Exhaust emission control device of internal combustion engine

A control device and exhaust emission technology, applied in electrical control, exhaust device, engine control and other directions, can solve problems such as full opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

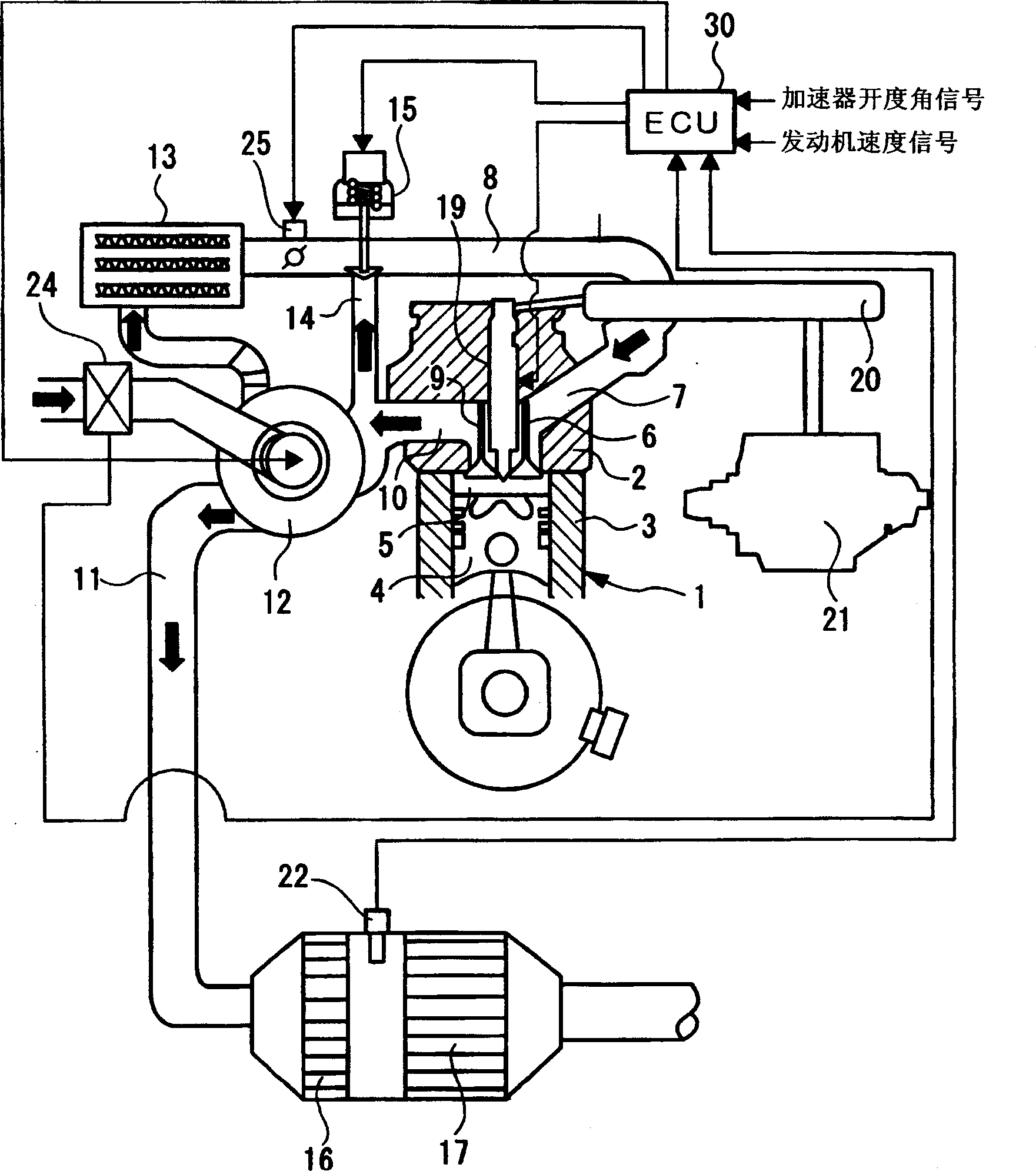

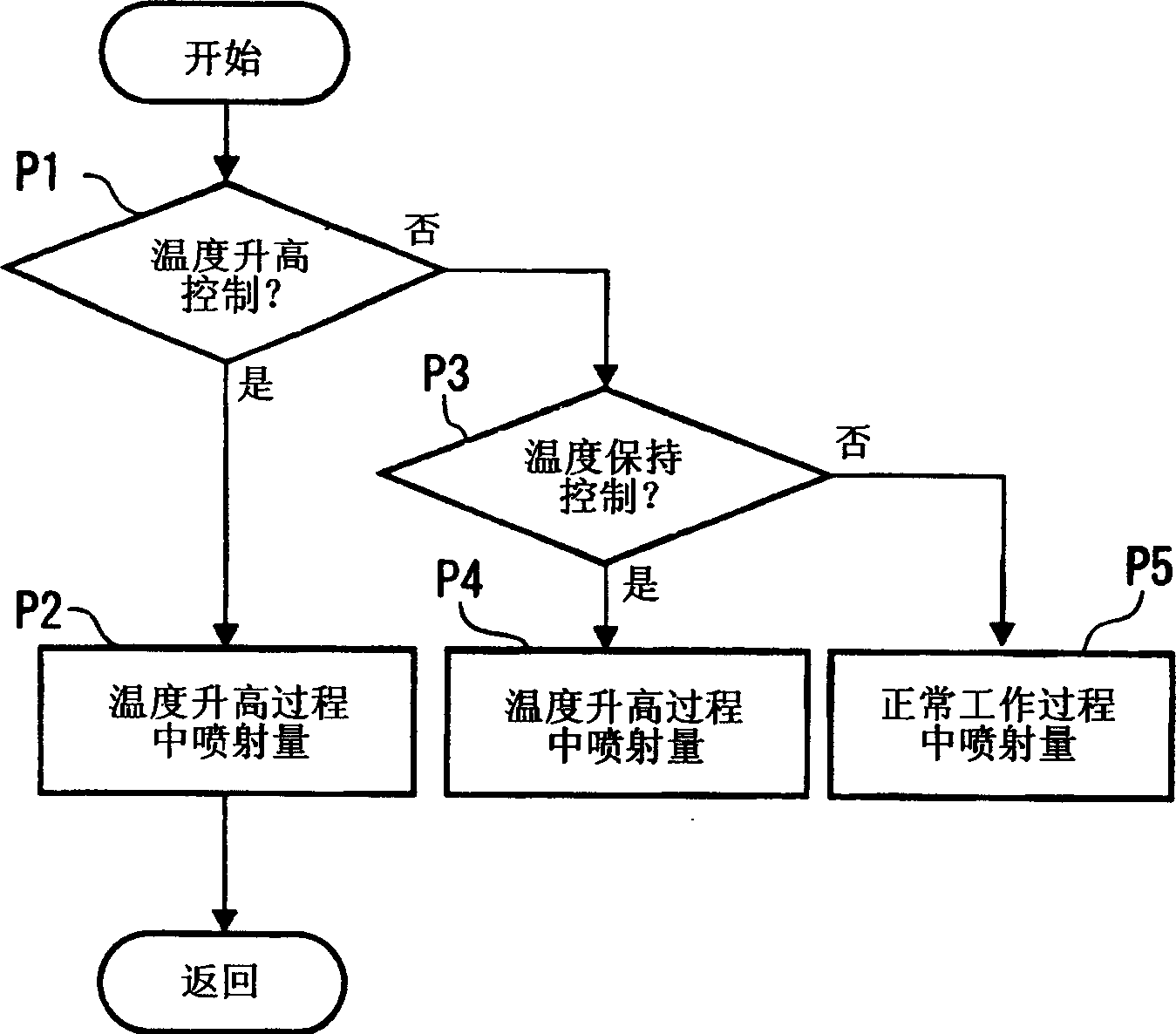

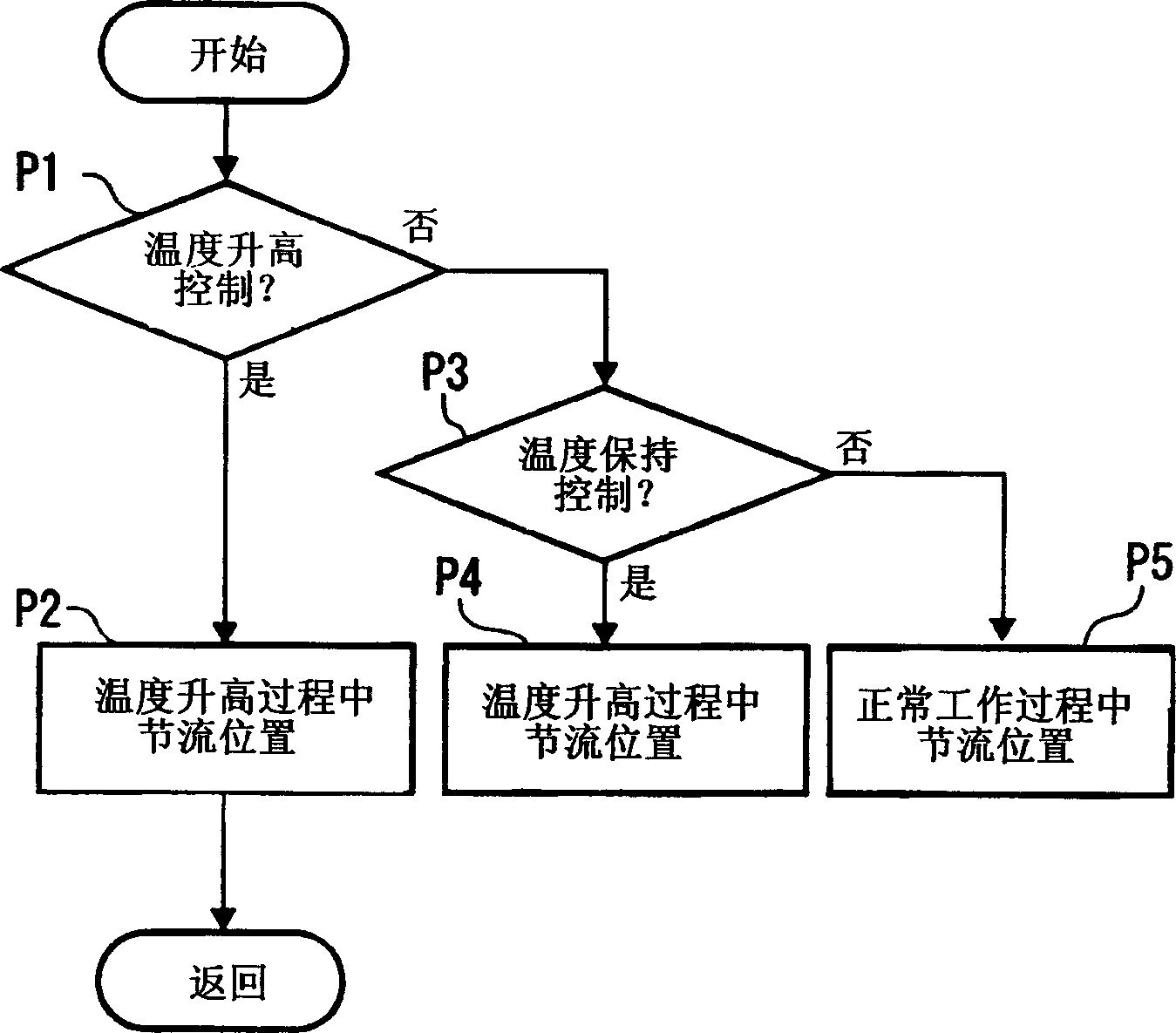

[0030] figure 1 is a schematic structural view showing a diesel engine exhaust emission control device according to an embodiment of the present invention. figure 2 is a flow chart of post-injection control. image 3 Is the flow chart of throttle valve control. Figure 4 It is a time table showing the relationship among DPF temperature, engine speed, throttle valve opening angle, accelerator opening angle, temperature maintenance control flag, and regeneration control flag. Figure 5(a) and 5(b) is a graph showing the effect of temperature maintenance control.

[0031] like figure 1 As shown, a multi-cylinder diesel engine (hereinafter referred to as an engine) 1 has a cylinder head 2 and a cylinder block 3 . A piston 4 is accommodated in the bore of each cylinder block 3 so that it can move in a reciprocating manner. The combustion chamber 5 is formed by the top surface of the piston, the wall surface of the cylinder bore, and the lower surface of the cylinder head.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com