Patents

Literature

50results about How to "Limit traffic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prediction method for PM2.5 concentration of fine particulate matters in air based on a stack selective integrated learning device

ActiveCN109615082ALimit emissionsLimit trafficMachine learningParticle suspension analysisPredictive methodsThree stage

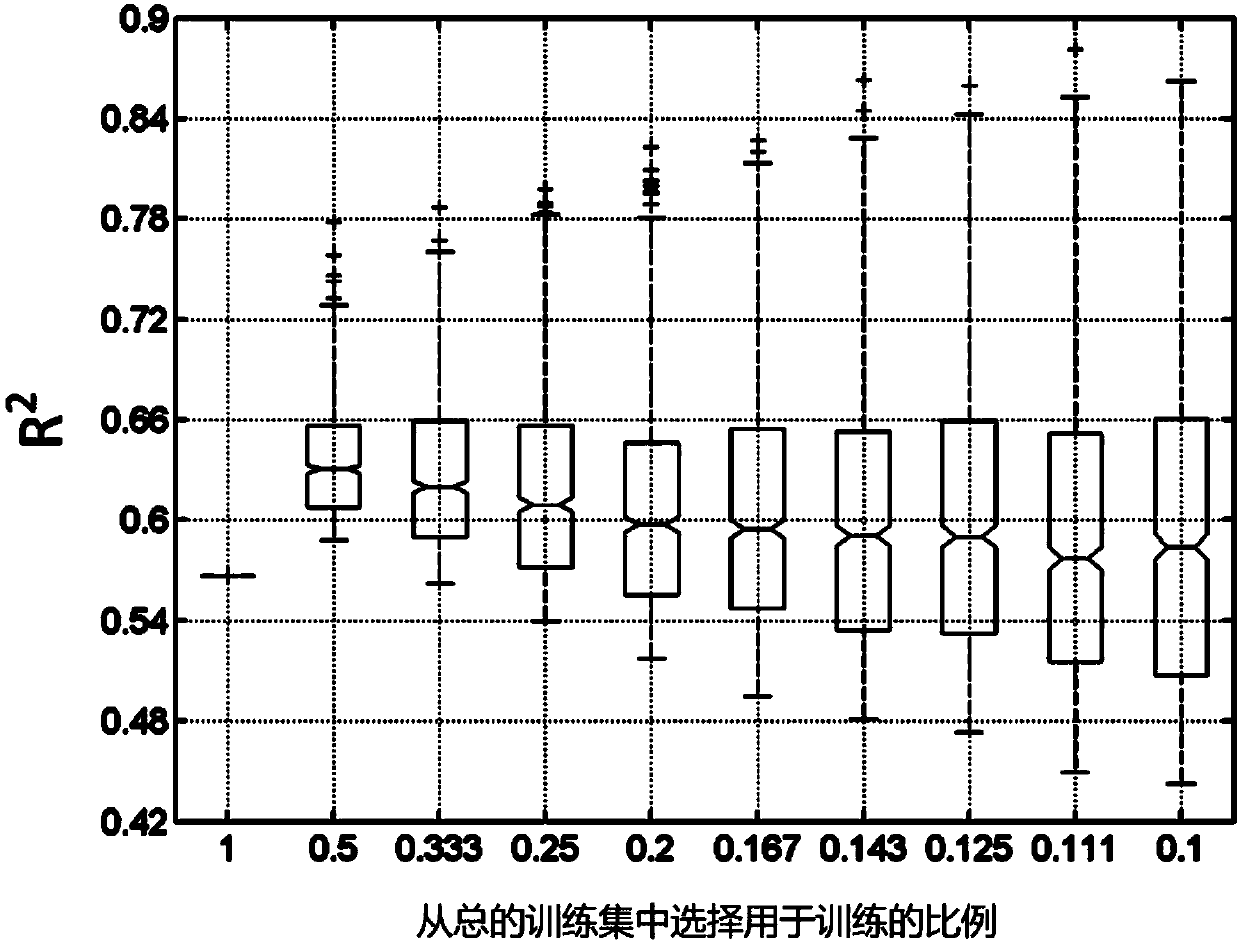

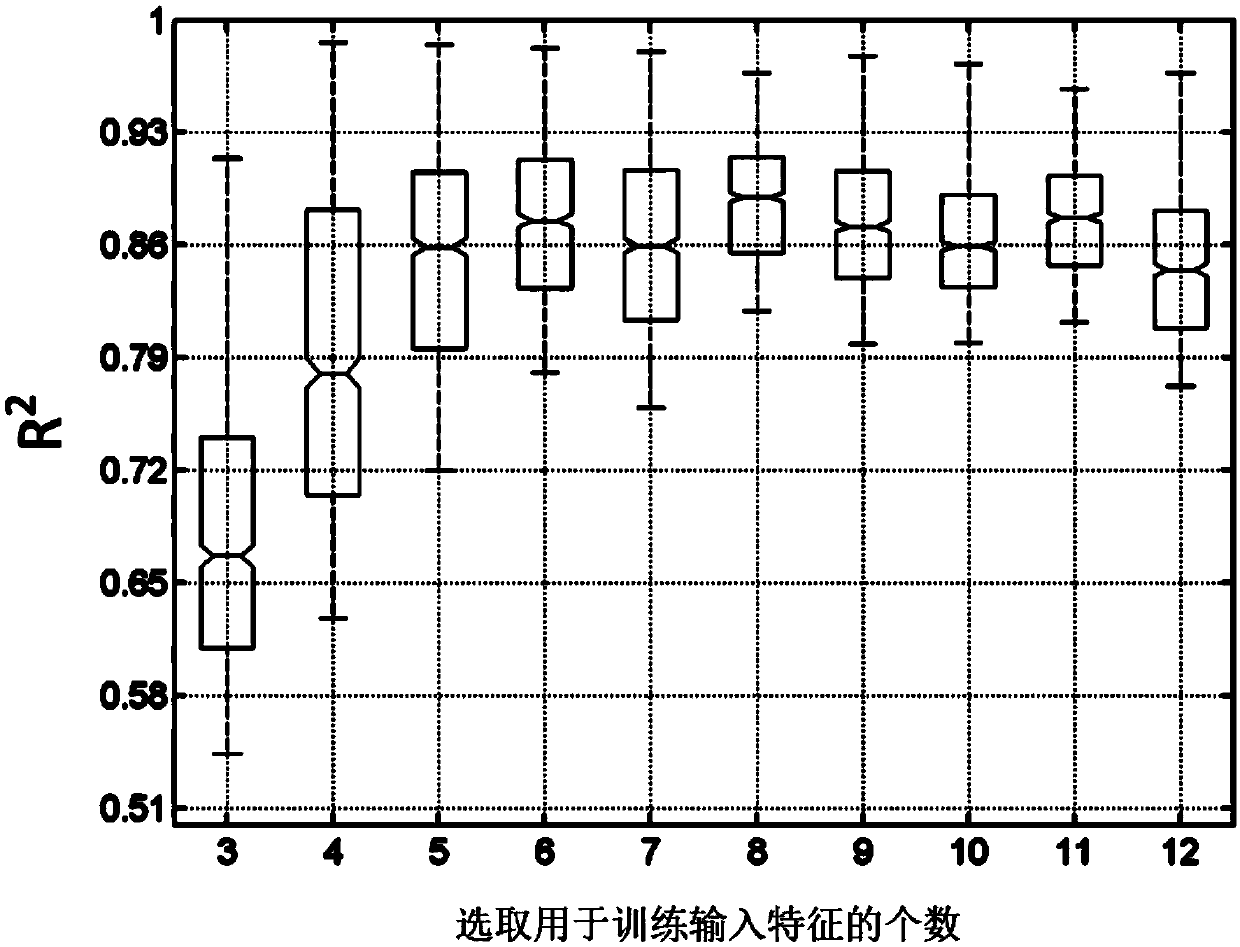

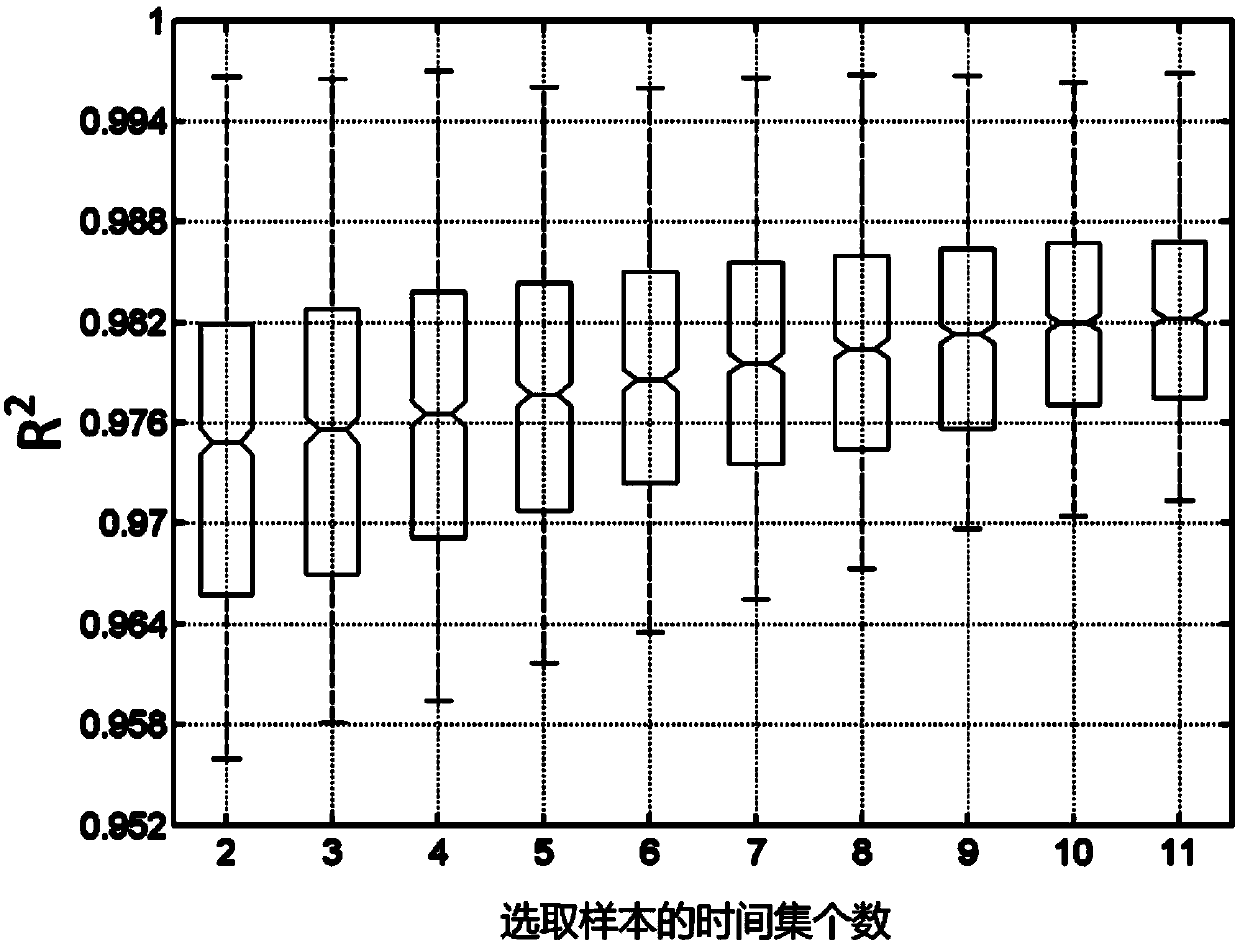

The invention relates to a prediction method for PM2.5 concentration of fine particulate matters in air based on a stack selective integrated learning device. The concentration of six pollutants in the air per hour in the past 24 hours and six meteorological indexes totally account for 24 groups and 12 characteristics to serve as input, and a PM2.5 concentration predicted value is obtained. The model is realized in a three-stage framework and comprises the following steps of: firstly, creating a plurality of base learners by properly selecting environmental factors, time factors and training samples; secondly, deleting the negative basis learners in the three categories according to a dynamic threshold value by adopting a trimming technology; and finally, integrating the selected forward basis learners by adopting a stacking technology so as to predict the future PM2.5 concentration. Compared with an existing method, the method has the advantages that prediction errors and the difficulty degree of data sources are obviously improved, people can be guided to travel healthily, and the government can be assisted to limit automobile flow, exhaust emission and the like.

Owner:BEIJING UNIV OF TECH

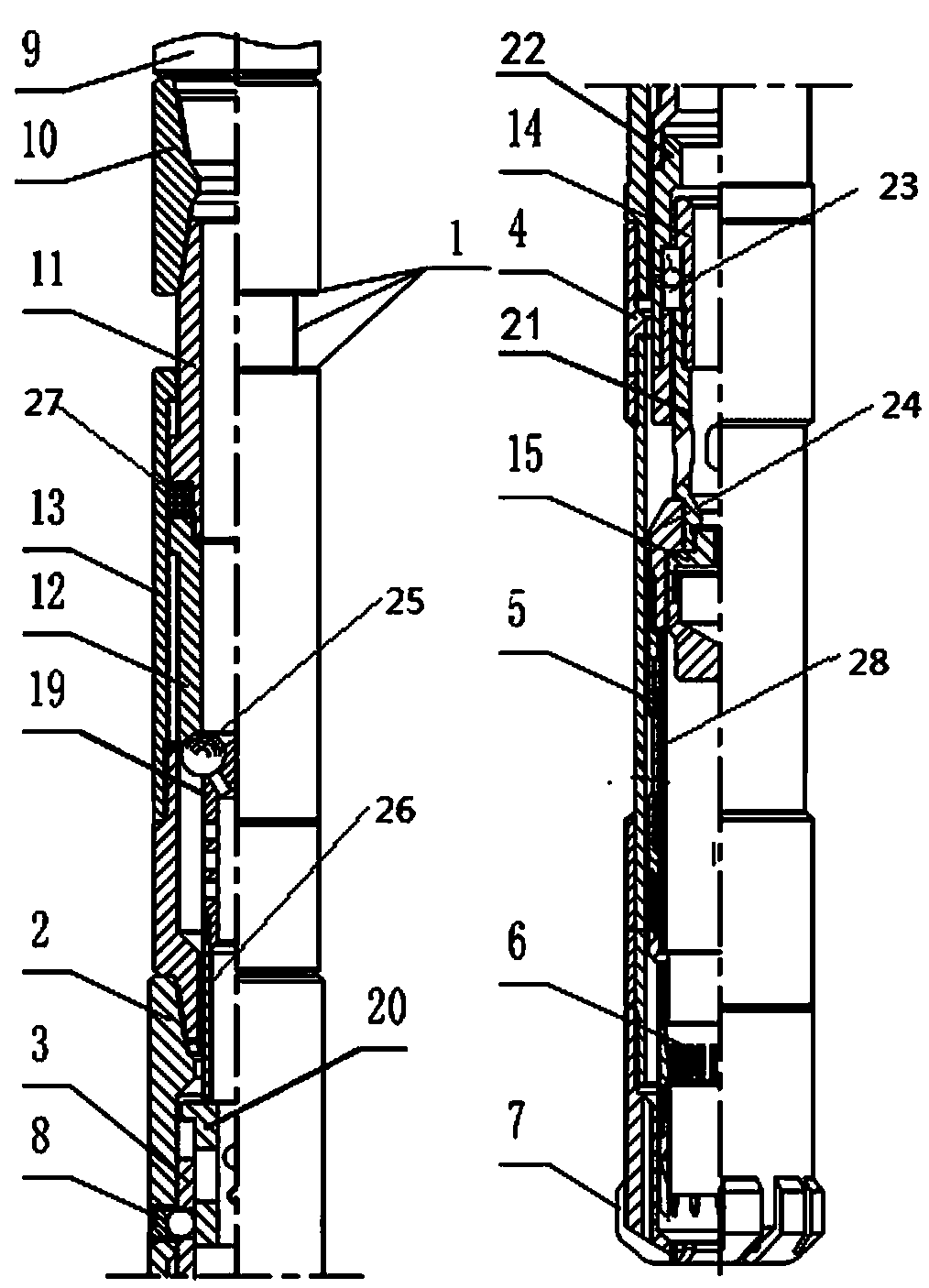

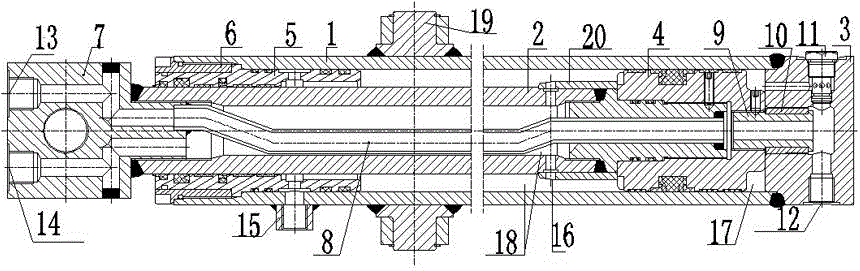

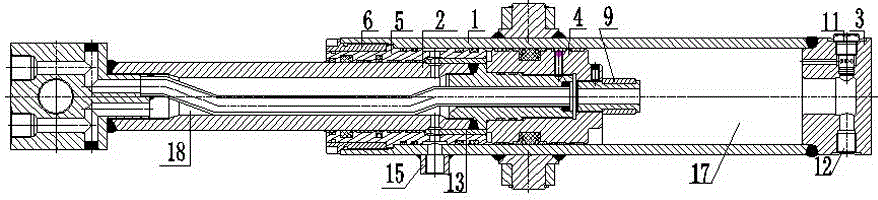

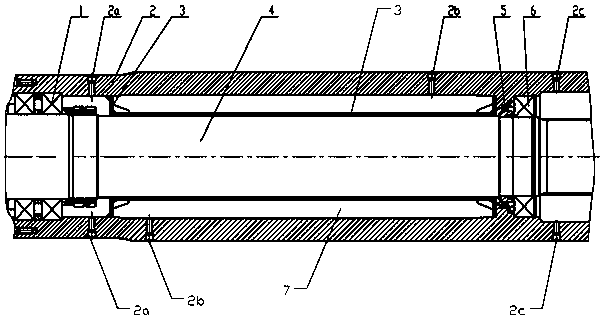

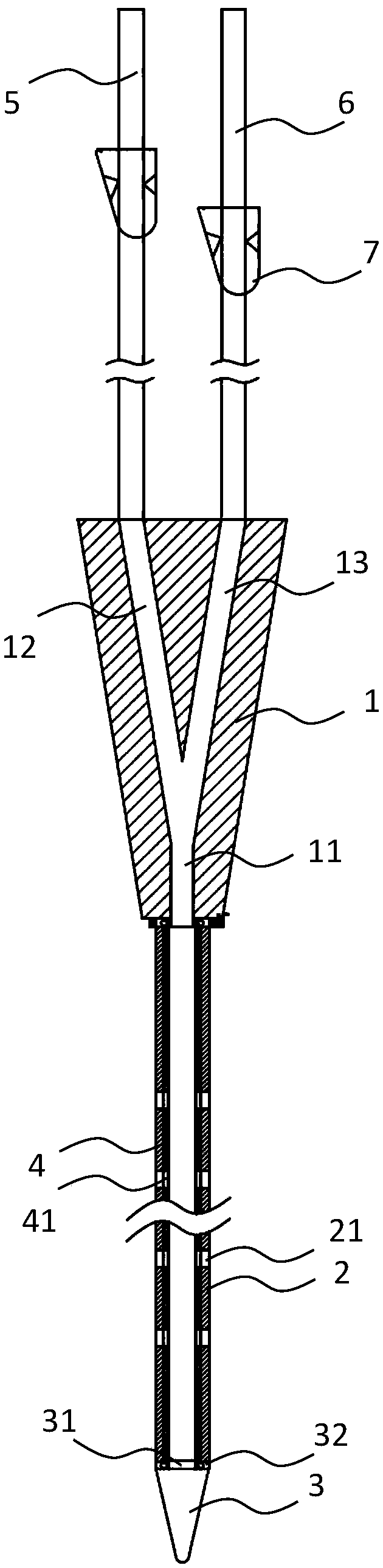

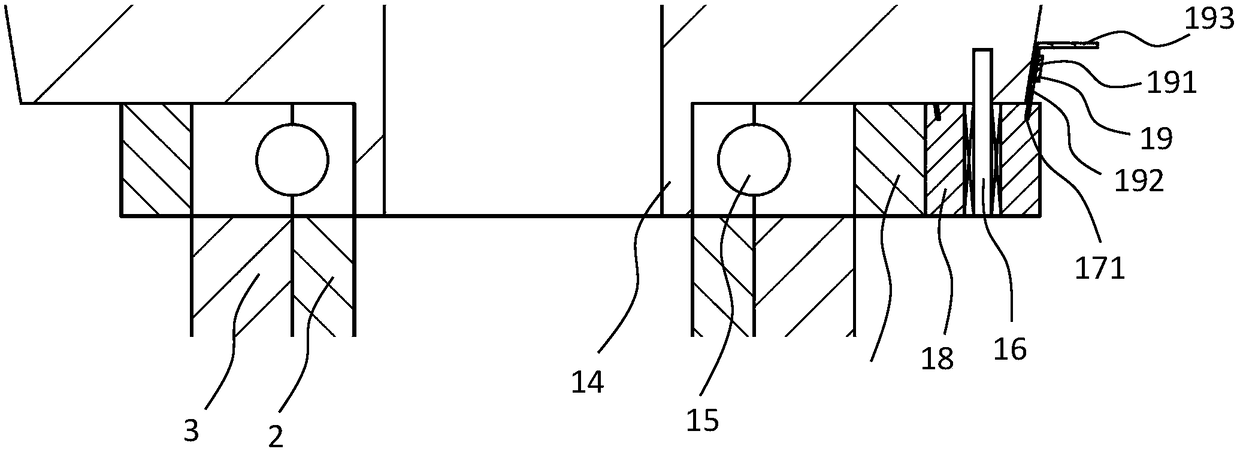

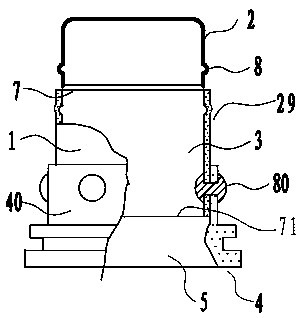

Differential type air-drilling coring device and differential type air-drilling coring method

The invention discloses a differential type air-drilling coring device and a differential type air-drilling coring method, wherein a differential mechanism, an orientation spool, an outer cylinder assembly and a coring dill bit are connected together up and down to form an outer cylinder assembly; a suspension assembly, an inner cylinder assembly and a core cutting mechanism are connected together up and down through threads to form an inner cylinder assembly; the suspension assembly is connected with the orientation spool through a suspension element; the whole inner cylinder assembly is suspended in the outer cylinder assembly; the core cutting mechanism is located in the position of the inner cavity of the coring dill bit; the whole set of coring device is in threaded connection with a drill tool. During the coring operation, the well drilling equipment drives the coring device to rotate to carry out the core-drilling work; after the core-drilling is finished, the suspension element is sheared off by pitching to ground and by virtue of the differential device of the coring device, and then the inner cylinder assembly descends so that the core cutting mechanism is enabled to work, and the rock core is protected against dropping out in the drilling process. The differential type air-drilling coring device and the differential type air-drilling coring method can be applied to the air-drilling coring field.

