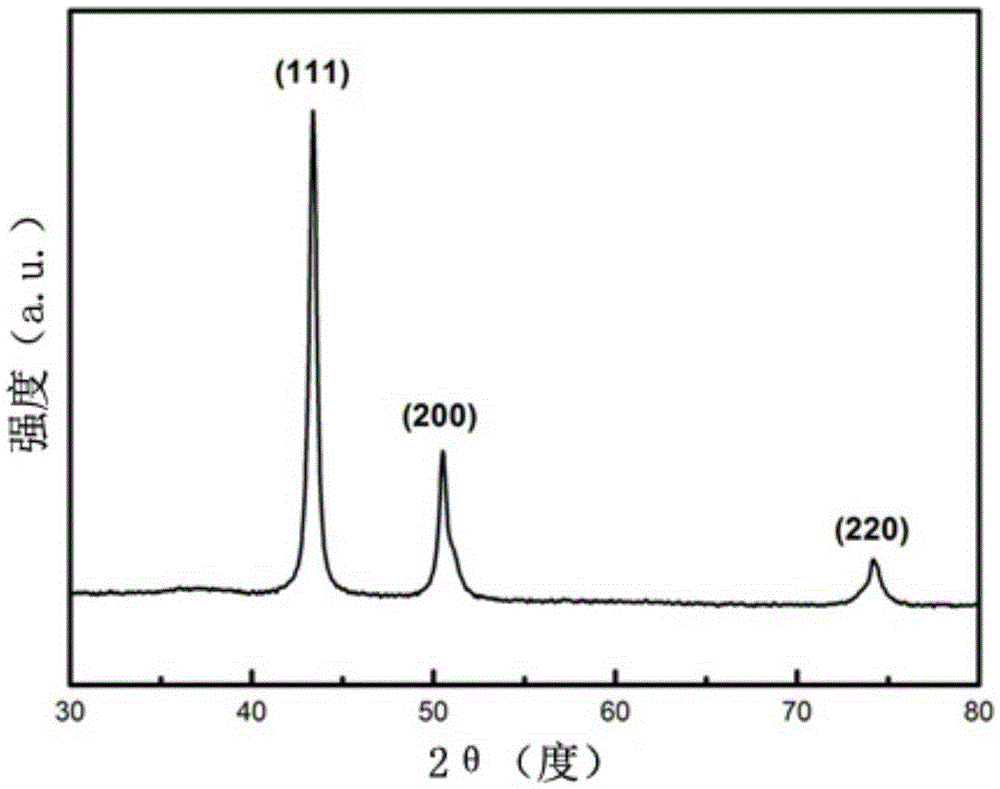

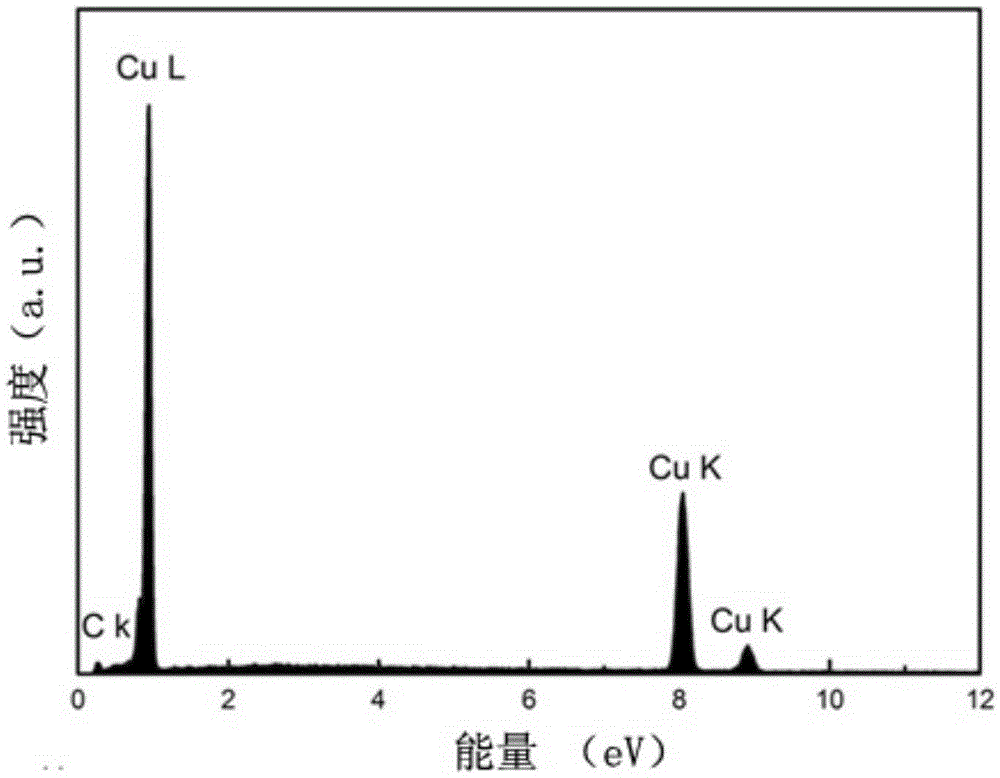

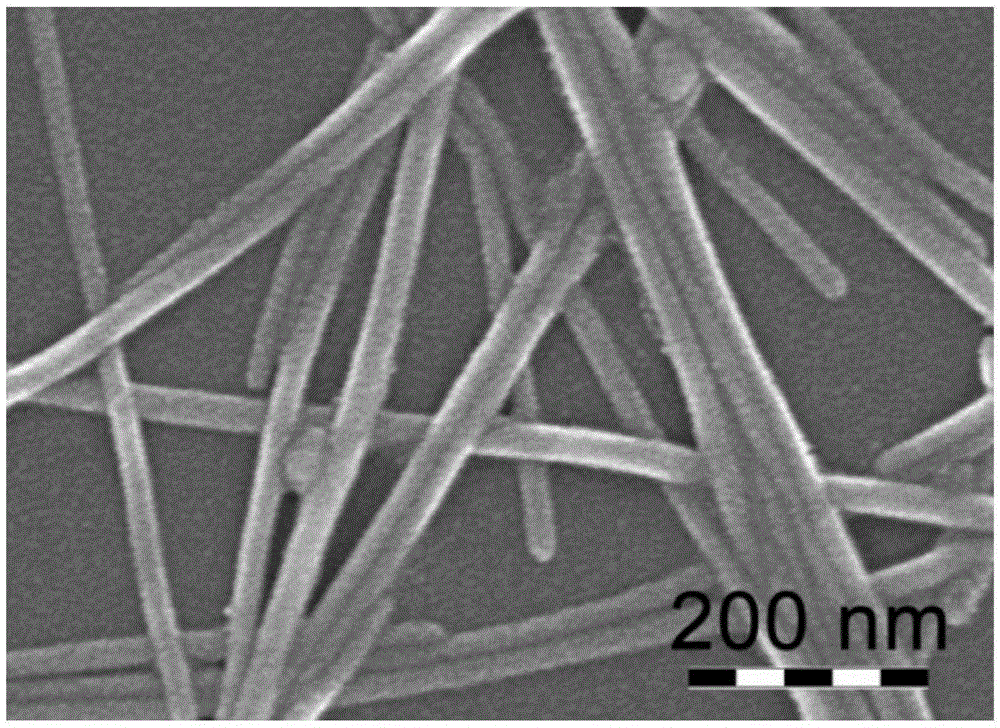

Method for preparing copper nanowires through oil-phase chemical reduction

A copper nanowire and chemical technology, applied in the field of materials, can solve problems such as difficult dispersion, harsh reaction conditions, and difficult application, and achieve the effects of easy operation and implementation, uniform size, and regular line shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing copper nanowires by oil-phase chemical reduction, comprising the steps of:

[0044] (1) Weighing medicines

[0045] Weigh respectively 0.2094g copper acetylacetonate, 0.0951g nickel chloride hexahydrate, and 0.2932g dimethyl dioctadecyl ammonium chloride (DDAC) in a 50 ml three-necked round-bottomed flask, then pipette 8 ml oleylamine. The magnet is placed at the bottom of the bottle.

[0046] (2) Nitrogen gas

[0047] Nitrogen was passed into the closed device system of the three-necked flask to check the airtightness of the device.

[0048] (3) Reaction condition setting

[0049] Turn on the heating switch of the heating mantle and set the heating temperature to 80°C. After maintaining this temperature for 20 minutes, the reaction temperature was set at 185° C., and the reaction time was 4 hours. The whole reaction process was kept under the protection of nitrogen.

[0050] (4) Washing and centrifugation

[0051] After the reaction, pour...

Embodiment 2

[0055] A method for preparing copper nanowires by oil-phase chemical reduction, comprising the steps of:

[0056] Weigh 0.2094g of copper acetylacetonate, 0.0951g of nickel chloride hexahydrate, and 0.2932g of DDAC into 50ml of three-port round bottom, and pipette 8ml of oleylamine. Under the condition of nitrogen protection, the mixed system was heated and stirred at 80° C. for 20 minutes, and then heated to 170° C. for 4 hours. Cool to room temperature, wash with n-hexane, and centrifuge to obtain a red precipitate at the bottom, which is copper nanowires.

Embodiment 3

[0058] A method for preparing copper nanowires by oil-phase chemical reduction, comprising the steps of:

[0059] Weigh 0.2094g of copper acetylacetonate, 0.0951g of nickel chloride hexahydrate, and 0.2932g of DDAC into 50ml of three-port round bottom, and pipette 8ml of oleylamine. Under the condition of nitrogen protection, the mixed system was heated and stirred at 80° C. for 20 min, and then heated to 200° C. for 4 h. Cool to room temperature, wash with n-hexane, and centrifuge to obtain a red precipitate at the bottom, which is copper nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com