Buffer device for telescopic hydraulic cylinder of folding arm type truck mounted crane

A technology of telescopic hydraulic cylinder and buffer device, applied in the direction of fluid pressure actuating device, crane, etc., can solve the problems of heavy object swing, the safety of the whole machine, stability impact, and the offset of the center of gravity of hoisting heavy objects, so as to eliminate the impact. force and noise, improved smoothness, improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

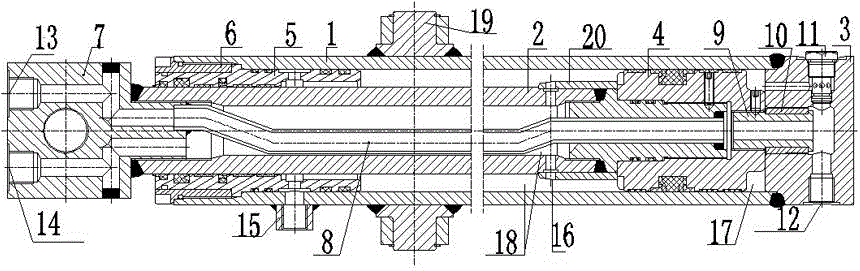

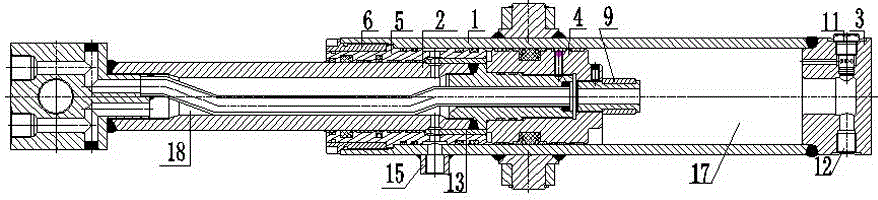

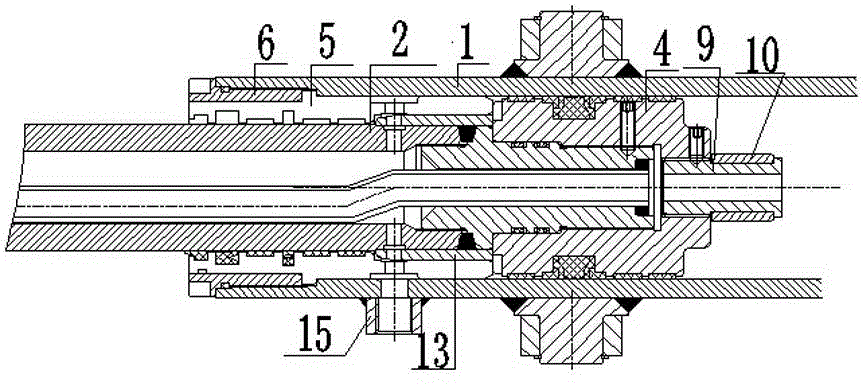

[0017] The present invention as figure 1 , 2 , 3, 4, and 5.

[0018] A telescopic hydraulic cylinder buffer device for a folding-arm type truck-mounted crane, comprising a cylinder barrel, a base 3 is provided at the tail end of the cylinder barrel 1, a piston rod 2 is installed inside the cylinder barrel 1, and a gap between the tail of the piston rod 2 and the inner wall of the cylinder barrel 1 is provided. There is a piston 4 between them, and a guide sleeve 5 is provided between the inner wall of the front cylinder 1 of the piston rod 2, and the guide sleeve 5 is fixed by the gland 6, so that the piston rod 2 slides along the inside of the guide sleeve 5, and the piston rod 2 There is a working end 7 on the top, and the cavity inside the piston rod 2 is provided with an oil pipe 8 along its length. , the tail end of the piston 4 is provided with a buffer sleeve-10 through the buffer sleeve gland 9, and the buffer sleeve-10 is co-installed with the base 3, and the base 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com