Owner:SINOPEC SSC +2

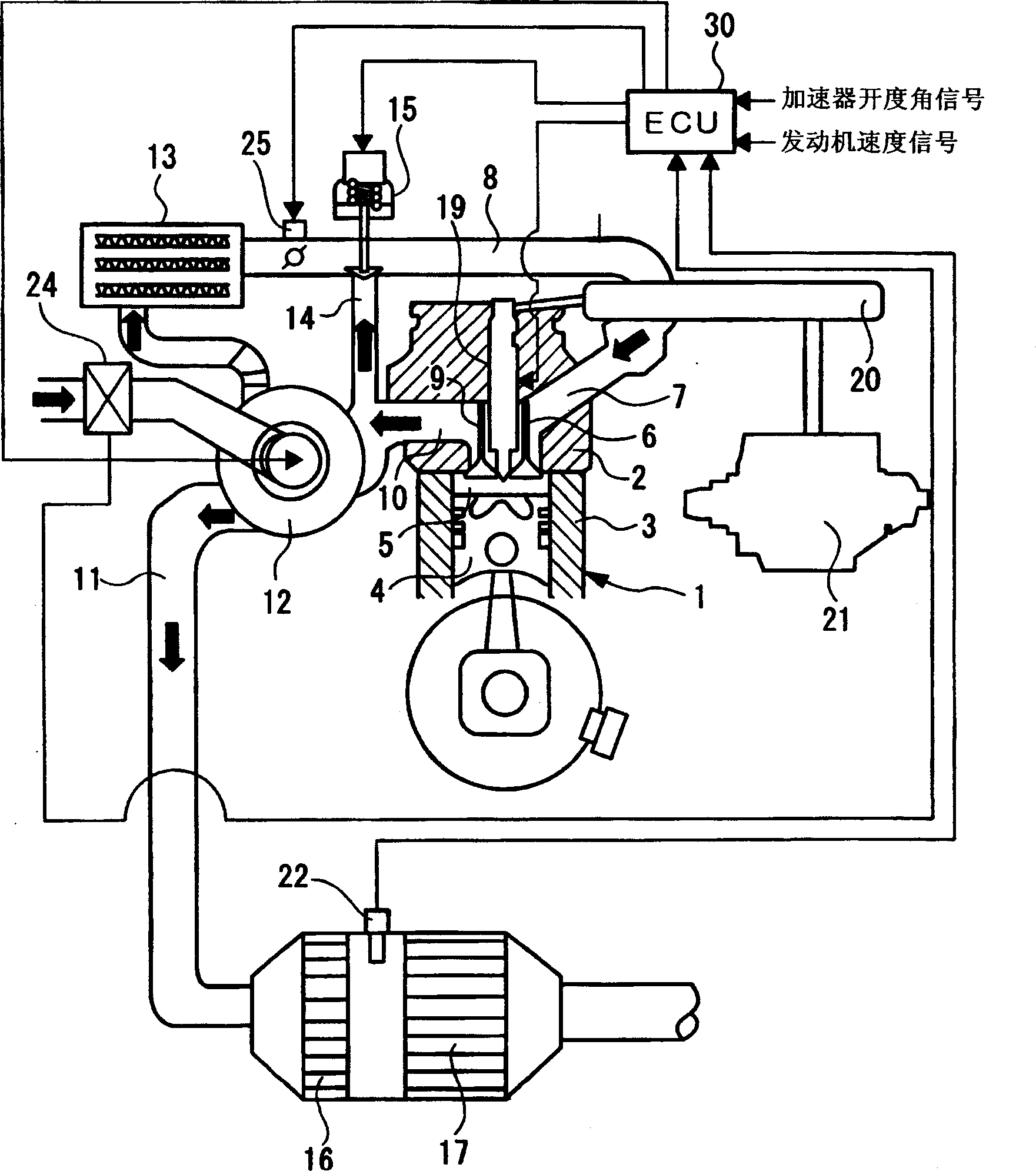

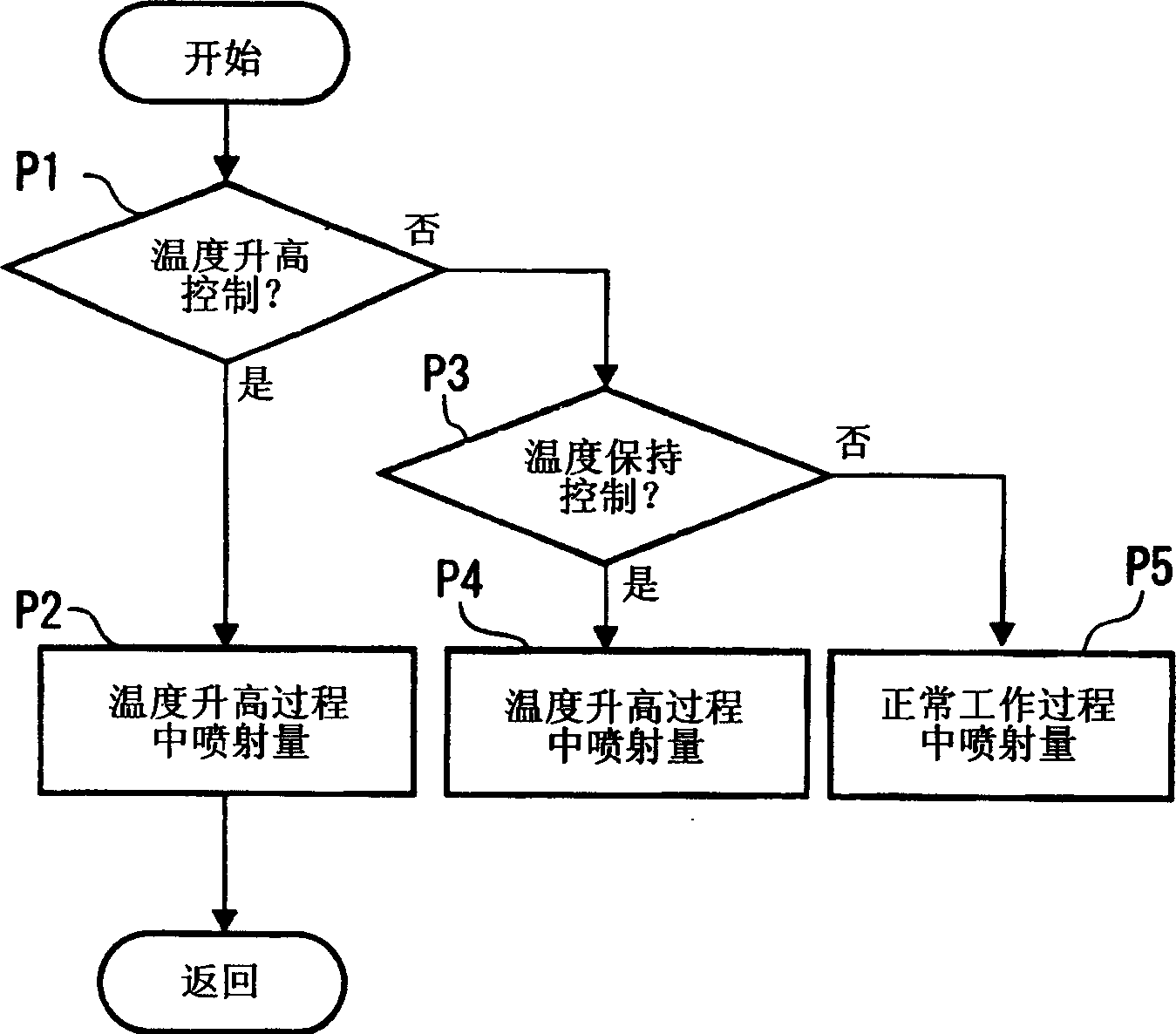

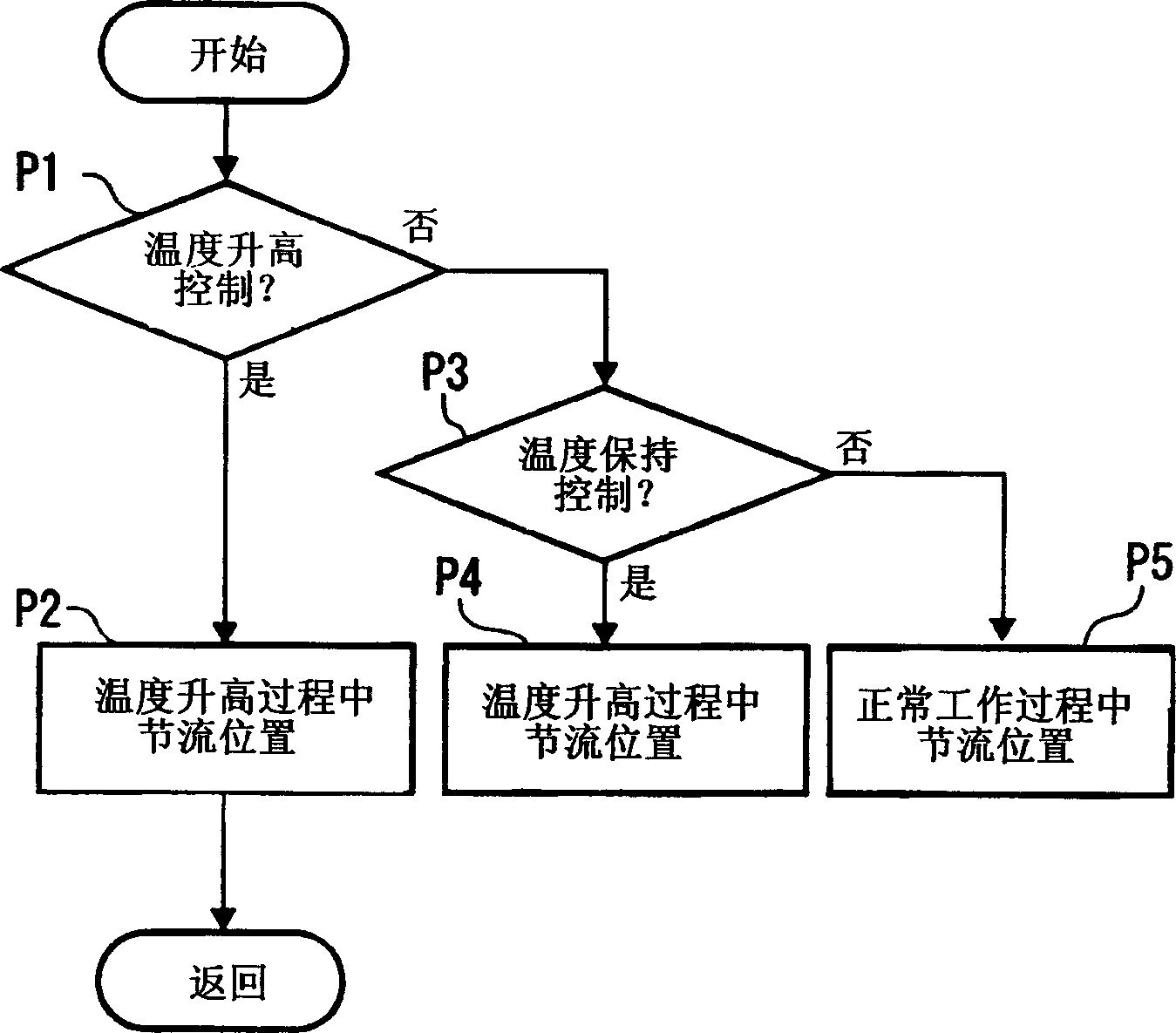

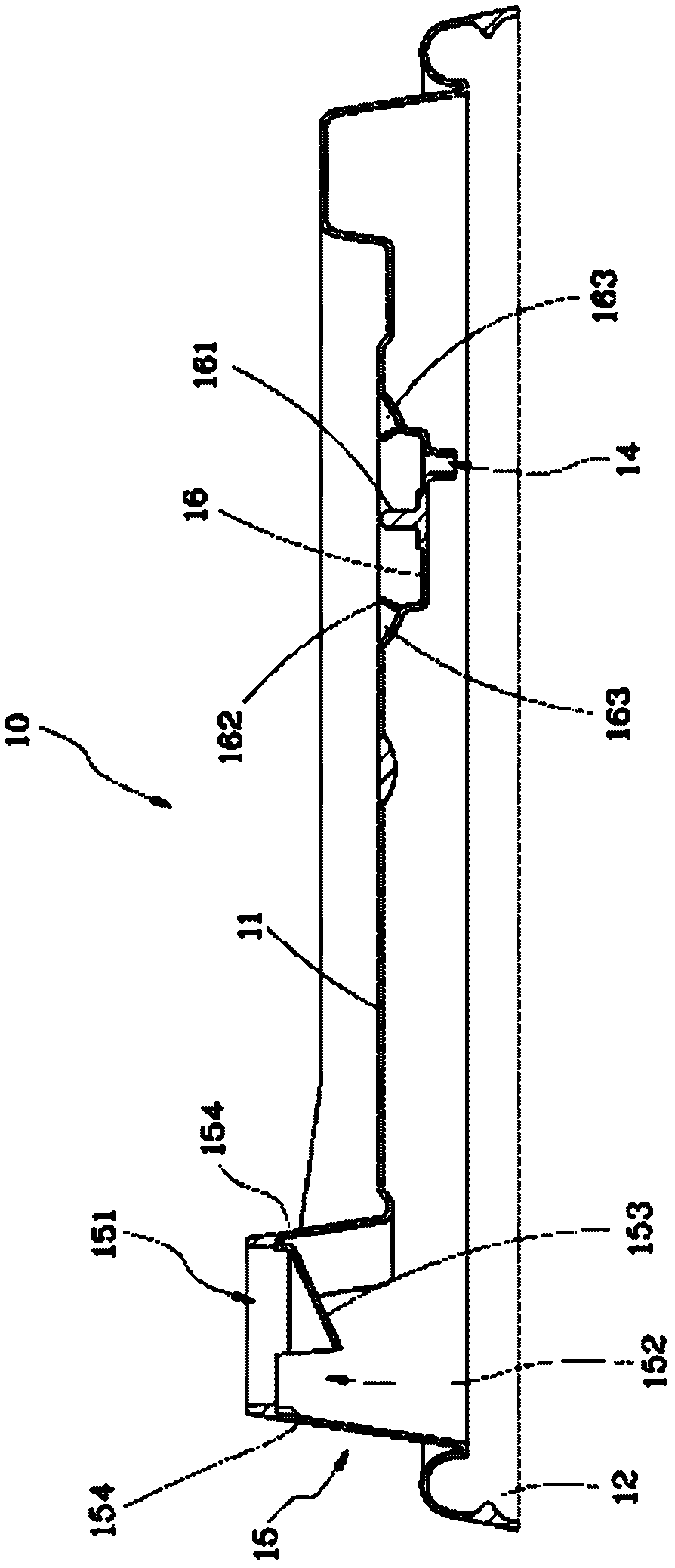

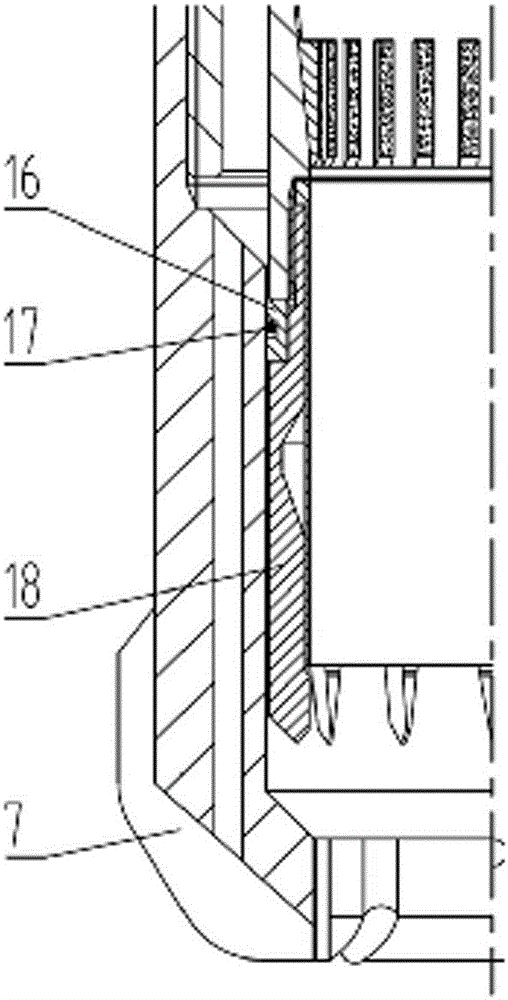

Exhaust emission control device of internal combustion engine

InactiveCN1779214ATemperature rises fastEnhanced temperature retentionElectrical controlInternal combustion piston enginesExternal combustion engineInternal combustion engine

An exhaust gas emission control device of an internal combustion engine, comprises: DPF (17) provided in an exhaust passage (11) of the diesel engine (1) ; a throttle valve (25) for regulating the volume of intake air into the diesel engine (1) ; temperature raise control means (30) for performing restriction of intake air or post-injection or exhaust-stroke injection in order to raise the temperature of the DPF (17); and ECU (30) for controlling the throttle valve (25) in accordance with the operating state of the diesel engine (1). The ECU (30) controls the throttle valve (25) in order to retain the temperature of the DPF (17) by restriction of intake air when interrupting temperature raise control during temperature raise of the DPF (17).

Owner:MITSUBISHI MOTORS CORP

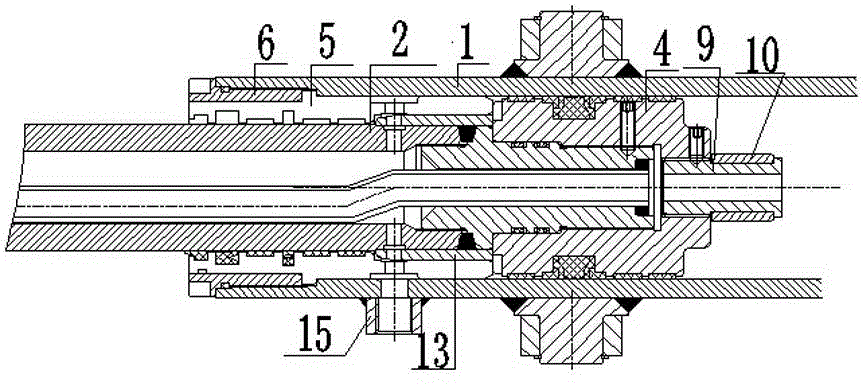

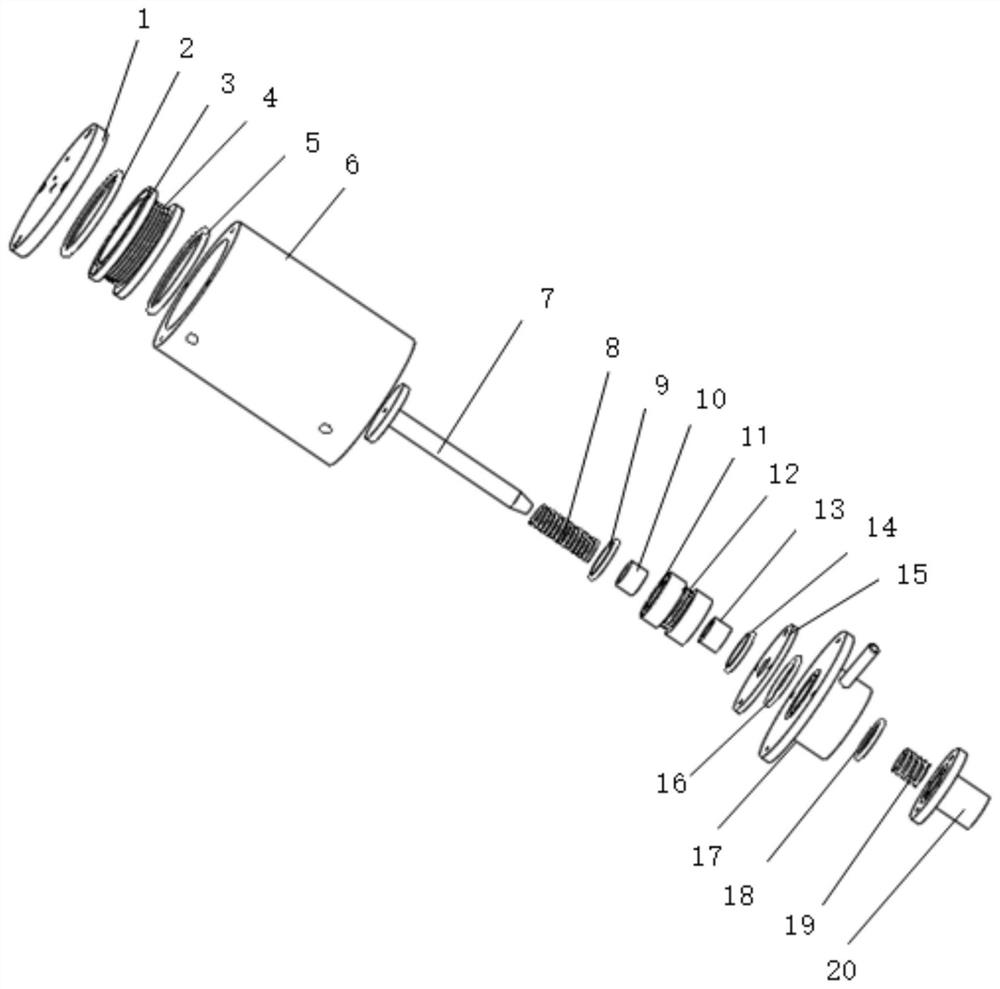

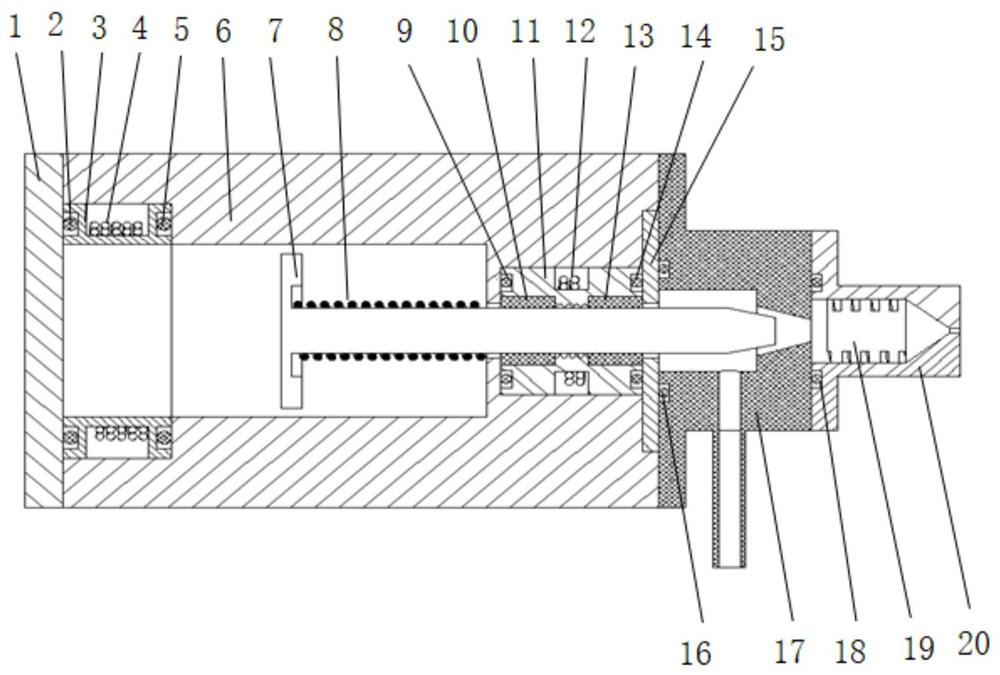

Large flow pipe-type breaking valve

The invention discloses a large flow pipe-type breaking valve which is characterized by comprising an air inlet valve, a locating sleeve, a plane one-way valve, a breaking shaft, a shield, a lantern ring, a one-way valve core, a stainless steel spring I, a spring seat, a stainless steel spring II, a stainless steel ball I, a supporting ring I, an O-type seal ring I, a one-way valve seal ring, an O-type sea ring II, a main valve seal ring, an O-type seal ring III, a compression spring, a stainless steel ball II, fluid channel technology holes I-IV, a spring hole, a symmetrical hole, a locating hole and a balance cavity. The pressure balance principle is used by the breaking valve, that is, the breaking valve can be automatically and securely separated when the two ends of the breaking valve are applied to the tension for not less than 600N (the breaking force is adjustable) under the circumstance that the pressure fluid or the fluid passes through a hose, and the two ends of the breaking valve can be automatically, effectively and reliably sealed, and no fluid leaks, thereby being capable of playing the role of breaking and protecting on the high pressure hose for below 25MPa, at the same time, the breaking valve is stable and reliable in breaking force, large in flow, low in maintenance cost, convenient to maintain and reusable.

