Method for massively preparing overlength copper nanowires

A copper nanowire, ultra-long technology, applied in nanotechnology and other directions, can solve the problem of difficult to achieve large-scale production of high-temperature pressure vessels, and achieve the effects of a wide range of size control, controllable morphology, and uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

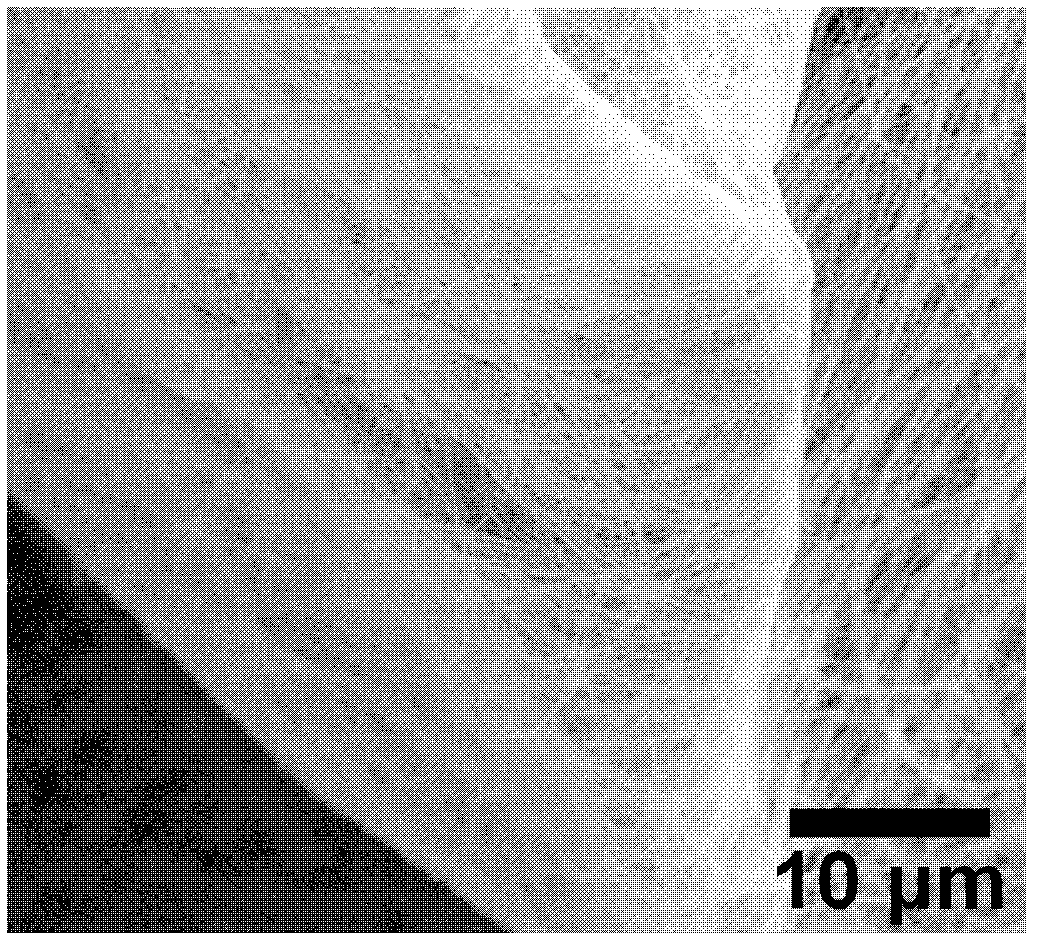

[0032] First prepare 100 ml of mixed solvent of ethylene glycol, dimethylformamide and water according to the volume ratio of 1:1:3; take 0.3 g of copper chloride and add it to the mixed solvent by ultrasonic vibration to dissolve, then take 1 g of hexadecylamine and add Into the above solution, stirred for 20 minutes and then ultrasonically oscillated for 30 minutes to obtain a uniform emulsion, then added 0.5 grams of polyethylene glycol (average molecular weight 800) and 0.5 grams of polyvinylpyrrolidone (average molecular weight 33000), and stirred for another 20 minutes Then this mixed emulsion is transferred in 250 milliliters of round bottom flasks, is heated to boiling reflux, and continues to keep boiling reflux 3 hours, then stops heating, obtains brick red mixed solution. After the reaction stopped, wash with 100 ml each of water and ethanol and centrifuge, then wash and centrifuge with 100 ml each of n-hexane and chloroform, and finally dry the resulting precipitate...

