Large flow pipe-type breaking valve

A technology of breaking valve and large flow, applied in the direction of safety valve, balance valve, valve device, etc., to achieve the effect of stable and reliable breaking force, low maintenance cost and preventing fluid impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

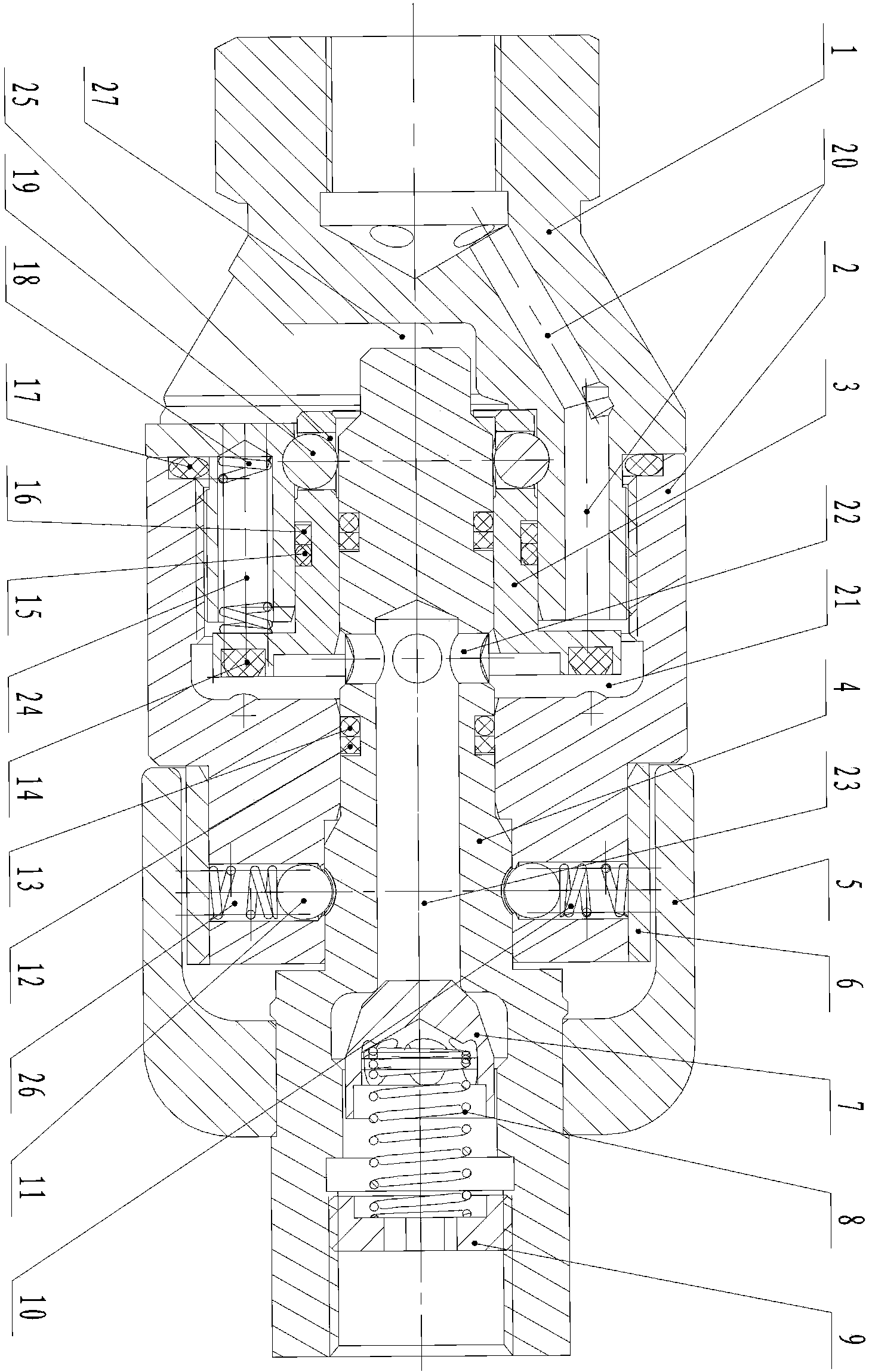

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0036]In order to overcome the deficiencies of the prior art, the present invention provides a large-flow tubular breakaway valve, which is provided with an air intake plug 1, a positioning sleeve 2, a breakaway shaft 4 and a plane check valve 3 to form a completely sealed cavity. Inside, there are fluid channel process holes I20, fluid channel process holes II21, fluid channel process holes III22, and fluid channel process holes IV23 for fluid passage. An exposed balance cavity is provided in the middle of the intake plug 1 to solve the problem of unbalance of the valve body itself caused by icing at low temperature. The positioning structure composed of plane check valve, stainless steel ball and intake plug can effectively prevent fluid impact and make the valve body balanced and stable. There are four symmetrical fluid passages I20 in the body of the intake plug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com