Owner:CHENGDU ANDERSON MEASUREMENT

Cup lid for additive to be conveniently added therein

Owner:FIELDCENT

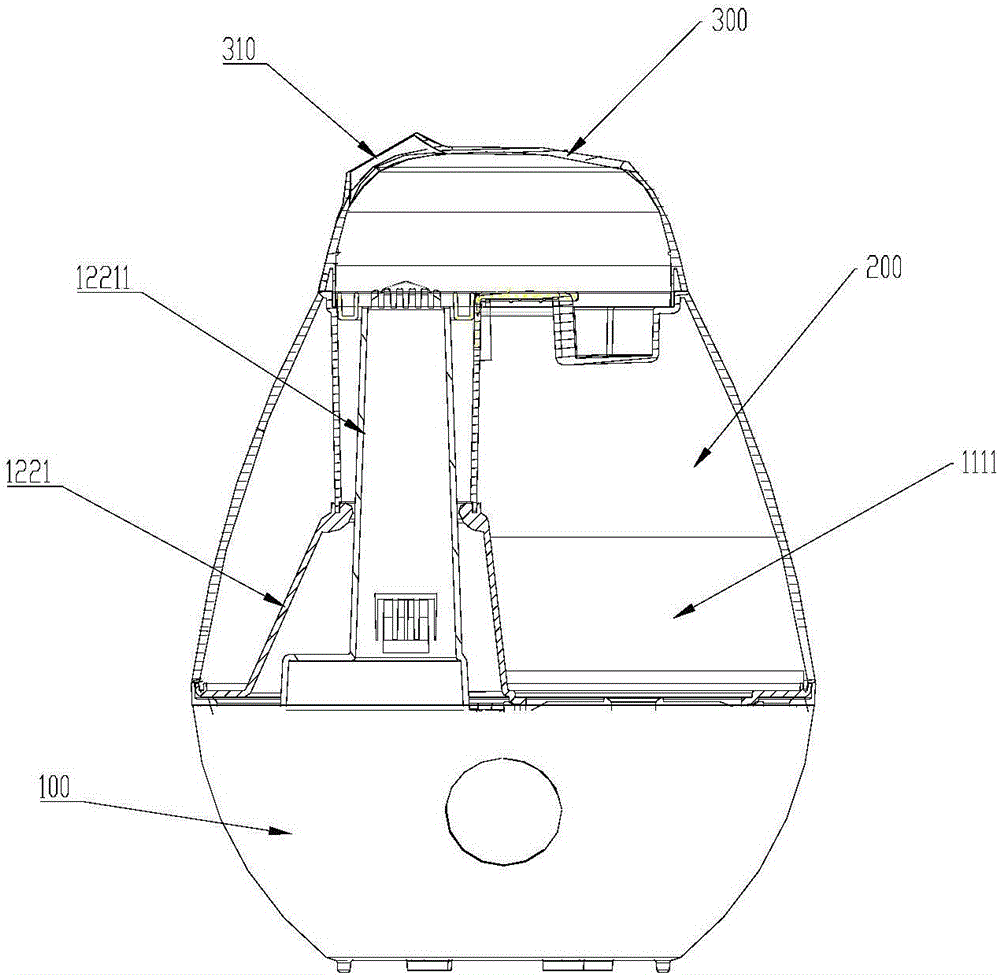

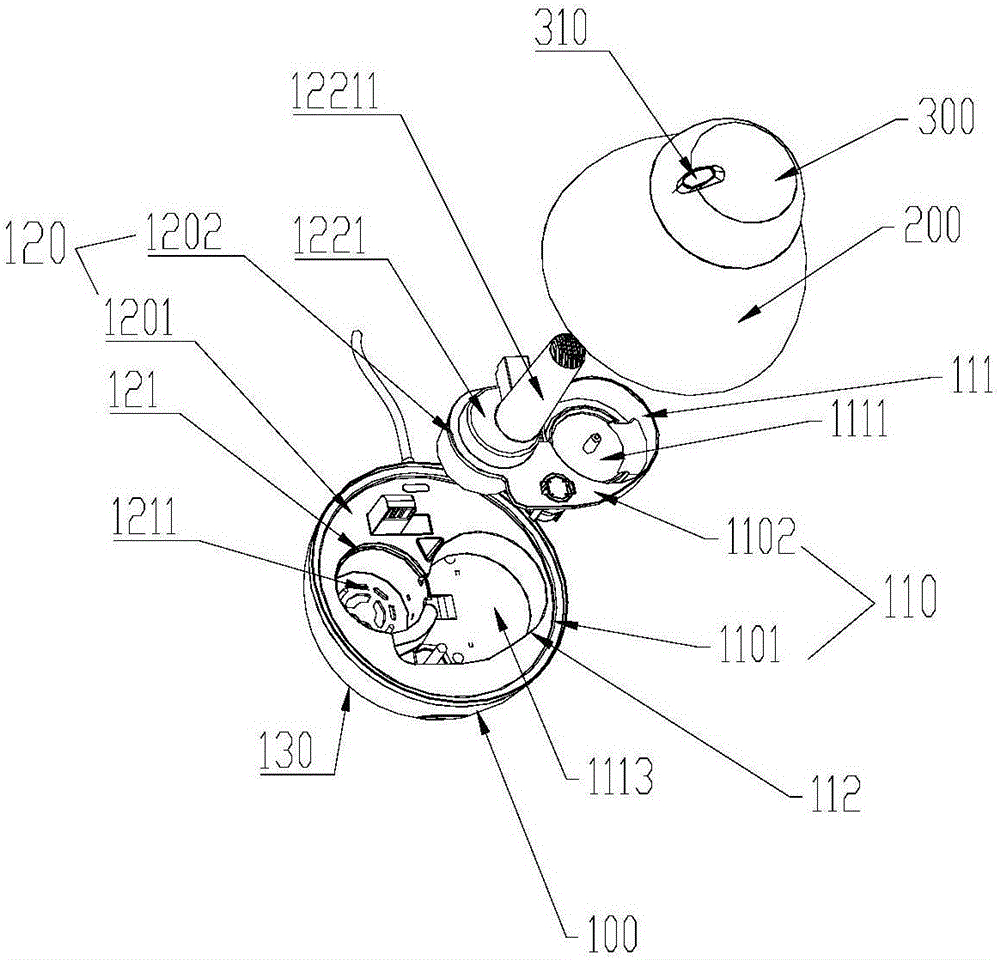

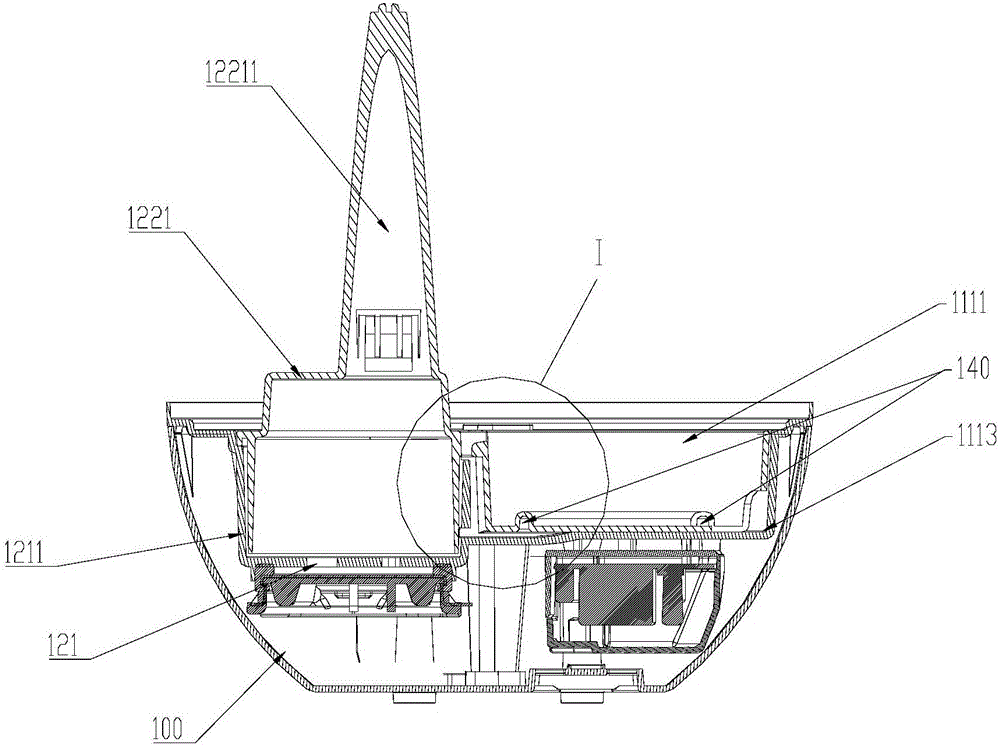

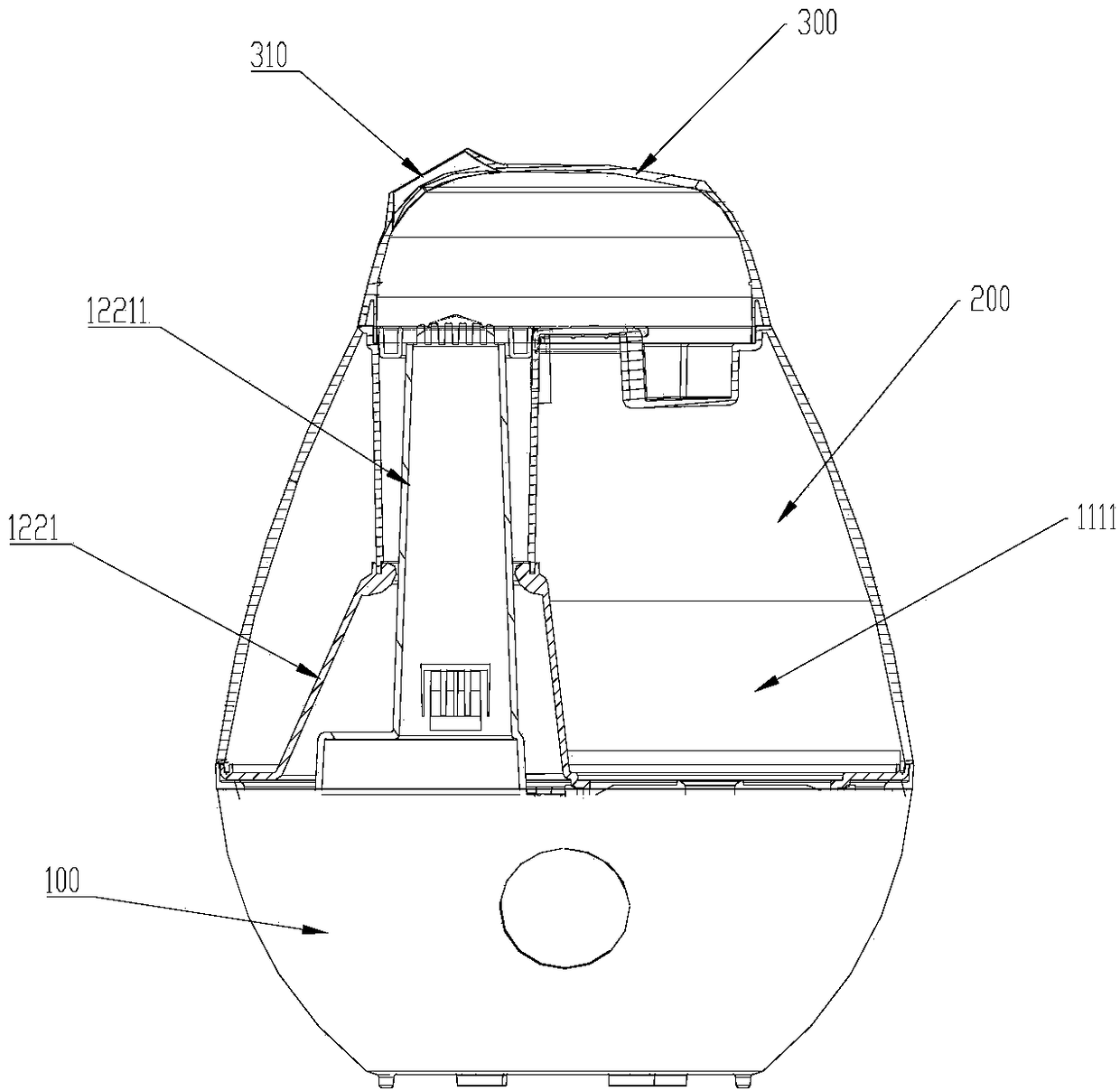

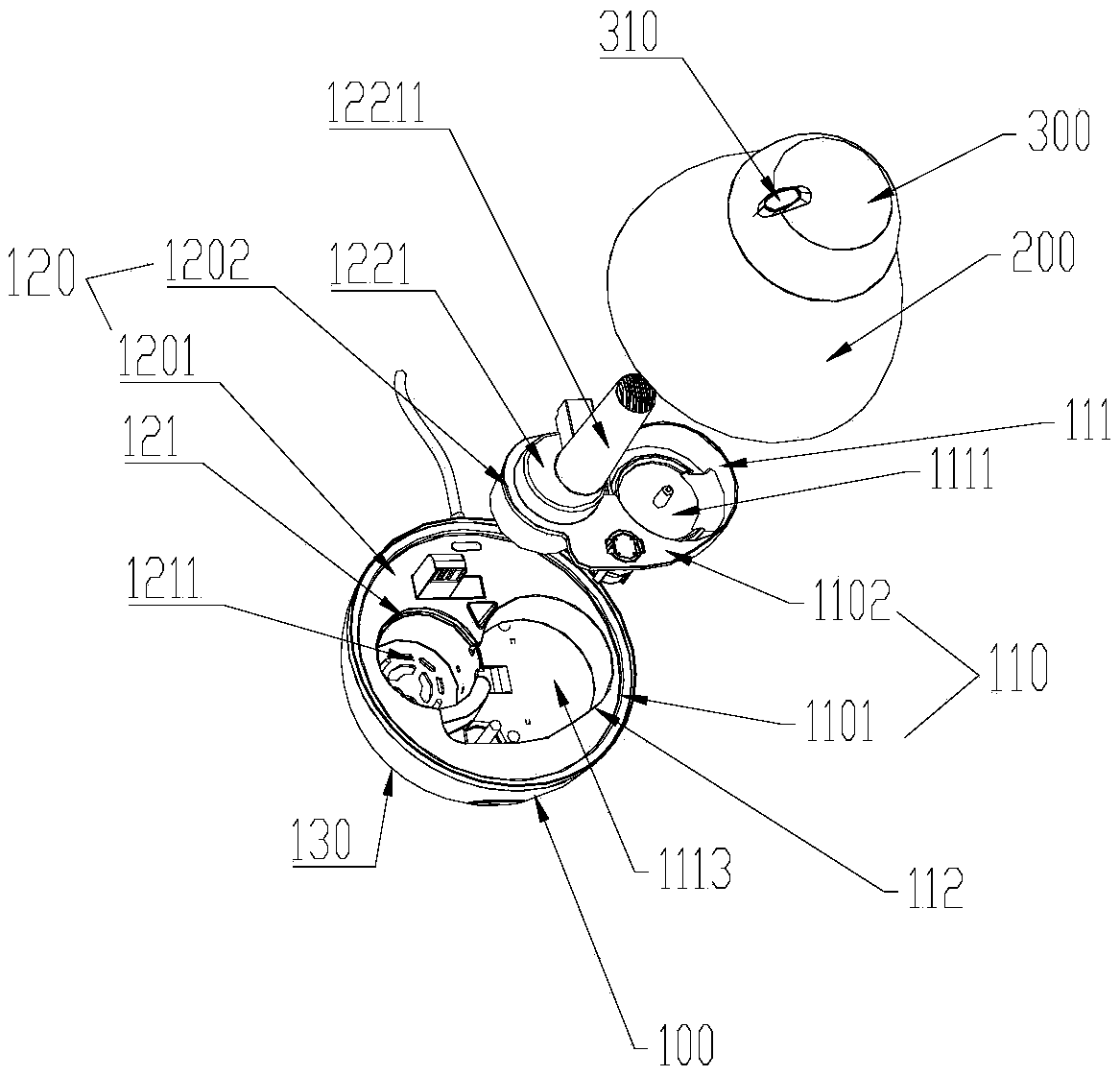

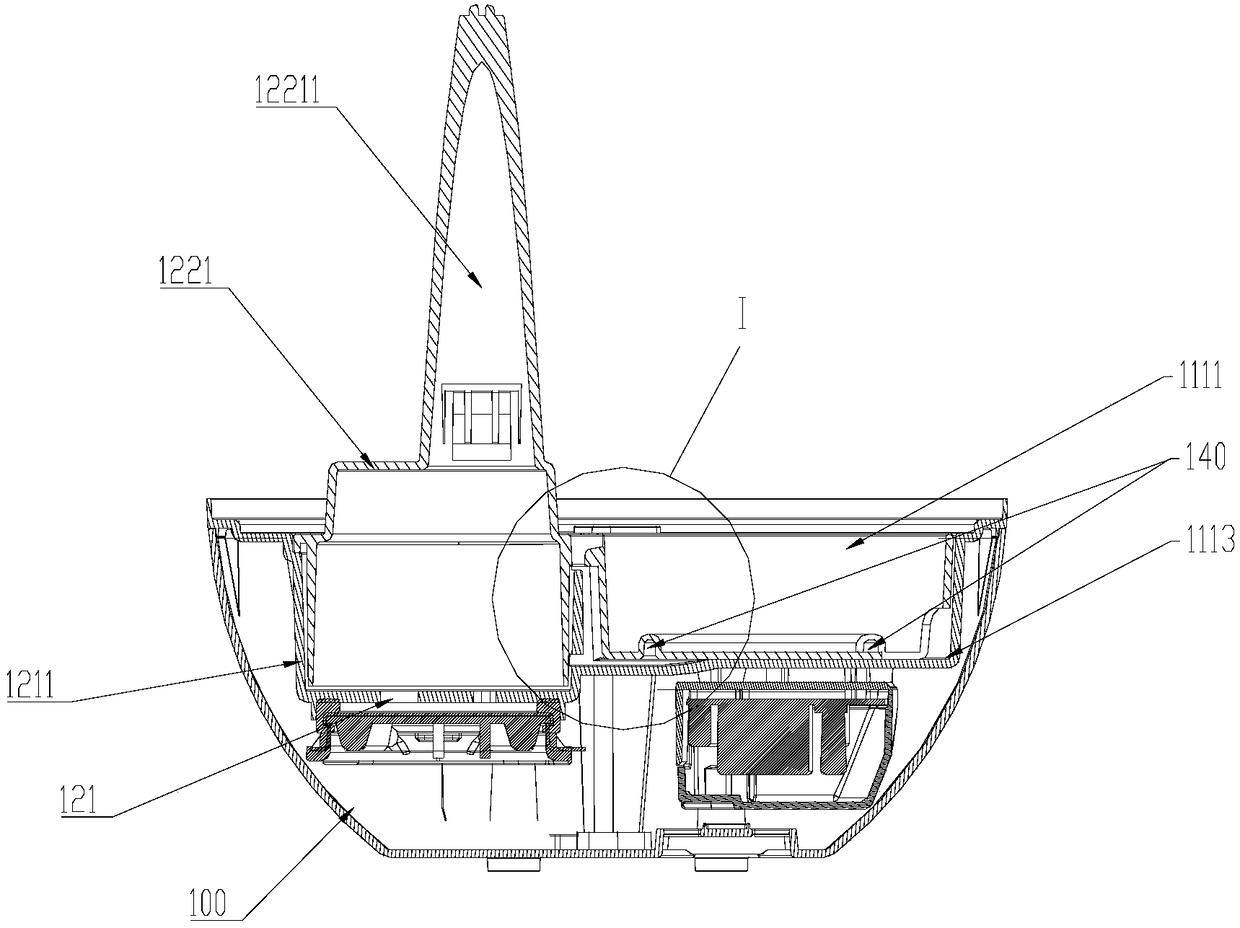

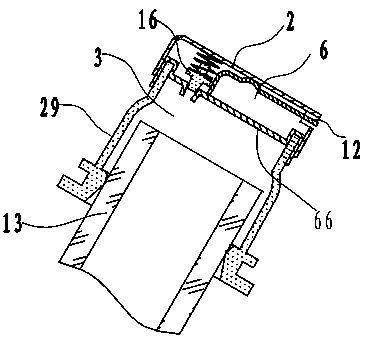

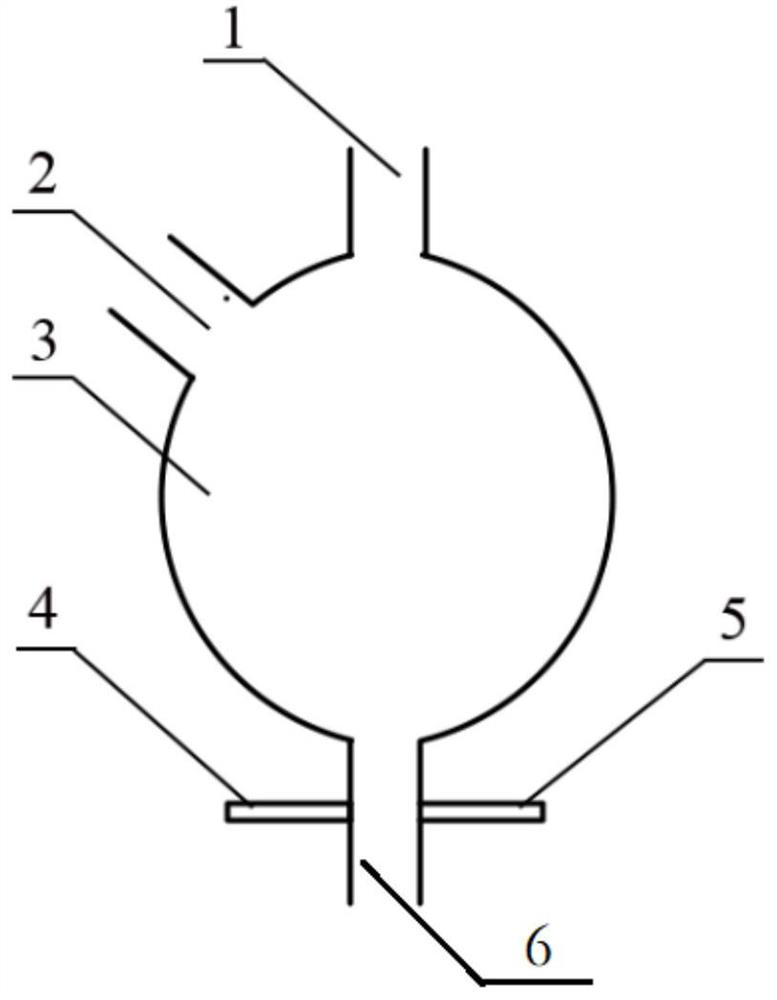

Humidifier

ActiveCN105864946AImprove heating efficiencyPrevent spilloverLighting and heating apparatusAir humidification systemsLiquid storage tankEngineering

The invention relates to a humidifier. The humidifier comprises a base and a liquid storage box, wherein the base is fixedly connected with the liquid storage box, and the liquid storage box is positioned above a liquid storage tank of the base and is used for conveying liquid to the liquid storage tank; the base comprises a pedestal, a first assembly and a second assembly, and the first assembly and the second assembly are arranged on the pedestal in parallel along the horizontal direction; the first assembly comprises a first component with the liquid storage tank, the second assembly comprises a second component with a heating tank, and both the liquid storage tank and the heating tank are open upward; the liquid storage tank is communicated with the heating tank by virtue of at least one passage; the first communication position of the liquid storage tank and the passage is higher than the second communication position of the heating tank and the passage. According to the humidifier, the heating efficiency of the humidifier is improved, and the energy consumption is reduced. In addition, air in the liquid storage box is effectively prevented from being heated, so as not to press liquid in the liquid storage box into the liquid storage tank, so that the phenomenon of liquid overflowing caused by excessive liquid in the liquid storage tank is prevented.

Owner:GREE ELECTRIC APPLIANCES INC

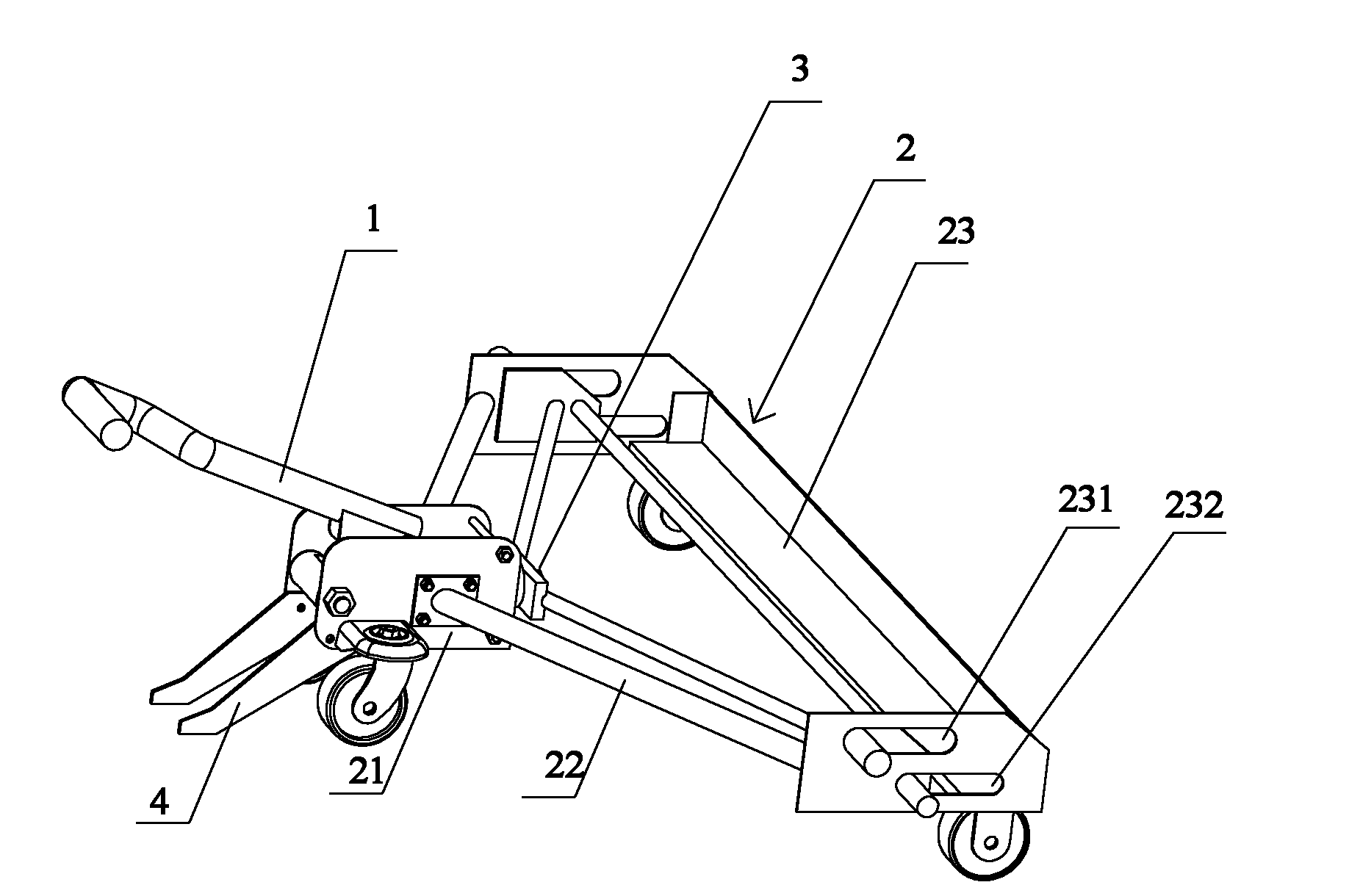

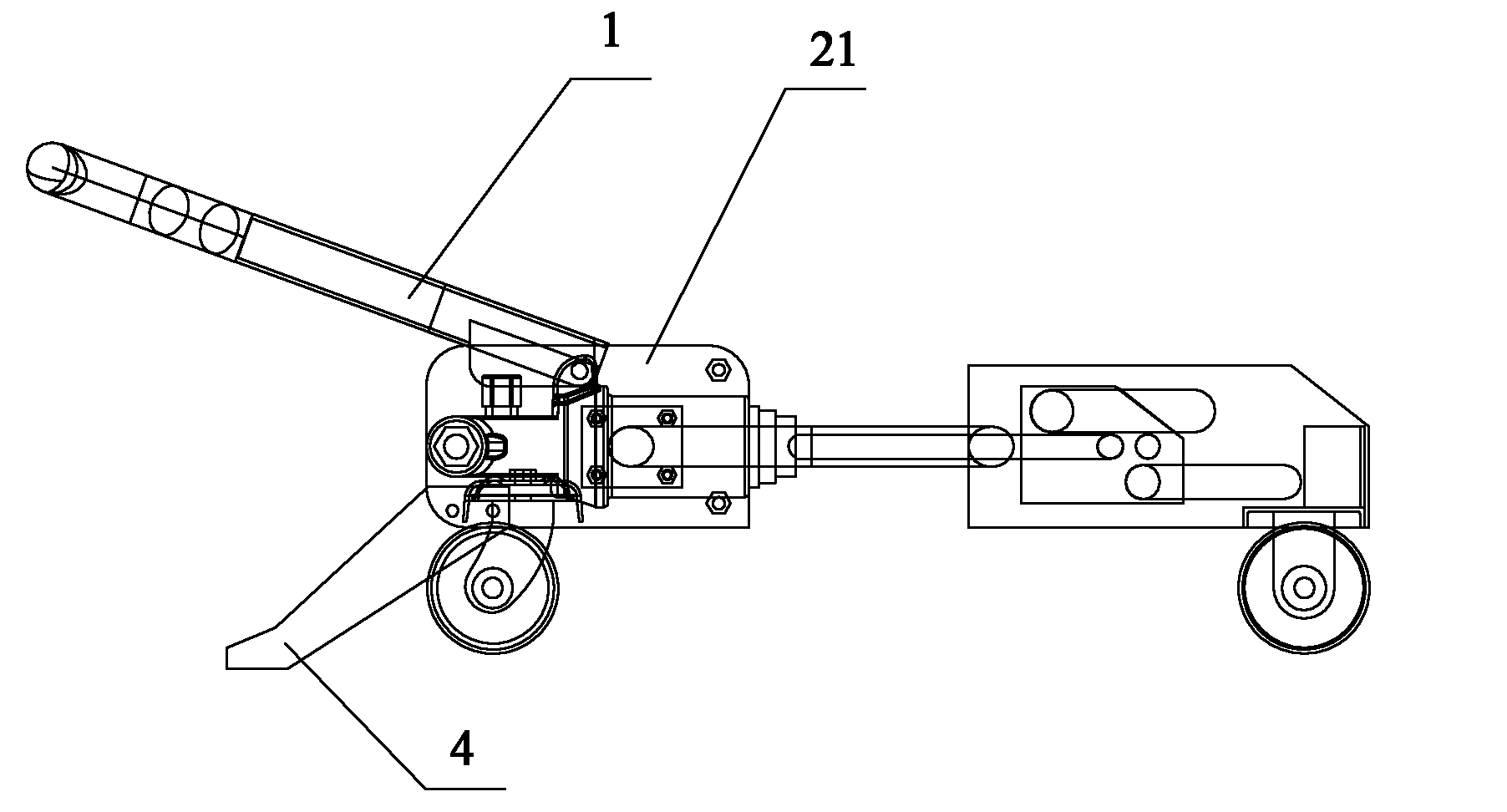

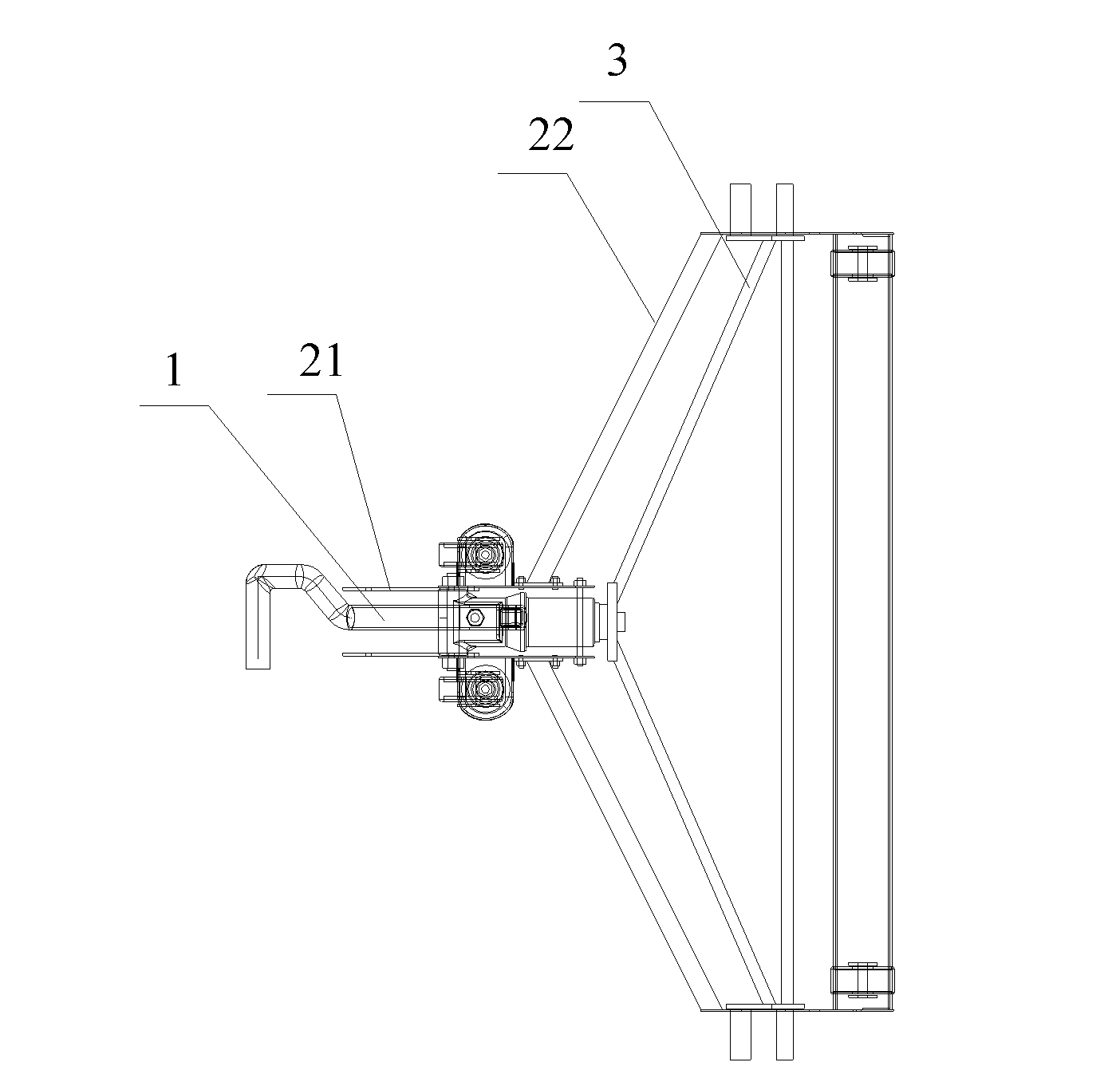

Electrometric handcart tool

ActiveCN102097749ALimit flow valueFlow rate limitingLifting devicesSubstation/switching arrangement casingsEngineeringPower output

The embodiment of the invention provides an electrometric handcart tool, which comprises a hydraulic power device, a mounting bracket and a pushing device, wherein the hydraulic power device is fixed on the mounting bracket; the two sides of the front end of the mounting bracket are provided with two horizontally extended slot hoes with different heights respectively; the pushing device is arranged in the mounting bracket; the two sides of the front end of the pushing device are provided with two pushing pins with the different heights respectively; the two pushing pins on each side of the front end of the pushing device pass through the two slot holes on the same side of the front end of the mounting bracket from the inner side of the mounting bracket respectively; the power output end of the hydraulic power device is fixedly connected with the rear end of the pushing device, so that the power output end drives the pushing pins of the pushing device to move to and fro in the slot holes of the mounting bracket; and the throttling valves are arranged in a discharge oil line and a return oil line.

Owner:NINGBO ELECTRIC POWER BUREA

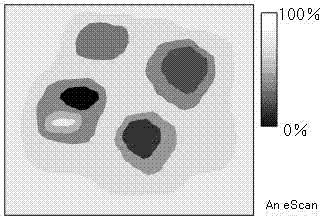

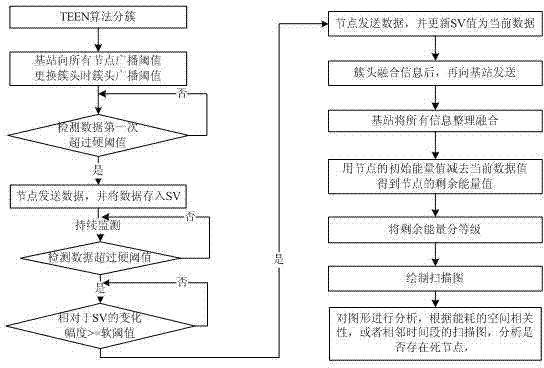

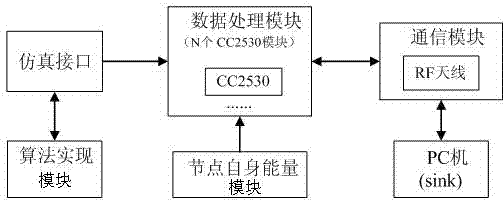

Method and device for collecting energy state of wireless sensor network

InactiveCN103546901ALimit trafficReduce energy consumptionPower managementEnergy efficient ICTSelf-energyWireless sensor networking

The invention discloses a method and a device for collecting an energy state of a wireless sensor network. The method includes that data inquiry and transmission uses a threshold value detection method, test data is processed by a base station, initial energy of nodes is used to subtract a current data to obtain residual energy of the nodes, and then a residual energy distribution map of the nodes with the residual energy lower than a certain specific value in a network is drawn. The device comprises an algorithm implementation module, a simulation interface, a data processing module, a node self-energy module, a communication module and a PC (personal computer) machine. Number of the nodes participating in communication and calculation is limited by setting a threshold value, node information of the residual energy within customers' needs range is only obtained, other non-user interesting nodes do not participate in communication, and accordingly communication traffic is greatly lowered, and energy consumption is saved. Relationship of precision and energy consumption is effectively balanced by adjusting the threshold value.