Embodiment 2

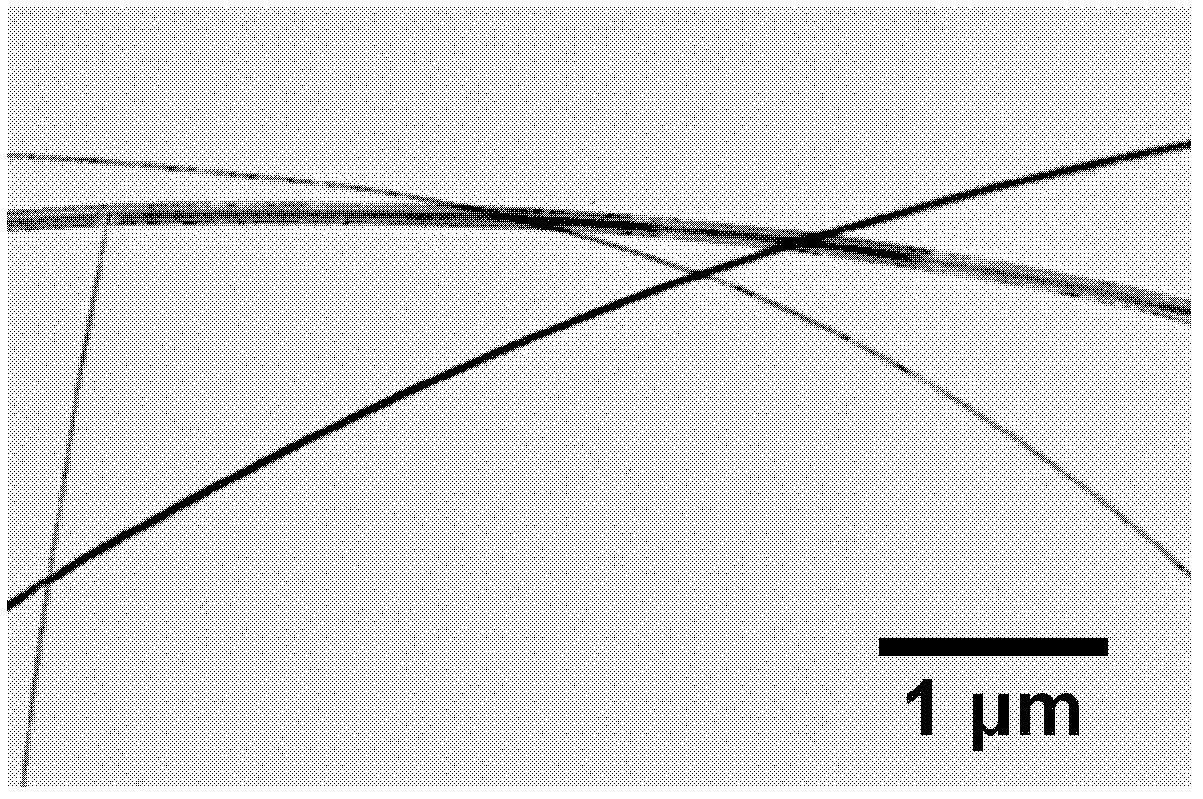

[0034] The process is similar to that of Example 1, but when preparing copper nanowires, hexadecylamine is replaced by octadecylamine, and the amount is reduced to 0.5 g. The sonication time of the mixed solution was extended to 60 minutes, and other conditions remained unchanged. After the reaction is finished, wash and centrifuge with ethanol, ultrapure water, n-hexane and chloroform, and dry the precipitate at low temperature until it becomes a dry powder to obtain copper nanowires with a diameter of 70 nanometers. figure 2 A scanning electron microscope image of a copper nanowire with a diameter of 70 nm, by figure 2 It can be seen that the copper nanowires with a diameter of 70 nm still maintain an ultra-long axial length.

