Preparation method of copper nanowire arrays with porous structure and film conductivity measuring method thereof

A technology of copper nanowires and arrays, applied in the field of preparing copper nanowire arrays, can solve the problems of poor repeatability of the reaction, restrictions on large-scale production of copper nanowires, slow reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

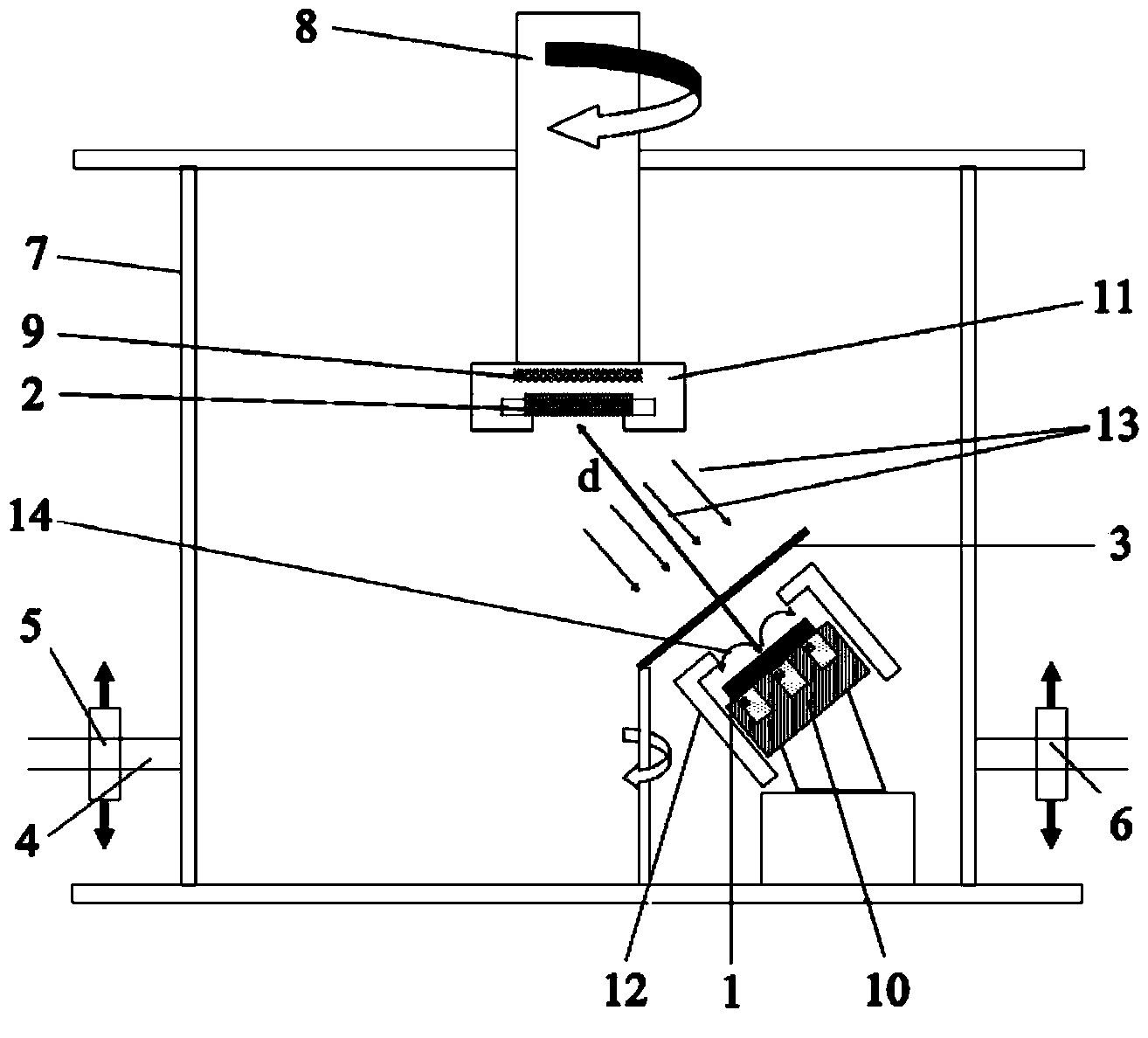

[0039] Magnetron sputtering apparatus: JGP-450a multi-target magnetron sputtering deposition system (Shenyang Scientific Instrument Development Center Co., Ltd., Chinese Academy of Sciences);

[0040] Substrate type: aluminum nitride;

[0041] Adjust the distance d=90mm between the sample stage 2 and the radio frequency stage 1;

[0042] Vacuumize the vacuum chamber 7 to make the vacuum degree in the vacuum chamber 7 reach 3.4×10 -4 Pa;

[0043] Turn on the heating control power supply 9, and turn on the sample rotation stage 8 to keep the substrate temperature at room temperature;

[0044] Fill the vacuum chamber 7 with argon, and adjust the air pressure to 1.5Pa;

[0045] Adjust the DC current to 110mA and the voltage to 0.30kV

[0046] Deposition time 2h;

[0047] After the preparation, turn off the DC power supply, anneal in situ for 20 minutes, and cool naturally to room temperature 25° C., then take out the aluminum nitride substrate with the copper nanowire array t...