Owner:CHANGZHOU UNIV

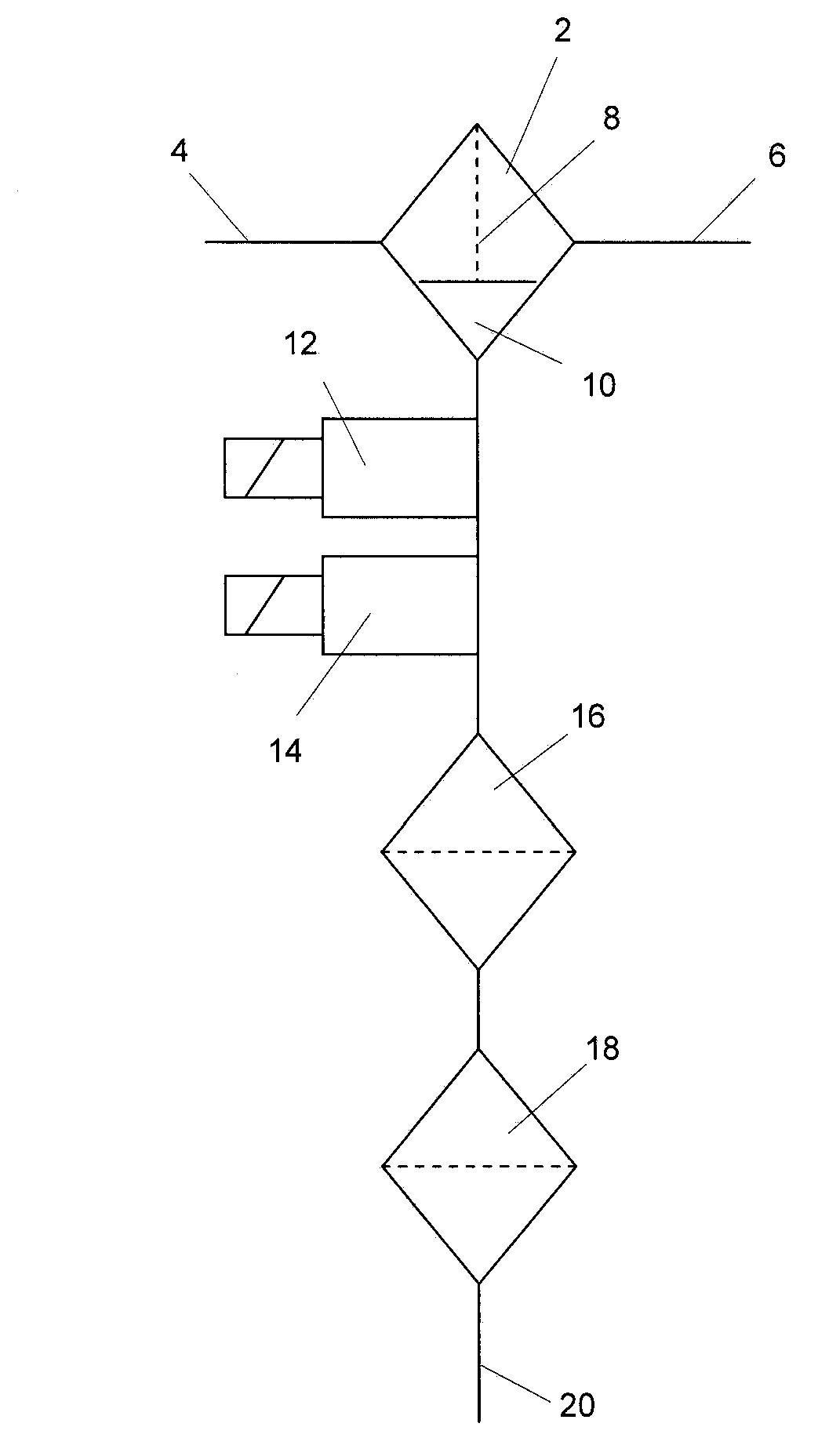

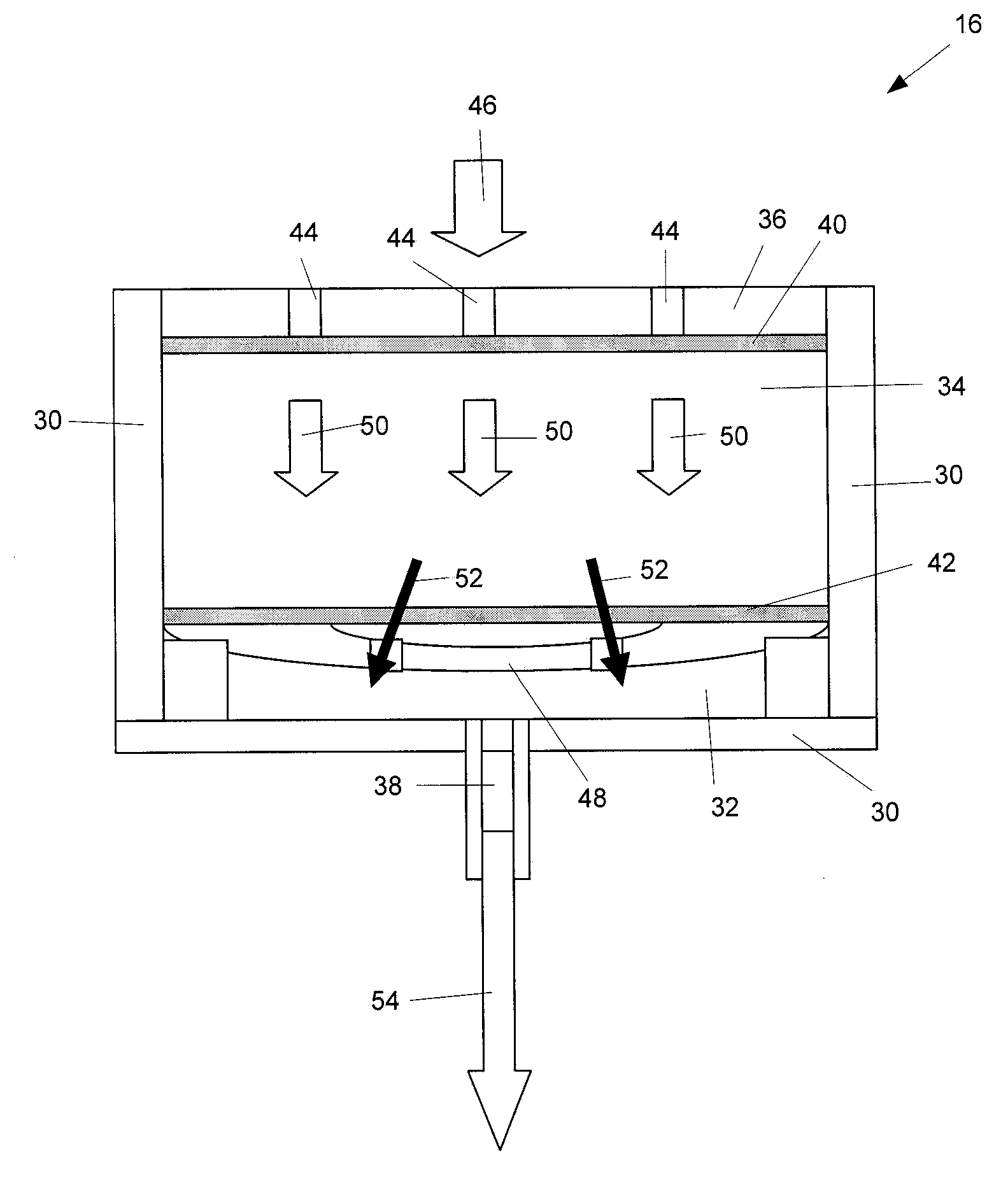

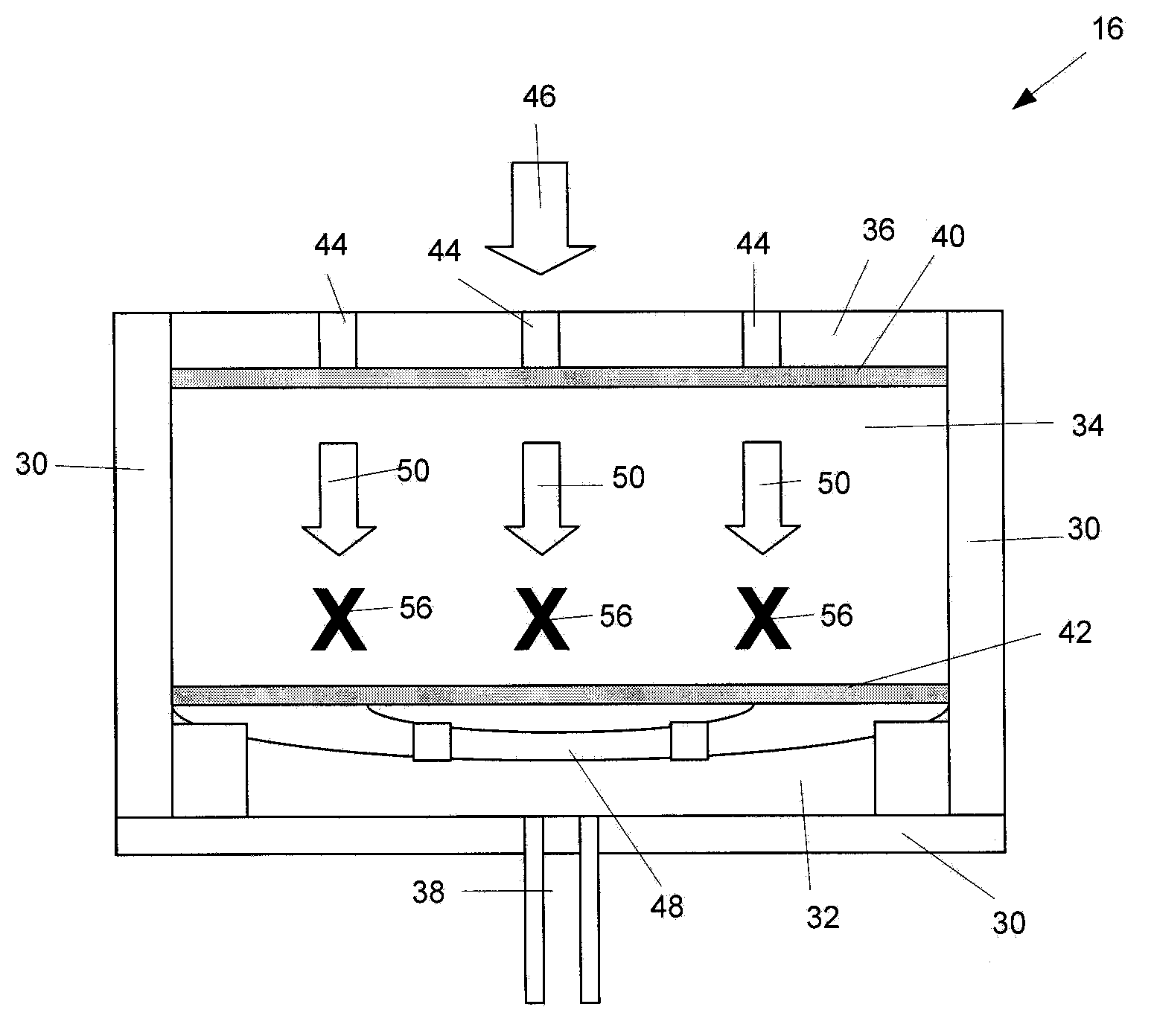

A valve

ActiveCN103459819ALimit trafficIncrease the differential pressureOperating means/releasing devices for valvesMachines/enginesDifferential pressureFilter media

The invention discloses a valve (16) comprising a housing (30), a valve filter media (34) and an actuator (48). The housing (30) defines a chamber (32) having an inlet (44) and an outlet (48). The valve filter media (34) is positioned within the chamber (30) and arranged such that liquids flowing between the inlet (44) and the outlet (48) pass through the valve filter media (34). The valve filter media (34) is arranged to absorb hydrocarbons causing the valve filter media (34) to change its material properties thereby restricting the flow of liquids through the valve (16) and increasing the pressure differential across the valve filter media (34). The actuator (48) has at least a first portion positioned within the housing chamber (32). If the pressure differential across the valve filter media (34) exceeds a predetermined threshold the valve filter media (34) is arranged to bear against the actuator (48) causing the actuator (48) to restrict the flow of liquids through the valve (16).