Embodiment 3

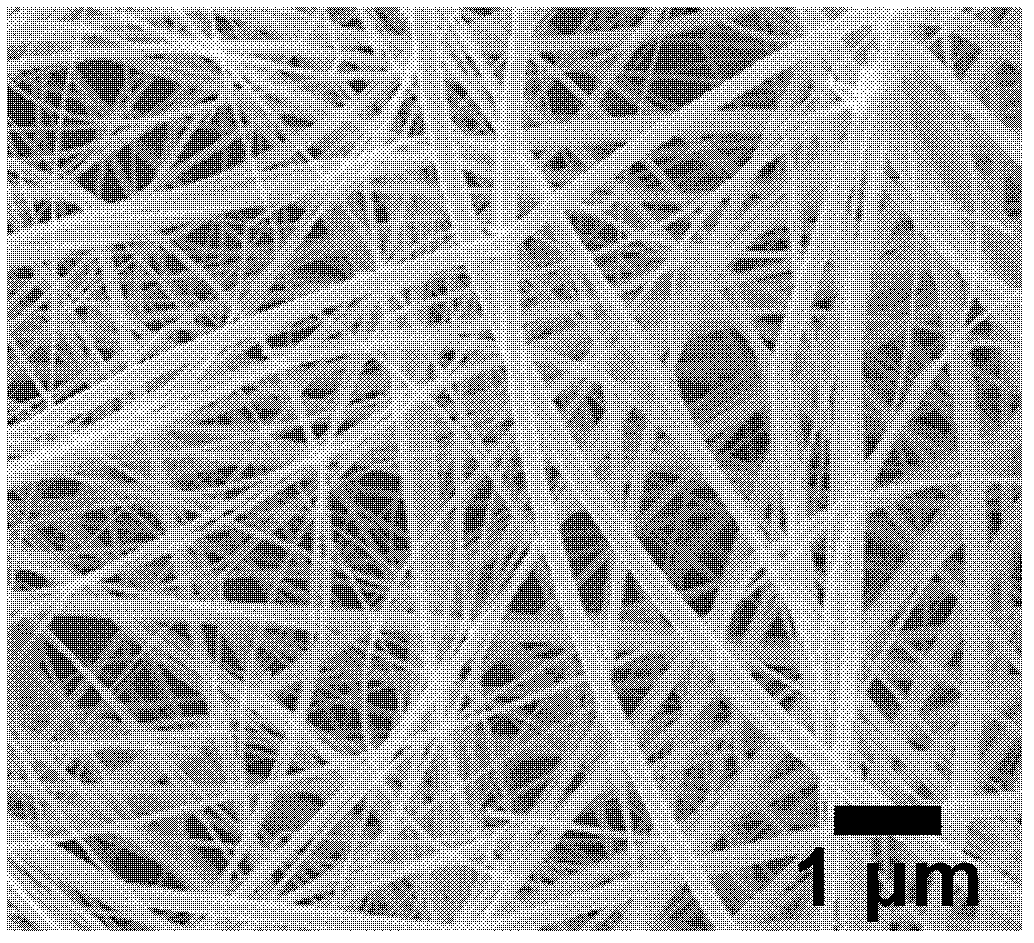

[0036] Similar to the process of Example 1, but when preparing copper nanowires, the amount of copper salt was increased to 2 grams, and then the stirring and dissolving time of the mixed solution and cetylamine was extended to 60 minutes, and the ultrasonic oscillation time was extended to 90 minutes. Other conditions remain unchanged. After the reaction is finished, wash and centrifuge with ethanol, ultrapure water, n-hexane and chloroform, and dry the precipitate at low temperature until it becomes a dry powder to obtain copper nanowires with a diameter of 120 nanometers. image 3 A scanning electron microscope image of a copper nanowire with a diameter of 120 nm, by image 3 It can be seen that while the diameter of copper nanowires increases, the axial length can be made very long, while still maintaining high purity and high monodispersity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com