Embodiment 2

[0050] Magnetron sputtering apparatus: JGP-450a multi-target magnetron sputtering deposition system (Shenyang Scientific Instrument Development Center Co., Ltd., Chinese Academy of Sciences)

[0051] Adjust the distance d=90mm between sample stage 2 and RF stage 1

[0052] Vacuumize the vacuum chamber 7 to make the vacuum degree in the vacuum chamber 7 reach 3.4×10 -4 Pa;

[0053] Turn on the heating control power supply 9, and turn on the sample rotation table 8, so that the substrate temperature rises to 100°C;

[0054] Rush into the vacuum chamber 7 with argon, and adjust the air pressure to 1.5Pa;

[0055] Adjust the DC current to 110mA and the voltage to 0.30kV

[0056] Deposition time 2h;

[0057] After the preparation, turn off the DC power supply, anneal in situ for 20 minutes, and cool naturally to room temperature 25° C., then take out the aluminum nitride substrate with the copper nanowire array thin film.

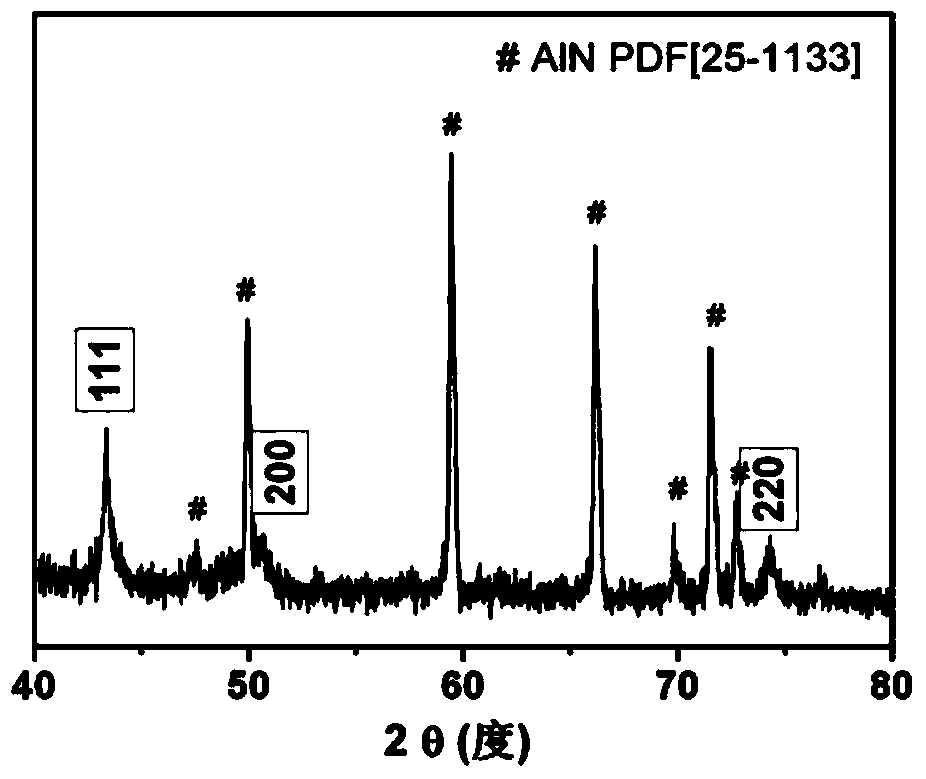

[0058] Adopt X-ray diffractometer to carry out phase ...

Embodiment 3

[0060] Magnetron sputtering apparatus: JGP-450a multi-target magnetron sputtering deposition system (Shenyang Scientific Instrument Development Center Co., Ltd., Chinese Academy of Sciences)

[0061] Substrate type: aluminum nitride;

[0062] Adjust the distance d=90mm between sample stage 2 and RF stage 1

[0063] Vacuumize the vacuum chamber 7 to make the vacuum degree in the vacuum chamber 7 reach 3.4×10 -4 Pa;

[0064] Turn on the heating control power supply 9, and turn on the sample rotation table 8, so that the substrate temperature rises to 200°C;

[0065] Rush into the vacuum chamber 7 with argon, and adjust the air pressure to 1.5Pa;

[0066] Adjust the DC current to 110mA and the voltage to 0.30kV

[0067] Deposition time 2h;

[0068] After the preparation, turn off the DC power supply, anneal in situ for 20 minutes, and cool naturally to room temperature 25° C., then take out the aluminum nitride substrate with the copper nanowire array thin film.

[0069] Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com