Owner:PARKER HANNIFIN MFG LTD

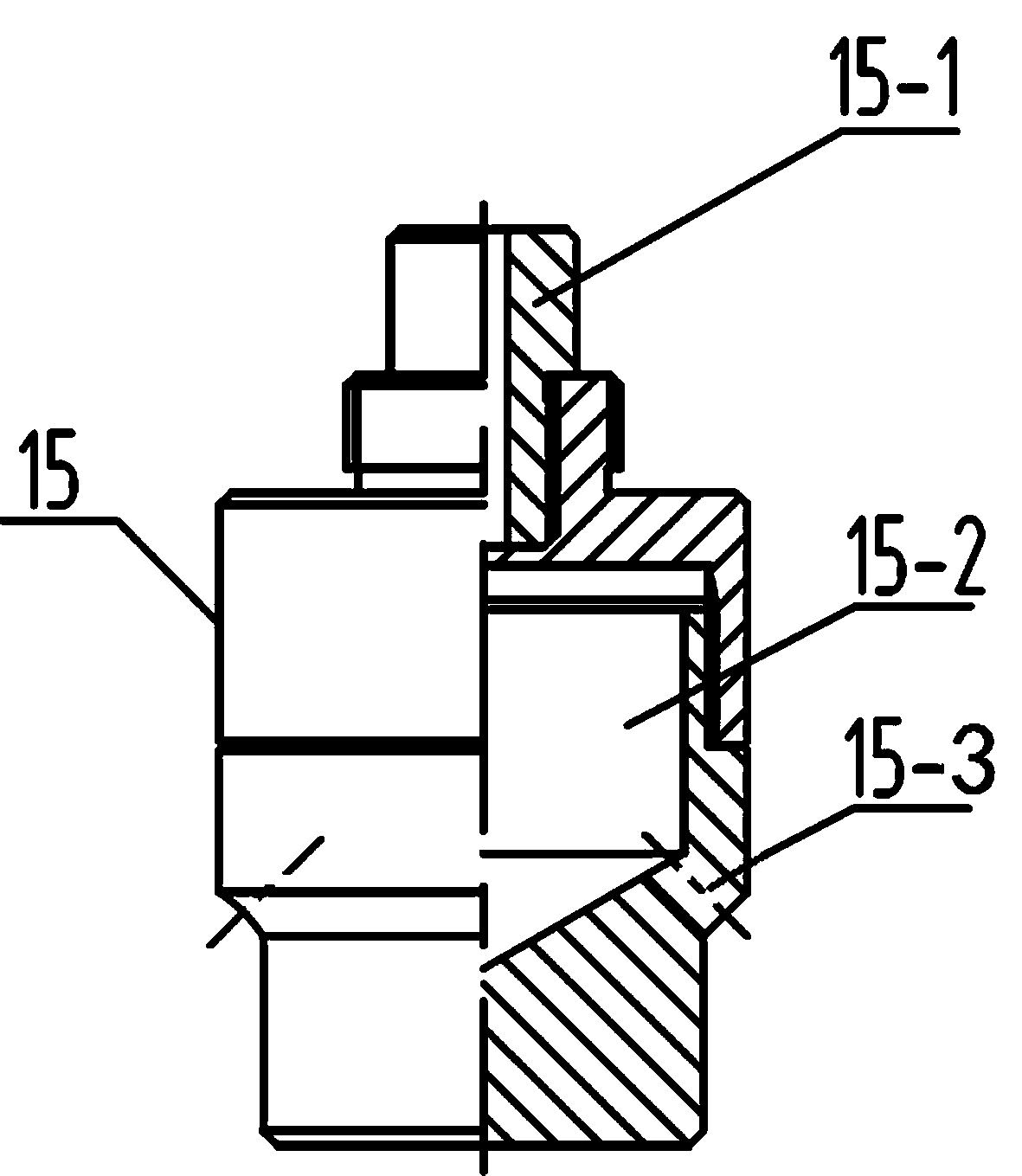

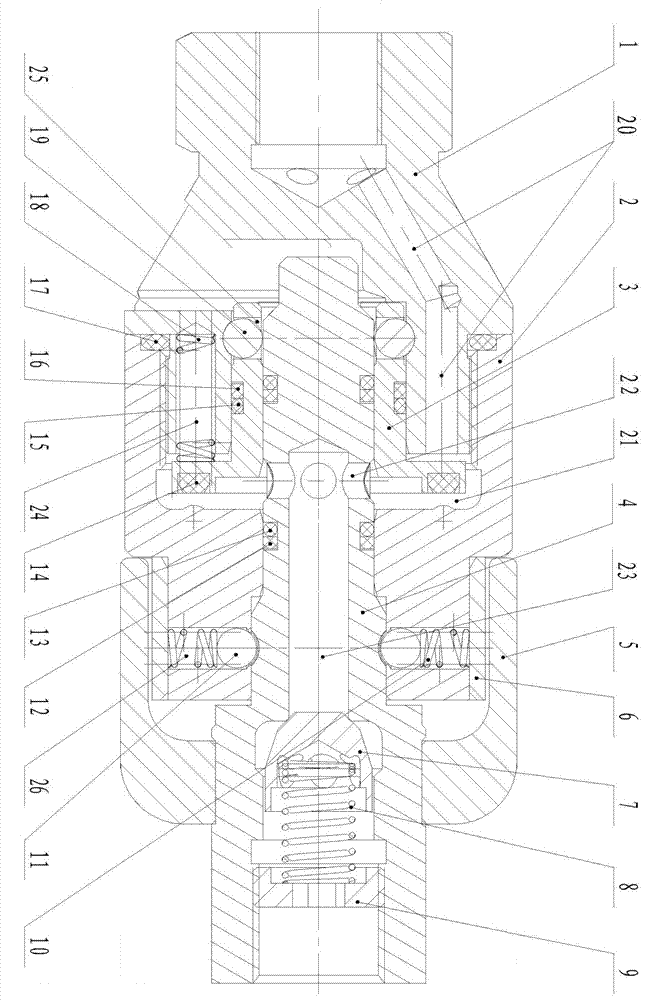

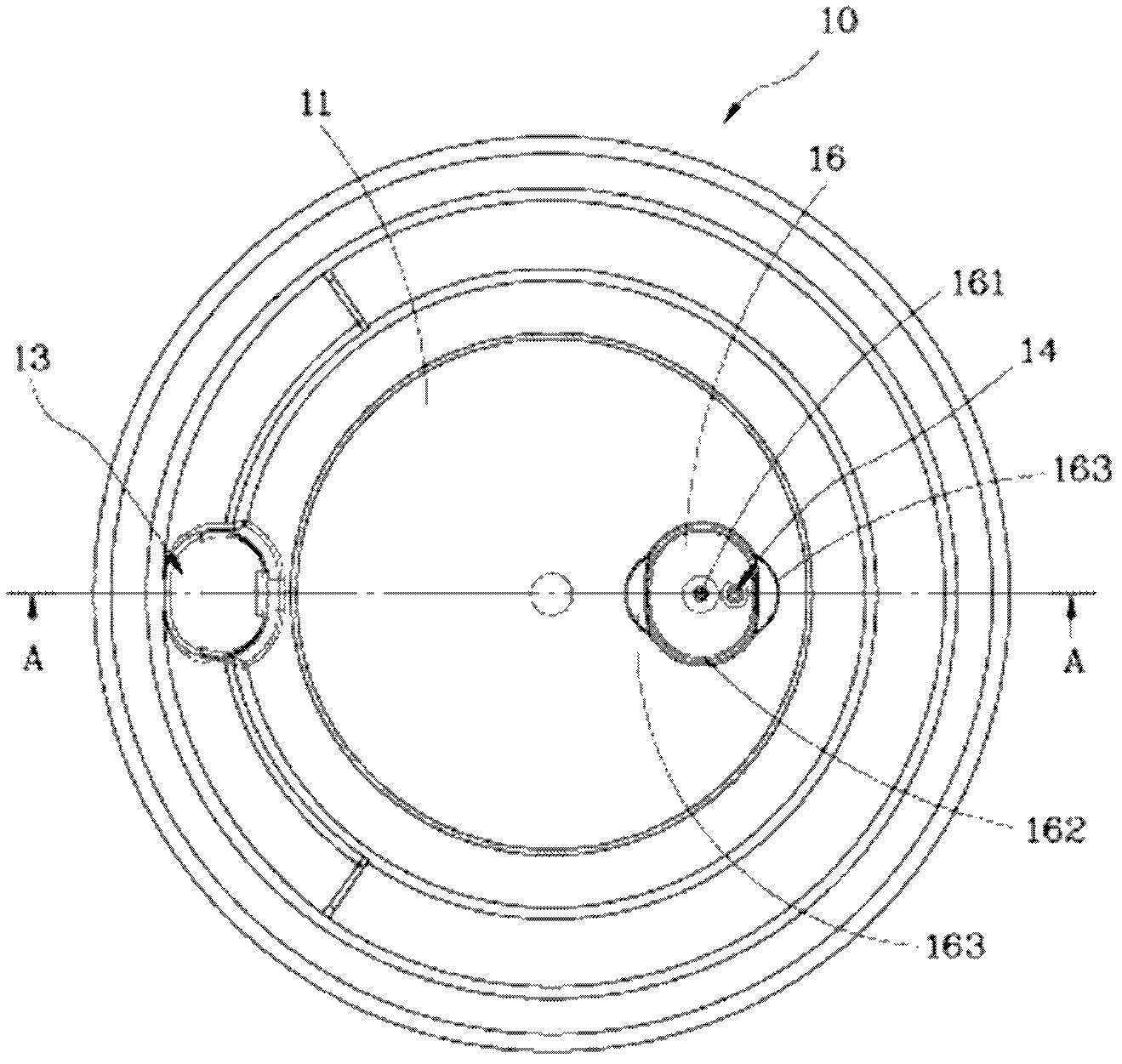

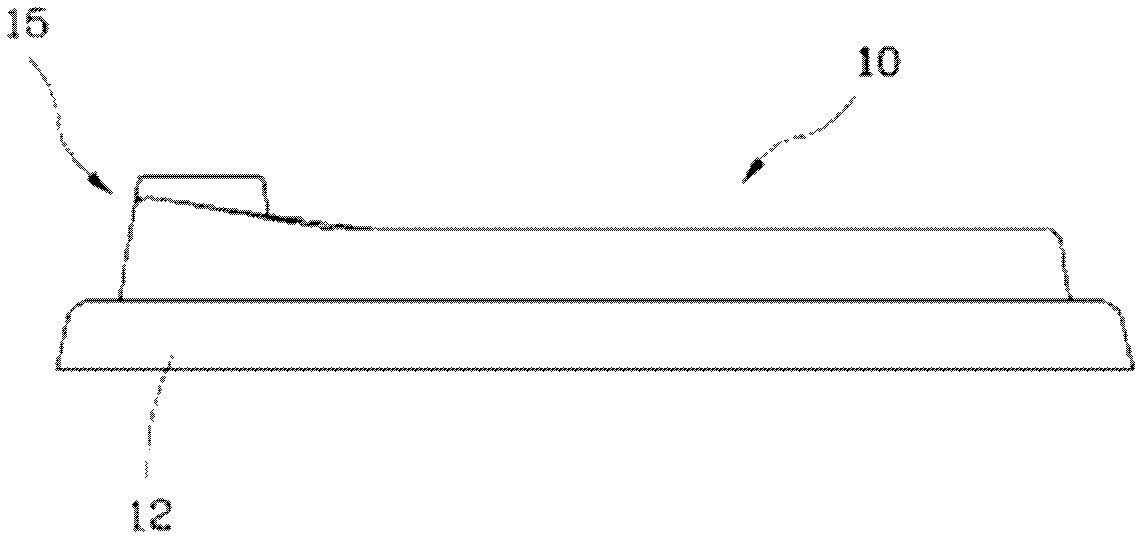

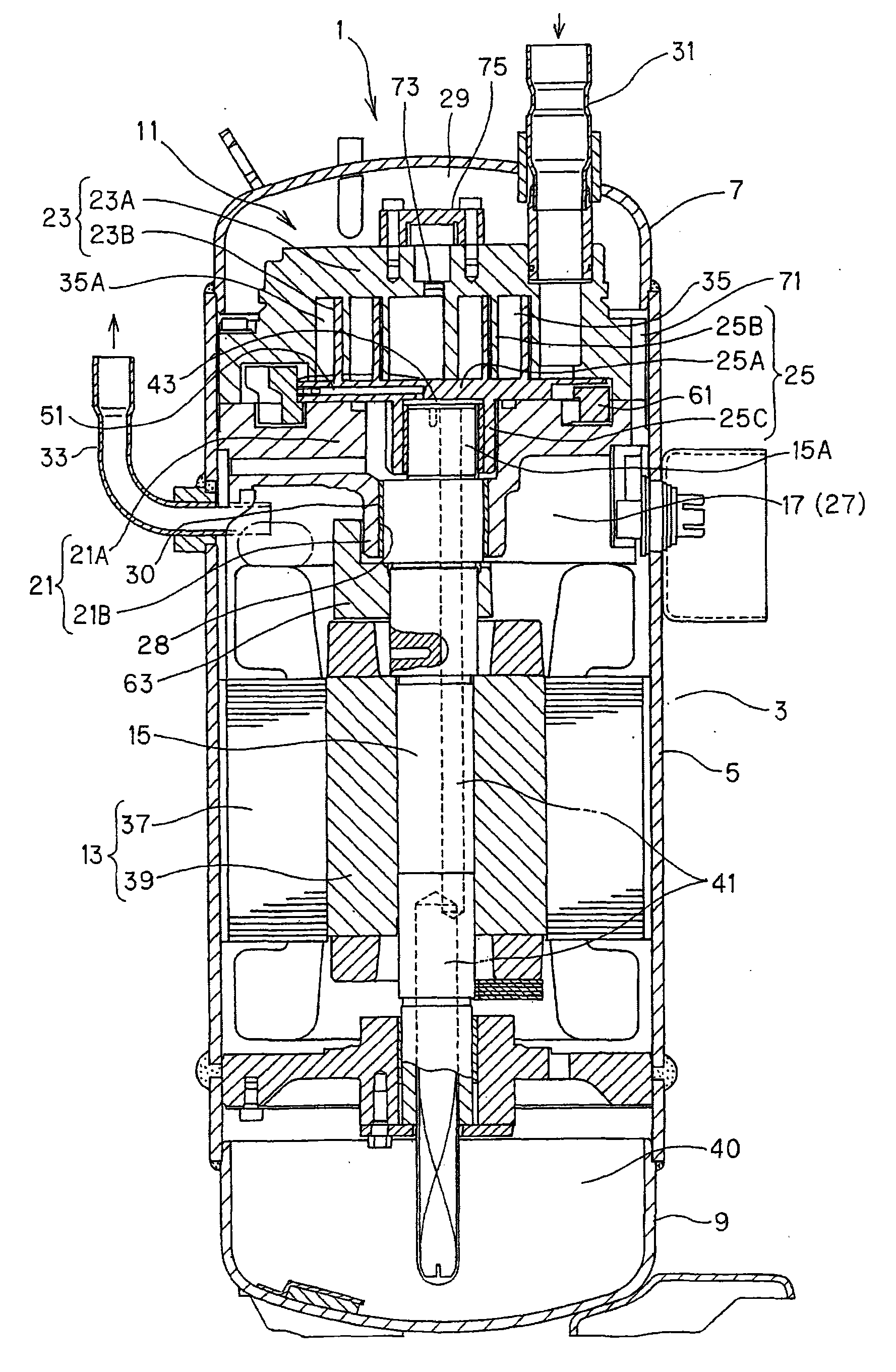

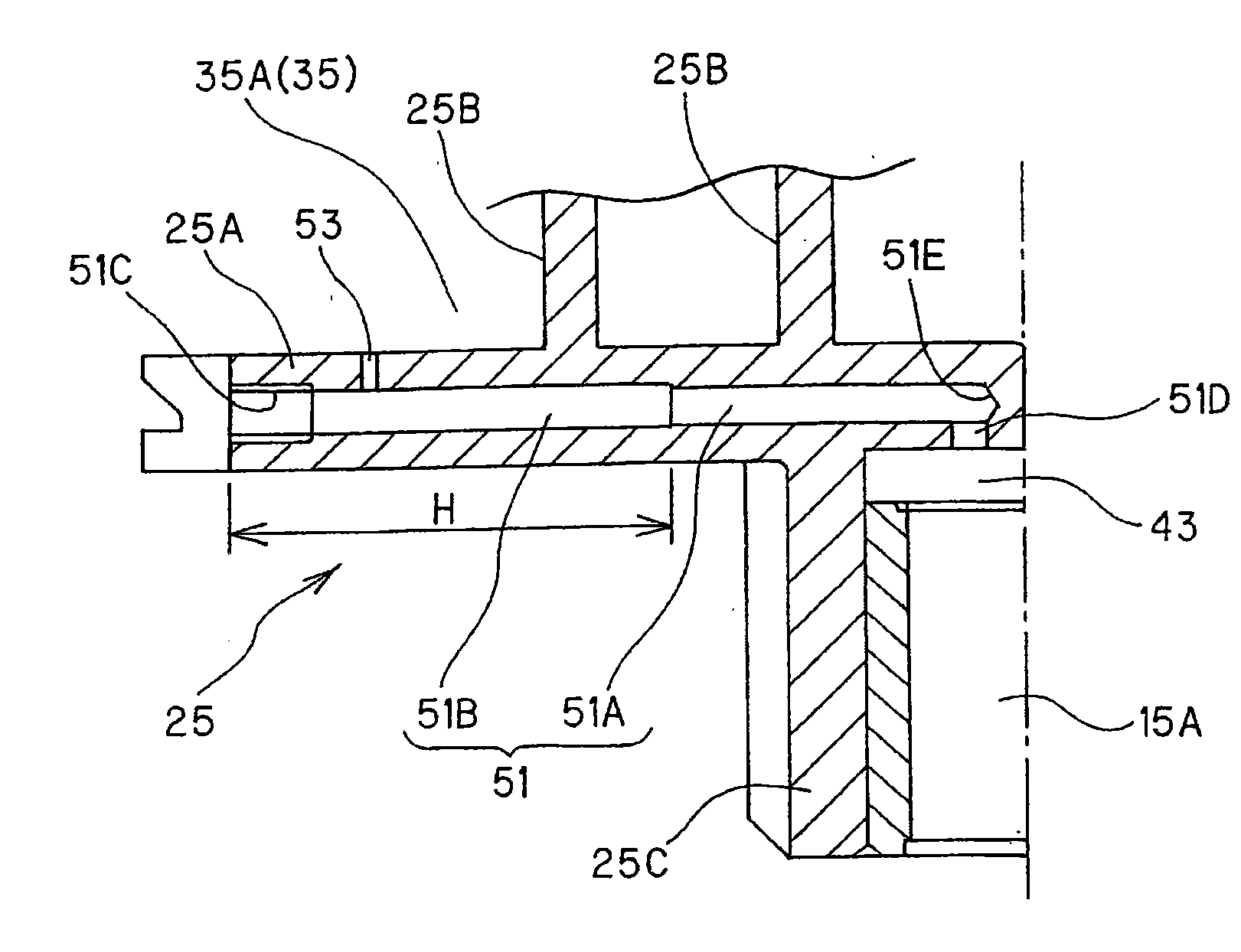

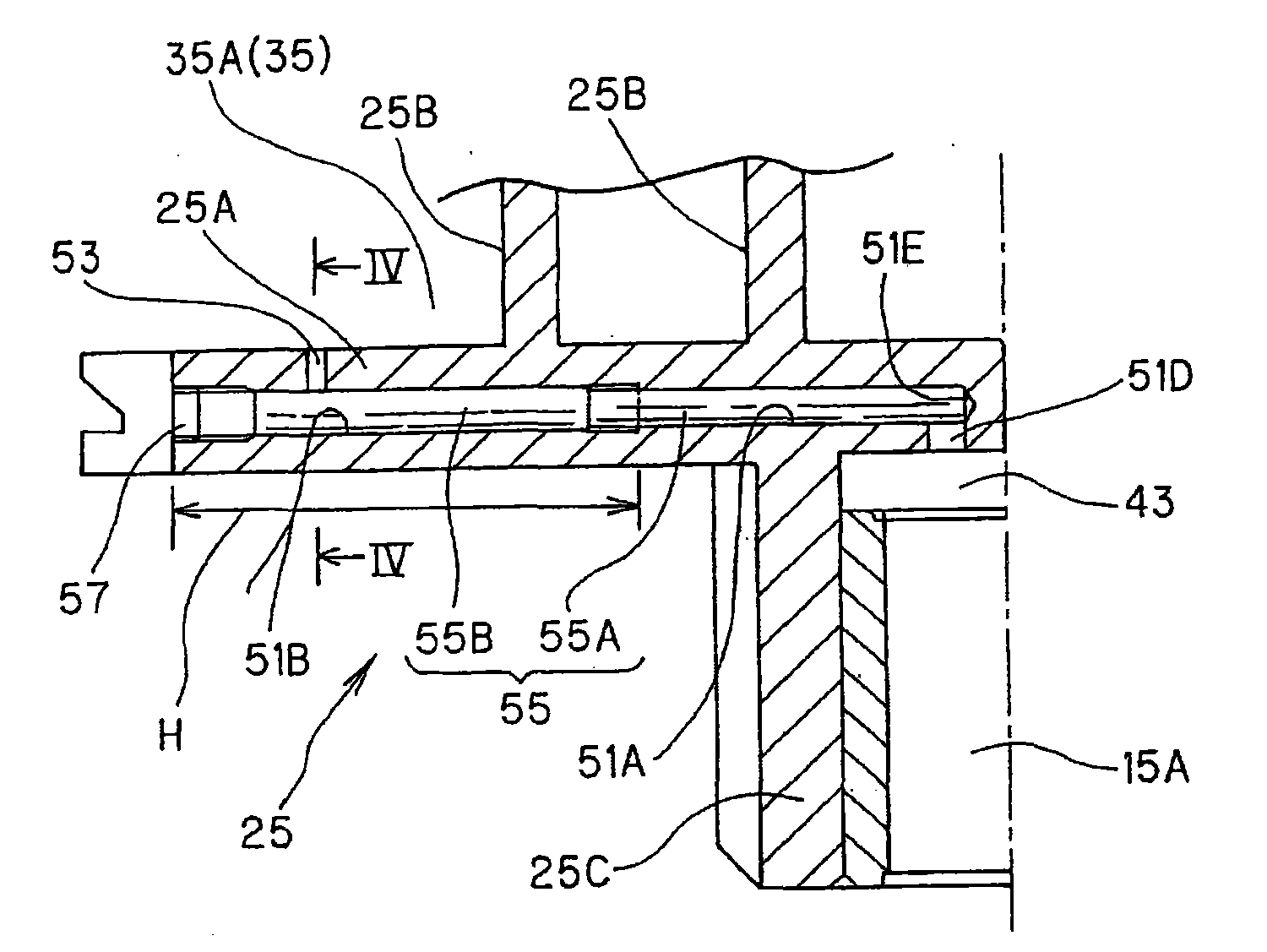

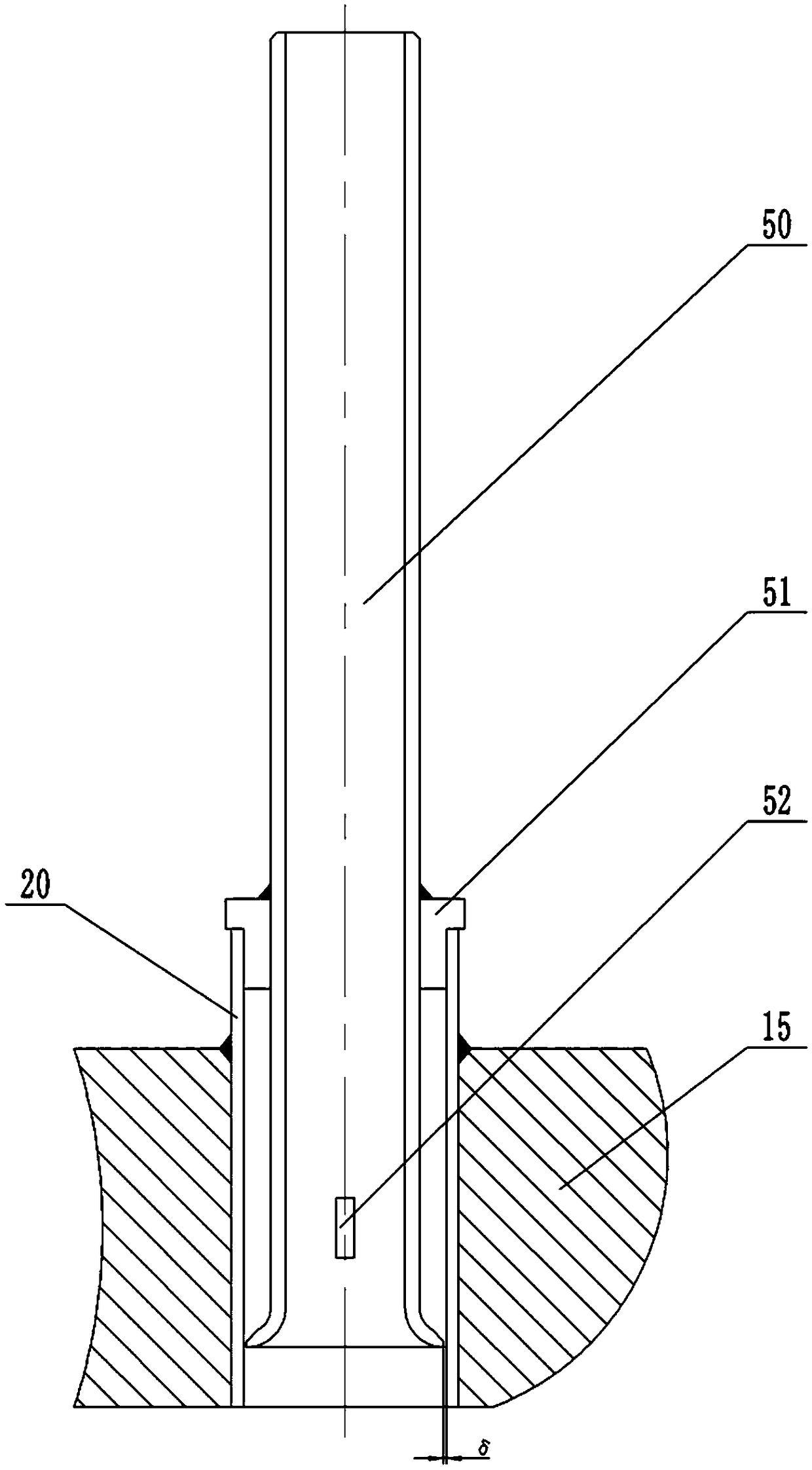

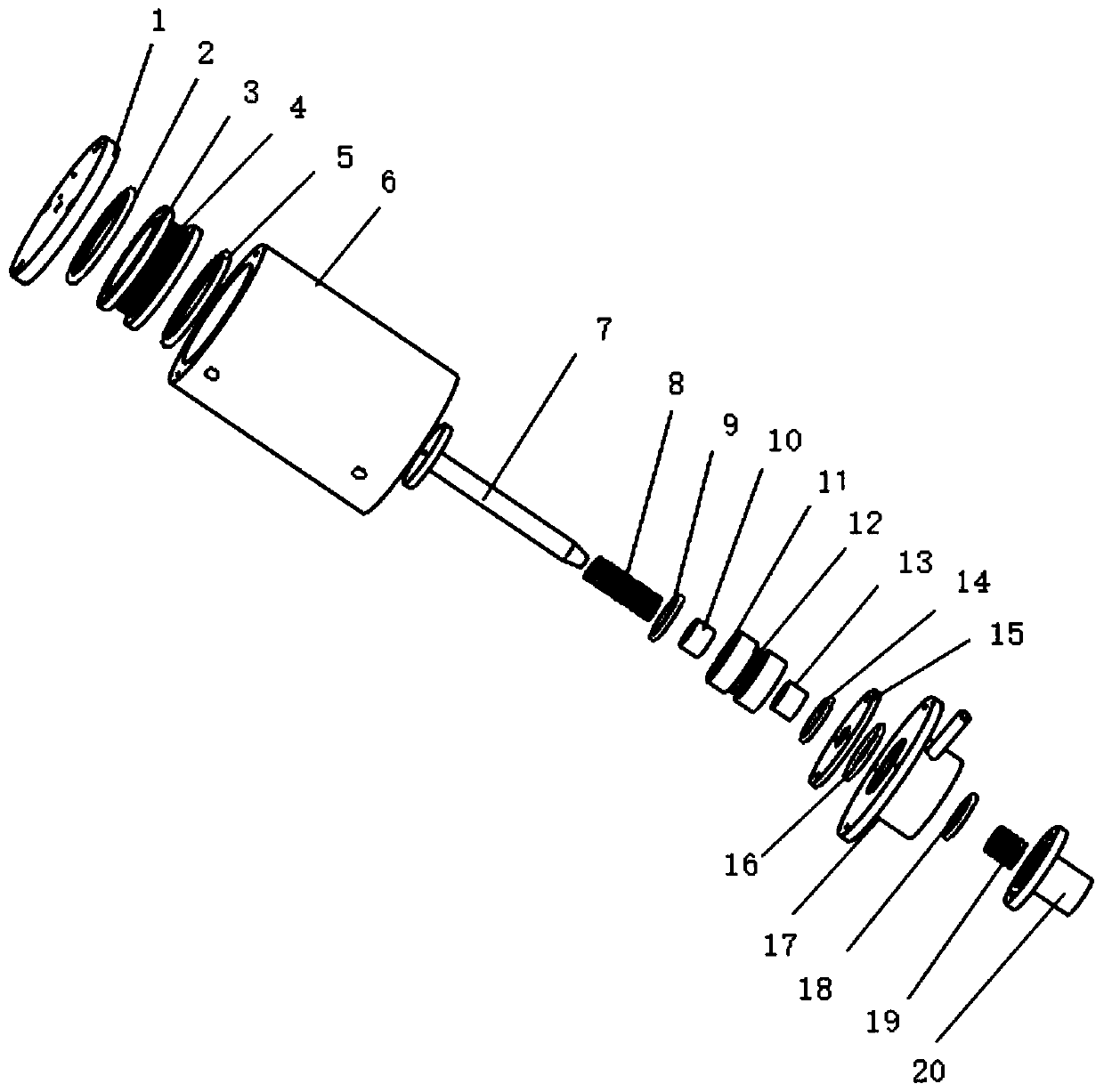

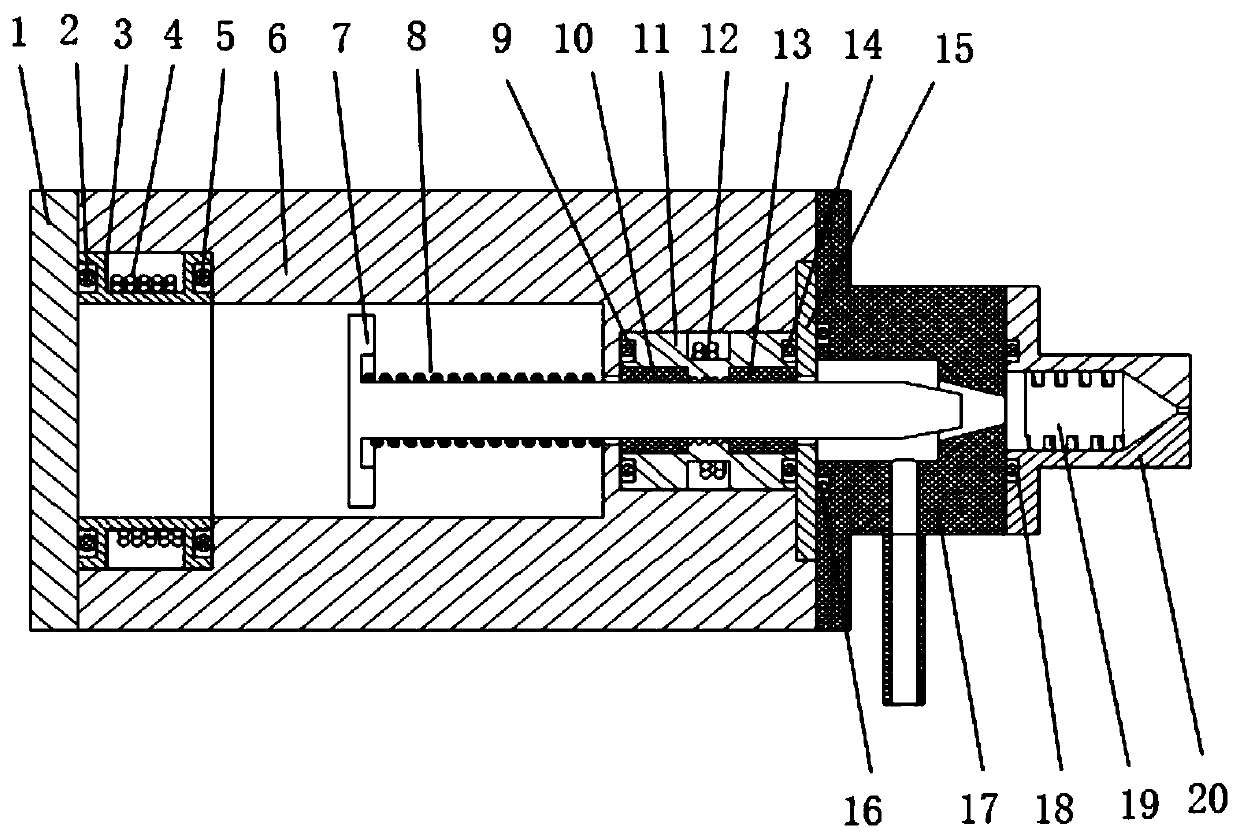

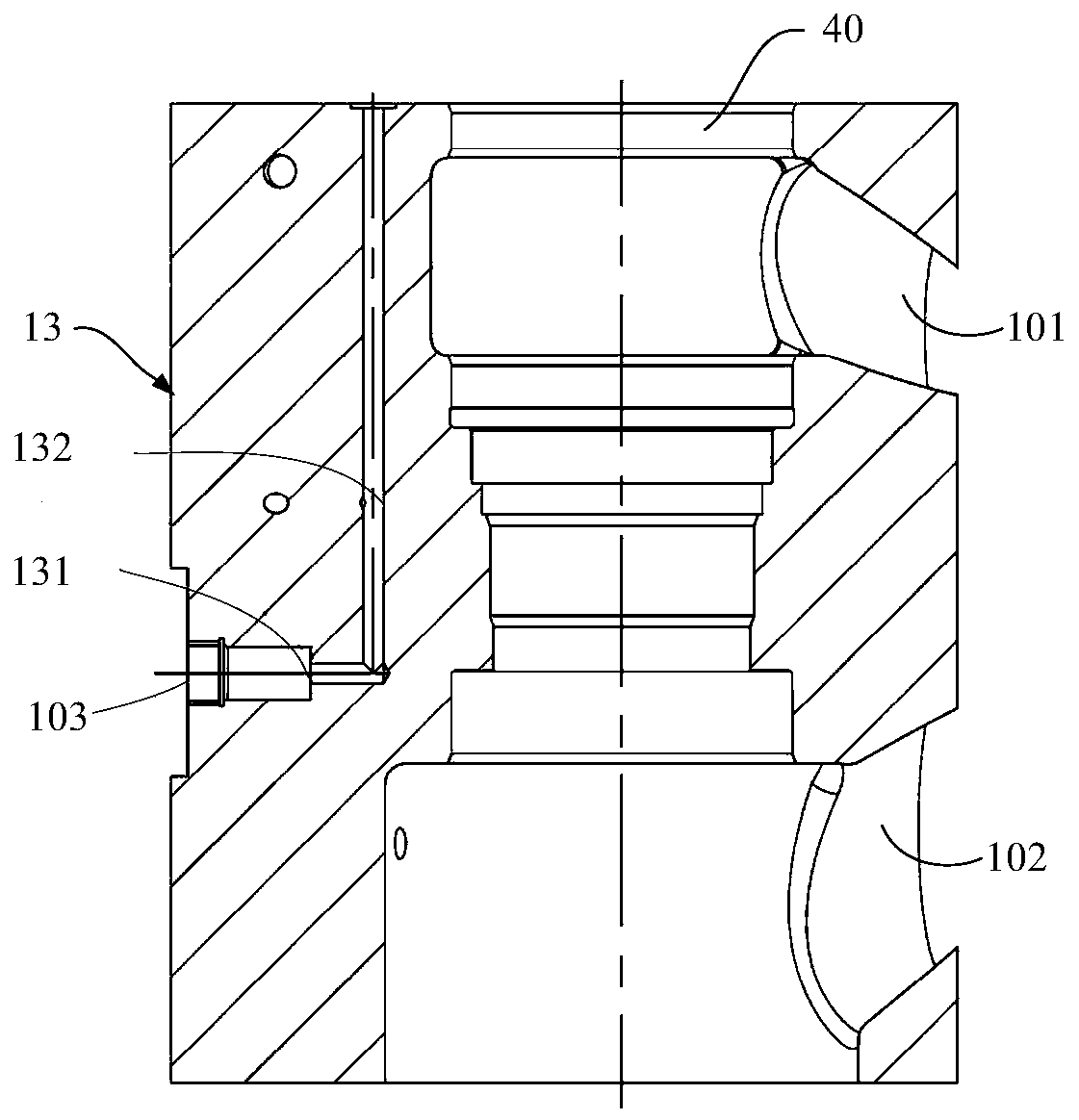

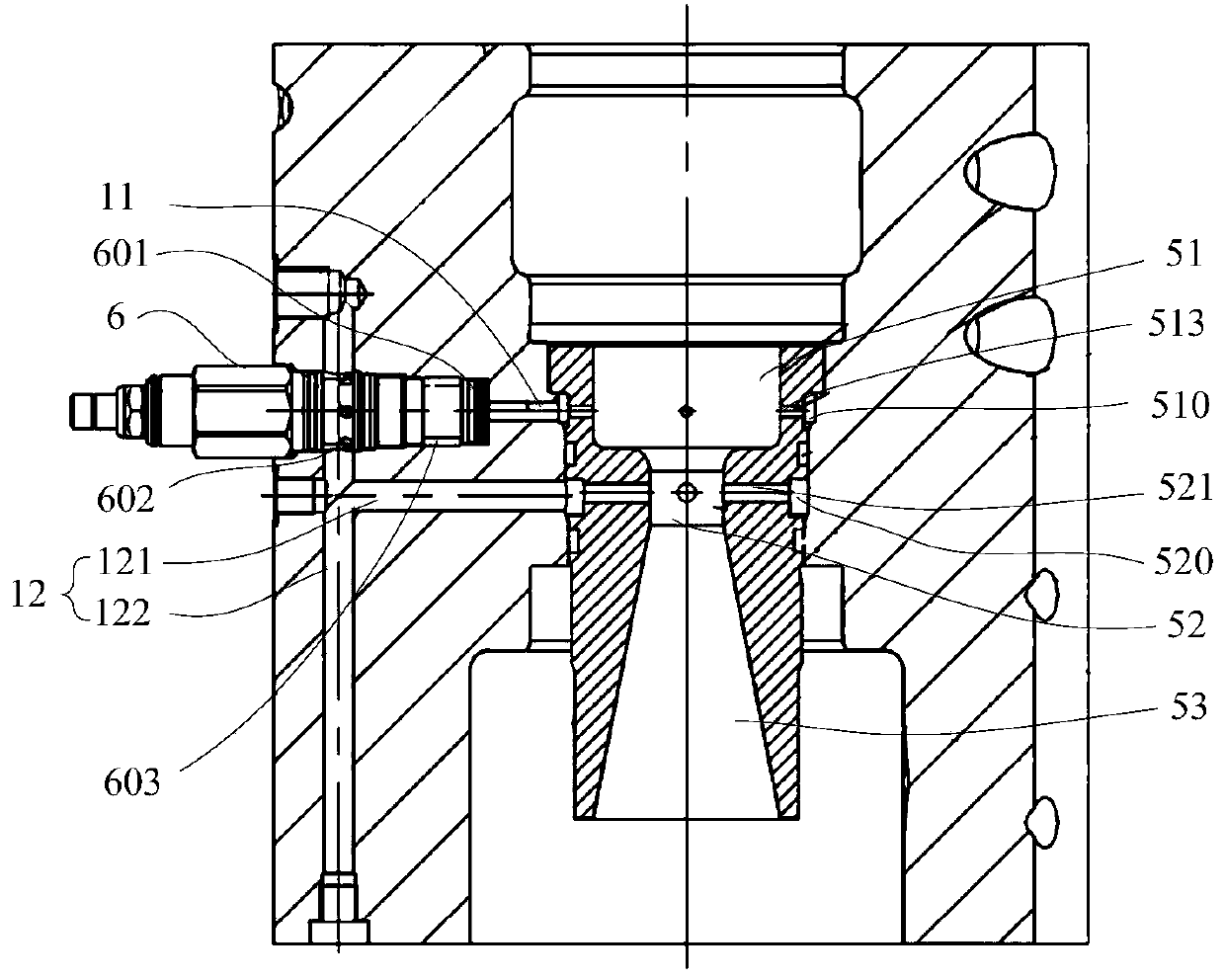

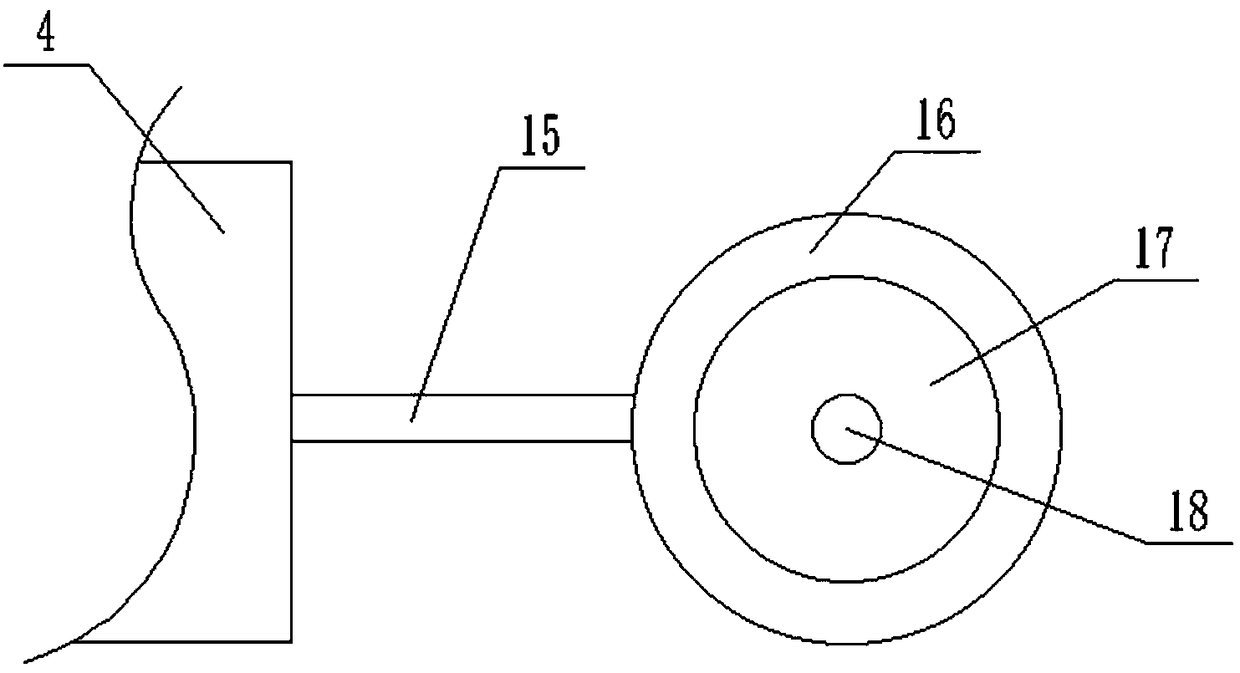

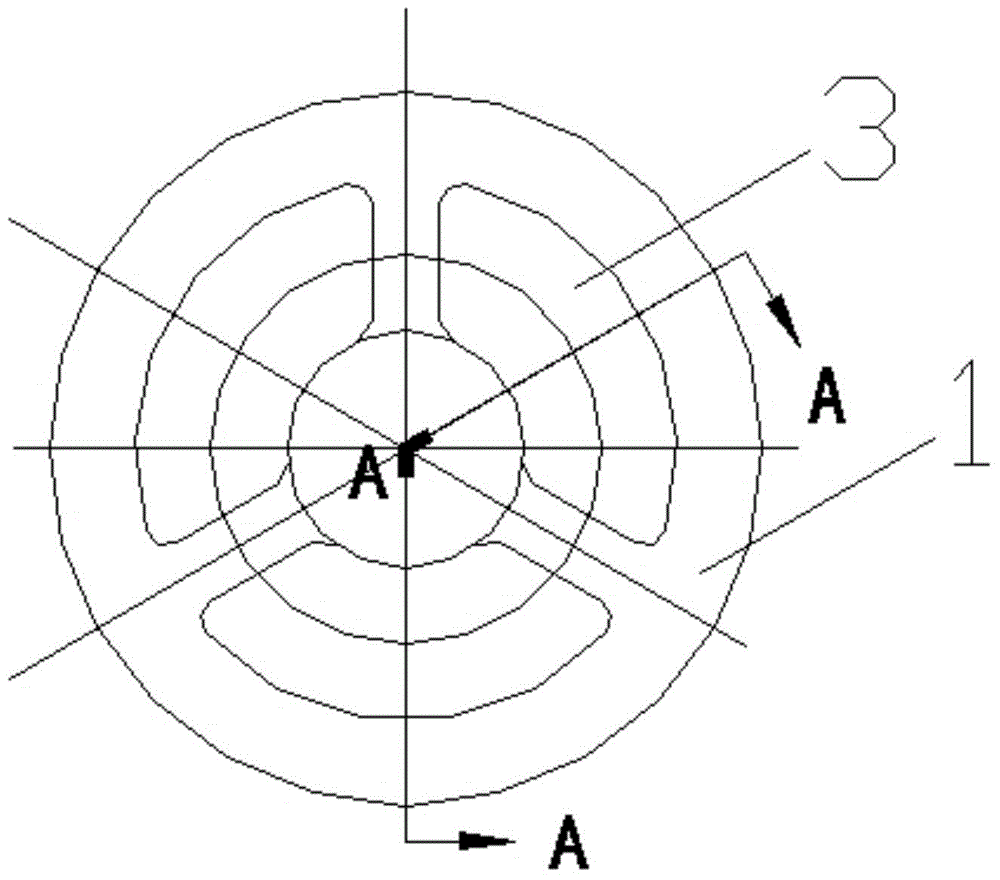

Scroll type compressor

InactiveCN101865133ALimit trafficLow costRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringHigh pressure

The invention provides a scroll type compressor that can restrict the flow rate of lubricating oil without requiring a high processing precision and can be manufactured in low cost. An intercommunication path (51) for supplying a lubricating oil to a low-pressure portion (35A) in a scroll is arranged in a movable scroll (25). One end of the intercommunication path is opened to the outside and linearly extends inside. A high-pressure opening (51D) communicated with a high-pressure portion (43) in a sealed container and a low-pressure opening (53) opened to the low-pressure portion (35A) in the scroll are disposed on an inner peripheral surface. The intercommunication path (51) is configured as follows: a bottom hole (51A) opened to the outside at one end is formed; and reaming processing is conducted from one end to a position of a predetermined depth H on the lower hole (51A) to form an insertion hole (51B). A pin member (55), which is abutted against the inner end of the bottom hole (51A)and set to be smaller than the diameter of the insertion hole (51B), is inserted in the intercommunication path (51); the pin member (55) is extruded to the inner end so as to close the one end of the intercommunication path by a screw member (57).

