Sealing rings, protective sleeves and header

A technology of sealing ring and protective sleeve, applied in the field of heat collecting box, can solve the problems of high product cost, inoperability, low thermal conductivity of glass, etc., to save the process of cleaning waste residue, good heat absorption efficiency, and reduce cleaning time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

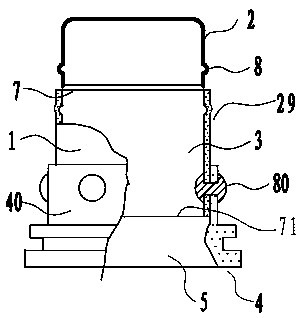

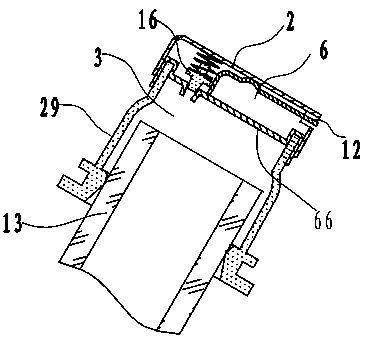

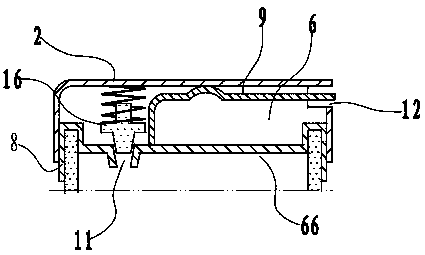

[0029] figure 1 Among them, the casing 1 is a through silicon rubber round tube with an upper opening 7 and a lower opening 71, and the heat conductor 2 is an inverted teacup-shaped cavity with a circular opening made of a stainless steel sheet. The upper opening 7 and the heat conductor 2 There are also corresponding dimensions at the interconnection. The annular protrusion on the surface of the heat conductor 2 is engaged with the annular groove of the sleeve 1 as a fastener 8. The lower opening 71 communicates with the inner hole 5 of the sealing ring 4, and the sealing ring 4. The axially protruding short tube 40 is riveted with the sleeve pipe 1 through the rivet 80. The outer diameter of the sleeve pipe 1 is not greater than the center distance between the adjacent two inner tank holes. The sleeve pipe 1 has an open space for the connected vacuum tube The protective chamber 3 placed in the mouth end, the sealing ring, the casing and the heat conductor are connected in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com