The preparation method of copper nanowire is: prep...

Embodiment 1

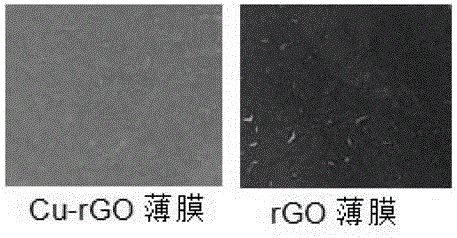

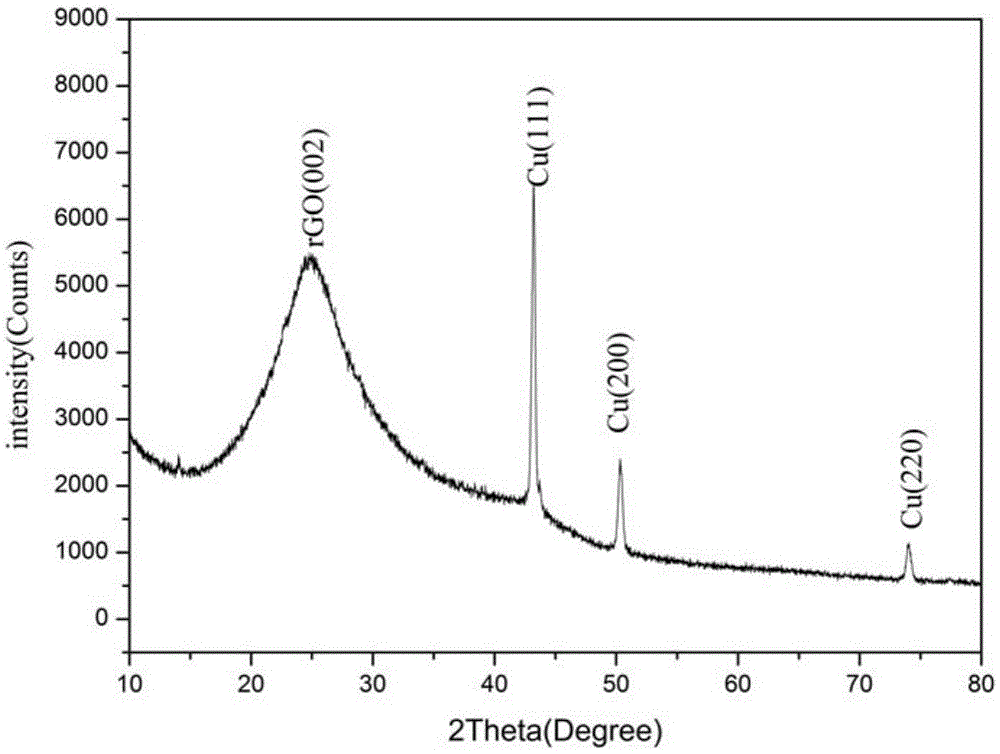

[0024] Take a 50mL beaker, measure 22mL of ethylene glycol solution, pour 5mg of reddish-brown Cu nanowires into it, stir and sonicate, repeat several times to obtain a reddish-brown solution, add 50mg of ascorbic acid and 3.1mL of 8mg / mL graphene oxide, and then proceed Stir and sonicate until the graphene oxide is uniformly dispersed, then move it to a hydrothermal reaction kettle, place the reaction kettle in a blast drying oven at 120°C for 4 hours, and finally lower the temperature to room temperature to obtain Cu nanowires- Reduced graphene oxide composite hydrogels.

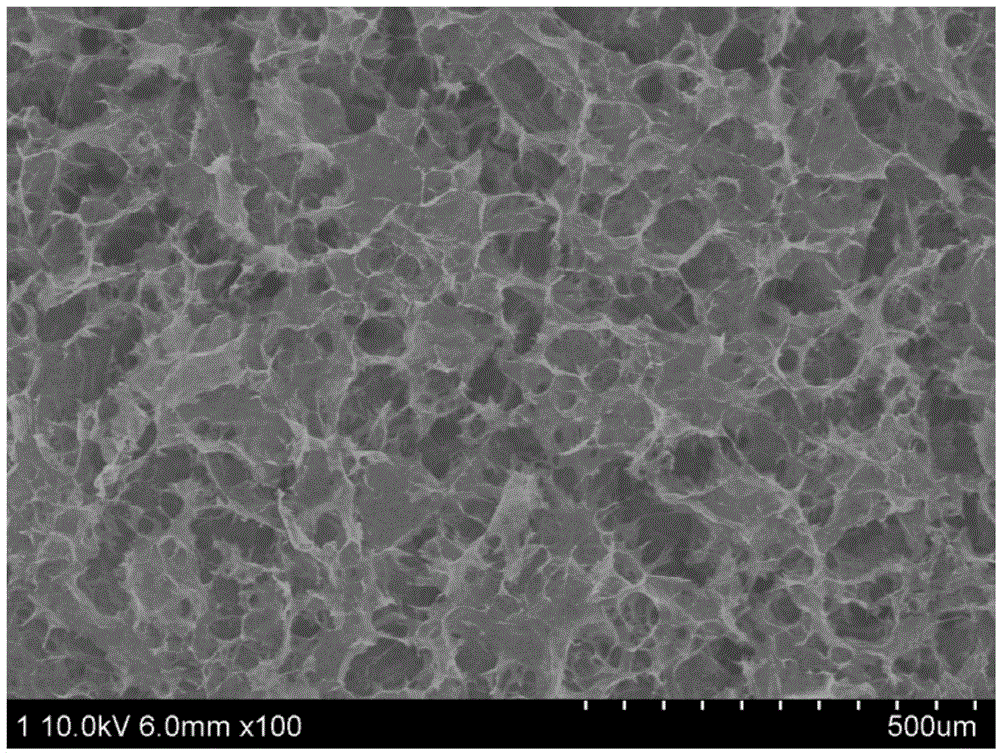

[0025] Rinse the Cu nanowire-reduced graphene oxide composite hydrogel in the hydrothermal reactor with deionized water for 4-5 times, then pour it into a 100mL beaker and rinse for 3-4 times, in order to remove the gel surface of organic solvents. Then it was dialyzed in 500 mL of 0.5 wt% hydrazine hydrate solution for 16 hours, in order to remove the organic solvent in the gel. Finally, pour it into a ...

Embodiment 2

[0027] Take a 50mL beaker, measure 22mL ethylene glycol solution, pour 10mg reddish-brown Cu nanowires into it, stir, sonicate, repeat several times to obtain a reddish-brown solution, add 50mg ascorbic acid and 3.1mL8mg / mL graphene oxide, and then proceed Stir and sonicate until the graphene oxide is uniformly dispersed, then move it to a hydrothermal reaction kettle, place the reaction kettle in a blast drying oven at 120°C for 4 hours, and finally lower the temperature to room temperature to obtain Cu nanowires- Reduced graphene oxide composite hydrogels.

[0028] Rinse the Cu nanowire-reduced graphene oxide composite hydrogel in the hydrothermal reactor with deionized water for 4-5 times, and pour it into a 100mL beaker for 3-4 times. Then place it in 500mL0.5wt% hydrazine hydrate solution for dialysis for 16h, and finally pour it into a 150mL beaker, rinse it with deionized water after 3 times, put it on a magnetic stirrer to stir evenly, and ultrasonically , until a bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com