Owner:SANYO ELECTRIC CO LTD

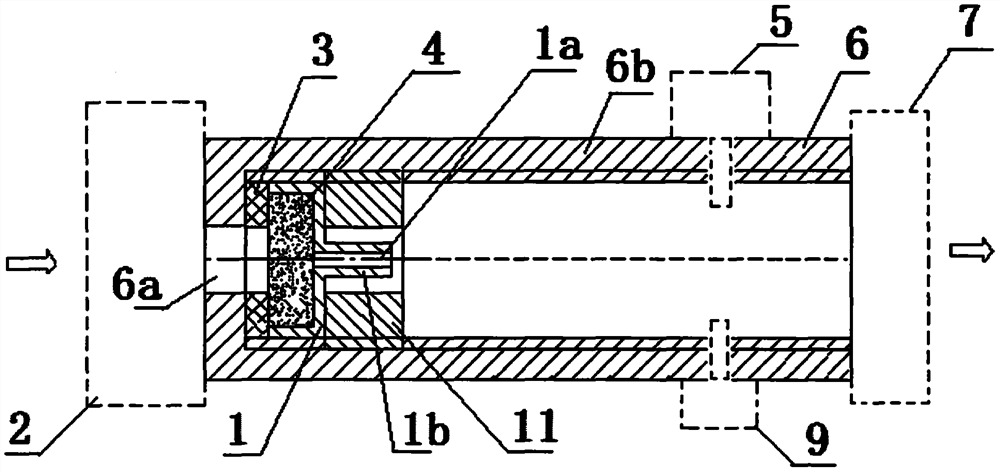

Buffer device for telescopic hydraulic cylinder of folding arm type truck mounted crane

InactiveCN106144922AImprove stabilityEliminate impact and noiseFluid-pressure actuatorsCranesTruckEnvironmental geology

The invention discloses a buffer device for a telescopic hydraulic cylinder of a folding arm type truck mounted crane. A cavity is formed in a piston rod and further provided with an oil pipe in the length direction of the cavity, and the two ends of the oil pipe penetrate out of a piston and a head so that a rodless cavity oil line can be formed; the tail end of the piston is provided with a first buffer sleeve through a buffer sleeve gland; a base is internally provided with a first rodless oil cavity oil inlet through a one-way valve, and the first rodless oil cavity oil inlet communicates with the rodless cavity oil line; the head is provided with a second rodless oil cavity oil inlet connected with the oil pipe and further provided with a second rod oil cavity oil inlet, and the second rod oil cavity oil inlet and the cavity in the piston rod form a rod oil cavity; the rod oil cavity communicates with the second rod oil cavity oil inlet through oil holes formed in the piston rod; and a first rod oil cavity oil inlet penetrates through a guide sleeve from the side wall of a cylinder barrel and communicates with the rod oil cavity. The two oil lines are conducive to telescopic movement of the piston rod, and the floating buffer sleeve is additionally arranged so as to limit the hydraulic oil flow, so that a decelerating buffer effect of stretching out and drawing back is achieved; and accordingly the smoothness and safety of the crane in the operation process are improved.

Owner:湖北佳恒科技股份有限公司

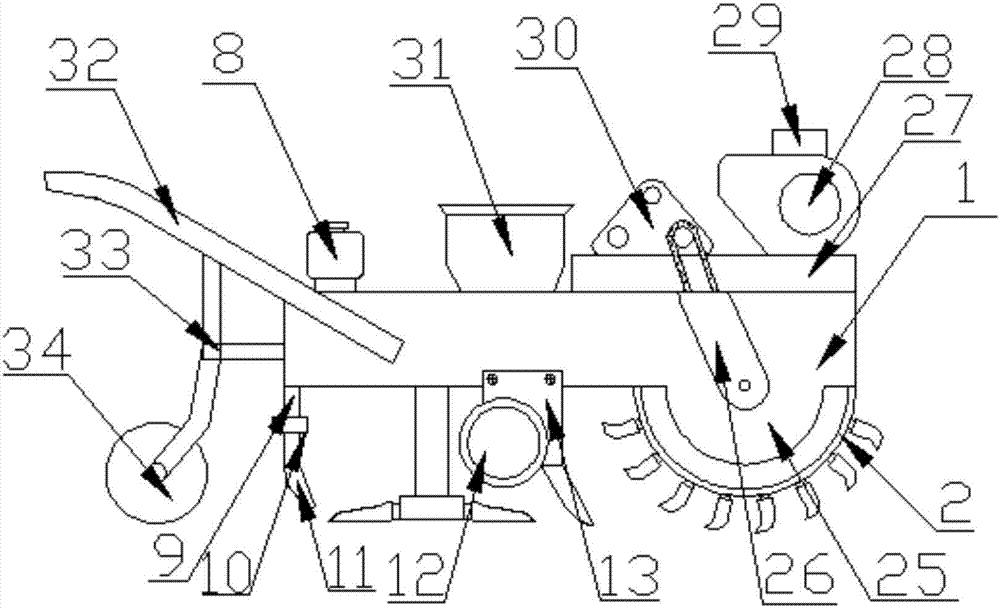

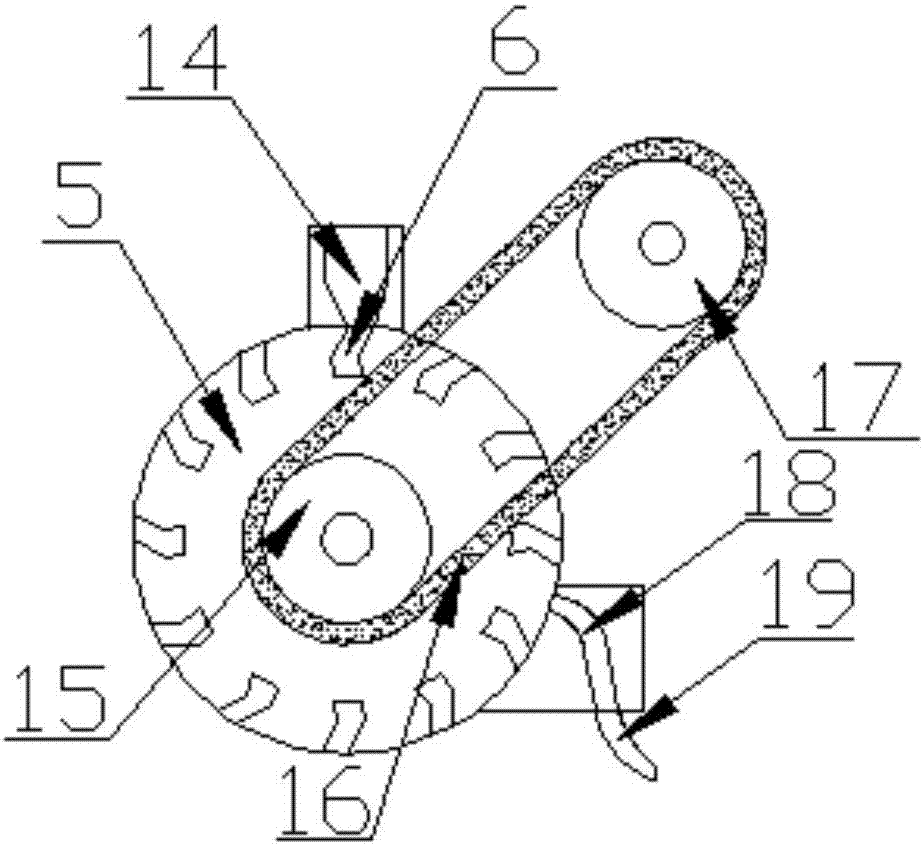

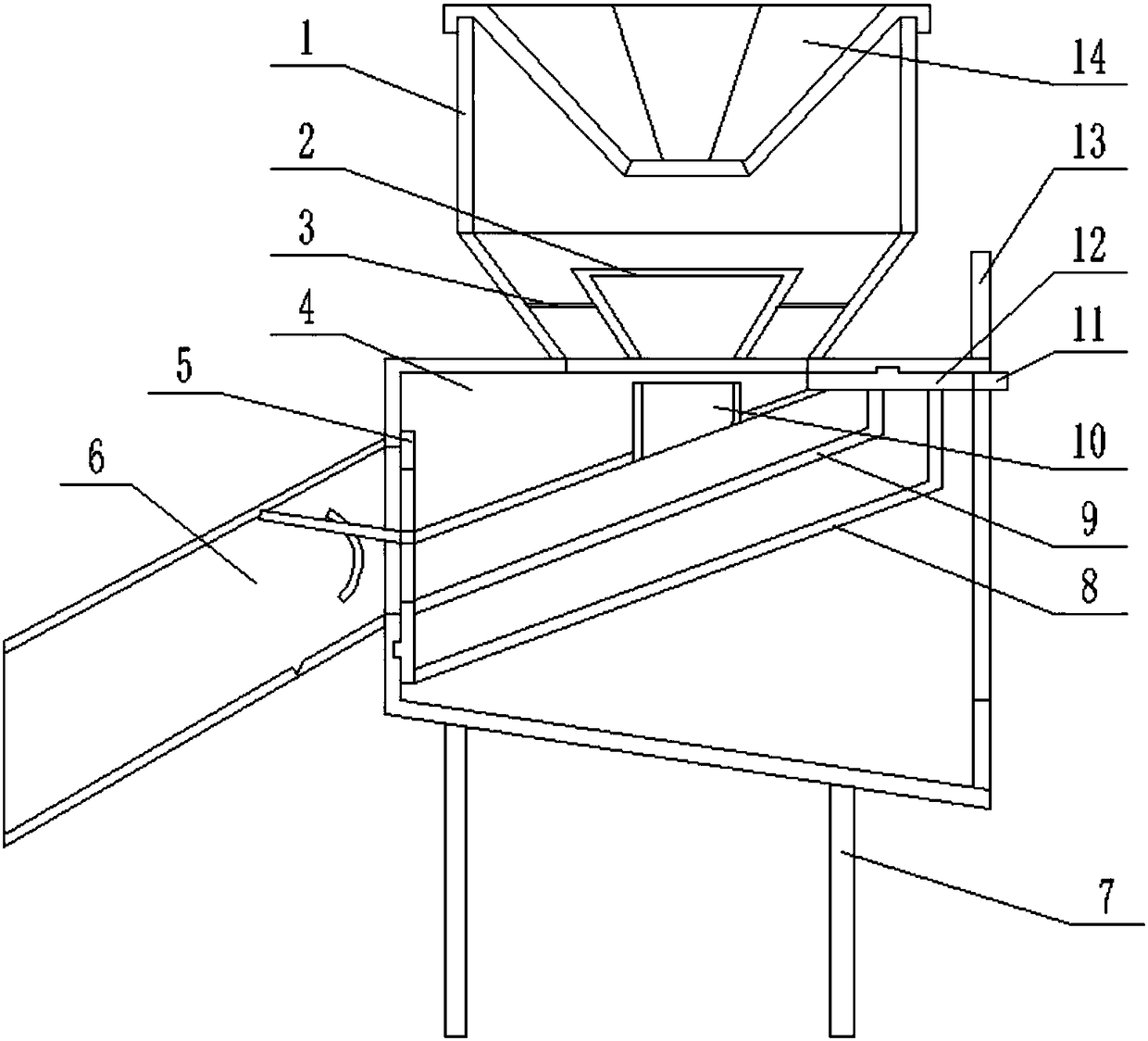

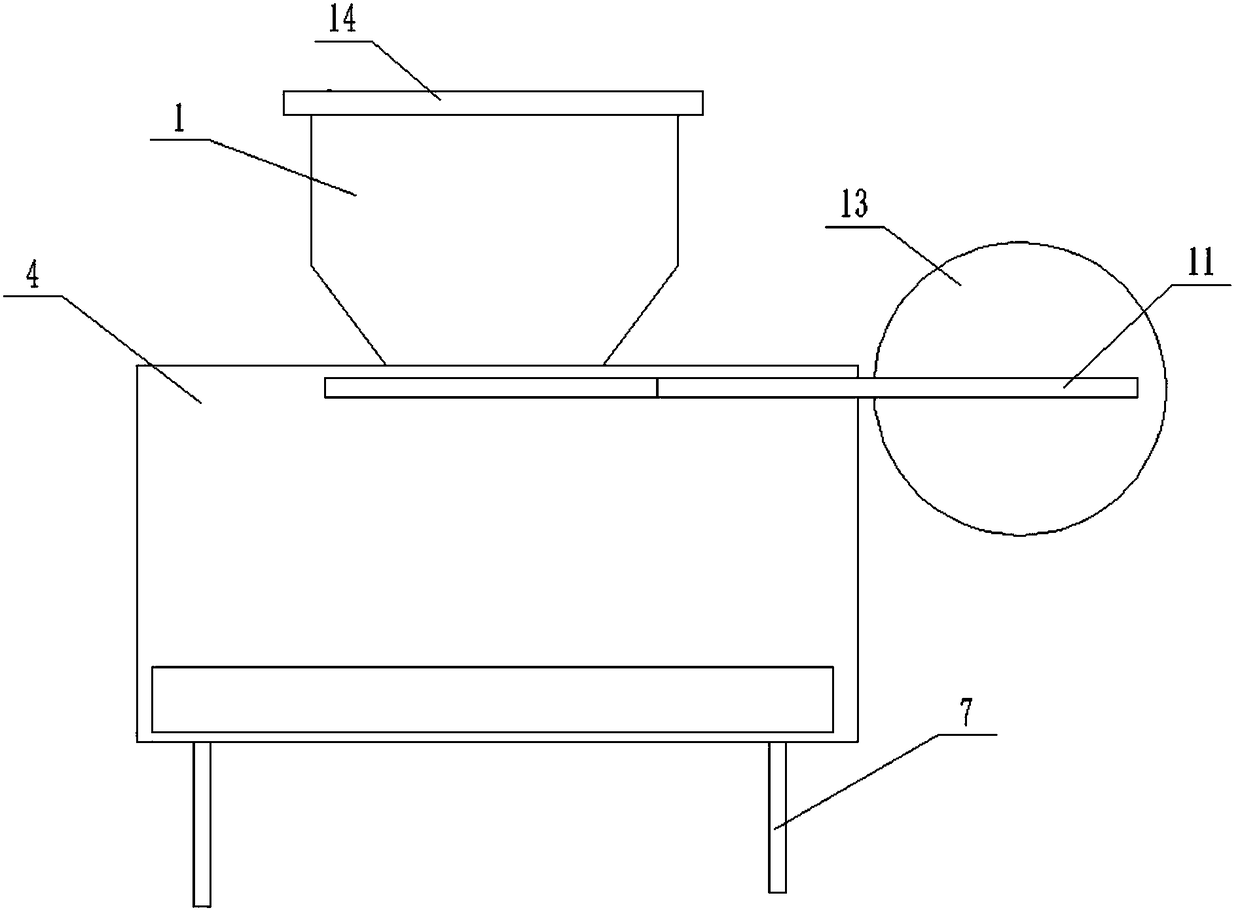

Agricultural seeder

InactiveCN107509414ALimit trafficReduce workloadPlantingWatering devicesAgricultural engineeringSowing

The invention discloses an agricultural seeder, which comprises a seeder body. One side of the seeder body is provided with a soil-turning disc, one side of the soil-turning disc is provided with a soil-turning hook, and one side of the soil-turning hook is provided with a There is an arc-shaped groove for turning soil, one side of the arc-shaped groove for turning soil is provided with a sowing disc, one side of the sowing disc is provided with a seed storage tank, one side of the seed storage tank is provided with a soil sweeper, and one side of the soil sweeper is provided with a There is a water tank, one side of the water tank is provided with a water tank communication pipe, one side of the water tank communication pipe is provided with a flow limiting valve, and one side of the flow limiting valve is provided with a water nozzle. The present invention can complete the bedding of the land after sowing while turning the soil and sowing, saves time and effort, reduces the workload of people, and brings convenience to production, and does not require manpower when watering the seeds To do it, there is a water tank on the planter, and the flow limiting valve can limit the flow of water, and it can be watered independently, which is more convenient.

Owner:DEQING JINGYING INFORMATION TECH CO LTD

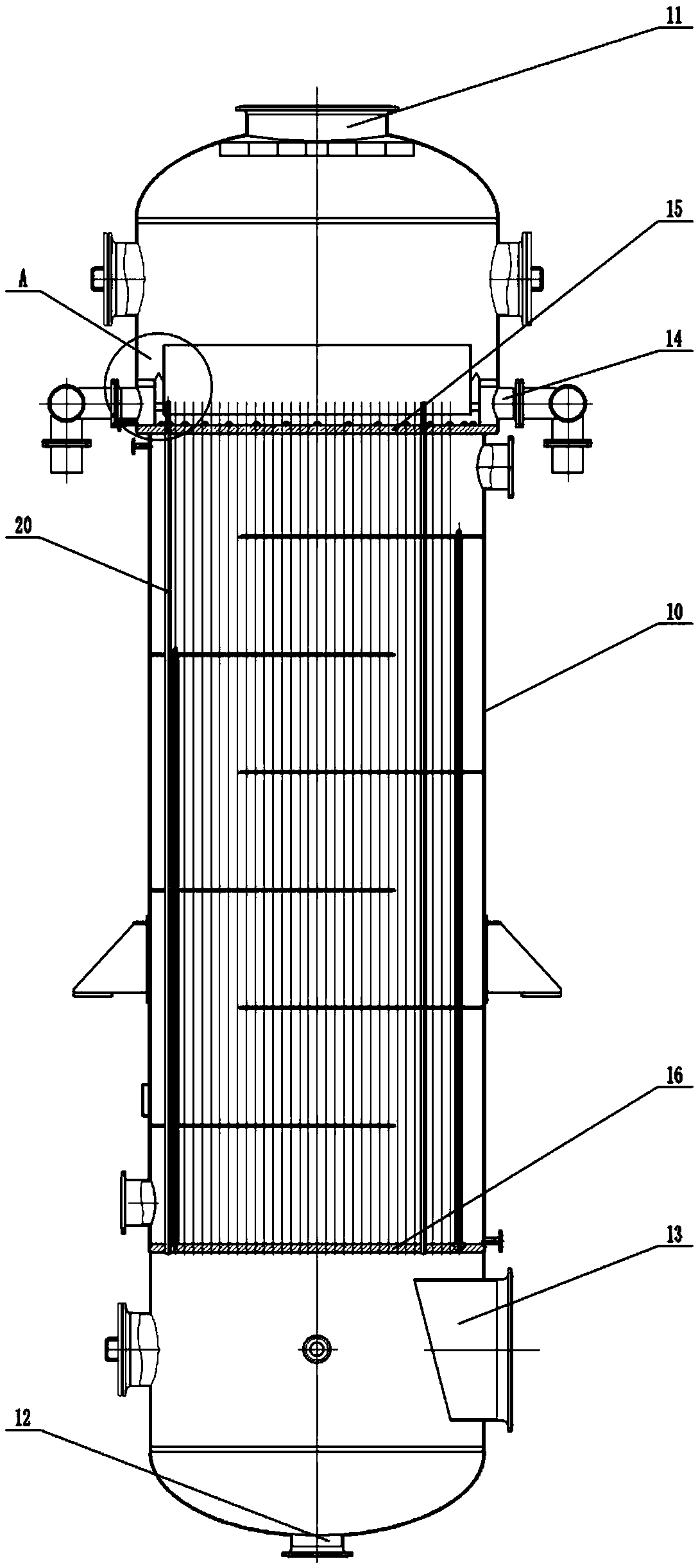

Falling-film reactor

The invention belongs to the technical field of an absorption reaction device, and particularly discloses a falling-film reactor. The falling-film reactor comprises a reactor shell, wherein the upperside wall of the reactor shell is provided with a liquid inlet, an upper pipe plate and a lower pipe plate are fixed in the reactor shell, the upper pipe plate is located on the upper part of the reactor shell and located below the liquid inlet, and the lower pipe plate is located on the lower part of the reactor shell; the upper pipe plate is provided with a liquid distribution drum, and a plurality of flow guide pipes are arranged between the upper pipe plate and the lower pipe plate in a penetrating manner; the lower side wall of the liquid distribution drum is provided with a plurality ofthrough holes, and the top side wall of the liquid distribution drum is provided with a plurality of sawtooth-shaped grooves; an overflow plate located in the liquid distribution drum is arranged above the upper pipe plate, a flow passage is formed between the liquid distribution drum and the overflow plate, the flow guide pipe is located in the overflow plate, the top of the overflow plate is located above the liquid distribution drum, and the height of the bottom of the overflow plate is lower than the height of the upper part of the flow guide pipe; and a falling film apparatus is arrangedin the upper part of the flow guide pipe. By utilizing the falling film reactor of the invention, uniformity in film falling can be realized, and the dry pipe phenomenon can be effectively avoided.

Owner:CHONGQING SHANJU CHEM MACHINERY

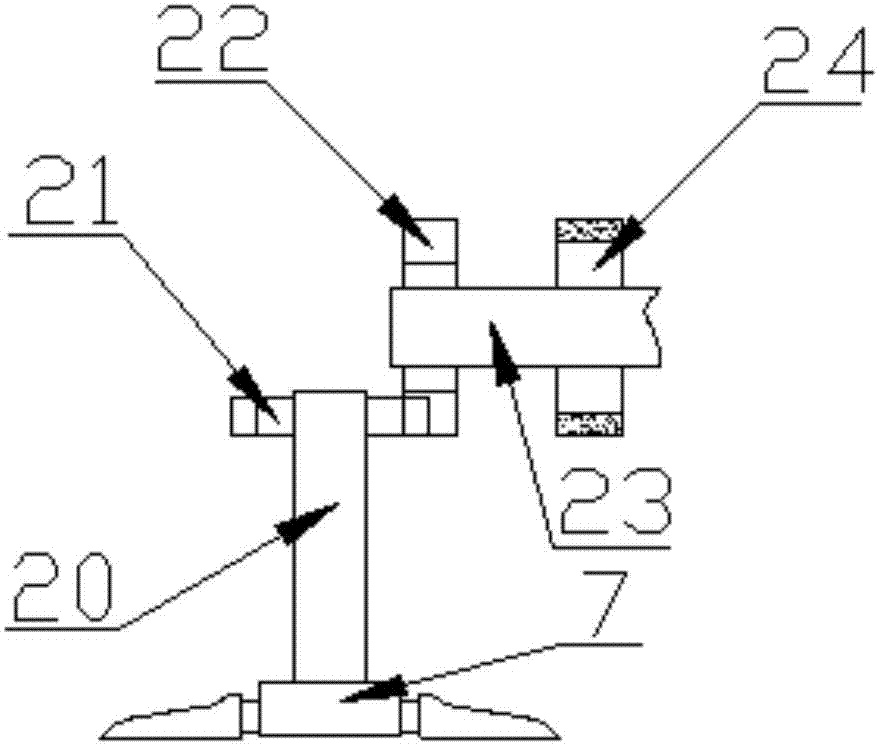

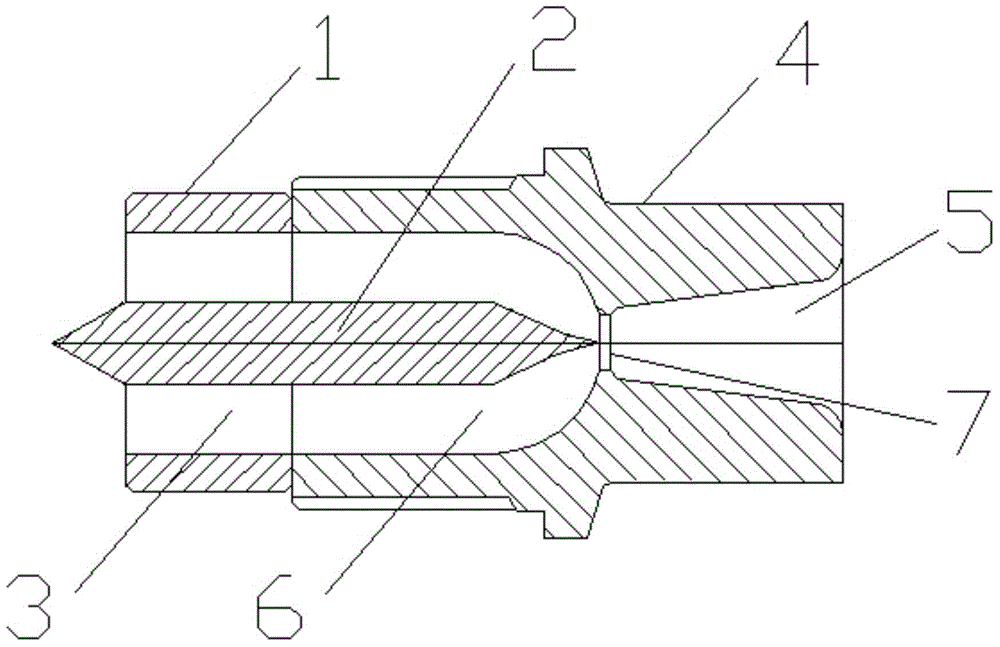

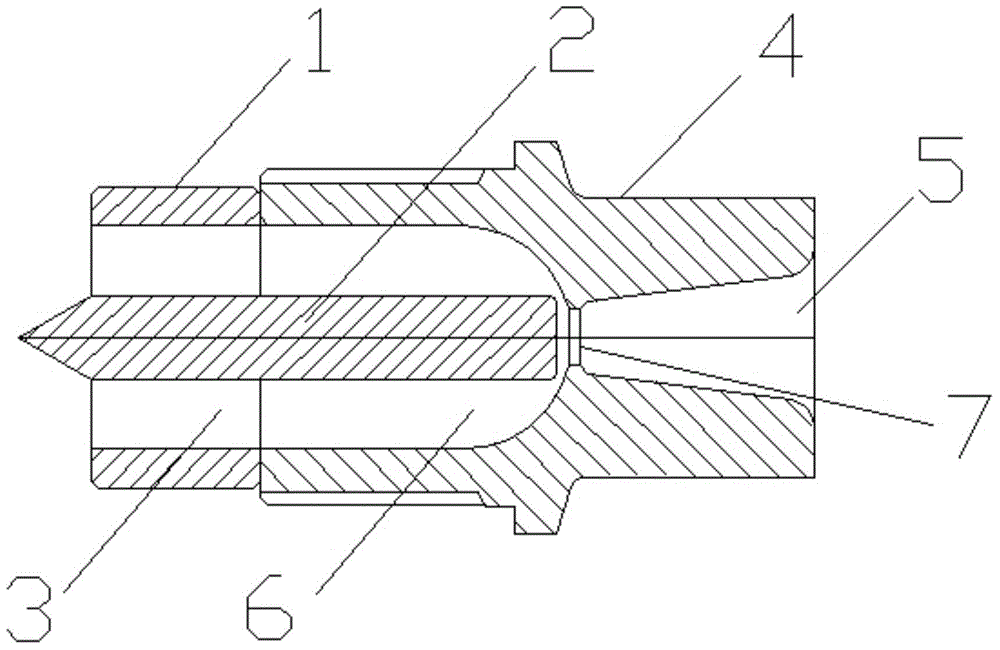

Agricultural swirl nozzle mechanism based on magnetorheological fluid micro-motion pressure change

ActiveCN110961266APrecisely control flowPrecisely control the ejection particle sizeSpray nozzlesInsect catchers and killersAgricultural engineeringAgricultural pesticides

The invention relates to the field of agricultural pesticide liquid nozzles, in particular to an agricultural swirl nozzle mechanism based on magnetorheological fluid micro-motion pressure change. Theagricultural swirl nozzle mechanism comprises a magnetorheological fluid variable push rod and a swirl nozzle structure. The magnetorheological fluid variable push rod comprises a magnetorheologicalfluid bearing cavity, a spacer bush, a first electrifying coil, a second electrifying coil, a pressure change push rod and a sealing spacer bush, wherein the spacer bush is arranged in a rear end column hole of the magnetorheological fluid bearing cavity, the first electrifying coil is wound on the spacer bush, the sealing spacer bush is arranged in a front end column hole of the magnetorheological fluid bearing cavity, and the second electrifying coil is wound outside the sealing spacer bush; and the side, provided with the piston, of the pressure change push rod is located in the magnetorheological fluid bearing cavity and provided with a reset spring. A swirl spool of the swirl nozzle structure is arranged in a swirl chamber, the swirl chamber is arranged at the front end of a liquid passing cavity, and the liquid passing cavity is arranged on the magnetorheological fluid bearing cavity. The mechanism utilizes the state change of magnetorheological fluid under the action of a magnetic field to cause the pressure change of the magnetic flow bearing cavity, and the pressure change push rod is pushed to move outwards, and the flow and the spraying particle size of pesticide liquidcan be conveniently and accurately controlled.

Owner:SOUTH CHINA AGRI UNIV

Hydraulic control valve set

PendingCN111577690ADecompression achievedReduce openingServomotor componentsFluid-pressure actuator componentsControl valvesOil intake

The invention provides a hydraulic control valve set, and belongs to the field of hydraulic devices. The hydraulic control valve set comprises a valve body and a valve deck, wherein a main oil inlet,a main oil return opening, a main control oil opening and a communicating oil opening are formed in the valve body, the hydraulic control valve set further comprises a valve sleeve, a valve element, aVenturi tube and a direction valve, the valve sleeve is fixedly inserted into the valve body, one end of the valve element is sealed and arranged towards the valve deck to form a control cavity, theVenturi tube is inserted into the valve body, the Venturi tube comprises an inlet section, a middle section and an outlet section which sequentially extend backwards to the valve cover, the directionvalve is fixedly installed on the valve body, a first control oil port of the direction valve communicates with the inlet section, a second control oil port of the direction valve communicates with the middle section, a working oil port of the direction valve communicates with the control cavity, and when an oil pressure difference value between the first control oil port and the second control oil port is larger than a set threshold value of the direction valve, the working oil port communicates with the second control oil port. According to the hydraulic control valve set, the flow can be effectively controlled through the hydraulic control valve set.

Owner:WUHAN MARINE MACHINERY PLANT

Sand screening device applied to road and bridge construction

The invention relates to a screening device and particularly relates to a sand screening device applied to road and bridge construction. The sand screening device can realize multi-stage screening andseparated discharging and can also limit the flow rate of sand which enters the device. A clamping block III on a screening device III is in interference fit with a clamping groove I; a clamping block IV on the screening device III is connected to the lower end of a sliding plate II; the screening device III is positioned above a screening device II; a supporting plate is positioned above a flowchannel; a side baffle is fixedly connected to the side surface of a screening device I in a welding way; a bracket is fixedly connected to the lower end of a screening box in a welding way; one end of a fixed rod is fixedly connected to the side surface of the screening box in a welding way; a motor bracket is fixedly connected to the other end of the fixed rod in a welding way; a motor is fixedly connected to the motor bracket through a bolt; a rotating shaft is arranged on the motor; a rotary disc is fixedly connected to the rotating shaft through a key; one end of a transmission rod is movably connected to an eccentric position of the rotary disc; and the other end of a rotating rod is movably connected to a sliding plate II via a through hole II.

Owner:江苏久聚建设工程有限公司

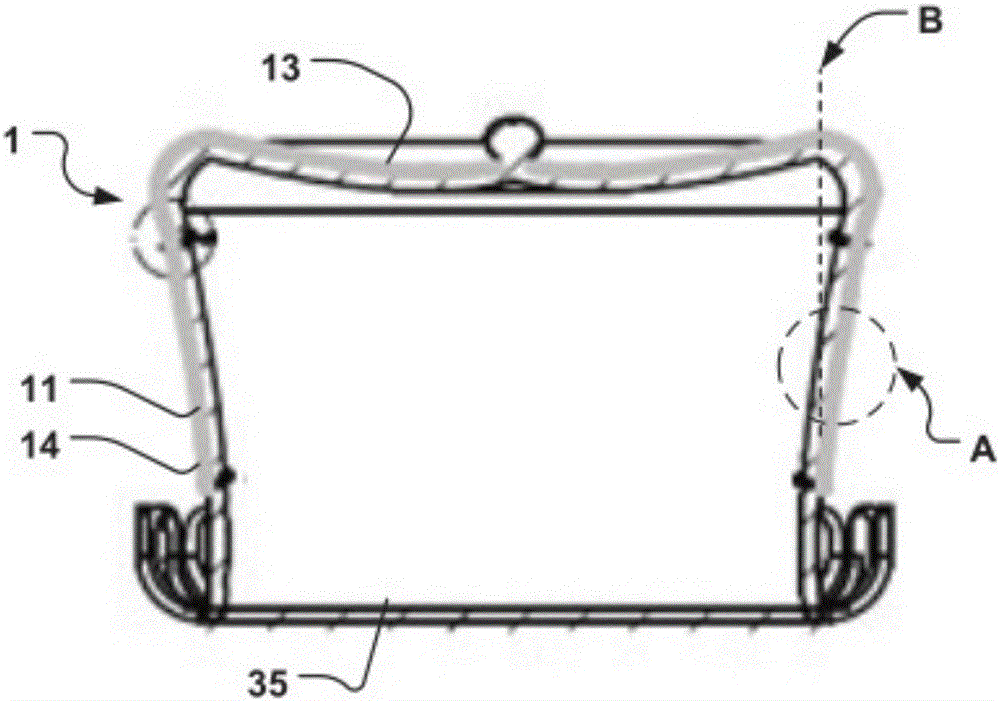

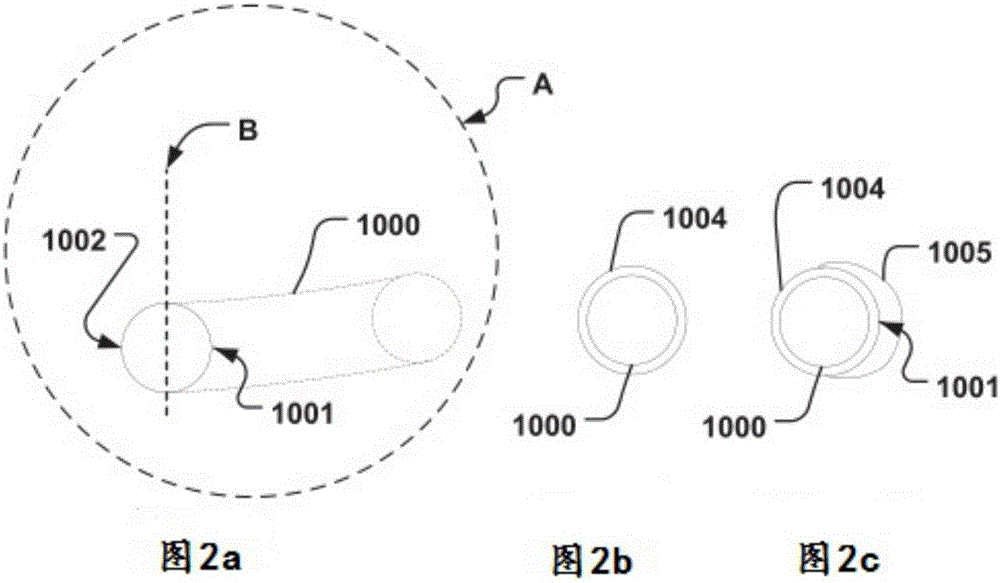

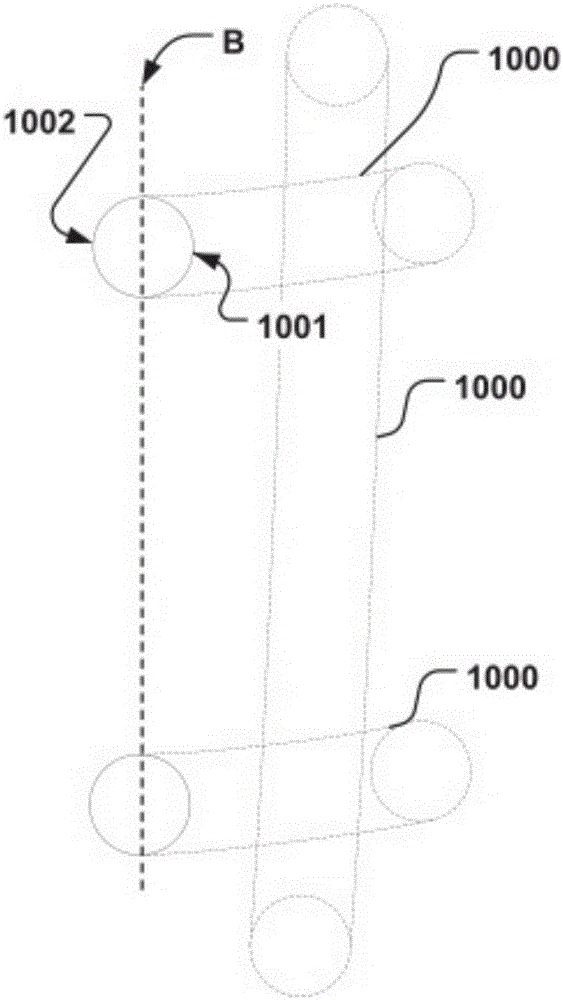

A medical implant for occluding an opening in a body and a method of producing such a medical implant

ActiveCN105682562AReduce frictionAchieve the desired functionOcculdersBinding forceBiomedical engineering

The disclosure relates to a medical implant for occluding an opening in a body and a method of producing such a medical implant. Disclosed is an improved occluder, which provides improved occlusion, improved sealing and improved endothelialization. A method is disclosed comprising braiding, knitting or weaving together strands to form a body mesh of strands forming a plurality of adjacent cells delimited by the strands. The method further comprises applying a first coating to said strands, and applying a second coating to at least part of an external surface of said medical implant, wherein said first coating provides a binding force to said second coating such that said second coating adheres to said strands.

Owner:OCCLUTECH HLDG

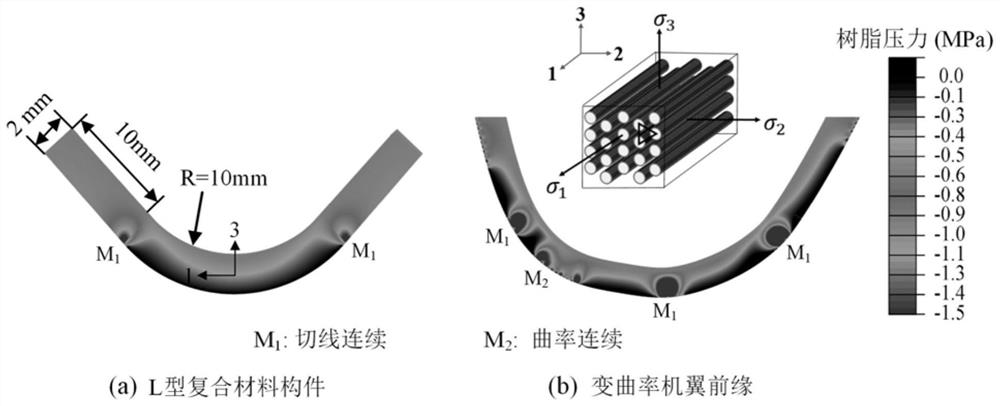

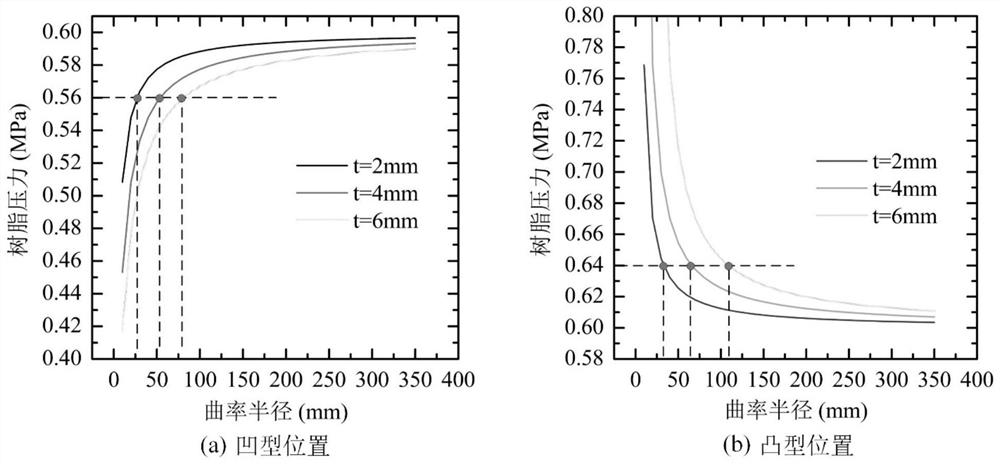

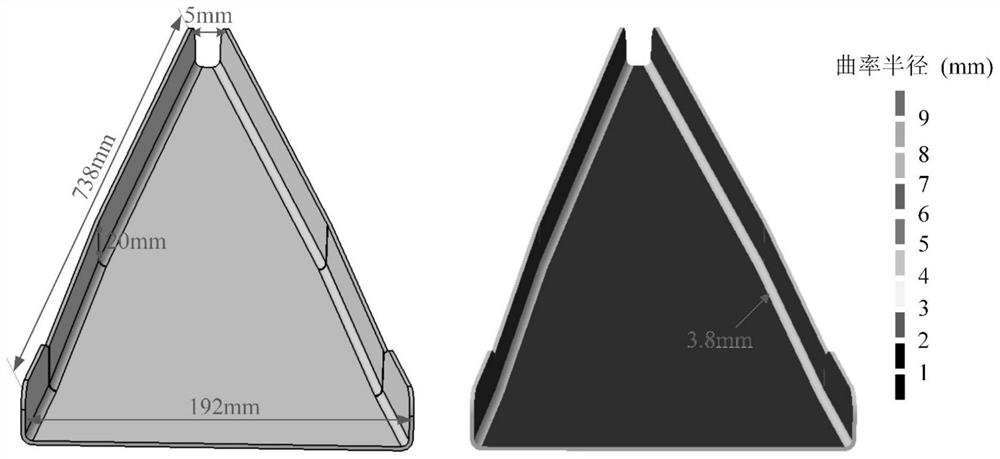

Resin flow zone control method in composite material component

A resin flow zone control method in a composite material component is characterized in that the composite material component is divided into a plurality of areas with close resin pressure according to resin pressure distribution in a composite material, micro-flow valves are arranged on the boundary of the areas, mutual flow of resin between different areas is limited, complex flowing in the component is converted into independent flowing in the areas, large-range flowing of resin under the action of pressure difference in the curing process of the composite material component is avoided, and the curing thickness of the composite material component with the complex profile is effectively controlled. The method solves the problem that resin flow is difficult to control in the curing process of the composite material component with the complex profile, and has the advantages of being easy to operate, good in control effect and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

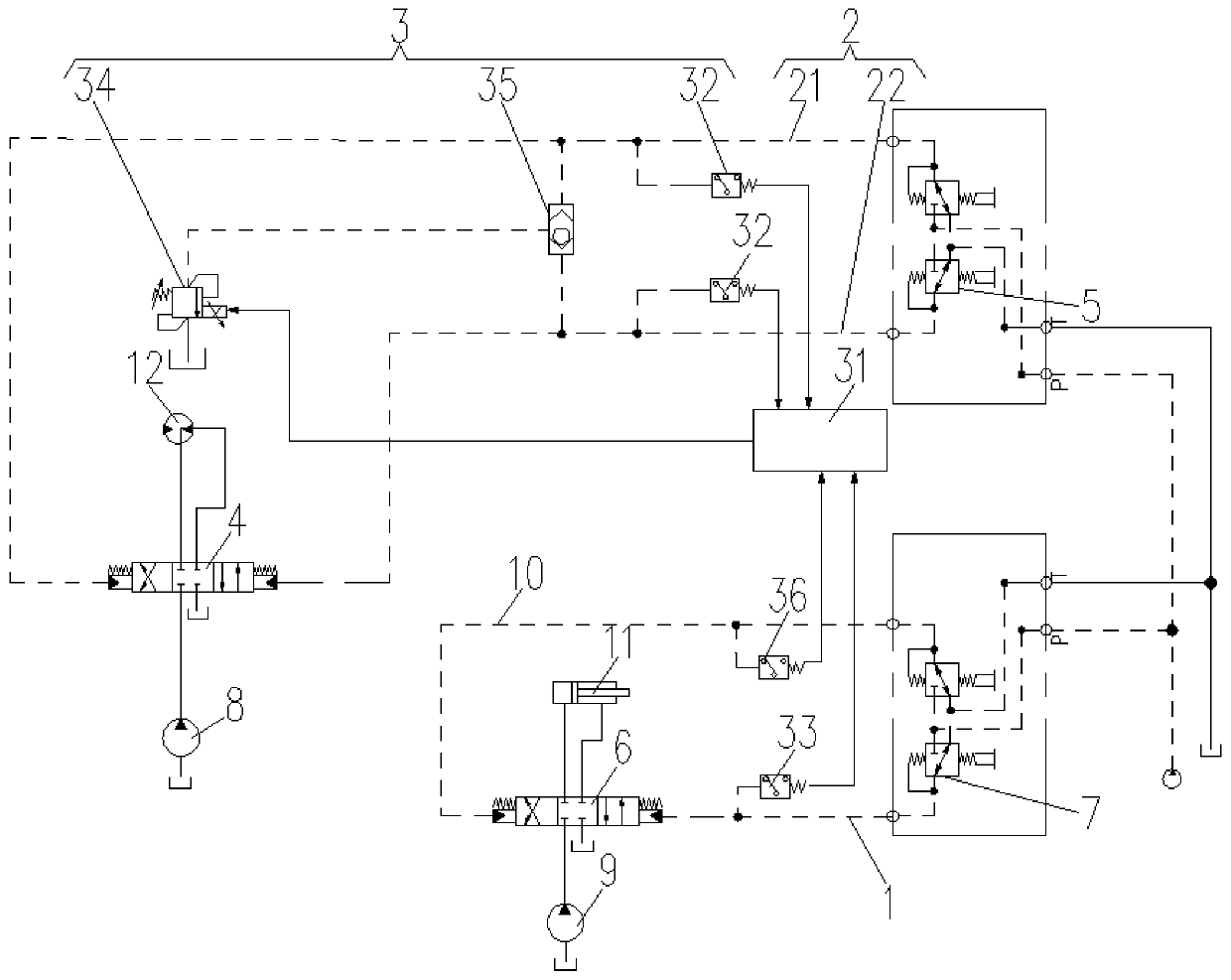

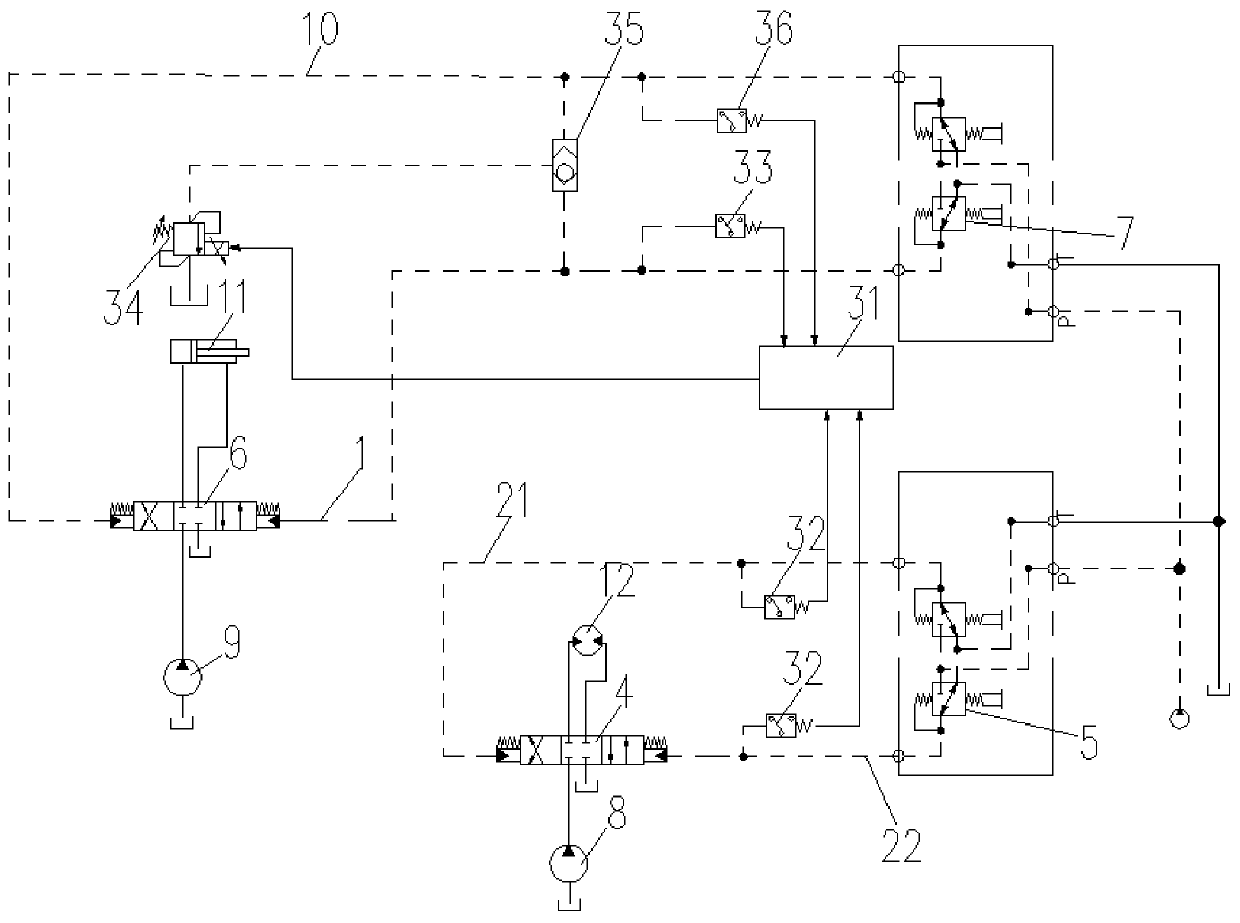

Hydraulic system and control method thereof

PendingCN110778548AControl speedLimit trafficServomotor componentsMechanical machines/dredgersControl engineeringControl theory

The invention provides a hydraulic system and a control method thereof, and relates to the hydraulic technical field. The hydraulic system includes a rotary pilot oil circuit, a lifting pilot oil circuit and a control mechanism. The control mechanism includes a controller, a rotary pressure sensor, a lifting pressure sensor and a pressure regulating component; the rotary pressure sensor is arranged on the rotary pilot oil circuit and is used for detecting a pilot pressure signal of the rotary pilot oil circuit and sending the pilot pressure signal to the controller; the lifting pressure sensoris arranged on the lifting pilot oil circuit and used for detecting a pilot pressure signal of the lifting pilot oil circuit and sending the pilot pressure signal to the controller; the pressure regulating component is arranged on the lifting pilot oil circuit and / or the rotary pilot oil circuit; the pressure regulating component is connected to the controller, and when the rotary pressure sensor and the lifting pressure sensor detect the pilot pressure signal at the same time, the controller controls the pressure regulating component to adjust the pressure of the pilot oil circuit which isin communication with the pressure regulating component. The difference between the rotating speed of a rotary motor and the lifting speed of a movable arm can be adjusted to meet the requirements ofvarious working conditions.

Owner:SANY HEAVY MACHINERY

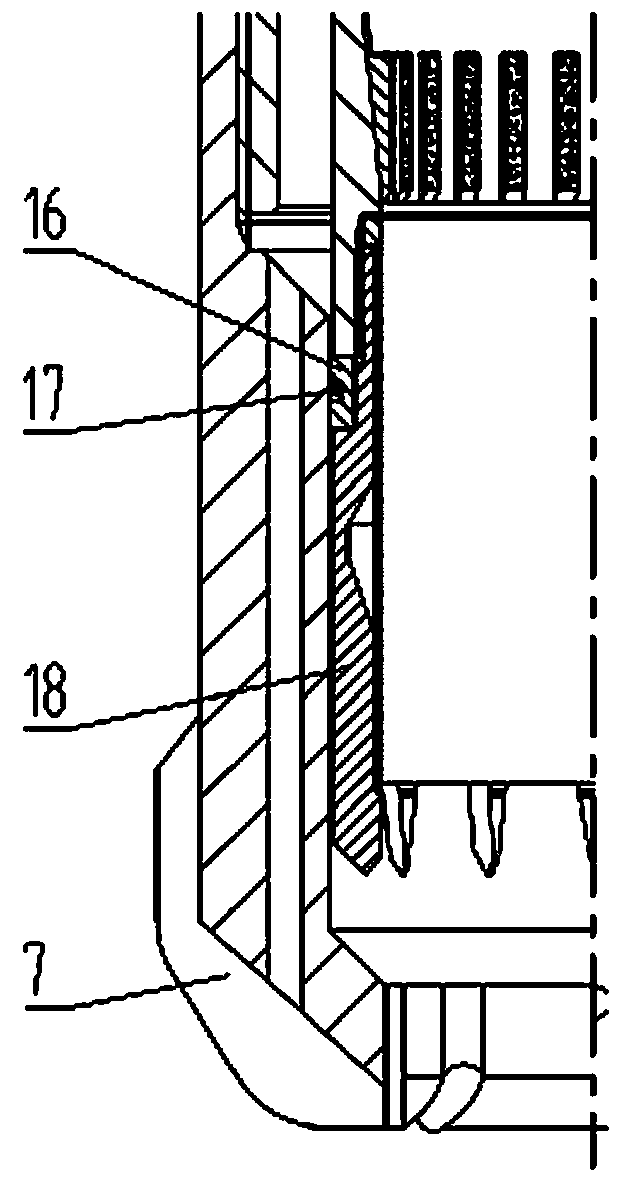

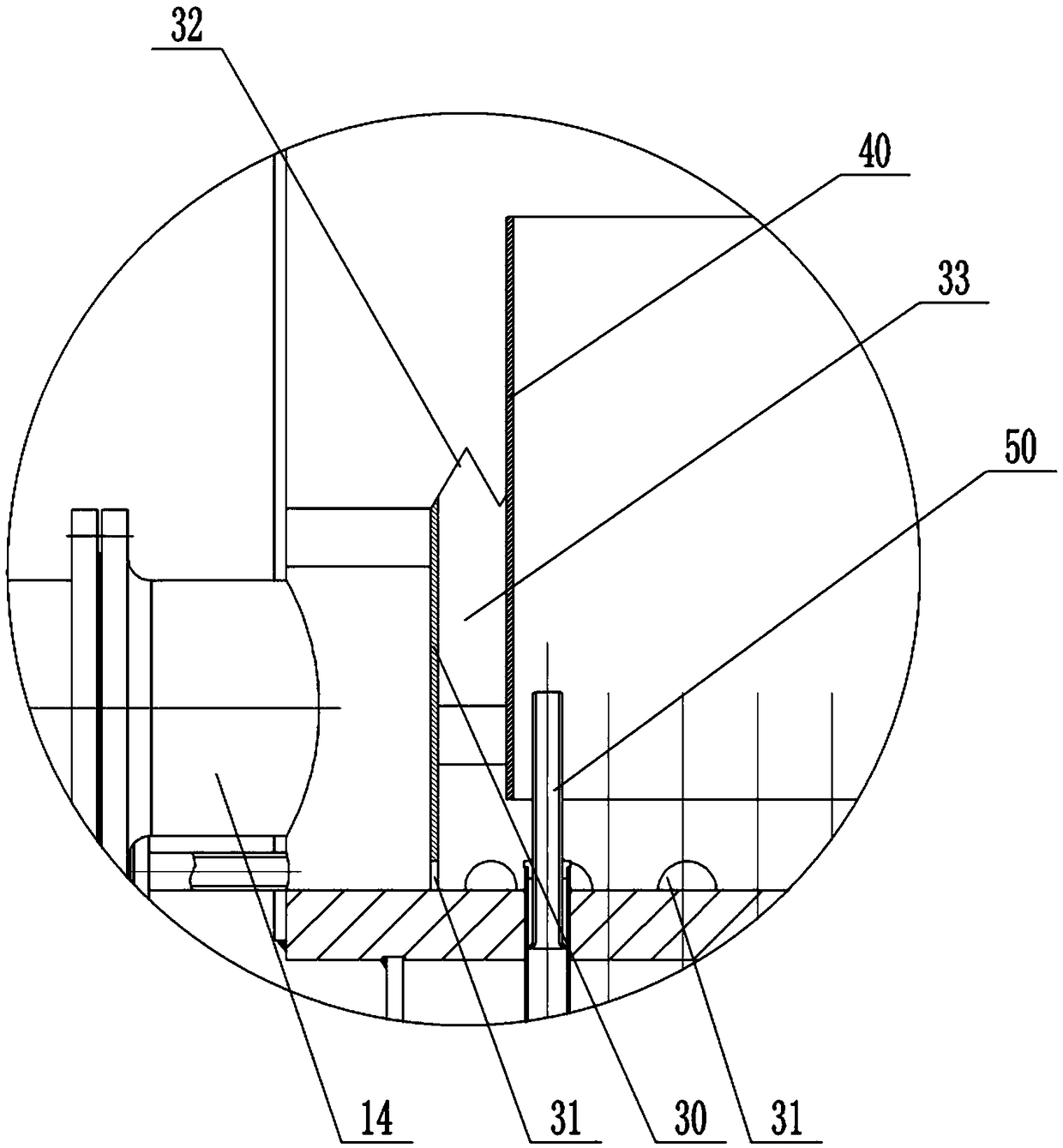

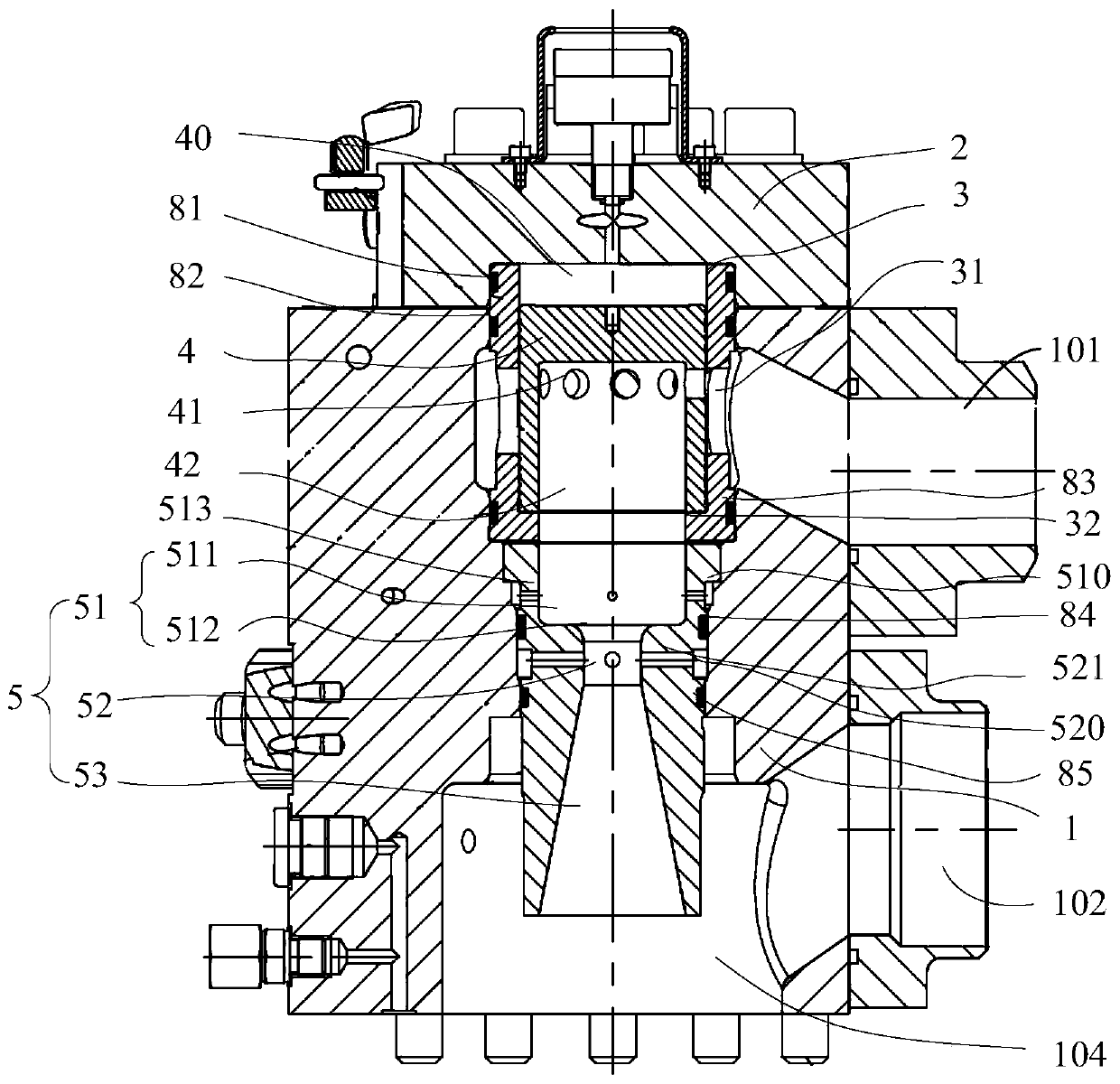

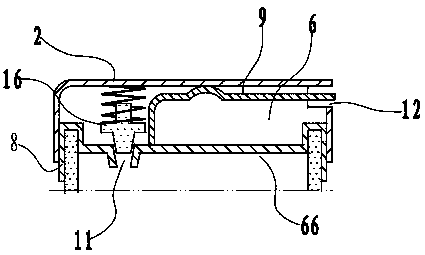

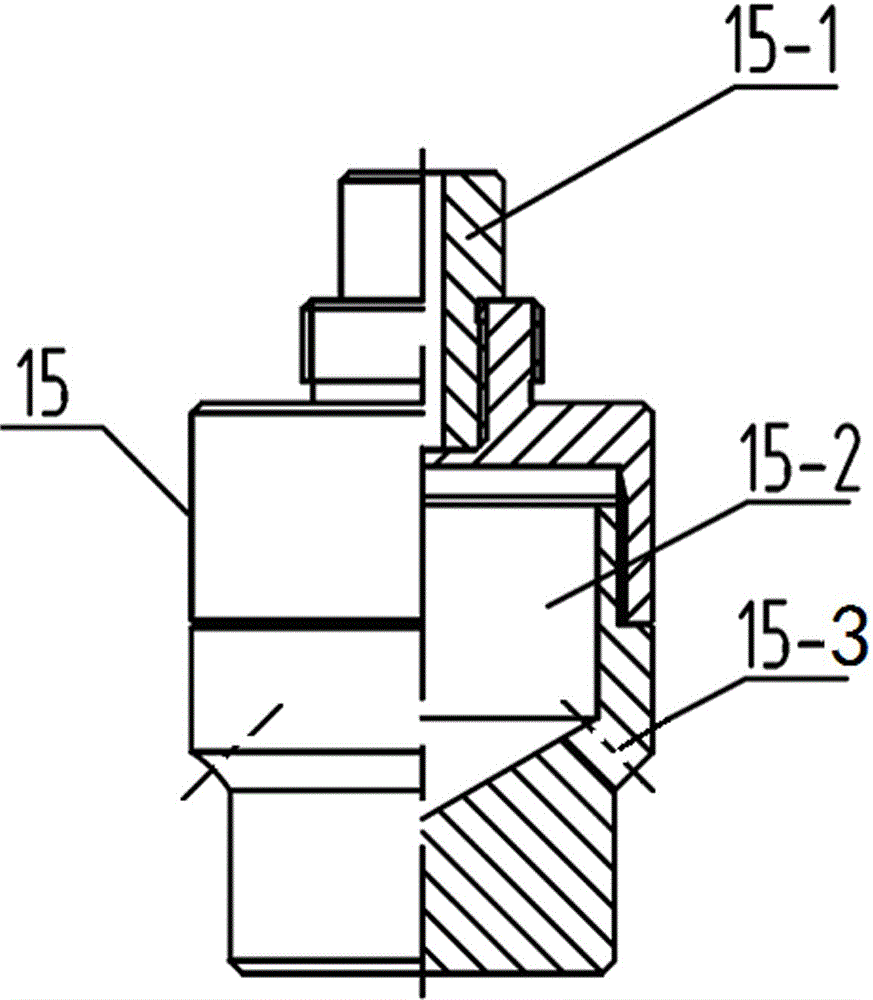

An Oxygen Concentration Detection Structure for Oxygen-enriched Air Used in Airborne Separators

ActiveCN111239337BLimit trafficSmall fluctuationDispersed particle filtrationAnalysing gaseous mixturesPhysical chemistryPartial pressure

The invention discloses an oxygen-enriched air oxygen concentration detection structure for an airborne separator, which belongs to gas oxygen concentration detection technology, and is characterized in that it includes an airborne separator (2), a sampling pipeline (6), a pressure sensor (5), oxygen partial pressure sensor (9), one-way valve (7), gasket (3), filter current limiting assembly, locking screw ring (11); The oxygen concentration detection structure of oxygen-enriched air improves the accuracy, reliability and service life of the system by filtering impurities in oxygen-enriched air, limiting gas flow and reducing gas fluctuations.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

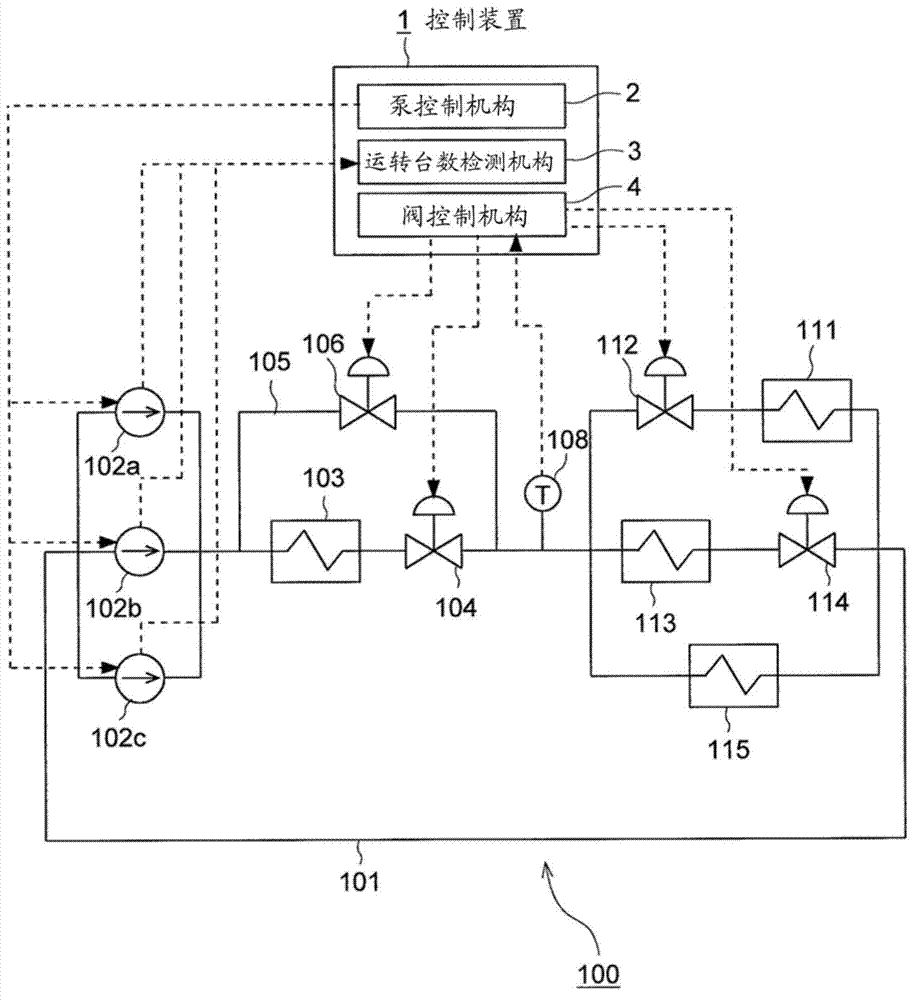

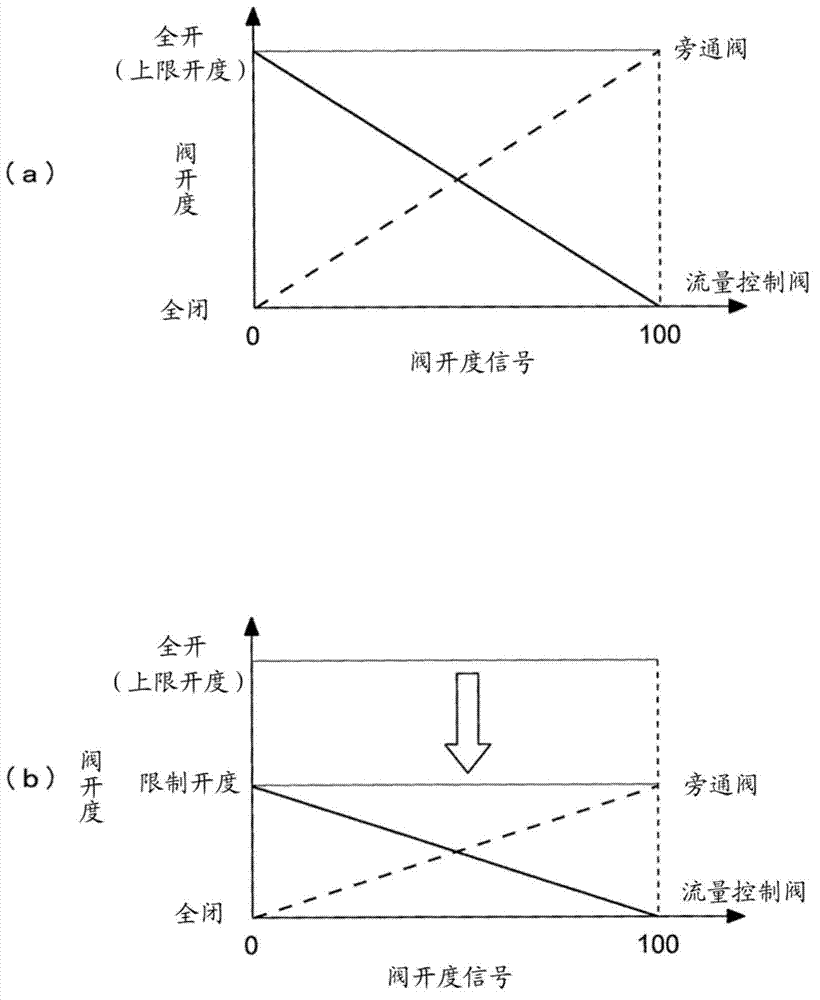

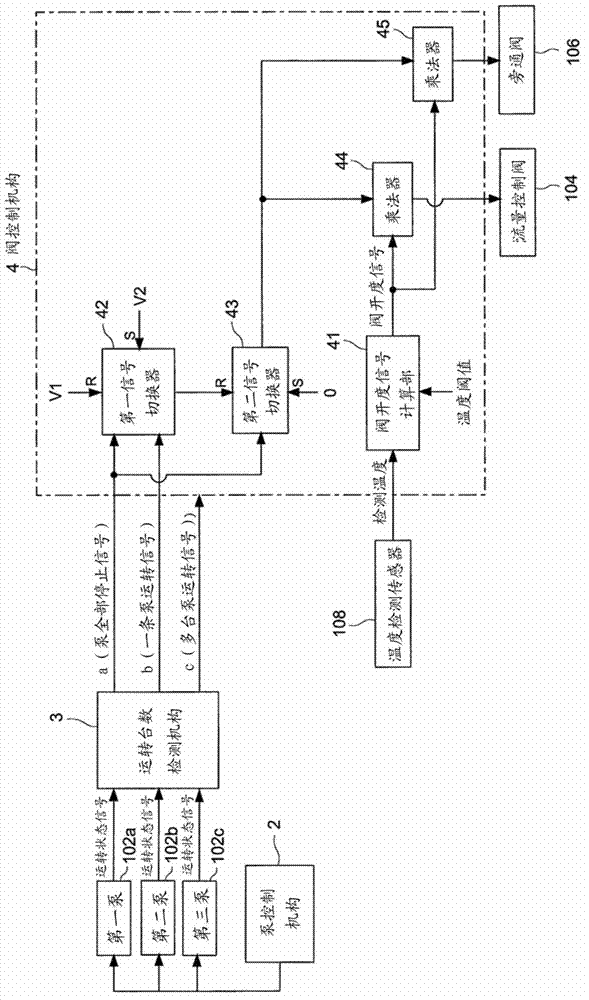

Cooling system control method and device

ActiveCN103104453BReduce starting torqueReduce capacityPlant parameters regulationNuclear energy generationControl signalAtomic power plant

Owner:MITSUBISHI POWER LTD

A Cutting Arm Structure Favorable for Bearings to Keep Lubricated

Owner:XUZHOU XUGONG FOUND CONSTR MACHINERY

a humidifier

ActiveCN105864946BImprove heating efficiencyPrevent spilloverLighting and heating apparatusAir humidification systemsLiquid storage tankEngineering

The invention relates to a humidifier. The humidifier comprises a base and a liquid storage box, wherein the base is fixedly connected with the liquid storage box, and the liquid storage box is positioned above a liquid storage tank of the base and is used for conveying liquid to the liquid storage tank; the base comprises a pedestal, a first assembly and a second assembly, and the first assembly and the second assembly are arranged on the pedestal in parallel along the horizontal direction; the first assembly comprises a first component with the liquid storage tank, the second assembly comprises a second component with a heating tank, and both the liquid storage tank and the heating tank are open upward; the liquid storage tank is communicated with the heating tank by virtue of at least one passage; the first communication position of the liquid storage tank and the passage is higher than the second communication position of the heating tank and the passage. According to the humidifier, the heating efficiency of the humidifier is improved, and the energy consumption is reduced. In addition, air in the liquid storage box is effectively prevented from being heated, so as not to press liquid in the liquid storage box into the liquid storage tank, so that the phenomenon of liquid overflowing caused by excessive liquid in the liquid storage tank is prevented.

Owner:GREE ELECTRIC APPLIANCES INC

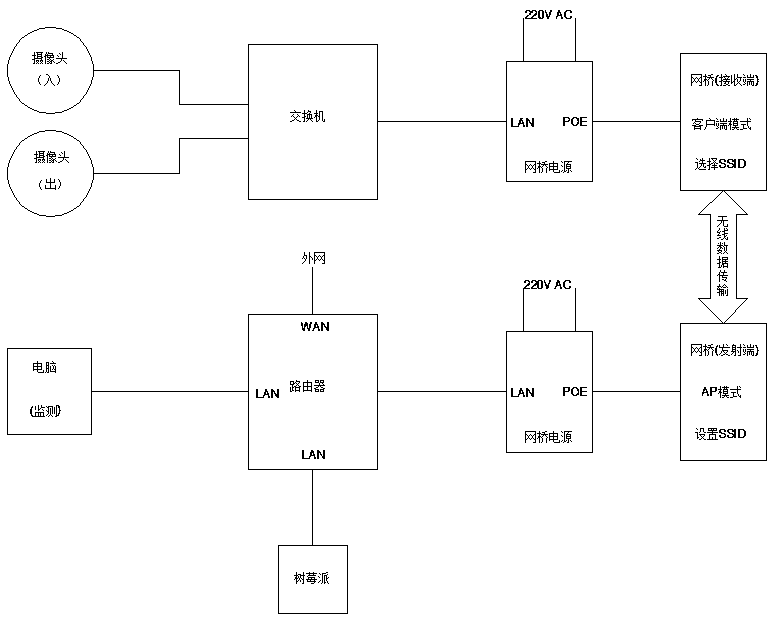

Data transmission method based on wireless broadband networking technology

InactiveCN110602019ATime-consuming and labor-intensive solutionLow costData switching networksBody area networkGeolocation

The invention discloses a data transmission method based on a wireless broadband networking technology, which is based on data transmission of the wireless broadband networking technology and mainly solves the problem of network communication of an intelligent sensing system between exit and entrance ports of a community. It is understood from the effect that it is a Mac layer interconnection device linking a wireless local area network segment and a wired local area network segment, and can be used to connect two or more independent network segments, which are typically located between buildings at a distance of hundreds of meters or even thousands of meters. The method is applied to network communication between different entrance and exit gates of a community. Firstly, the two local area networks are not isolated due to the influence of the geographic position, the distance is within the transmission range, and the two local area networks can be connected through data transmission based on the wireless broadband networking technology. In this way, time and labor consumption of common wiring is effectively avoided, and the cost can be greatly reduced.

Owner:河北城投智慧科技有限公司

A dual-lumen deep vein blood filter tube device

ActiveCN109157689ASmooth outAvoid secondary placementOther blood circulation devicesHaemofiltrationVeinEngineering

The invention discloses a double-lumen deep vein blood filter tube device, comprising a connector, a blood suction vessel and an occlusion head. A liquid inlet cham, a liquid outlet chamber and a liquid return cham are arranged in that connecting body, the liquid inlet ends of the liquid inlet chamber and the liquid return cham are arranged in an open manner, the liquid outlet ends of the liquid outlet chamber are arranged in an open manner, and the liquid outlet ends of the liquid return chamber and the liquid inlet ends of the liquid outlet chamber are communicated with the liquid outlet ends of the liquid inlet chamber; One end of the blood suction vessel is connected with the plug, the other end of the blood suction vessel is connected with the connector, and the liquid inlet cavity iscommunicated with the inner cavity of the blood suction vessel; A plurality of groups of liquid inlet units are uniformly distributed in the circumferential direction of the blood suction vessel, each group of liquid inlet units comprises a plurality of liquid inlet holes, and a plurality of liquid inlet holes of each group of liquid inlet units are equally spaced on the blood suction vessel along the axial direction of the blood suction vessel. The invention ensures smooth extraction of blood in human blood vessel by blood filter tube, avoids secondary placement of blood filter tube due to no bleeding, and improves blood filtration efficiency.

Owner:中国人民解放军陆军特色医学中心

Mechanism of agricultural swirl nozzle based on magnetorheological fluid micro-motion variable pressure

ActiveCN110961266BPrecisely control flowPrecisely control the ejection particle sizeSpray nozzlesInsect catchers and killersMagnetic currentTransformer

The invention relates to the field of pesticide liquid agricultural nozzles, which is an agricultural swirl nozzle mechanism based on magnetorheological fluid micro-movement variable pressure, including magnetorheological fluid variable push rod and swirl nozzle structure; magnetorheological fluid variable push rod includes The magnetorheological fluid bearing cavity, the spacer, the first energized coil, the second energized coil, the pressure transformation push rod and the sealing spacer, the spacer is installed in the rear end column hole of the magnetorheological fluid bearing cavity, and the first energized coil is wound On the spacer, the sealed spacer is placed in the front-end column hole of the magnetorheological fluid bearing chamber and the second energized coil is wound outside; the side of the pressure-transforming push rod with the piston is in the magnetorheological fluid bearing chamber and is equipped with a reset Spring; the swirl spool of the swirl nozzle structure is loaded into the swirl chamber, the swirl chamber is installed at the front end of the liquid passage chamber, and the liquid passage chamber is installed on the magnetorheological fluid bearing chamber. The mechanism uses the state change of the magnetorheological fluid under the action of the magnetic field to cause the pressure change of the magnetic flow bearing chamber to push the pressure changing push rod to move outward, so as to conveniently and accurately control the flow rate of the pesticide liquid and the sprayed particle size.

Owner:SOUTH CHINA AGRI UNIV

Sealing rings, protective sleeves and header

InactiveCN110068156ASpeed limitLimit trafficSolar heating energyCollector casingsVacuum tubeEngineering

The invention relates to sealing rings, protective sleeves and a header, and belongs to the field of solar heat utilization. The sealing rings are located at inner container holes of the header so asto play the sealing effect between vacuum pipes and the inner container holes, the sealing rings are connected with sleeves, the sleeves are provided with upper openings and lower openings, the upperopenings and connected heat conductors mutually correspond to each other in size and shape of the connection position, the lower openings communicate with inner holes of the sealing rings, the outer diameter of the sleeves are not larger than the center distance between two adjacent inner container holes, and the sleeves are provided with protective cavities which can contain the opening ends of the vacuum pipes connected with the sealing rings. The protective sleeves are formed by connecting the heat conductors and the sleeves, the header is characterized in that the sealing rings of the protective sleeves are arranged at the inner container holes, the sleeves and the heat conductors are arranged in a cavity of an inner container of the header, water in the header and the opening ends ofthe vacuum pipes can be effectively isolated by the protective sleeves, so that the phenomenon that the overheated vacuum pipes are in direct contact with cold water in the header and therefore are burst and damaged is avoided, and the heat collection vacuum pipes are effectively protected.

Owner:丁力

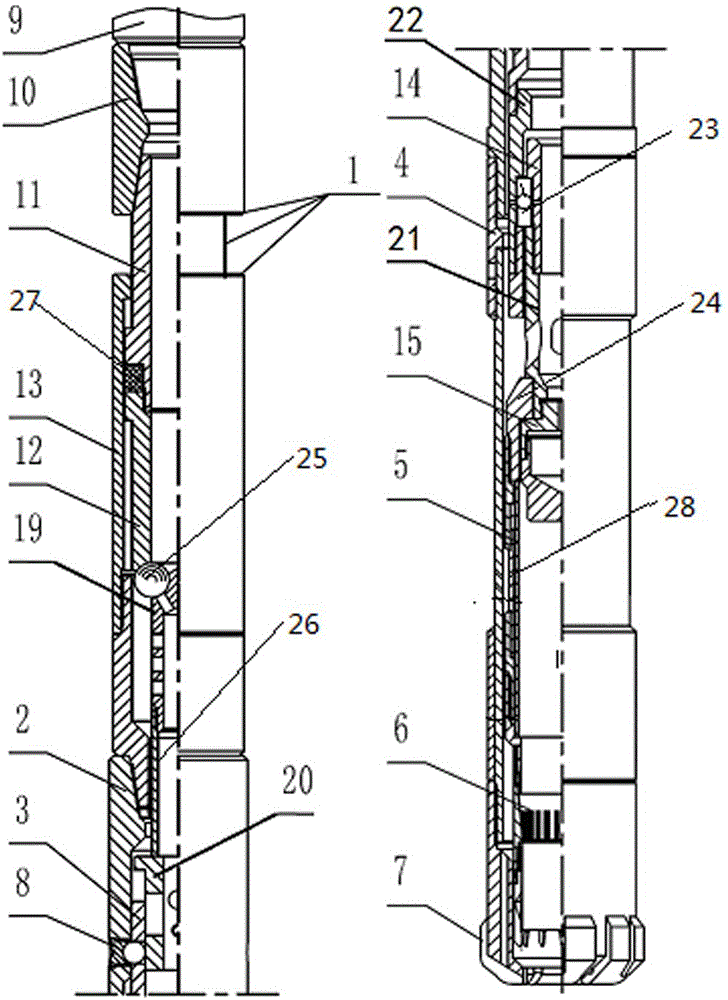

Differential air drilling coring device and method

The invention discloses a differential type air-drilling coring device and a differential type air-drilling coring method, wherein a differential mechanism, an orientation spool, an outer cylinder assembly and a coring dill bit are connected together up and down to form an outer cylinder assembly; a suspension assembly, an inner cylinder assembly and a core cutting mechanism are connected together up and down through threads to form an inner cylinder assembly; the suspension assembly is connected with the orientation spool through a suspension element; the whole inner cylinder assembly is suspended in the outer cylinder assembly; the core cutting mechanism is located in the position of the inner cavity of the coring dill bit; the whole set of coring device is in threaded connection with a drill tool. During the coring operation, the well drilling equipment drives the coring device to rotate to carry out the core-drilling work; after the core-drilling is finished, the suspension element is sheared off by pitching to ground and by virtue of the differential device of the coring device, and then the inner cylinder assembly descends so that the core cutting mechanism is enabled to work, and the rock core is protected against dropping out in the drilling process. The differential type air-drilling coring device and the differential type air-drilling coring method can be applied to the air-drilling coring field.

Owner:CHINA PETROCHEMICAL CORP +3

Torpedo needle

The invention discloses a torpedo needle, which comprises a slug umbrella head, a slug rod and a fixed cover; center of one end of the fixed cover is provided with a rubber port; center of the other end of the fixed cover is provided with a fixed cover inner cavity; the inner cavity of the fixed cover is communicated with a rubber port by an inner cavity hole; the slug umbrella head is provided with a charging chamber; the slug rod is equipped in the center part of the slug umbrella head; one end of the slug rod is a flat end and the other end is a tip end; the slug rod penetrates into the inner cavity of the fixed cover; the flat end is located in the inner cavity of the fixed cover; the flat end is matched with the inner cavity hole, thereby an appropriate flow of melt materials can enter the rubber port; the tip end penetrates the slug umbrella head and protrudes from the slug umbrella head; one side of the slug umbrella head tightly contacts the circumferential part of one side of the fixed cover inner cavity. The flat end structure of the slug rod can effectively limit flow of melt material, thereby reducing melted materials at the rubber port and cooling fully, and preventing salivating and wire drawing.

Owner:SUZHOU HTS MOLD

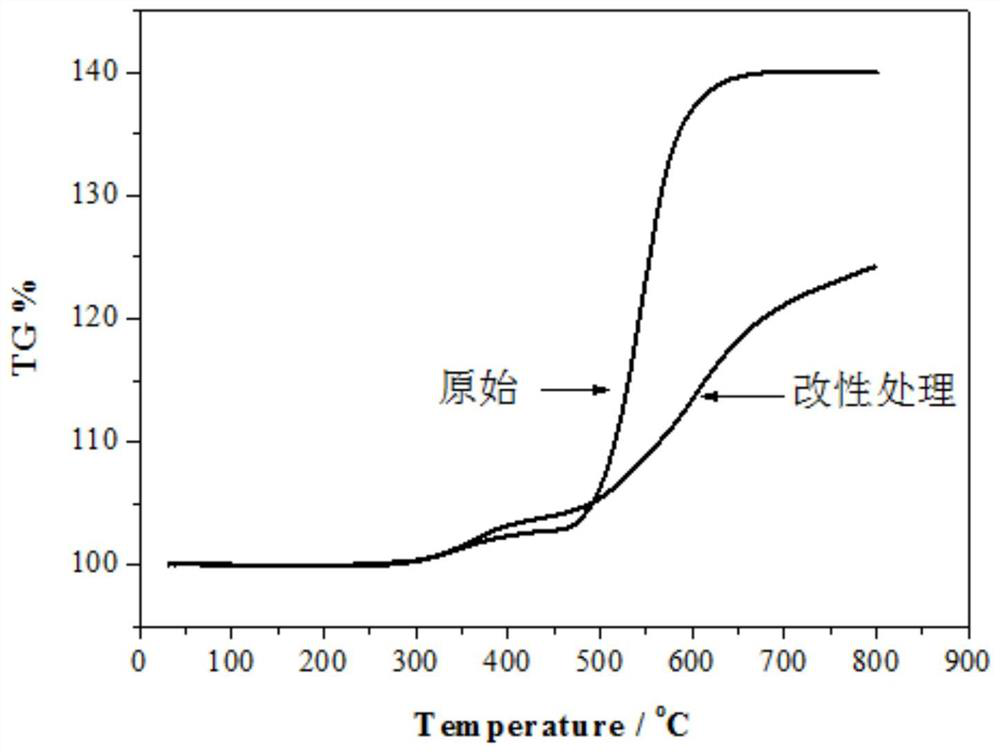

A method for improving high-temperature and high-salt properties of iron powder by using plasma electrolysis

ActiveCN110586932BEvenly distributedGuaranteed modification effectElectrolytic inorganic material coatingTransportation and packagingElectrolysisIron powder

The invention relates to a method for improving the high-temperature and high-salt properties of iron powder by using plasma electrolysis, and belongs to the technical field of iron powder surface modification. The method adopts the method of transporting the iron powder and the electrolyte solution separately, so that the iron powder and the electrolyte solution are mixed and immediately processed by the electrolytic plasma arc area, so as to avoid the problem of iron powder sedimentation or floating in the one-time preparation of the mixed suspension, and adopt a small The continuous batch processing method ensures the comprehensive quality of the iron powder modification treatment, and at the same time reduces the discharge area of the cathode electrode, which is conducive to reducing costs and improving safety factors. The method of the invention has the advantages of simple operation, high production efficiency and low cost, and can ensure the improvement of the high-temperature and high-salt properties of the iron powder, and has good application prospects.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com